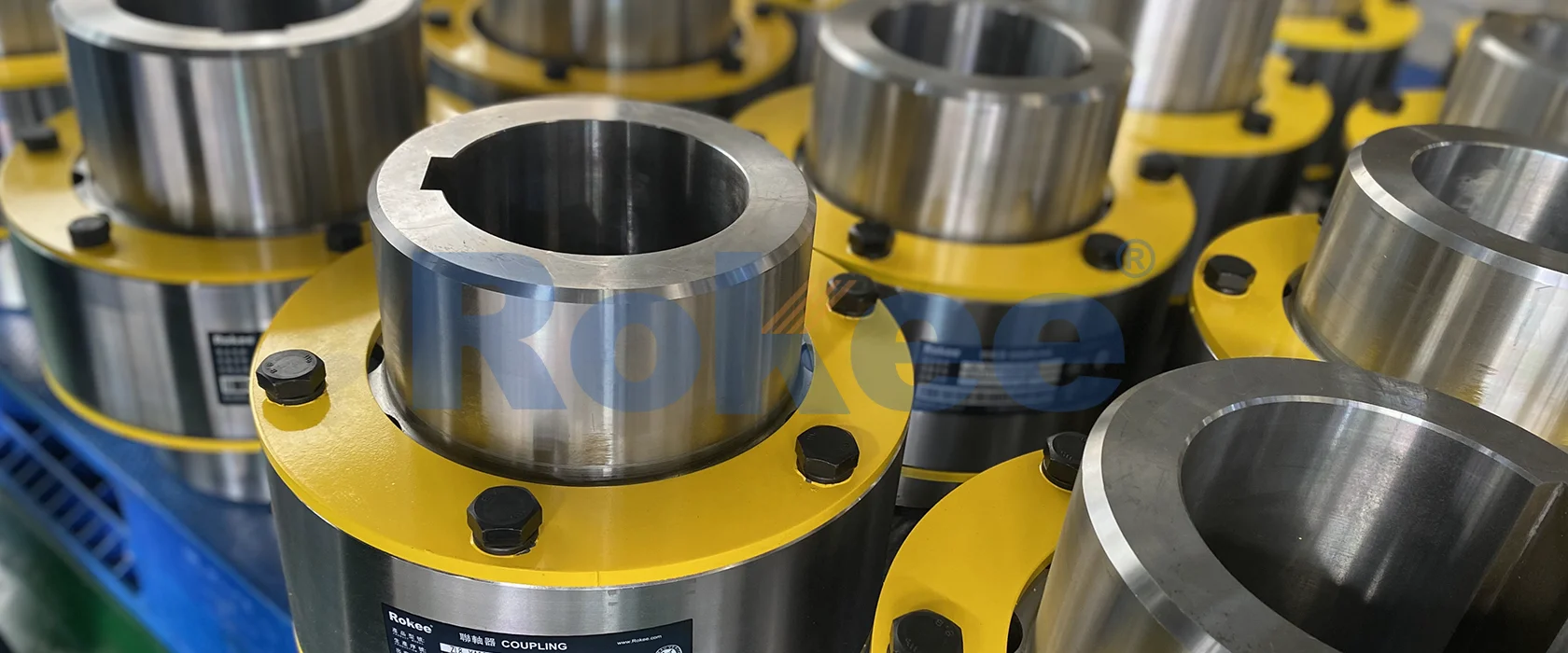

Rokee is a well-known high-quality supplier of Pin Couplings and technical services in China, customize pin couplings according to user drawings, alternatively, if the user provides pin couplings parameters, we can select the model and design drawings for you, support wholesale and export.

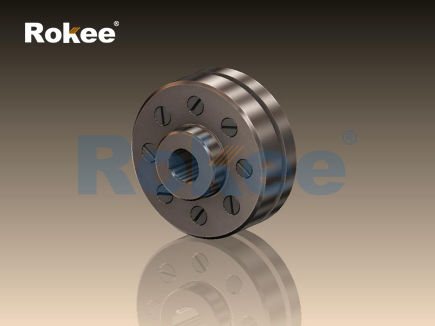

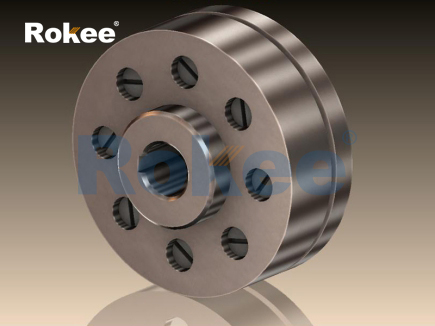

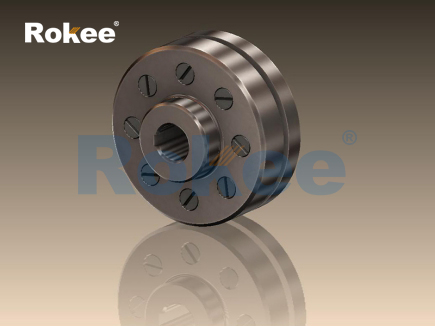

Pin coupling is a commonly used mechanical transmission component, belonging to a type of elastic coupling. It is mainly used to connect two shafts or shafts with rotating parts, compensating for the relative displacement between the two shafts while transmitting motion and power. This type of coupling is widely used in various mechanical transmission systems due to its simple structure, easy disassembly and assembly, and easy maintenance.

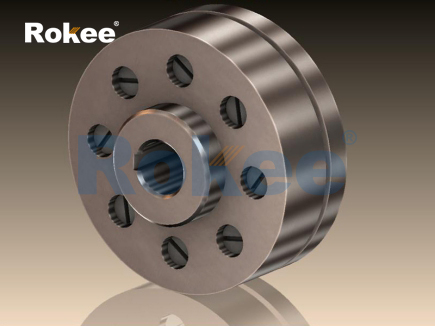

Half coupling: usually two, connecting the driving shaft and the driven shaft respectively, usually made of cast steel or high-quality carbon steel, with high strength and high wear resistance.

Column pin: a key component that connects two half couplings, usually made of alloy steel material, with a hardened surface treatment. The quantity generally ranges from 4-12, depending on the specifications of the coupling.

Elastic sleeve/rubber ring: an elastic element installed on a column pin, usually made of elastic materials such as rubber and polyurethane, used to absorb vibration and impact.

Retaining ring/pressure plate: used to fix the position of the column pin and prevent it from falling off during operation.

Protective cover: Some models are equipped with protective covers to prevent dust from entering and grease from leaking, while also improving safety.

The pin coupling achieves power transmission through the cooperation of column pins and elastic sleeves. When the driving shaft rotates, the half coupling drives the column pin to rotate, and the column pin then transmits the torque to the other half coupling through the elastic sleeve, thereby driving the driven shaft to rotate. Elastic components can absorb vibrations, compensate for small deviations in axial, radial, and angular directions while transmitting torque.

Good vibration damping performance: Elastic components can effectively absorb impacts and vibrations

Compensation capability: can compensate for axial displacement of 0.5-3mm, radial displacement of 0.2-0.6mm, and angular displacement of 1 ° -2 °

Simple structure: fewer parts, easy to manufacture and install

Easy to maintain: No lubrication required, just regularly check the condition of the elastic components

Overload protection: When the load exceeds the design value, the elastic element will be damaged first, protecting the critical components of the equipment

According to their structural and performance characteristics, pin couplings can be divided into various types:

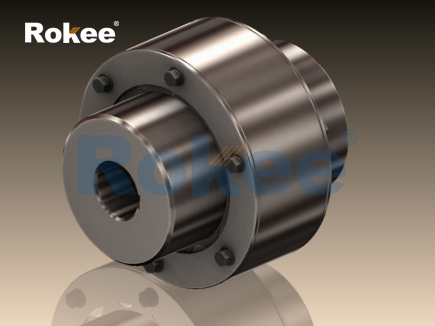

Standard pin coupling

The most common type is suitable for general working conditions, with elastic elements made of rubber or polyurethane sleeves.

Column pin coupling with brake wheel

Integrate brake wheels on the half coupling for transmission systems that require braking.

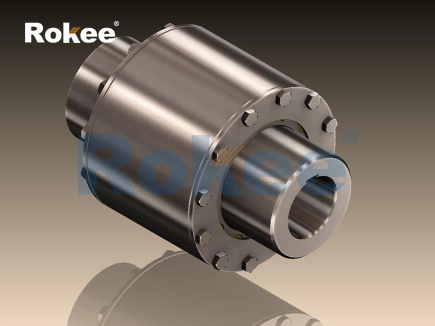

Flange type pin coupling

Adopting flange connection method, suitable for high torque transmission occasions.

High speed pin coupling

Specially designed for high-speed operation scenarios, with a maximum speed of over 5000rpm.

Corrosion resistant pin coupling

Made of corrosion-resistant materials such as stainless steel, suitable for corrosive environments such as chemical and marine industries.

Transmission torque: Select the corresponding specifications based on the required torque of the equipment

Speed range: Ensure that the rated speed of the coupling is higher than the working speed

Shaft diameter matching: The coupling shaft hole should match the diameter of the connected shaft

Work environment: Consider factors such as temperature, humidity, corrosiveness, etc

Displacement compensation requirement: Select the corresponding compensation capability model based on the alignment of the two axes

Installation space: Consider whether the outer diameter and length of the coupling meet the space constraints

Check if the coupling model matches the equipment

Clean the shaft end and coupling inner hole

Install the half couplings on both shafts separately, ensuring they are installed in place

Adjust the alignment of the two axes and control the deviation within the allowable range

Install column pins and elastic components, paying attention to uniform fastening

Install protective cover (if any)

Regularly check the wear of elastic components and replace them in a timely manner

Check if the fasteners are loose

Observe whether there is any abnormal vibration or noise during the operation of the coupling

Avoid operating beyond rated torque and speed

The inspection cycle should be shortened in harsh environments

Abnormal vibration:

Reason: Poor alignment, damaged elastic components, imbalance

Exclusion: Re centering, replacing elastic components, and performing dynamic balancing

Overheating phenomenon:

Reason: Overload, poor lubrication, friction

Exclusion: Check the load, improve lubrication, and eliminate friction sources

Excessive noise:

Reason: Loose and severely worn parts

Exclusion: Tighten loose parts, replace worn parts

Rapid damage of elastic components:

Reason: Overload, environmental factors, material aging

Exclusion: Adjust the load, improve the environment, and select suitable materials

Pump equipment: centrifugal pump, plunger pump, vacuum pump, etc

Fan system: centrifugal fan, axial flow fan

Conveyor machinery: belt conveyor, chain conveyor

Construction Machinery: Cranes, Excavators

Power generation equipment: diesel generator sets, wind turbines

Metallurgical equipment: rolling mill, continuous casting machine

Petrochemical equipment: compressors, mixers

As an economical and practical transmission component, the pin coupling plays an important role in modern industrial production. Correctly selecting, installing, and maintaining pin couplings can not only ensure the reliable operation of the transmission system, but also extend the service life of the equipment. With the advancement of materials science and manufacturing technology, the performance of pin couplings will continue to improve, and their application fields will also be further expanded.

« Pin Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/pin-couplings.html