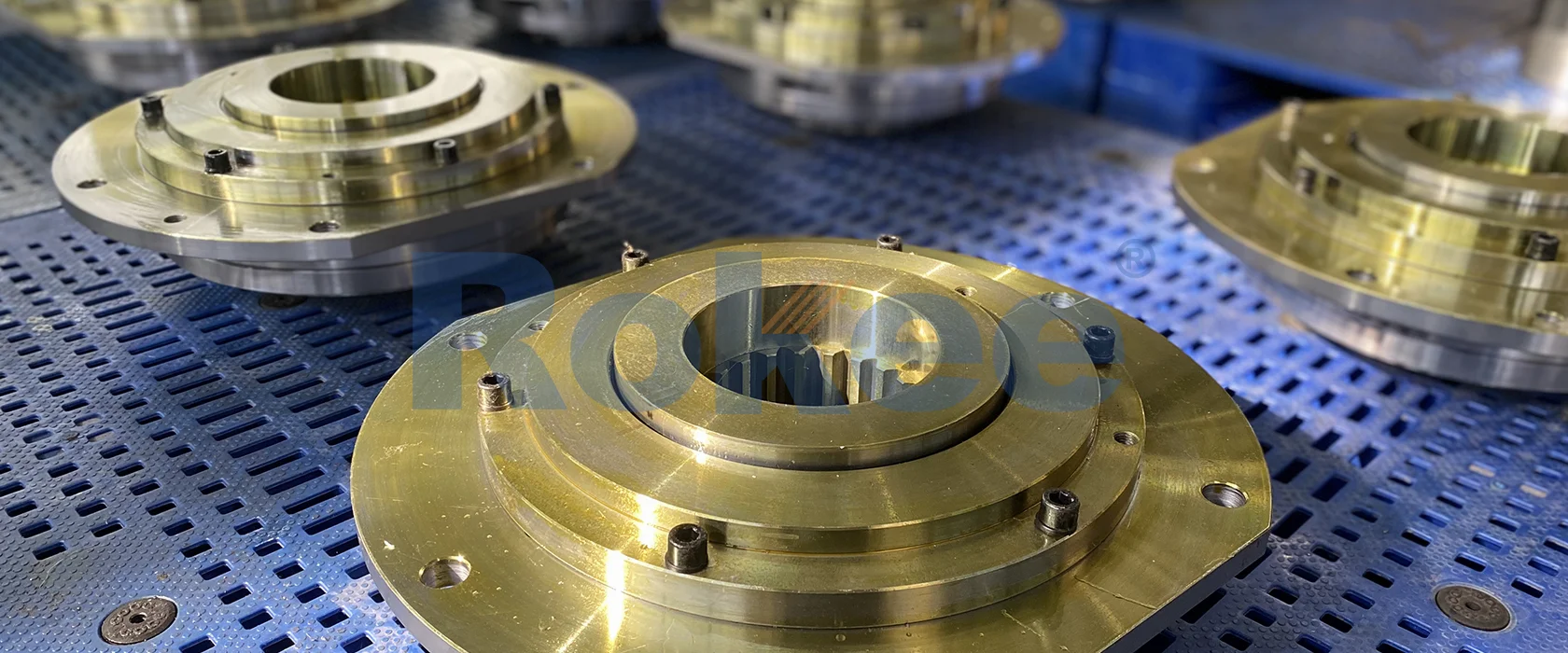

Rokee is a well-known high-quality supplier of Drum Couplings and technical services in China, customize drum couplings according to user drawings, alternatively, if the user provides drum couplings parameters, we can select the model and design drawings for you, support wholesale and export.

As a special mechanical transmission device, the drum coupling plays a crucial role in modern industrial equipment. This type of coupling is designed specifically for drum type equipment, mainly used to connect the drive shaft and drum shaft, achieve effective torque transmission, and compensate for the relative displacement between the two shafts.

The working principle is based on the synergistic effect of elastic deformation and friction. When the drive shaft rotates, the coupling transmits torque to the drum shaft through its internal elastic elements or friction surfaces. Its uniqueness lies in its ability to adapt to axial displacement caused by changes in the diameter of the drum during operation, which is a special function that ordinary couplings cannot achieve. During the process of coiling or unwinding materials (such as metal strips, paper, film, etc.), as the number of layers of material on the spool increases or decreases, the effective diameter of the spool will change, resulting in a change in the relative position between the drive shaft and the spool shaft. The drum coupling, through special design, can automatically compensate for this dynamic change, maintaining the continuity and stability of the transmission.

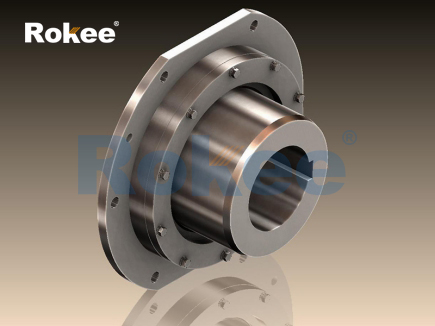

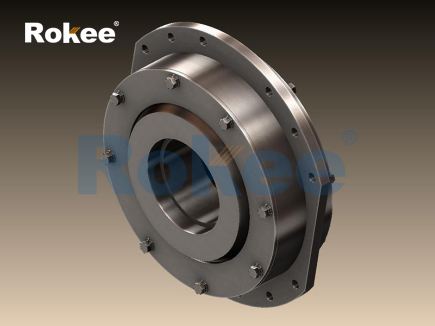

Mechanical drum coupling

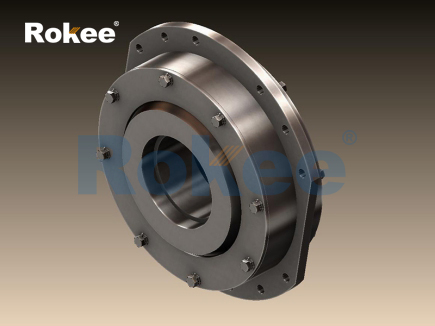

The gear type drum coupling adopts an internal and external gear meshing structure, which transmits torque through a gear pair. Its characteristics are high load-bearing capacity and high transmission accuracy, suitable for heavy-duty coiling equipment. Typical applications include rolling mills, coilers, and non-ferrous metal processing production lines in the steel industry. This type of coupling is usually made of high-quality alloy steel and undergoes precision machining and heat treatment to ensure reliable operation under high-speed and heavy-duty conditions.

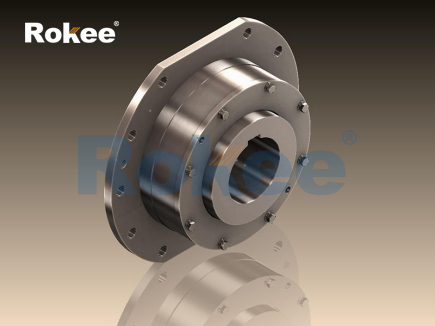

The keyway type coupling has a relatively simple structure and transmits torque through the connection between the key and keyway. It is suitable for situations with low to medium loads and low precision requirements, and has the characteristics of low cost and easy maintenance. However, this type of coupling has limited ability to compensate for axial displacement and is typically used in applications where the diameter of the drum does not change significantly.

Hydraulic drum coupling

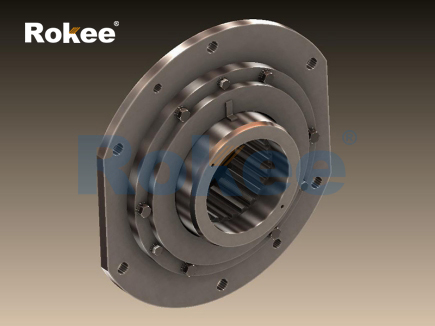

The hydraulic expansion sleeve coupling uses hydraulic principles to achieve hub connection, and expands the inner sleeve of the coupling through high-pressure oil, forming an interference fit with the shaft. The significant features of this type of coupling are easy assembly and disassembly, good alignment, and the ability to transmit high torque. On modern continuous production lines, hydraulic expansion sleeve couplings are highly favored for their quick replacement characteristics, which can significantly reduce equipment downtime.

The hydraulic friction coupling adopts a multi plate friction plate structure, and the torque transmitted is controlled by hydraulic pressure. This design enables the coupling to have overload protection function. When the load exceeds the set value, the friction plate will slip, avoiding equipment damage. This type is particularly suitable for precision winding equipment that requires high system protection.

Electromagnetic drum coupling

Electromagnetic powder couplings use electromagnetic fields to control the solidification state of magnetic powder and transmit torque. Its biggest feature is the ability to achieve stepless speed regulation and soft start, making it particularly suitable for winding applications that require strict tension control, such as plastic film and high-end paper production. This type of coupling has fast response speed and high control accuracy, but the initial investment cost is relatively high.

The electromagnetic eddy current coupling works based on the principle of eddy current, and changes the transmitted torque by adjusting the excitation current. It does not generate mechanical wear, has low maintenance costs, and is suitable for occasions that require frequent start stop or speed regulation. In production environments with high environmental requirements, this non-contact transmission method has significant advantages due to its oil-free and low-noise characteristics.

The rated torque is the primary parameter for selecting a coupling, which represents the maximum torque value that the coupling can transmit stably for a long time. During engineering design, it is necessary to consider peak torque and sustained operating torque, while retaining appropriate safety margins. For applications with high impact loads, coupling types with buffering characteristics should be selected.

Compensation capability includes displacement compensation in three dimensions: axial, radial, and angular. The drum coupling particularly emphasizes the axial compensation capability, as the change in drum diameter during the winding process mainly leads to axial displacement. The axial compensation of high-quality drum couplings can reach ± 100mm or even larger, which can meet the needs of most industrial applications.

The maximum speed determines the applicable speed range of the coupling. The dynamic balance performance of the coupling is crucial during high-speed operation. Excessive unbalance can cause vibration, affecting equipment accuracy and service life. For applications with speeds exceeding 1000rpm, coupling products that have undergone precision dynamic balancing testing should be selected.

The torsional stiffness reflects the ability of the coupling to resist torsional deformation and has a significant impact on the dynamic characteristics of the transmission system. High stiffness couplings have high transmission accuracy but poor buffering capacity, making them suitable for precision positioning systems; Low stiffness couplings can absorb vibrations and impacts, making them suitable for situations with significant torsional vibrations.

Load characteristic analysis is the first step in selection. A coupling with a simple structure can be used for constant loads, while for impact loads or variable loads, a type with buffering or overload protection function needs to be considered. In the hot rolling production line of the steel industry, hydraulic or elastic couplings with good buffering performance are usually selected due to the drastic changes in load.

Installation space limitations are often overlooked but very important. Compact equipment requires the selection of couplings with small radial dimensions, such as diaphragm or bellows couplings; In the case of limited axial space, a nested design coupling can be considered. Modern coupling manufacturers offer modular products that can be customized according to spatial constraints.

Environmental conditions impose different requirements on the material and sealing performance of couplings. High temperature environments require the use of heat-resistant materials, such as stainless steel or special alloys; Good sealing protection is required in damp or dusty environments; For corrosive environments, anti-corrosion measures such as plastic or ceramic coatings should be considered. Environmental adaptability becomes a key factor in the selection of couplings in offshore platforms or chemical winding equipment.

Maintaining convenience is particularly important for continuous production equipment. The easy to disassemble structural design, long-lasting friction materials, and convenient lubrication system can significantly reduce maintenance time and costs. On some production lines that operate continuously for 24 hours, it is possible to choose coupling products that are maintenance free or have a maintenance cycle of several years.

Precise alignment is the foundation for ensuring the normal operation of the coupling. Even with the use of couplings with strong compensation capabilities, good alignment can extend the service life. Modern tools such as laser alignment instruments can control the alignment error within 0.05mm, significantly reducing vibration and wear. During the installation process, the steps provided by the manufacturer should be followed, with special attention paid to the tightening sequence and torque values of the bolts.

Lubrication management directly affects the performance and lifespan of the coupling. Gear couplings require regular replacement of lubricating oil to maintain the oil level within the standard range; Friction type couplings require checking the wear of the friction plates and timely replacement.

Establishing standardized lubrication records and cycles can prevent early failure caused by poor lubrication.

State monitoring technology is becoming increasingly important in modern equipment management. Vibration analysis, temperature monitoring, and noise detection can detect coupling abnormalities early. Advanced online monitoring systems can collect real-time operational data, analyze and predict remaining service life through algorithms, and achieve predictive maintenance. Installing such systems on critical equipment, although increasing initial investment, can avoid greater losses caused by unexpected shutdowns.

Common fault handling requires a systematic approach. Excessive vibration may indicate poor alignment or component wear; Abnormal noise often indicates insufficient lubrication or damaged parts; If the temperature is too high, it may be due to overload or abnormal friction surface.

Establishing a fault tree analysis model can quickly locate the root cause of problems and improve maintenance efficiency.

The steel rolling industry is a typical application area of drum couplings. In the hot rolling production line, the drum coupling bears enormous torque and drastic load changes, while compensating for the significant change in steel coil diameter from "empty coil" to "full coil" during the coiling process. The specially designed heavy-duty gear coupling can work reliably under such harsh conditions, ensuring the stable operation of a production line that produces millions of tons of steel annually.

Paper making machinery has special requirements for drum couplings. Accurate tension control is required during the paper production process to avoid paper wrinkling or breakage. The tension control system using electromagnetic powder coupling has fast response speed, high adjustment accuracy, and can produce high-quality paper with uniform thickness. At the same time, the humid environment of paper mills requires couplings to have good rust prevention and sealing performance.

The high-performance drum couplings used in plastic film production lines face challenges of high speed and high precision. The production speed of biaxially oriented films can reach 400-600 meters per minute, and the coupling must operate smoothly at such high speeds without introducing vibration. The magnetic coupling supported by air bearings is an ideal choice for this type of application. It does not require mechanical contact, has almost no wear, and can maintain stable transmission performance for a long time.

The drum coupling in cable manufacturing equipment needs to handle special material characteristics. When coiling the cable, it is necessary to ensure sufficient tension to tightly wrap the cable, while avoiding excessive stretching that may cause deformation of the insulation layer. The hydraulic coupling equipped with a torque limiter can accurately control the winding tension and automatically disengage when overloaded, protecting expensive cable products from damage.

The drum coupling is transforming from a simple mechanical component to a core component of intelligent transmission systems, with its technological content and added value constantly increasing. The correct selection and use of drum couplings is of great significance for ensuring the efficient and stable operation of production equipment, and is also one of the key factors for industrial enterprises to enhance their competitiveness.

« Drum Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/drum-couplings.html