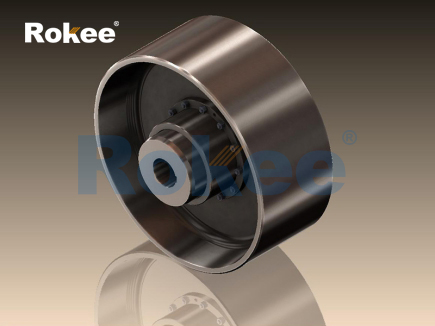

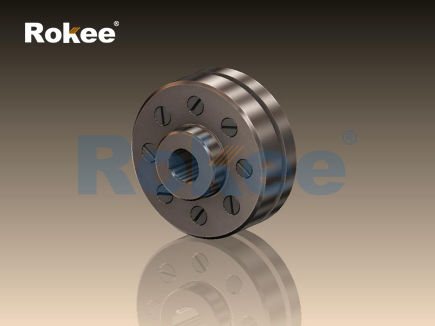

Rokee is a well-known high-quality supplier of Brake Drum Couplings and technical services in China, customize brake drum couplings according to user drawings, alternatively, if the user provides brake drum couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Brake drum coupling is a mechanical device that integrates transmission and braking functions. It combines the functions of coupling and brake, and plays an important role in modern mechanical transmission systems. This device can not only transmit torque and motion under normal operating conditions, but also achieve rapid braking when needed, effectively improving the safety, response speed, and work efficiency of mechanical equipment.

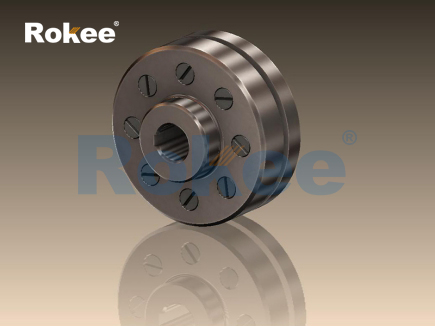

Coupling body: responsible for power transmission

Brake wheel/brake disc: brake function executing component

Friction material: generates braking force

Brake actuator (electromagnetic, hydraulic or pneumatic)

Connecting components and fixing devices

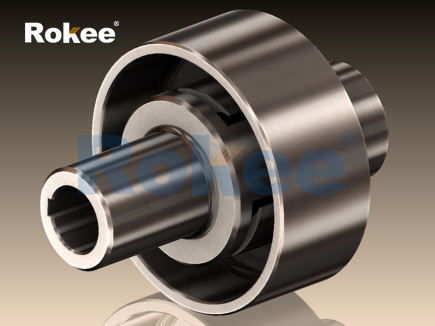

The working mechanism of the brake drum coupling is based on the organic combination of mechanical transmission and friction braking. In normal operation, power is transmitted smoothly through the coupling section, and the braking mechanism is in a separated state; When braking is required, the control system triggers the braking mechanism to bring the friction material into contact with the braking wheel, achieving deceleration and stopping through friction torque.

Power transmission process:

The input shaft transmits power to the coupling through elastic or rigid connections

The coupling transmits power to the output shaft

The brake wheel rotates synchronously with the shaft throughout the entire transmission process

Braking process:

After receiving the braking signal, the actuator (electromagnet, hydraulic cylinder, etc.) generates a force

Friction material is pressed onto the surface of the brake wheel

Friction generates braking torque, causing the system to decelerate to a stop

After the brake is released, the friction material separates from the brake wheel, and the system returns to free rotation

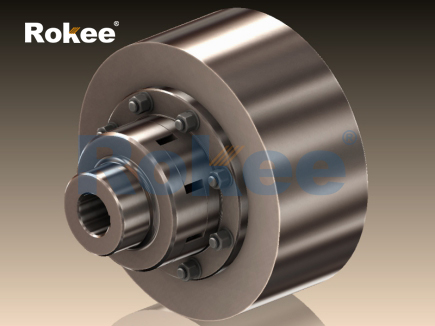

Classified by braking method

Electromagnetic brake coupling: using electromagnetic force to achieve braking, with fast response speed

Hydraulic brake coupling: Controlled by hydraulic pressure for braking, with adjustable braking force

Pneumatic brake coupling: using compressed air as a power source, suitable for explosion-proof environments

Mechanical brake coupling: braking is achieved through a mechanical mechanism, with a simple and reliable structure

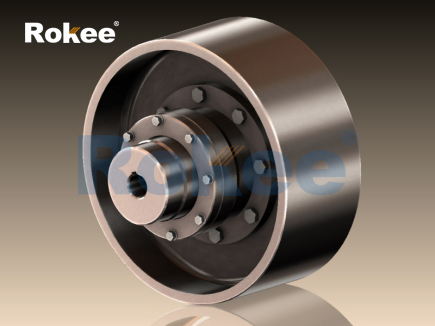

Classified by coupling structure

Elastic brake coupling: with buffering and vibration absorption function

Rigid brake coupling: high transmission accuracy, no elastic deformation

Gear brake coupling: suitable for high torque applications

Diaphragm brake coupling: high precision, no backlash

special type

Safety brake coupling: automatic braking when overloaded

Bidirectional brake coupling: effective braking in both forward and reverse directions

Quick response brake coupling: extremely short braking time (<50ms)

Key performance parameters:

Rated torque: The maximum torque that the coupling can continuously transmit

Maximum braking torque: the maximum braking torque that the braking device can generate

Response time: the time required from issuing the braking command to complete braking

Moment of inertia: affects the acceleration/deceleration performance of the system

Working temperature range: Suitable for different environmental conditions

Protection level: dustproof and waterproof ability

Selection considerations:

Load characteristics: Consider peak torque, impact load, cycle times, etc

Speed range: Ensure safe operation at the highest speed

Installation space: size limitations and connection methods

Environmental conditions: temperature, humidity, corrosiveness, explosion-proof requirements, etc

Control mode: Compatibility with existing control systems

Maintenance requirement: maintenance free or regular maintenance design

Due to its unique functional combination, brake drum couplings are widely used in multiple industrial fields

Industrial Automation

Robot Joint Drive System

CNC machine spindle brake

Automated production line positioning control

Lifting and transportation equipment

Crane lifting mechanism

Elevator drive system

Emergency braking of conveyor belt

new energy sector

Wind turbine yaw braking

Solar tracking system

Electric vehicle transmission system

Special application scenarios

Precision braking for military equipment

Medical equipment safety protection

Aerospace Auxiliary Systems

Daily maintenance points:

Regularly check the wear of friction materials (recommended every 500 working hours)

Keep the brake surface clean to prevent oil contamination

Check the sealing of the pneumatic/hydraulic system

Monitor changes in brake response time

Regularly lubricate moving parts (non friction surfaces)

Common faults and solutions:

Insufficient braking force: Check for wear of friction materials and sufficient pressure

Brake overheating: Check whether the braking frequency is too high and the heat dissipation conditions

Abnormal noise: Check for alignment accuracy, loose or damaged components

Slow response: Check the status of the control system and actuator

Uneven wear: Check installation parallelism and brake surface flatness

As an important component of modern transmission systems, the technological development of brake drum couplings will continue to drive the improvement of mechanical equipment performance. In the future, with the integration of new materials, intelligent control and other technologies, brake drum couplings will achieve greater breakthroughs in accuracy, reliability and functionality, providing stronger support for the development of industrial automation.

« Brake Drum Couplings » Post Date: 2024/4/23 , https://www.rokeecoupling.net/tags/brake-drum-couplings.html