Rokee is a well-known high-quality supplier of Universal Couplings and technical services in China, customize universal couplings according to user drawings, alternatively, if the user provides universal couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Universal coupling is a mechanical device that can transmit torque and rotational motion when two shafts are not concentric or have a certain degree of angular deviation. This unique performance makes it an indispensable key component in modern mechanical transmission systems. Compared with traditional rigid couplings, the most significant feature of universal couplings is their ability to compensate for angles. It can allow a certain angle (usually up to 15-45 degrees) between two connecting shafts while maintaining continuous power transmission. This feature has irreplaceable value in vehicle transmission systems, industrial machinery, and various occasions that require non-linear transmission.

Cross axis: the core component, in the shape of a cross, with four shaft necks perpendicular to each other

Bearing sleeve: a precision bearing component installed on the four journals of the cross shaft

Yoke fork: a fork shaped component that connects the driving shaft and the driven shaft, usually used in pairs

Seals: Protect internal bearings from contamination and maintain lubrication

Lubrication system: including oil injection nozzle and internal oil passage

The working principle of universal coupling is based on spherical kinematics. When the active shaft rotates, the first yoke fork drives the cross shaft to rotate, and the cross shaft then transmits the motion to the second yoke fork, thereby achieving power transmission. Due to the fact that the cross axis can freely swing in two mutually perpendicular planes, it can compensate for the angular deviation between the two axes.

It is worth noting that the single universal coupling will generate speed fluctuations during the transmission process, and the rotational speed of the driven shaft will undergo periodic changes when the driving shaft rotates at a constant speed. This unevenness can be eliminated by using a dual universal coupling arrangement (keeping the input and output shafts parallel) or by using a constant velocity universal coupling.

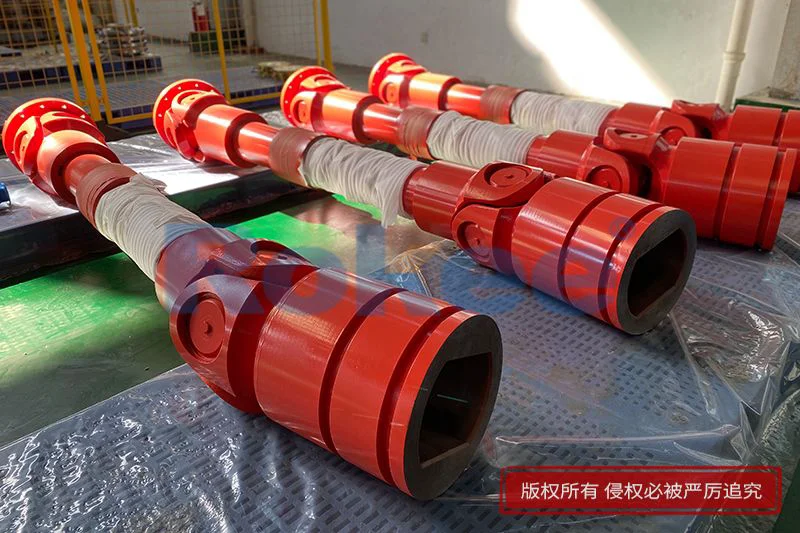

Cross axis universal coupling

The most traditional and common type, characterized by simple structure and strong load-bearing capacity. Suitable for medium to low speed and high torque transmission scenarios, such as truck drive shafts, construction machinery, etc.

Ball cage universal coupling

The representative of constant velocity universal coupling achieves true constant velocity transmission through precise ball path and cage design. Widely used in front wheel drive vehicles, the drive shaft has the advantages of low vibration and low noise.

Double universal coupling

Connected by two single universal couplings through an intermediate shaft, speed fluctuations can be eliminated through reasonable arrangement. Commonly found in long-distance transmission shaft systems, such as ship propulsion systems, large industrial equipment, etc.

Flexible universal coupling

Using elastic components such as rubber and polyurethane to replace some metal parts, it has the function of vibration reduction and noise reduction. Suitable for precision transmission applications that require absorption of vibration and impact.

Rated torque: the maximum torque value that the coupling can continuously transmit

Maximum speed: the maximum speed for safe operation, closely related to balance accuracy

Compensation angle: maximum allowable working angle for a single section (usually 15 ° -45 °)

Axial displacement compensation: Some models can provide limited axial displacement compensation capability

Transmission efficiency: typically between 98% and 99.5%, depending on the type and operating conditions

Service life: closely related to lubrication conditions, working environment, and load characteristics

automotive industry

Transmission shaft system

Front wheel drive half axle

Steering system linkage device

industrial machinery

Long axis transmission of large equipment such as rolling mills and paper machines

Connection between machine tool spindle and drive motor

Rotating equipment such as pumps and compressors

construction machinery

The transmission system of excavators and loaders

Crane slewing mechanism

Power transmission of agricultural machinery

Special Equipment

Ship propulsion system

Wind turbine

Aerospace Auxiliary Systems

Selection considerations

Transmitting power and torque requirements

Deviation between two axes (angle, radial, axial)

Working environment (temperature, humidity, corrosiveness, etc.)

Speed range and balance requirements

Installation space restrictions

Installation precautions

Ensure appropriate alignment accuracy

Tighten the connecting bolts according to the specifications

For the dual universal coupling system, pay attention to the correct arrangement of phase angles

Ensure sufficient lubrication before initial operation

Maintenance points

Regularly check the lubrication condition and replenish or replace lubricating grease on time

Monitor abnormal vibrations and noise

Check the condition of the seals to prevent contaminants from entering

Regularly check the wear of the cross shaft and bearings

With the development of industry and intelligent manufacturing, universal coupling technology is also constantly advancing. In the future, it will become more intelligent, efficient, and reliable, providing better solutions for various complex transmission needs.

A universal coupling, also commonly referred to as a universal joint or U-joint, is a fundamental mechanical component designed to transmit rotational motion and torque between two shafts whose axes are not perfectly aligned. This mechanical device plays an indispensable role in numerous industrial, automotive, agricultural, and aerospace applications, enabling smooth power transfer even when the connected shafts are inclined at an angle or experience relative displacement during operation. Unlike rigid couplings that require precise alignment to function effectively, universal couplings offer a high degree of flexibility, making them essential for systems where perfect coaxial alignment is either impossible or impractical to maintain. The versatility of universal couplings stems from their unique design, which allows for angular misalignment, axial movement, and in some cases, radial offset, while minimizing energy loss and ensuring reliable torque transmission.

The basic structure of a standard universal coupling consists of several key components that work in harmony to achieve its functional purpose. At the core of the assembly are two yokes, which are U-shaped connectors attached to the ends of the driving and driven shafts. These yokes are linked by a cross-shaped element known as a spider or cross shaft, with bearings installed at each of the four arms of the spider to facilitate smooth rotation and reduce friction. The bearings, typically needle roller or sliding bearings, allow the spider to pivot freely within the yokes as the angle between the shafts changes, ensuring that rotational motion is transmitted without excessive wear or binding. In some designs, the yokes are connected to the shafts via flange or spline connections, which provide a secure and rigid attachment while allowing for minor adjustments to accommodate installation tolerances. Additionally, many universal couplings incorporate a lubrication system, including oil nozzles and sealing devices, to ensure long-term reliability by reducing friction between moving parts and protecting against contamination.

The working principle of a universal coupling is rooted in the ability of the cross shaft to transfer rotational motion between the two misaligned yokes. When the driving shaft rotates, it imparts rotational force to the attached yoke, which in turn drives the cross shaft. The cross shaft then transmits this motion to the second yoke, which rotates the driven shaft. A critical characteristic of this mechanism is its ability to accommodate angular misalignment between the shafts. As the angle between the driving and driven shafts varies—whether due to dynamic deflection during operation, installation errors, or structural movement—the spider pivots within the bearings, maintaining continuous contact with both yokes and ensuring uninterrupted power transmission. However, it is important to note that a single universal coupling exhibits a non-uniform rotational speed at the driven shaft when there is an angle between the shafts. This speed fluctuation, known as angular velocity variation, occurs because the effective radius of the yoke arms changes as the cross shaft rotates, leading to periodic acceleration and deceleration of the driven shaft. This phenomenon can result in vibration, noise, and increased wear in high-speed applications, which has led to the development of specialized designs to mitigate these effects.

To address the speed fluctuation issue associated with single universal couplings, engineers have developed double universal couplings, which consist of two single couplings connected by an intermediate shaft. In this configuration, the two couplings are oriented 90 degrees out of phase with each other, which cancels out the angular velocity variation and ensures constant speed transmission between the driving and driven shafts. The intermediate shaft serves as a bridge between the two couplings, allowing for greater angular misalignment compensation while maintaining uniform rotation. This design is particularly valuable in applications where precision and smooth operation are critical, such as automotive drivetrains and high-speed industrial machinery. Another specialized type of universal coupling is the constant velocity (CV) joint, which is designed to eliminate speed fluctuations entirely, even at large angles. CV joints achieve this through a more complex design that typically involves ball bearings enclosed in a grooved housing, allowing for smooth power transmission with a constant velocity ratio regardless of the angle between the shafts. Common variations of CV joints include the Rzeppa joint, which is widely used in front-wheel-drive vehicles, and the tripod joint, which offers excellent angular compensation capabilities for heavy-duty applications.

In addition to these primary types, there are several other variants of universal couplings tailored to specific application requirements. The Oldham coupling, for example, is a type of universal coupling that uses two parallel disks with a tongue-and-groove arrangement to transmit torque while compensating for radial and angular misalignment. This design offers high torsional stiffness and low backlash, making it suitable for precision motion control applications such as robotics and machine tools. The Hookes coupling, named after the 17th-century scientist Robert Hooke, is a simple single-joint design that remains widely used in low-speed, heavy-duty applications due to its durability and cost-effectiveness. Plastic universal couplings, meanwhile, are lightweight alternatives suitable for low-torque applications where corrosion resistance and noise reduction are priorities, such as in small appliances and medical equipment. Each type of universal coupling exhibits unique characteristics in terms of angular compensation range, torque capacity, speed tolerance, and maintenance requirements, making the selection process dependent on the specific needs of the application.

The selection of materials for universal couplings is a critical factor that directly impacts their performance, durability, and suitability for different operating environments. The most common materials used in the construction of universal couplings include carbon steel, alloy steel, aluminum, and composite materials. Carbon steel is widely used for standard couplings due to its high strength, durability, and cost-effectiveness, making it suitable for moderate torque and speed applications. Alloy steel, which incorporates elements such as chromium, manganese, and nickel, offers enhanced mechanical properties, including higher tensile strength, wear resistance, and toughness, making it ideal for heavy-duty applications such as rolling mills, cranes, and mining equipment. Aluminum is preferred for lightweight applications where reducing overall system weight is a priority, such as in aerospace and automotive components, although it has lower torque capacity compared to steel. Composite materials, such as fiber-reinforced polymers, are emerging as alternatives for specialized applications, offering benefits such as corrosion resistance, vibration damping, and reduced inertia, though their use is currently limited by higher manufacturing costs and lower load-bearing capabilities.

The performance of a universal coupling is also influenced by various design considerations, including torque capacity, angular misalignment tolerance, and dynamic balancing. Torque capacity refers to the maximum amount of rotational force that the coupling can transmit without failure, which is determined by the material strength, cross-sectional dimensions of the components, and the quality of the bearings. Angular misalignment tolerance is the maximum angle between the driving and driven shafts that the coupling can accommodate while maintaining efficient power transmission, with typical values ranging from 5 degrees to 45 degrees depending on the design. Dynamic balancing is a critical process for high-speed applications, as unbalanced couplings can generate excessive centrifugal forces, leading to vibration, noise, and accelerated wear. Couplings intended for high-speed operation undergo precision dynamic balancing to ensure that the mass is evenly distributed, minimizing these adverse effects. Additionally, the design of the lubrication system is essential for extending the service life of the coupling, as proper lubrication reduces friction between the spider and bearings, prevents corrosion, and removes heat generated during operation. The choice of lubricant depends on the operating temperature, load conditions, and environmental factors, with high-temperature greases and synthetic lubricants commonly used for extreme conditions.

Universal couplings find application across a wide range of industries, each with unique requirements that leverage the flexibility and reliability of these components. In the automotive industry, universal couplings are a key component of drivetrains, connecting the engine to the wheels and accommodating the angular changes caused by suspension movement and vehicle articulation. Single universal couplings are often used in rear-wheel-drive vehicles, while CV joints are standard in front-wheel-drive and all-wheel-drive vehicles to ensure smooth power transmission during steering. In industrial machinery, universal couplings are used in a variety of equipment, including pumps, compressors, conveyors, and machine tools, where they compensate for misalignment between motors and driven components. Metallurgical and mining equipment, such as rolling mills and crushers, rely on heavy-duty universal couplings to transmit high torque under harsh operating conditions, often in environments with dust, vibration, and extreme temperatures.

The agricultural industry also benefits significantly from the use of universal couplings, which are employed in tractors, harvesters, and other farm equipment to connect engines to implements such as plows, mowers, and balers. These couplings must withstand the rugged conditions of agricultural operations, including frequent angle changes, shock loads, and exposure to dirt and moisture. In the marine industry, universal couplings are used in ship propulsion systems, connecting the engine to the propeller shaft and accommodating the misalignment caused by hull flexure and thermal expansion. Aerospace applications utilize lightweight and high-precision universal couplings in aircraft engines, rotor systems, and auxiliary equipment, where reliability and performance under extreme conditions are paramount. Even in specialized fields such as robotics and medical equipment, universal couplings play a role in enabling precise motion control and power transmission in compact spaces.

Despite their versatility and widespread use, universal couplings are not without limitations, and understanding these drawbacks is essential for proper application and maintenance. One of the primary limitations of single universal couplings is the speed fluctuation and vibration they generate at misaligned angles, which can reduce the efficiency of the system and increase wear on other components. This issue can be mitigated by using double couplings or CV joints, but these designs are more complex and costly. Another limitation is the high wear rate of moving parts, particularly the spider bearings, which are subjected to continuous friction and load. Regular lubrication and inspection are necessary to prevent premature failure, and in harsh environments, seals may be required to protect against contamination from dust, water, or corrosive substances. Installation accuracy is also critical, as excessive initial misalignment can increase additional loads on the coupling and connected components, reducing service life and efficiency. Finally, universal couplings have limited suitability for extremely high-speed applications, as even balanced designs may experience excessive vibration and wear at very high rotational speeds.

Proper maintenance is essential for maximizing the service life and performance of universal couplings. Regular inspection is the foundation of effective maintenance, involving checks for wear, damage, and lubrication status. The spider bearings should be inspected for signs of wear, such as excessive play, noise, or discoloration, which indicate the need for replacement. The yokes and cross shaft should be examined for cracks, deformation, or surface damage, as these can compromise the structural integrity of the coupling. Lubrication should be performed at regular intervals, with the frequency determined by the operating conditions—more frequent lubrication is required for high-load, high-temperature, or dusty environments. When lubricating, it is important to use the appropriate type of lubricant and to ensure that all moving parts are adequately coated, while excess lubricant should be removed to prevent the accumulation of dirt and debris. Seals should be checked regularly for leaks and replaced if damaged to maintain the integrity of the lubrication system.

In addition to routine maintenance, proper installation is crucial for ensuring the optimal performance of universal couplings. During installation, the alignment of the driving and driven shafts should be checked and adjusted to within the coupling’s specified tolerance. Laser alignment tools are commonly used to achieve precise alignment, reducing the risk of excessive wear and vibration. The yokes should be securely fastened to the shafts using the appropriate fasteners, with torque applied uniformly to ensure a tight and even connection. Spline connections, if present, should be cleaned and lubricated before assembly to prevent binding and wear. It is also important to consider the thermal expansion of components during operation, as temperature changes can affect the alignment and performance of the coupling. In applications where thermal expansion is significant, provisions should be made to accommodate this movement, such as using telescoping shafts or flexible mounts.

The evolution of universal couplings has been driven by advances in materials science, manufacturing technology, and engineering design. Early universal couplings, dating back to ancient times with primitive gimbal designs, were simple in construction and limited in performance. The modern universal coupling as we know it today was developed through the contributions of several scientists and engineers, including Gerolamo Cardano, who documented gimbal mechanisms in the 16th century, and Robert Hooke, who analyzed the joint’s motion and coined the term “universal joint” in the 17th century. Hooke also proposed the use of double universal joints to eliminate speed fluctuations, a design that remains widely used today. In the 20th century, the development of CV joints revolutionized automotive and industrial applications, enabling constant speed transmission at large angles. Advances in manufacturing techniques, such as precision machining, 3D printing, and automated CAD modeling, have further improved the quality, accuracy, and production efficiency of universal couplings. Automated CAD modeling systems, for example, can generate complex coupling designs in a fraction of the time required for manual modeling, ensuring geometric accuracy and reducing design errors.

Recent innovations in universal coupling design have focused on improving performance, reducing maintenance requirements, and expanding their application range. One area of innovation is the development of self-lubricating couplings, which incorporate solid lubricants or sealed bearing units to eliminate the need for regular lubrication, reducing maintenance costs and improving reliability in hard-to-reach locations. Another trend is the integration of sensor technology for condition monitoring, allowing for real-time detection of wear, vibration, and temperature changes. These smart couplings enable predictive maintenance, allowing operators to address potential issues before they result in equipment failure, minimizing downtime and repair costs. Advances in composite materials have also led to the development of lightweight, corrosion-resistant couplings that offer improved performance in harsh environments, while additive manufacturing techniques have enabled the production of complex, customized coupling designs that were previously impractical to manufacture.

As industries continue to evolve, the demand for more efficient, reliable, and versatile universal couplings is expected to grow. The automotive industry, in particular, is driving innovation with the shift toward electric vehicles, which require couplings that can handle high torque and speed while maintaining compact dimensions. The renewable energy sector, including wind and solar power, also presents new opportunities for universal couplings, as they are used in wind turbine drivetrains and solar tracking systems to accommodate misalignment and transmit power efficiently. In the aerospace industry, the need for lightweight, high-performance couplings continues to push the boundaries of material science and design, with a focus on reducing weight and improving fuel efficiency. Additionally, the trend toward industrial automation and robotics is increasing the demand for precision universal couplings that can provide accurate motion control in compact spaces.

In conclusion, universal couplings are essential mechanical components that enable reliable power transmission between misaligned shafts across a wide range of industries. Their unique design, which combines flexibility with high torque capacity, makes them indispensable for applications where perfect alignment is impractical or impossible. From simple single-joint designs to complex CV joints and double couplings, there is a universal coupling variant suited to nearly every application, with materials and configurations tailored to specific operating conditions. While universal couplings have inherent limitations, such as speed fluctuation and wear, these can be effectively managed through proper design selection, installation, and maintenance. As technology continues to advance, universal couplings are likely to become more efficient, durable, and intelligent, further expanding their role in modern mechanical systems. Whether in automotive drivetrains, industrial machinery, agricultural equipment, or aerospace systems, universal couplings will remain a critical component, ensuring the smooth and reliable operation of countless mechanical systems for years to come.

« Universal Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/universal-couplings.html