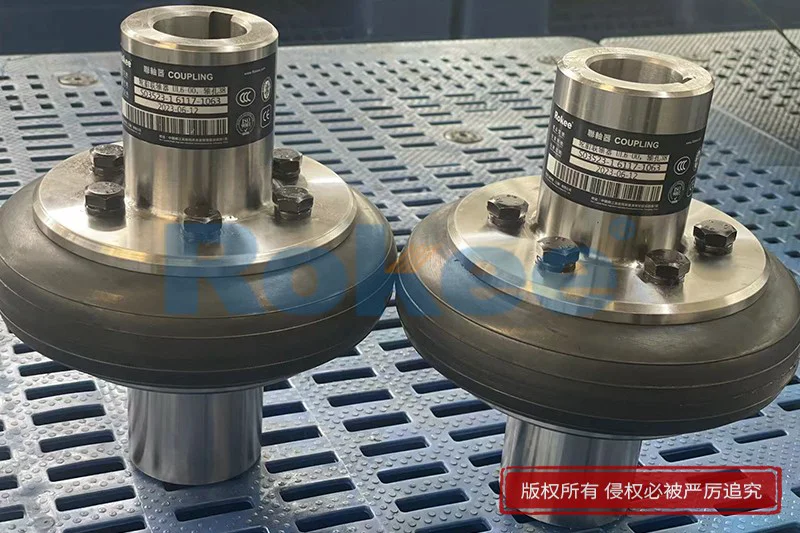

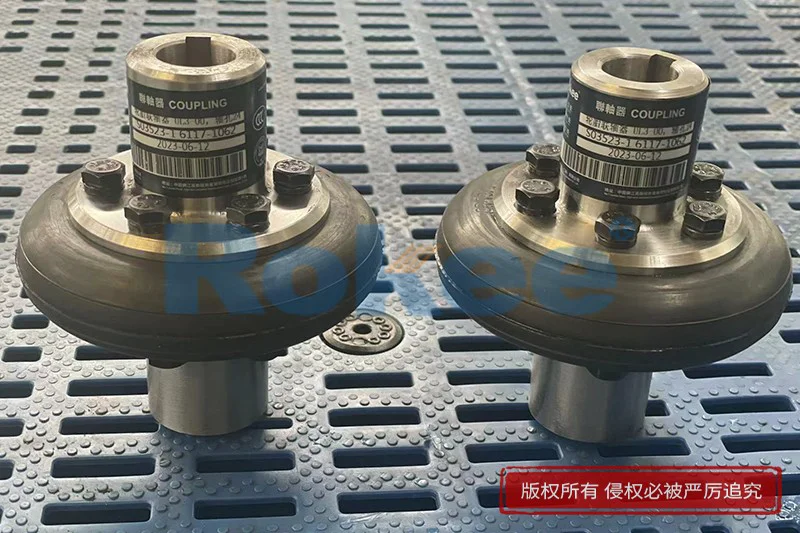

Safe Coupling

Rokee is a well-known Safe Coupling supplier from china, the page show cases of Safe Coupling, provide customized services based on user's drawings, and supporting exports.

A safe coupling is a specially designed mechanical device in industrial transmission systems, whose core function is to automatically disconnect power transmission when the system is overloaded, thereby protecting expensive mechanical equipment from damage. Unlike ordinary couplings that simply transmit torque, safety couplings integrate overload protection mechanisms and become an indispensable safety component in modern industrial automation systems. This type of coupling is widely used in applications that require precise torque control and protection of sensitive equipment, such as packaging machinery, printing equipment, robot systems, CNC machine tools, and automated production lines.

Working principle of safety coupling

The core technology of a safety coupling lies in its overload protection mechanism, which mainly has the following working modes:

Mechanical cutting principle: using a cutting pin design, when overload occurs, the pin is cut off, immediately cutting off power transmission. This type of coupling has a simple structure and low cost, but requires manual replacement of the shear pin to resume operation.

Friction type disengagement mechanism: uses preset friction force to transmit torque, and the friction surface slips when overloaded. This type of coupling can automatically reset without manual intervention and is suitable for situations where overload occurs frequently.

Magnetic coupling technology: By transmitting torque through the magnetic force of permanent magnets, the magnetic coupling is disconnected when overloaded. This contactless design has the characteristics of zero wear and maintenance free, making it particularly suitable for clean environments.

Hydraulic/Pneumatic Overload Protection: Utilizing fluid pressure to control torque transmission, the disengagement torque value can be accurately set by adjusting the pressure.

The main types of safe couplings

Shear pin safety coupling

The most traditional type of safety coupling consists of two half couplings and a shear pin. The diameter and material of the pin are accurately calculated to ensure fracture under the set torque. Suitable for situations where frequent overloading is not allowed and shutdown for replacement is allowed.

Advantages: Simple structure, low cost, precise torque setting

Disadvantage: Need to stop the machine to replace the pin, unable to reset automaticallyFriction type safety coupling

Adopting a spring preloaded friction plate structure, the disengagement torque is set by adjusting the spring pressure. Modern high-end models are equipped with torque indicators that can visually display overload conditions.

Advantages: Automatic reset, can be operated frequently

Disadvantage: Friction plates will wear out and require regular maintenanceMagnetic safe coupling

A non-contact coupling composed of permanent magnets, which automatically disengages the magnetic coupling when overloaded. The latest model uses rare earth magnetic materials, which are small in size but have high torque transmission.

Advantages: Zero wear, maintenance free, suitable for clean environments

Disadvantages: High cost, magnetic attenuation problemHydraulic safety coupling

By controlling torque transmission through hydraulic oil pressure, adjustable pressure means that the disengagement torque can be precisely set. Commonly used for large industrial equipment.

Advantages: Wide torque setting range, can be remotely monitored

Disadvantages: The system is complex and requires a hydraulic unit

Key points for selecting safe couplings

Choosing a suitable safety coupling requires consideration of multiple factors:

Torque characteristics:

Normal working torque

Maximum allowable torque

Set the disengagement torque value (usually 1.5-2 times the working torque)Dynamic characteristics:

speed range

torsional stiffness

inertia matchingEnvironmental factors:

Working temperature range

Protection grade

Adaptability to corrosive environmentsInstallation and maintenance:

Axial/radial space limitation

Accuracy requirements for alignment

Maintenance cycle and convenienceIntelligent functional requirements:

Overload signal output

Status monitoring interface

Remote reset capability

As the "safety valve" of industrial transmission systems, the importance of safe couplings has become increasingly prominent with the improvement of equipment automation. Modern safety couplings have evolved from simple mechanical protection devices to high-tech products that integrate machinery, electronics, and intelligent diagnosis. In the future, with the development of materials science, sensor technology, and the Internet of Things, safety couplings will become more intelligent and networked, becoming an indispensable intelligent component in industrial equipment.

Enterprises should comprehensively consider technical parameters, usage environment, and long-term operating costs when selecting, and choose the most suitable safety coupling solution for their own process requirements. Regular maintenance and proper use are also key factors in ensuring optimal performance of safety couplings.

With excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc.

« Safe Coupling » Post Date: 2024/4/25 , https://www.rokeecoupling.net/cases/safe-coupling.html

Other Cases

Jaw Flexible Coupling With Brake Disc

Jaw Flexible Coupling With Brake Disc Universal Joint Couplings For Steel Mills

Universal Joint Couplings For Steel Mills UL6 Rubber Tyre Coupling

UL6 Rubber Tyre Coupling Bearing Seat Type 650 Cardan Shaft

Bearing Seat Type 650 Cardan Shaft UL3 Rubber Tire Coupling

UL3 Rubber Tire Coupling MLPK Flexible Coupling With Brake Disc

MLPK Flexible Coupling With Brake Disc LT15 Elastic Sleeve Pin Coupling

LT15 Elastic Sleeve Pin Coupling SWC180WD Cardan Shaft

SWC180WD Cardan Shaft JS Grid Flex Coupling

JS Grid Flex Coupling Half Set Of Plum Blossom Coupling

Half Set Of Plum Blossom Coupling