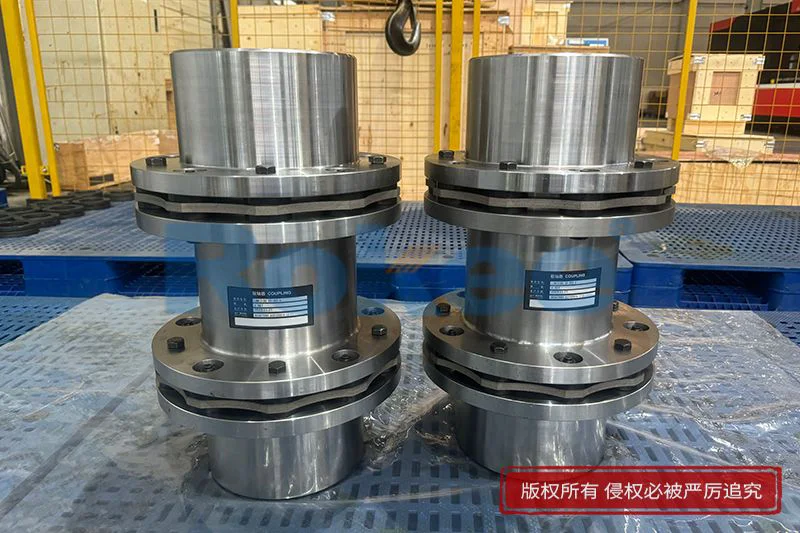

XL Star Coupling

Rokee is a well-known XL Star Coupling supplier from china, the page show cases of XL Star Coupling, provide customized services based on user's drawings, and supporting exports.

XL star coupling is an advanced elastic coupling that uses a unique star shaped elastic body design and plays a key role in industrial transmission systems. This type of coupling is renowned for its excellent shock absorption performance, high torque transmission capability, and good misalignment compensation characteristics, and is widely used in various mechanical transmission systems.

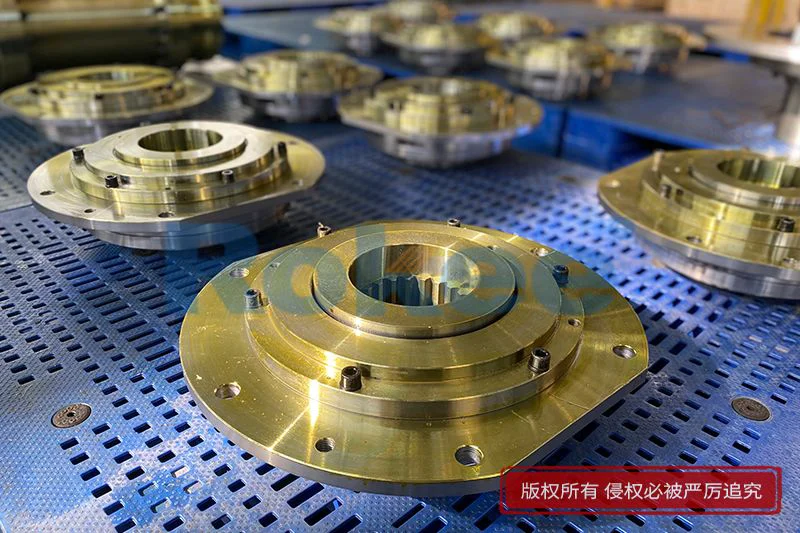

The XL star coupling consists of three main components:

Two metal wheels: usually made of high-strength aluminum alloy or steel material, with internal or external tooth profiles

Star shaped elastic element: made of high-performance polyurethane or other elastic materials, placed between two wheel hubs

Connection and fastening system: including fixing components such as bolts and nuts

When power is transmitted from the driving end to the driven end, the star shaped elastic body works alternately in compression and tension states, absorbing vibration and impact through its elastic deformation, while allowing for a certain degree of axial, radial, and angular deviation.

Technical features and advantages

Excellent shock absorption performance

Can reduce system vibration by 40-60%

Effectively absorb high-frequency vibrations and instantaneous impacts

Reduce transmission system noise by 5-10 decibelsCompensation ability for misalignment

Axial deviation compensation: ± 0.5-1.5mm

Radial deviation compensation: 0.2-0.8mm

Angular deviation compensation: 1 ° -3 °Other advantages

Maintenance free design, long service life

Lightweight structure with small moment of inertia

Easy to install, no need for special tools

Excellent oil and corrosion resistance

Selection considerations

Transmitting torque demand

Axis diameter size matching

Working environment conditions

Inaccurate degree requirement

speed range

XL star couplings are widely used in:

Industrial automation: robotic arms, conveyor systems

Pumps and Compressors: Various Fluid Transport Equipment

Power generation equipment: wind turbines, small generator sets

Engineering Machinery: Construction Equipment, Agricultural Machinery

Shipbuilding industry: propulsion system auxiliary equipment

Correct installation steps

Clean the contact surface between the shaft end and the coupling

Check the fit size between the shaft and the coupling

Use special tools for alignment adjustment

Tighten the bolts according to the recommended torque value

Conduct trial operation inspection

Maintenance precautions

Regularly check the wear of the elastomer

Monitor abnormal operating temperature

Check the looseness of fasteners

Avoid contact with strong acid and alkali media

Conduct a comprehensive inspection every 6-12 months

The XL star coupling with its excellent performance and reliability, has become an indispensable key component in modern industrial transmission systems, and its technology and application scope are still constantly expanding.

With excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc.

« XL Star Coupling » Post Date: 2024/4/25 , https://www.rokeecoupling.net/cases/xl-star-coupling.html

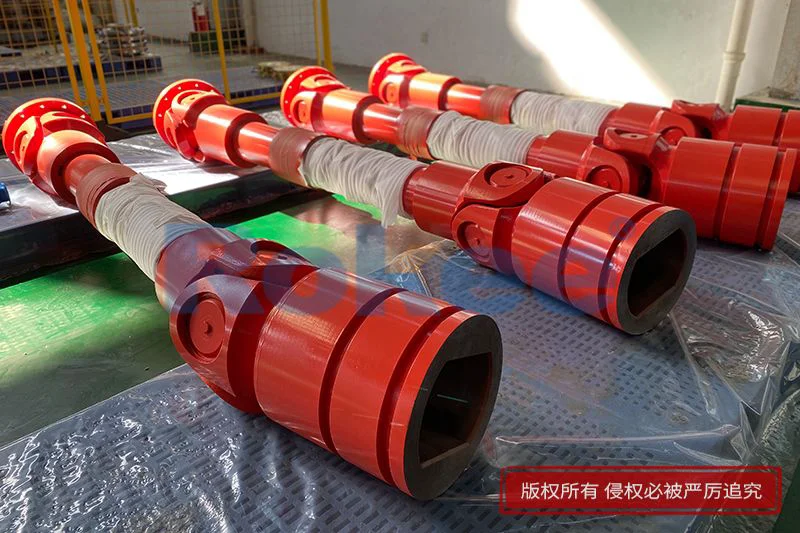

Other Cases

GIICL Tooth Coupling

GIICL Tooth Coupling Expansion Sleeve Coupling

Expansion Sleeve Coupling Double Diaphragm Flexible Coupling

Double Diaphragm Flexible Coupling Wind Power Yaw System Gear Ring

Wind Power Yaw System Gear Ring Drum Gear Coupling With Intermediate Tube

Drum Gear Coupling With Intermediate Tube WJ Spherical Roller Coupling For Drum

WJ Spherical Roller Coupling For Drum WJ Spherical Roller Coupling

WJ Spherical Roller Coupling LK Elastic Block Coupling

LK Elastic Block Coupling Telescopic Universal Joint Drive Shaft

Telescopic Universal Joint Drive Shaft Wind Power Spindle Lock Panel

Wind Power Spindle Lock Panel