Rokee is a well-known high-quality supplier of Curved Tooth Couplings and technical services in China, customize curved tooth couplings according to user drawings, alternatively, if the user provides curved tooth couplings parameters, we can select the model and design drawings for you, support wholesale and export.

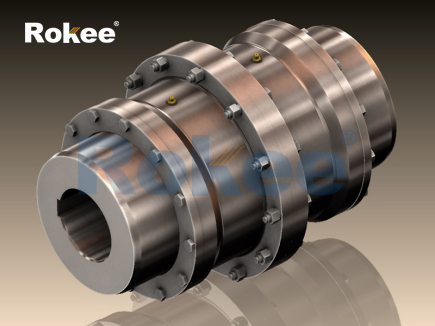

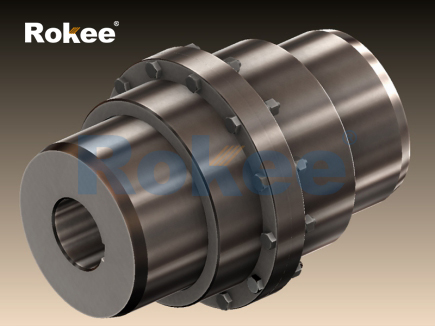

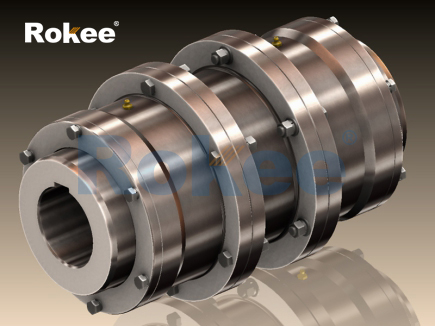

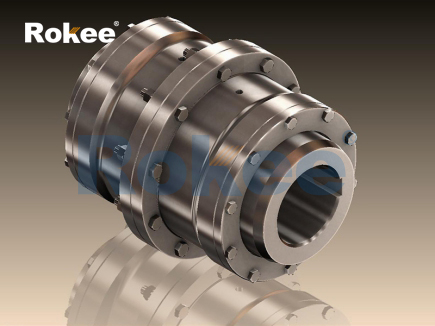

Curved tooth coupling is an advanced high-performance mechanical transmission component that plays a crucial role in modern industrial equipment. This type of coupling is named after its special drum gear design, which has superior deflection compensation capability and higher transmission efficiency compared to traditional spur gear couplings.

The core feature of drum shaped teeth is that their gear profile is a drum shaped curve. This unique design enables the coupling to compensate for possible radial, angular, and axial deviations between shaft systems while transmitting torque. Industrial application data shows that the service life of curved tooth couplings is usually 30-50% longer than traditional spur gear couplings, and the torque transmission efficiency can reach over 98%.

Drum shaped wheel hub: Made of special alloy steel forging, the tooth surface is precision ground to form a drum shaped contour. The latest design trend is to use involute drum shaped teeth, which can make the contact stress distribution more uniform and improve the bearing capacity by about 20%.

External gear sleeve: It is usually made of high-quality carbon steel or alloy steel, and the internal teeth are precisely matched with the drum shaped gear hub. Advanced surface hardening processes, such as carburizing quenching or nitriding treatment, can achieve a tooth surface hardness of HRC58-62, significantly improving wear resistance.

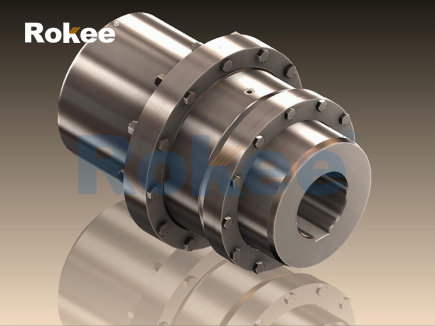

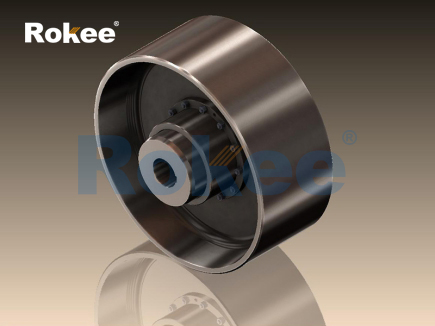

Sealing system: Modern drum gear couplings are equipped with multiple sealing devices, including radial sealing rings and end face seals, effectively preventing lubricant leakage and pollutant intrusion.

Lubrication structure: High end models are equipped with an automatic lubrication system, which achieves continuous lubrication through built-in oil passages and oil storage chambers. Research data shows that optimizing lubrication can reduce tooth wear by up to 60% and significantly extend maintenance cycles.

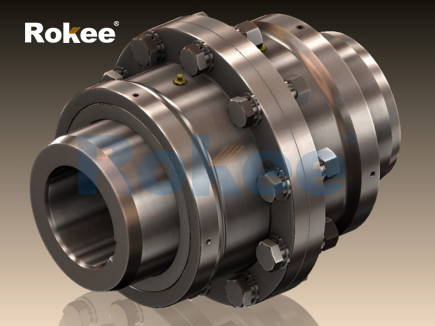

Deviation compensation mechanism: When there is misalignment between the two axes, the drum shaped tooth surface will produce controllable relative sliding. Through the special surface design of the tooth surface, the sliding friction is converted into rolling friction, reducing wear. Actual test data shows that under the same operating conditions, the vibration level of the drum gear coupling is 40-60% lower than that of the straight gear coupling.

Torque transmission characteristics: The design of multiple teeth meshing simultaneously achieves uniform distribution of load. Advanced finite element analysis shows that the optimized drum tooth design can reduce the load on a single tooth by 30% and increase the overall load-bearing capacity by 25%.

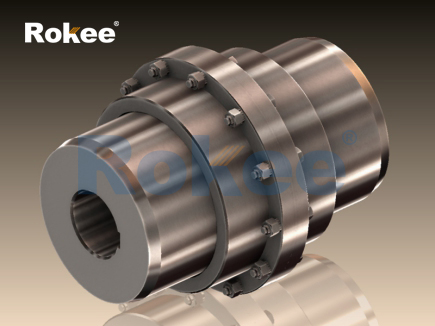

Allow for larger radial deviations (up to 0.5-1.5mm) and angular deviations (up to 1.5 °)

The vibration and noise reduction effect is significant, and the noise level can be reduced by 5-8dB

The axial displacement compensation capability is usually within ± 0.5mm range

The maximum speed can reach 10000rpm (varies according to specifications)

Calculate the maximum torque under actual operating conditions

Measure the misalignment of the shaft system

Determine the working environment conditions (temperature, humidity, corrosiveness, etc.)

Consider the start-up characteristics and possible impact loads

Choose an appropriate safety factor (usually 1.5-2.0)

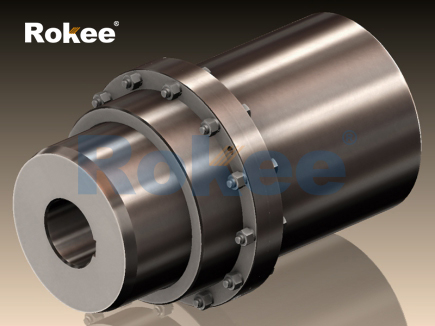

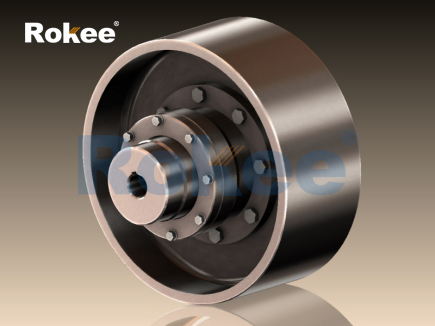

In the field of heavy industry: metallurgical rolling mills, mining machinery, heavy-duty machine tools, etc. For example, in a hot rolling production line, the curved tooth coupling can withstand an impact torque of up to 30000 Nm, compensating for the axial movement of the rolling mill rolls.

Energy equipment: generator sets, compressors, and pumps. In gas turbine applications, specially designed drum gear couplings can operate stably for over 50000 hours at a speed of 6000rpm.

Shipbuilding industry: In ship propulsion systems, corrosion-resistant drum gear couplings can compensate for shaft system deviations caused by ship deformation and resist seawater corrosion.

Chemical equipment: curved tooth couplings made of stainless steel or specially coated materials perform well in corrosive environments.

« Curved Tooth Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/curved-tooth-couplings.html