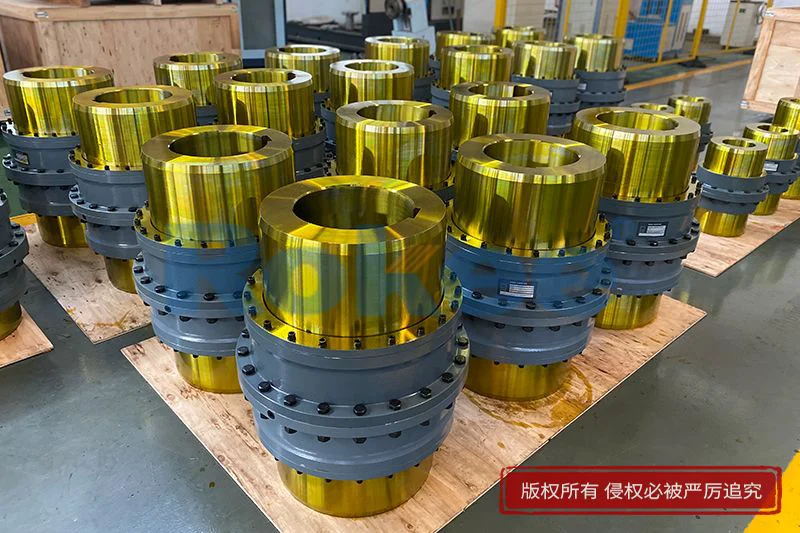

Rokee is a well-known high-quality supplier of Teeth Couplings and technical services in China, customize teeth couplings according to user drawings, alternatively, if the user provides teeth couplings parameters, we can select the model and design drawings for you, support wholesale and export.

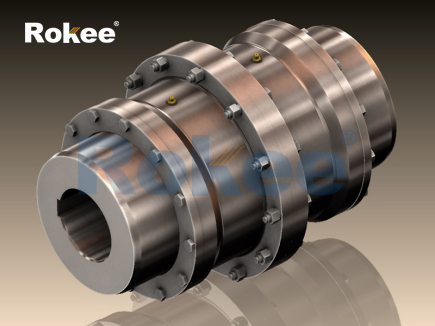

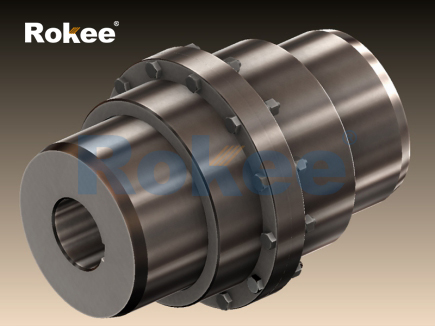

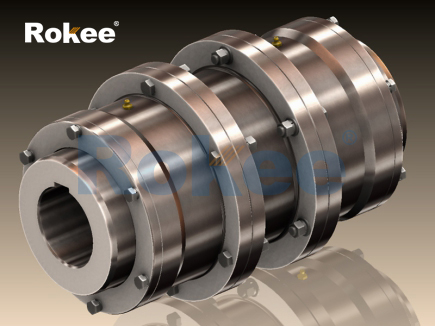

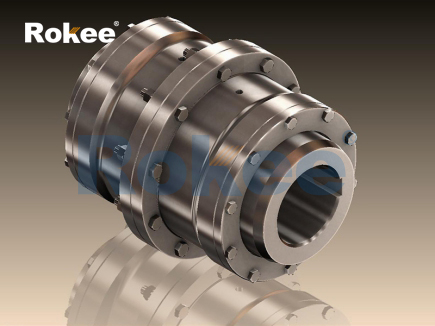

Teeth coupling is a high torque transmission device widely used in industrial machinery transmission systems, which achieves reliable connection between shafts through internal and external gear meshing. This type of coupling has become the preferred connection solution for heavy-duty industrial applications due to its excellent load-bearing capacity, good compensation performance, and long service life.

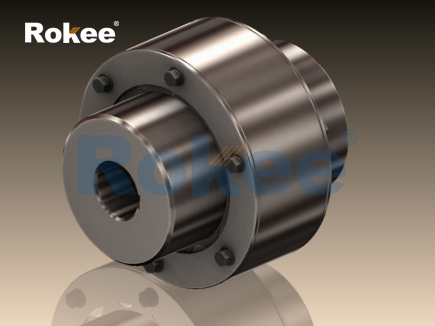

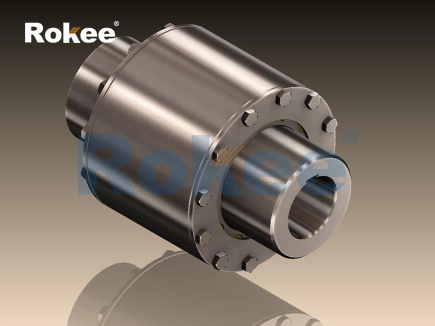

External gear sleeve: usually installed on the drive shaft or driven shaft, with an external gear structure

Internal gear ring: an internal gear component that matches with the external gear sleeve

Flange: used to connect and fix various components

Sealing device: protects the internal lubrication system

Fasteners: Ensure reliable connections between components

When the drive shaft rotates, torque is transmitted through the meshing of the outer gear sleeve and the inner gear ring, while allowing for a certain degree of axial, radial, and angular deviation compensation.

High torque transmission capability: The toothed meshing design can withstand extremely high torque and is suitable for heavy machinery

Excellent deviation compensation capability:

Axial deviation compensation: ± 3-7mm

Radial deviation compensation: 0.5-5mm

Angular deviation compensation: 0.5 ° -1.5 °

Long life design: High quality materials and precision machining ensure a long service life

Easy maintenance: usually lubricated with grease, with a long maintenance cycle

Impact resistance performance: can effectively buffer the impact load during startup and shutdown

Classified by structural form

Full tooth coupling: The inner and outer teeth mesh around the entire circumference, ensuring even torque transmission

Half tooth coupling: Partial tooth meshing, used for specific working conditions

Flange type teeth coupling: with flange connection, more stable installation

Divided by compensation capacity

Standard compensation type: suitable for general deviation compensation needs

High compensation type: with greater deviation compensation capability

Limit compensation type: limit the maximum compensation amount to protect the equipment

Classified by application environment

Ordinary industrial type: standard design, used in conventional environments

Anti corrosion type: special material treatment, used in corrosive environments

Explosion proof type: used in flammable and explosive places

High speed type: special dynamic balance design, used in high-speed situations

Installation steps:

Check the integrity of each component and clean the mating surfaces

Measure and record the distance between the shaft ends

Install using hot or hydraulic tools to avoid direct impact

Ensure that the axial insertion depth meets the requirements

Tighten the connecting bolts according to the torque requirements

Check the alignment to ensure it is within the specified deviation range

Lubrication maintenance:

Lubricant selection:

Normal working condition: NLGI 2 # lithium grease

High temperature environment: synthetic lubricating grease

Heavy load condition: Lubricating grease containing extreme pressure additives

Lubrication cycle:

Regular operation: Supplement lubrication every 3-6 months

Adverse environment: shortened to 1-3 months

Continuous operation: determined based on the number of operating hours

Lubrication control:

Initial lubrication: Fill 1/2-2/3 of the cavity

Supplemental lubrication: Inject an appropriate amount each time to avoid excessive lubrication

Common faults and solutions:

Abnormal vibration: check the alignment, bearing status, and dynamic balance

Excessive temperature rise: Check lubrication and load conditions

Abnormal noise: Check the wear of the tooth surface and the meshing clearance

Leakage: Check the condition of the seals and the quality of the lubricating grease

Heavy industry:

Steel mill

mining machinery

Lifting equipment

Energy industry:

generator set

Wind turbine

Oil drilling and production equipment

Shipbuilding industry:

Ship propulsion system

deck machinery

Auxiliary transmission

Transportation:

Railway locomotive

heavy-duty truck

engineering vehicle

General Machinery:

compressor

Pump

fan

Compared with elastic couplings:

Advantages: Higher torque capacity, longer service life

Disadvantages: High cost, stricter installation requirements

Compared to diaphragm couplings:

Advantages: Better deviation compensation capability, stronger impact resistance

Disadvantages: Requires lubrication and maintenance, heavy weight

Compared to universal couplings:

Advantages: Higher transmission efficiency and wider speed range

Disadvantage: Relatively small angle compensation capability

Compared to hydraulic couplings:

Advantages: Simple structure, higher efficiency

Disadvantage: No overload protection function

As a key component in the field of mechanical transmission, the technological progress of teeth couplings will continue to drive the performance and reliability improvement of the entire industrial equipment. Future research and development will place greater emphasis on optimizing lifecycle costs and environmental friendliness, while maintaining its advantageous position in the field of heavy-duty transmission.

In the complex network of mechanical power transmission systems, teeth couplings stand out as indispensable components that bridge the gap between rotating shafts, ensuring the seamless transfer of torque while accommodating inherent misalignments. These mechanical devices, classified as movable rigid couplings, rely on the meshing of internal and external gears to transmit rotational motion, making them a cornerstone in numerous industrial operations. From heavy-duty metallurgical plants to precision power generation units, teeth couplings demonstrate remarkable versatility and reliability, adapting to diverse operational conditions while maintaining high performance standards. Their design, which balances compactness with robust load-bearing capacity, has made them a preferred choice for engineers seeking efficient and durable solutions for shaft connection.

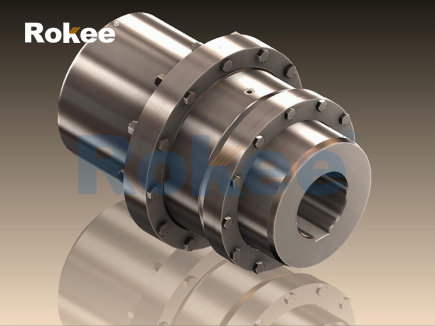

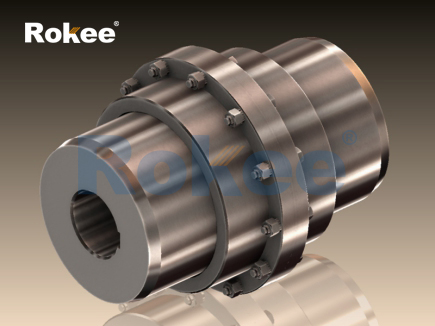

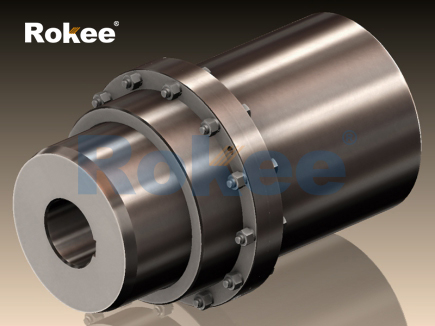

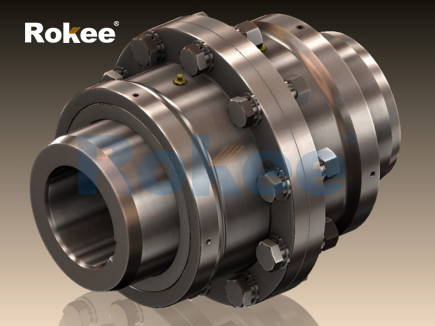

The fundamental structure of a teeth coupling is defined by simplicity and functionality, consisting of core components that work in harmony to facilitate torque transmission and misalignment compensation. At the heart of the coupling are two primary elements: an internal gear ring and a flange half-coupling with external teeth, both featuring the same number of teeth to ensure precise meshing. The internal gear ring is a circular component with gear teeth machined on its inner surface, designed to engage seamlessly with the external teeth of the flange half-coupling. The flange half-coupling, typically a sleeve-like structure with external teeth on its outer circumference, is connected to the rotating shafts via keyways, ensuring a secure fit that prevents slippage during operation. Complementing these core components are end caps and sealing devices, which play critical roles in protecting the internal gear mechanism. End caps serve to secure the components in place, maintaining structural integrity, while sealing devices prevent the ingress of dust, debris, and moisture—factors that can accelerate wear and compromise performance. For smaller-sized teeth couplings, the end cap and internal gear ring are often integrated into a single unit, optimizing structural compactness and reducing assembly complexity.

The working principle of teeth couplings revolves around the mechanical interaction between meshing gears, combining torque transmission with the ability to compensate for shaft misalignments. When the driving shaft rotates, torque is transferred to the external gear sleeve via a key connection, initiating rotational motion. The external teeth of the sleeve then engage with the internal teeth of the gear ring, transferring the torque to the driven shaft and enabling synchronized rotation. A defining characteristic of teeth couplings is their capacity to accommodate relative displacements between the two shafts, which may arise due to installation errors, thermal expansion, or operational vibrations. These displacements typically manifest in three forms: radial displacement (offset between shaft axes), axial displacement (parallel movement along the shaft axis), and angular displacement (tilt between shaft axes). As the shafts experience such displacements, the tooth surfaces of the internal and external gears undergo periodic axial sliding relative to each other. This sliding motion, facilitated by the gear design and adequate lubrication, allows the coupling to adapt to misalignments without disrupting torque transmission, ensuring stable and continuous operation of the mechanical system.

Material selection is a critical factor in determining the performance, durability, and suitability of teeth couplings for specific operational conditions. The choice of materials is influenced by factors such as load magnitude, rotational speed, operating temperature, environmental conditions (e.g., corrosion, dust), and mechanical requirements (e.g., strength, toughness, wear resistance). High-strength alloy steels are widely used for manufacturing teeth couplings, with one of the most common being a chromium-molybdenum alloy that offers an exceptional combination of mechanical properties. This alloy exhibits high strength and toughness, good hardenability, and no significant temper brittleness, making it ideal for heavy-duty applications. After quenching and tempering treatment, followed by surface hardening, the material achieves a surface hardness ranging from 50 to 55 HRC, enhancing wear resistance while maintaining a tough core that can withstand impact loads. For applications with moderate load requirements and cost constraints, high-quality carbon steel forgings are a viable alternative. These materials undergo tempering to improve their mechanical properties, achieving a hardness of 220 to 250 HB, which balances performance and affordability.

In extreme operating conditions, such as high temperatures, corrosive environments, or applications requiring exceptional wear resistance, special alloy steels are employed. These alloys, often containing chromium, nickel, and molybdenum, undergo carburizing and quenching processes to achieve a surface hardness of 58 to 62 HRC, while retaining a core hardness of 30 to 35 HRC to maintain toughness. For applications where corrosion resistance is paramount, such as in the petroleum and chemical industries, stainless steel materials are preferred, as they can withstand exposure to corrosive media without degradation. Additionally, composite materials have emerged as innovative alternatives for specific use cases. Glass fiber-reinforced nylon composites, for example, offer excellent wear resistance with a wear coefficient of 0.12 under dry friction conditions, along with a wide operating temperature range of -40 ℃ to 120 ℃. These composite materials are often used in the manufacture of internal gear sleeves, providing vibration and noise reduction benefits, and are suitable for applications such as water pumps and hydraulic systems where lubrication-free operation is desired. The nominal torque range of nylon-based teeth couplings typically spans from 40 N·m to 3150 N·m, covering a broad spectrum of light to medium-duty applications.

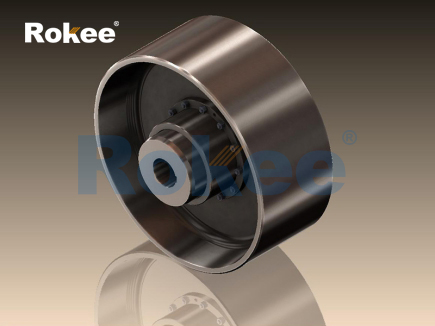

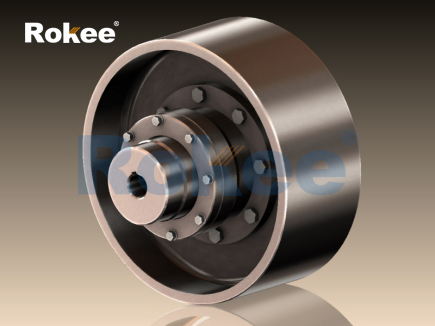

Teeth couplings are classified into distinct types based on the shape of their external teeth, with each type offering unique performance characteristics and suitability for specific applications. The two primary categories are straight tooth couplings and drum tooth couplings, with the latter being the most widely used in modern industrial settings due to its superior performance. Straight tooth couplings feature external teeth with a linear profile, where the tooth blank and pitch circle are machined as straight lines. These couplings compensate for relative shaft displacements by relying on increased backlash between the internal and external teeth, but their compensation capacity is limited. As a result, straight tooth couplings are gradually being phased out in new projects, as they are prone to poor tooth contact conditions and edge loading when misalignments exceed their limited range. Their use is now largely restricted to legacy systems or applications with minimal misalignment requirements and light loads.

Drum tooth couplings represent a significant advancement in teeth coupling design, addressing the limitations of straight tooth variants through innovative geometry. The external teeth of these couplings are machined into a spherical surface, with the center of the sphere aligned with the gear axis. This drum-shaped profile, combined with a larger tooth flank clearance compared to straight tooth couplings, delivers several key performance advantages. Drum tooth couplings exhibit a 15% to 30% higher load-bearing capacity than straight tooth couplings, making them ideal for heavy-duty applications. Their angular displacement compensation capability is also significantly enhanced, allowing for an allowable angular displacement of up to 1°30′—a 50% improvement over straight tooth designs. The spherical tooth profile improves tooth contact conditions, eliminating edge compression and ensuring uniform load distribution across the tooth surface, which reduces wear and extends service life. Additionally, the external gear sleeve of drum tooth couplings often features a flared tooth end, facilitating easier assembly and disassembly during maintenance. High-precision drum tooth couplings, after precision dynamic balancing treatment, can be used in high-speed applications such as gas turbine shaft systems, where rotational speeds may exceed 20,000 revolutions per minute. Another variant is the elastic pin toothed coupling, which incorporates nylon pins as buffer elements. These pins, with an elastic modulus of 3.2 GPa, can absorb up to 15% of impact loads, reducing vibration by 60% compared to rigid couplings, and offer axial compensation of ±0.7 mm. This design is cost-effective and commonly used in conveyor systems, fans, and other equipment where vibration damping is a priority.

The versatility of teeth couplings is reflected in their wide range of industrial applications, spanning diverse sectors where reliable torque transmission and misalignment compensation are critical. In the metallurgical industry, teeth couplings are extensively used in rolling mills, conveyor rollers, and other heavy-duty equipment that operates under high impact loads and frequent misalignments. Drum tooth couplings are particularly preferred here, as their robust design and high load-bearing capacity can withstand the rigorous conditions of steel production. The mining industry relies on teeth couplings for equipment such as crushers, ball mills, and conveyor systems, where operations are often conducted in dusty, harsh environments. For these applications, couplings are equipped with enhanced sealing designs to prevent dust ingress and protect the internal gear mechanism from premature wear.

The lifting and transportation sector, including bridge cranes, gantry cranes, and port machinery, demands high reliability and safety, making teeth couplings an ideal choice. Regular lubrication and maintenance are essential in these applications to ensure consistent performance and prevent unexpected failures that could lead to operational downtime or safety hazards. In the petroleum and chemical industry, teeth couplings are used in compressors, pumps, and other equipment that operates in corrosive environments. Stainless steel or special alloy materials are employed here to resist corrosion from chemicals and hydrocarbons, while advanced sealing systems prevent fluid leakage and contamination. The power generation industry, including thermal power plants, hydropower stations, and gas turbine units, relies on high-precision teeth couplings for high-speed shaft transmission. These couplings undergo rigorous dynamic balancing to ensure smooth operation at high rotational speeds, minimizing vibration and maximizing efficiency.

Lubrication and sealing are indispensable aspects of teeth coupling operation, directly influencing wear rates, power loss, and service life. The periodic axial sliding between meshing tooth surfaces inherently causes friction and wear, making adequate lubrication essential to reduce these effects. Lubricants form a protective film between the tooth surfaces, minimizing direct metal-to-metal contact, reducing friction, and dissipating heat generated during operation. The choice of lubrication method depends on factors such as rotational speed, load, operating temperature, and application requirements, with three primary methods commonly employed: reservoir lubrication, gravity-fed lubrication, and forced lubrication.

Reservoir lubrication involves filling the coupling housing with lubricant, which is retained by centrifugal force during rotation to form a continuous film on the gear surfaces. This method is simple and cost-effective but has limitations, as contaminants can accumulate in the reservoir, and heat dissipation is inefficient. It is typically used for low-speed, low-power applications. Gravity-fed lubrication uses nozzles to deliver lubricant to the meshing teeth, with excess lubricant draining through small holes in the sleeve. This method provides better cooling than reservoir lubrication but may struggle to maintain a consistent oil film under high loads or speeds. For high-speed, heavy-duty applications, forced lubrication systems are preferred. These systems use pumps to inject lubricant directly into the tooth meshing area at high pressure, ensuring thorough coverage and efficient heat dissipation. The continuous flow of lubricant flushes away contaminants, preventing buildup and extending component life. For couplings operating at moderate speeds, grease lubrication is a viable option, with 0 or 1 grade grease used to fill the coupling housing. Grease change intervals typically range from 6 to 12 months, depending on operating conditions, and require lubricants with good adhesion properties to remain in place during rotation.

Sealing systems work in tandem with lubrication to protect the internal gear mechanism. Effective seals prevent lubricant leakage and block the entry of dust, debris, and moisture, which can degrade lubricant quality and cause abrasive wear. Sealing designs vary based on coupling type and application, with common configurations including lip seals, labyrinth seals, and mechanical seals. Lip seals are simple and cost-effective, using a flexible lip to form a tight seal against the rotating shaft. Labyrinth seals feature a series of interlocking grooves that create a tortuous path for contaminants, offering excellent protection in dusty environments. Mechanical seals provide the highest level of sealing performance, using two precision-machined surfaces to form a leak-tight seal, making them suitable for high-pressure or corrosive applications. Regular inspection of seals is essential to detect wear or damage early, preventing lubricant loss and contamination.

Proper installation and alignment are critical to maximizing the performance and service life of teeth couplings. While these couplings can compensate for a certain degree of misalignment, excessive deviations from optimal alignment can lead to premature wear, increased vibration, and component failure. The installation process begins with thorough cleaning of the shaft surfaces and coupling components to remove dirt, rust, and debris, which can interfere with the fit and alignment. The coupling halves are then mounted on the respective shafts, ensuring a tight fit via keyways and set screws or shrink fits. Care must be taken to avoid over-tightening fasteners, which can cause deformation or damage to the shafts or coupling components.

Alignment is performed in two primary stages: radial alignment (ensuring the shafts are concentric) and angular alignment (ensuring the shaft axes are parallel). Specialized tools such as dial indicators, laser alignment devices, or optical alignment tools are used to measure alignment with high precision. For drum tooth couplings, the maximum allowable angular misalignment is typically 1°30′, while radial and axial misalignment limits vary based on the coupling size and design. Exceeding these limits can result in uneven tooth contact, generating additional axial forces and moments that cause accelerated wear, noise, and vibration. In severe cases, excessive misalignment can lead to tooth breakage, coupling disengagement, or damage to connected equipment such as bearings or shafts. After alignment, the coupling housing is assembled, and the appropriate lubricant is added in the correct quantity—typically filling the housing to half its capacity for oil lubrication or completely filling it for grease lubrication. A final check is performed to ensure all fasteners are secure, seals are intact, and the coupling rotates freely without binding or excessive vibration.

Despite their robust design, teeth couplings are susceptible to various failures, most of which are attributed to improper installation, inadequate lubrication, material fatigue, or operational overload. Understanding common failure modes and their root causes is essential for implementing effective preventive measures and minimizing downtime. One of the most prevalent failures is tooth surface wear, which can occur due to insufficient lubrication, contamination, misalignment, or material incompatibility. When lubrication is inadequate, the protective oil film between the teeth breaks down, leading to metal-to-metal contact, increased friction, and abrasive wear. Contaminants such as dust, grit, or metal particles in the lubricant act as abrasives, accelerating wear and causing surface damage. Misalignment results in uneven load distribution across the tooth surfaces, with localized areas experiencing excessive pressure and wear. Over time, severe wear can reduce the tooth thickness, compromising load-bearing capacity and increasing the risk of tooth breakage.

Tooth breakage is a catastrophic failure that typically occurs as a result of cumulative wear, overload, fatigue, or manufacturing defects. Overload conditions, such as sudden torque spikes or excessive load application, can cause immediate tooth failure, while fatigue failure develops gradually over time due to repeated stress cycles. Manufacturing defects, such as poor tooth profile accuracy, material inclusions, or improper heat treatment, can weaken the teeth and increase susceptibility to breakage. Another common failure mode is axial displacement of the internal gear ring, which is often caused by excessive misalignment. When the shafts are misaligned beyond the coupling's compensation capacity, additional axial forces are generated, pushing the internal gear ring out of position. This displacement can lead to incomplete tooth meshing, increased wear, and eventually, loss of torque transmission.

Fastener failure, such as broken bolts or loose set screws, is another issue that can compromise coupling performance. Loose fasteners can cause vibration, misalignment, and slippage, while broken bolts can lead to separation of the coupling halves. This type of failure is often attributed to improper torque application during installation, fatigue from repeated vibration, or corrosion of the fasteners. Seal failure, resulting in lubricant leakage and contamination, is a precursor to many other coupling failures and should be addressed promptly to prevent further damage.

Implementing a proactive maintenance strategy is key to extending the service life of teeth couplings, reducing the risk of unexpected failures, and optimizing operational efficiency. Regular inspection is the foundation of effective maintenance, with frequency determined by the application's operating conditions—heavy-duty or high-speed applications may require weekly inspections, while moderate-duty applications can be inspected monthly or quarterly. Inspections should include checking for lubricant leaks, seal integrity, fastener tightness, vibration levels, and unusual noise. Lubricant analysis is also a valuable tool, allowing maintenance personnel to detect contaminants, moisture, or metal particles in the lubricant, which indicate wear or seal failure. Based on the analysis results, lubricant can be replaced or filtered to maintain optimal performance.

Lubricant replacement intervals vary based on the lubrication method and operating conditions. For grease-lubricated couplings, replacement every 6 to 12 months is typical, while oil-lubricated couplings may require oil changes every 12 months or as recommended by lubricant analysis. When replacing lubricant, the coupling housing should be thoroughly cleaned to remove old lubricant, contaminants, and debris before refilling with the appropriate type and quantity of lubricant. Alignment checks should be performed periodically, especially after equipment maintenance, temperature changes, or operational disturbances, to ensure that misalignment remains within acceptable limits. Vibration monitoring using specialized equipment can detect early signs of misalignment, wear, or imbalance, allowing for corrective action before failures occur.

When wear or damage is detected, timely repair or replacement is essential to prevent further damage to the coupling and connected equipment. Minor wear can sometimes be addressed by reconditioning the tooth surfaces through grinding or polishing, but this is only feasible if the wear is within acceptable limits and the tooth profile remains intact. Seals, fasteners, or lubricant can be replaced as needed to restore performance. In cases of severe wear, tooth breakage, or structural damage, complete coupling replacement is necessary. When replacing a coupling, it is important to select a model that matches the original specifications in terms of load capacity, misalignment compensation, and dimensional compatibility. Additionally, the installation and alignment process should be repeated to ensure optimal performance of the new coupling.

The evolution of teeth coupling technology continues to be driven by the demand for higher performance, greater efficiency, and improved durability in industrial applications. Advances in manufacturing processes, such as computer numerical control (CNC) machining and precision grinding, have enabled the production of couplings with tighter tolerances and superior tooth profile accuracy. This precision enhances load distribution, reduces vibration, and extends service life, particularly in high-speed and high-precision applications. Material science innovations are also contributing to improved coupling performance, with the development of new alloys and composite materials that offer enhanced strength, wear resistance, and corrosion resistance. These materials allow couplings to operate in increasingly harsh environments, such as extreme temperatures, high corrosion, and heavy loads, without compromising performance.

Another area of innovation is the integration of smart monitoring technologies into teeth couplings. Sensors embedded in the coupling can measure parameters such as temperature, vibration, torque, and wear, providing real-time data to maintenance personnel. This predictive maintenance capability allows for the early detection of potential issues, reducing downtime and optimizing maintenance schedules. Additionally, advancements in lubrication technology, such as long-life lubricants and automated lubrication systems, are reducing the frequency of maintenance interventions and improving the reliability of coupling operation.

In conclusion, teeth couplings play a vital role in mechanical power transmission systems, offering a unique combination of high load-bearing capacity, misalignment compensation, and structural compactness. Their design, materials, and performance characteristics make them indispensable in a wide range of industrial sectors, from metallurgy and mining to power generation and petroleum processing. Proper material selection, lubrication, installation, and maintenance are essential to maximizing their service life and ensuring reliable operation. As industrial technology continues to advance, teeth couplings are evolving to meet the growing demands of modern machinery, with innovations in manufacturing, materials, and monitoring technologies driving improvements in performance and efficiency. By understanding the principles, applications, and maintenance requirements of teeth couplings, engineers and maintenance professionals can select, install, and maintain these critical components to optimize the performance and reliability of mechanical systems.

The importance of teeth couplings in industrial operations cannot be overstated, as they serve as the link between power sources and work equipment, ensuring that torque is transmitted efficiently and reliably. Their ability to adapt to misalignments and withstand harsh operating conditions makes them a versatile solution for diverse applications, while ongoing technological advancements continue to enhance their capabilities. Whether in heavy-duty industrial settings or precision machinery, teeth couplings remain a cornerstone of modern mechanical systems, contributing to the efficiency, safety, and productivity of industrial operations worldwide.

« Teeth Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/teeth-couplings.html