Rokee is a well-known high-quality supplier of Diaphragm Couplings and technical services in China, customize diaphragm couplings according to user drawings, alternatively, if the user provides diaphragm couplings parameters, we can select the model and design drawings for you, support wholesale and export.

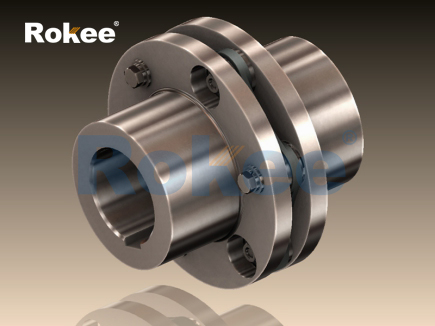

Diaphragm coupling is a high-performance flexible coupling that compensates for deviations between shaft systems through the elastic deformation of metal diaphragms. Metal diaphragm couplings are mainly composed of a metal diaphragm group in the middle, wheel hubs at both ends, and connecting bolts. Through precise mechanical design, they achieve dual functions of power transmission and deviation compensation.

The metal diaphragm group is the core component of the diaphragm coupling, usually made of stainless steel or high-strength alloy steel. These membranes are circular in shape, with a thickness typically between 0.2-1mm, and can be designed as single or multiple stacked pieces depending on the magnitude of the transmitted torque. The surface of the membrane is specially treated to improve fatigue life, and its edges are precisely machined with bolt holes for connecting the wheel hubs at both ends.

The wheel hub is forged from high-quality carbon steel or alloy steel and undergoes precision machining to ensure a good fit with the shaft. According to different connection methods, wheel hubs can be divided into various forms such as cone sleeve, clamping, or keyway to meet the needs of different application scenarios. The connecting bolts are made of high-strength alloy steel and undergo quenching and tempering treatment to ensure sufficient pre tightening force.

The elastic deformation mechanism of the diaphragm coupling is the basis for its functional implementation. When the drive shaft rotates, torque is transmitted to the diaphragm group through the hub, and the diaphragm undergoes slight elastic deformation while bearing the torque. This deformation can effectively transmit power and absorb various deviations between shaft systems.

In the aspect of axial deviation compensation, the diaphragm adapts to the axial displacement through the elastic deformation of its corrugated structure; For radial deviation, the bending deformation ability of the membrane can absorb radial misalignment; The angular deviation is compensated by the differential deformation of different parts in the membrane group. This multi-directional compensation capability makes diaphragm couplings an ideal choice for complex working conditions.

Technical parameters and performance characteristics of diaphragm couplings

The torque transmission capacity of diaphragm couplings is a key performance indicator, typically ranging from a few Newton meters to hundreds of thousands of Newton meters. The rated speed of modern high-performance diaphragm couplings can reach tens of thousands of revolutions per minute, suitable for various high-speed application scenarios. In terms of compensation capability, the axial compensation can generally reach ± 0.5-5mm, the radial compensation is 0.2-2mm, and the angular compensation is 0.5 ° -3 °.

Compared with traditional couplings, diaphragm couplings have significant advantages in backlash free transmission, which is crucial for precision transmission systems. Meanwhile, due to the absence of worn parts, it has a long service life and low maintenance costs. The rigidity of metal film sheets gives them excellent torsional stiffness and the ability to maintain precise phase relationships, making them particularly suitable for situations that require synchronous transmission.

In the energy and power industry, diaphragm couplings are widely used in key equipment such as steam turbines, generators, and gas turbines. Their high-speed capability and reliability meet the long-term stable operation needs of power equipment. Especially in nuclear power plants, high-performance diaphragm couplings are important components for ensuring safe operation.

In the field of petrochemicals, diaphragm couplings are used in various compressors, pumps, and fan equipment. Its corrosion resistance and high temperature resistance make it suitable for harsh industrial environments. In large centrifugal compressors, diaphragm couplings can transmit enormous torque and effectively absorb shaft deviations caused by thermal expansion.

The shipbuilding industry is another important application area of membrane couplings, especially for connecting main engines and propellers. The marine membrane coupling not only needs to withstand huge propulsion torque, but also needs to compensate for the shaft deviation caused by the deformation of the hull, while possessing certain vibration reduction performance.

In high-end manufacturing fields such as aviation engines and precision machine tools, diaphragm couplings play an irreplaceable role due to their high precision and stiffness. Modern five axis linkage machining centers, high-precision grinders, etc. all rely on high-performance diaphragm couplings to achieve precise transmission.

Load characteristic analysis is the first step in selection, which requires accurate calculation of the maximum torque, conventional working torque, and possible impact torque of the system. Simultaneously consider dynamic factors such as speed range and start stop frequency. For situations with reverse impact, membrane designs with higher fatigue strength should be selected.

Deviation assessment is equally crucial, requiring measurement or estimation of possible axial, radial, and angular deviations in the system. It is worth noting that thermal expansion during actual operation often leads to an increase in deviation, which is particularly important in high-temperature applications. When selecting, appropriate safety margins should be retained.

Environmental factors such as temperature, humidity, and corrosive media can all affect the performance of couplings. In special environments, it may be necessary to choose special materials for film sheets and surface treatments. In explosion-proof situations, the possibility of static electricity generated by couplings should also be considered.

The installation space limitation is often overlooked, but in practical applications it may become a decisive factor. Compact diaphragm couplings are particularly suitable for space constrained applications. At the same time, maintenance convenience should also be taken into consideration, and a coupling design that is easy to inspect can greatly reduce downtime.

Precision alignment is the primary requirement for installing diaphragm couplings. Modern laser alignment instruments can accurately measure shaft deviation and guide adjustment work. Even if the diaphragm coupling has compensation capability, good initial alignment can still significantly extend its service life. Special attention should be paid to the tightening sequence and torque value of bolts during installation, as uneven pre tightening force can lead to early failure of the diaphragm.

It is crucial to regularly check the condition of the membrane during daily maintenance. Early damage such as cracks and corrosion can be detected through visual inspection; Vibration monitoring can detect potential issues of increased deviation. For high-speed applications, dynamic balance checks should also be included in regular maintenance plans.

Although lubrication is not as critical as gear couplings, proper lubrication at bolt connections can ensure easy disassembly. It is also necessary to regularly check the condition of anti-corrosion coatings and supplement them in a corrosive environment. Establishing a complete maintenance file helps predict the remaining life of the coupling.

Compared to gear couplings, diaphragm couplings have the advantage of being maintenance free, saving the trouble of regular lubrication, and eliminating gear wear issues. In situations where high precision is required, the no backlash characteristic of diaphragm couplings is significantly better than that of gear couplings.

Compared with elastic couplings, the high rigidity of diaphragm couplings makes them more suitable for precision transmission and has better temperature stability, without performance changes caused by aging of elastic materials. The fatigue life of metal diaphragms is also much higher than that of elastic components such as rubber.

Although universal couplings have stronger angle compensation capabilities, diaphragm couplings have significant advantages in high-speed performance, with less vibration and higher efficiency. For situations that require both angle compensation and high-speed operation, diaphragm couplings are often a better choice.

Fatigue fracture is the most common form of failure, typically manifested as radial cracks on the membrane. This is often caused by long-term overloading or excessive compensation. Preventive measures include reasonable selection, regular inspections, and avoiding excessive misalignment.

Corrosion damage is common in harsh environments such as chemical engineering, manifested as pitting or uniform thinning of the membrane surface. Choosing corrosion-resistant materials and adding protective coatings are effective preventive measures. Abnormal vibration is often a precursor to malfunction, and the alignment status of the shaft system and the condition of the coupling should be checked immediately.

Loose bolts are another common issue that can lead to uneven load distribution. Using anti loosening bolts and regularly checking the fastening status can avoid such problems. When disassembling and repairing, attention should be paid to checking the deformation of the bolt holes. Excessive deformation may indicate that the diaphragm has been overloaded.

As an important component in the modern industrial transmission field, diaphragm couplings are still undergoing technological development and application expansion. In the future, with the continuous emergence of new materials and processes, diaphragm couplings will demonstrate their unique value in a wider range of fields, providing solid guarantees for the efficient and reliable operation of industrial equipment.

In the complex and precise field of mechanical power transmission, the search for components that balance reliability, efficiency, and adaptability has driven continuous innovation in coupling technology. Among the diverse range of coupling solutions available, the diaphragm coupling stands out as a high-performance metal elastic element flexible coupling, widely recognized for its ability to transmit torque efficiently while accommodating misalignments between connected shafts. Unlike traditional coupling designs that rely on rubber or plastic elastic components, diaphragm couplings utilize thin, precision-engineered metal diaphragms to achieve power transfer and deviation compensation, making them indispensable in numerous industrial applications where harsh conditions, high speeds, and precision are paramount. With the advancement of precision machining techniques, electron beam welding, and the development of high-strength alloy steels, diaphragm couplings have evolved into robust, reliable components capable of meeting the stringent demands of modern machinery.

At the core of a diaphragm coupling’s design is its ability to leverage the elastic deformation of metal diaphragms to transmit torque and compensate for axial, radial, and angular misalignments between two shafts. This fundamental working principle distinguishes it from rigid couplings, which require near-perfect alignment and are prone to transferring vibrations and stress concentrations to connected equipment. The basic structure of a diaphragm coupling typically consists of three primary components: two hubs (or sleeves) that attach to the driving and driven shafts, and a diaphragm assembly that connects these two hubs. The diaphragm assembly, often the most critical part of the coupling, is composed of multiple layers of ultra-thin, high-strength metal sheets—commonly stainless steel or surface-treated spring steel—stacked together. These sheets are precision machined with bolt holes and stress relief grooves to optimize their flexibility and durability. The number of diaphragm layers and their thickness are carefully calculated based on the application’s torque requirements and misalignment compensation needs, as the deformation capacity of the diaphragm is inversely proportional to its thickness. Thinner diaphragms offer greater flexibility but lower torque capacity, while thicker diaphragms provide higher torque transmission capabilities but reduced compensation ability. This balance between stiffness and flexibility is a key consideration in diaphragm coupling design.

Diaphragm assemblies are typically categorized into two main types: linkage-type and integral-type. Linkage-type diaphragms consist of multiple separate connecting rod arms that link the inner and outer rings of the assembly, allowing for independent flexing of each arm to accommodate misalignments. This design offers excellent angular compensation capabilities and is often used in applications where complex misalignments are common. Integral-type diaphragms, on the other hand, feature a continuous, one-piece ring structure with precision-machined slots that create flexible sections. This design provides higher torsional stiffness and is preferred in high-precision applications such as CNC machine tool spindles, where minimal backlash and precise torque transmission are essential. Some diaphragm couplings also incorporate an intermediate spool piece, creating a double diaphragm configuration. This design includes two diaphragm assemblies separated by a rigid spacer, significantly enhancing the coupling’s ability to compensate for axial, radial, and angular displacements compared to single diaphragm designs. The spool piece, typically welded to the diaphragms using electron beam welding—a process that ensures strong, precise joints without compromising material integrity—adds structural stability and allows for longer shaft distances between connected equipment.

The torque transmission mechanism of a diaphragm coupling is highly efficient, with energy transfer efficiencies often exceeding 99.8%. When the driving shaft rotates, torque is transferred to the diaphragm assembly through staggered bolt connections. These bolts are strategically positioned to ensure uniform torque distribution across the diaphragm layers, minimizing stress concentrations. As torque is applied, the diaphragms undergo slight elastic deformation, converting the rotational force into shear stress within the metal sheets. This deformation allows the torque to be transmitted to the driven shaft while absorbing any misalignments between the two shafts. Unlike gear couplings, which rely on interlocking teeth and require lubrication to reduce friction and wear, diaphragm couplings have no sliding components and operate without the need for lubrication. This lubrication-free design eliminates the risk of oil leaks, reduces maintenance requirements, and makes diaphragm couplings suitable for use in environments where contamination from lubricants could be problematic, such as food processing, chemical, or pharmaceutical industries.

One of the most notable advantages of diaphragm couplings is their exceptional environmental adaptability. The use of stainless steel or high-alloy diaphragms provides resistance to corrosion, acids, alkalis, and extreme temperatures. Depending on the material and design, diaphragm couplings can operate reliably in temperature ranges from -80℃ to 300℃, making them suitable for both cryogenic applications and high-temperature environments such as gas turbines and metallurgy furnaces. Their resistance to moisture, dust, and chemical exposure also makes them ideal for use in harsh industrial settings like mines, chemical plants, and offshore oil rigs. Additionally, diaphragm couplings produce minimal noise and vibration during operation. The metal diaphragms exhibit damping characteristics that reduce vibration transmission by 30% to 50% compared to gear couplings, contributing to quieter operation and extending the lifespan of connected equipment. This low-vibration performance is particularly beneficial in high-speed applications, where excessive vibration can lead to premature component failure and reduced precision.

The performance characteristics of diaphragm couplings make them suitable for a wide range of industrial applications across various sectors. In the energy industry, they are commonly used in generator sets, gas turbines, and wind turbines, where high rotational speeds, precise torque transmission, and resistance to harsh environmental conditions are critical. Gas turbines, for example, operate at extremely high speeds and generate significant heat, requiring a coupling that can withstand these conditions while compensating for thermal expansion and misalignments. Diaphragm couplings are also widely employed in the process industry, including pumps, compressors, and chemical reactors. Chemical pumps, in particular, benefit from the coupling’s corrosion resistance and lubrication-free design, as they often handle aggressive fluids that would degrade traditional elastic components. In high-end manufacturing, such as CNC machine tools and aviation power systems, diaphragm couplings are favored for their high torsional stiffness, low moment of inertia, and zero backlash. CNC machine tool spindles, which require precise positioning and high-speed operation, rely on diaphragm couplings to maintain accuracy while transmitting torque from the servo motor to the spindle.

Another important application area for diaphragm couplings is in marine and aerospace systems. Marine propulsion systems, including those used in ships and submarines, require couplings that can withstand saltwater corrosion, high torque, and variable loads. Diaphragm couplings meet these requirements by offering robust construction and resistance to harsh marine environments. In aerospace applications, such as helicopter power transmission systems, the lightweight design and high reliability of diaphragm couplings are essential, as every component must minimize weight while ensuring safe, consistent performance. The ability to operate without lubrication also eliminates the risk of oil contamination in sensitive aerospace components, further enhancing their suitability for these applications.

The assembly and installation of diaphragm couplings are critical steps that directly impact their performance and lifespan. Proper installation ensures that the coupling can effectively transmit torque, compensate for misalignments, and avoid premature failure. Before installation, it is essential to clean the end faces of the shafts and inspect the keyways, splines, or tapers for any damage or wear. The mating surfaces must be free of dirt, oil, and debris to ensure a secure fit between the hub and the shaft. Diaphragm couplings typically use either interference fits or clamping mechanisms to attach to the shafts. Interference fits, which involve heating the hub to expand it or cooling the shaft to contract it, allow for a tight, secure connection without the need for additional fasteners. This method, known astemperature difference assembly method, is preferred for high-torque applications as it ensures maximum contact between the hub and the shaft.

When using the temperature difference assembly method, care must be taken to avoid overheating the hub. The maximum heating temperature for steel hubs is generally limited to 400℃, as temperatures exceeding 430℃ can cause changes in the material’s microstructure, reducing its strength and durability. Heating can be achieved through oil bath heating, oven heating, or torch heating, with oil bath heating being the most common method for industrial applications due to its ability to provide uniform temperature distribution. After heating, the hub is quickly positioned on the shaft and allowed to cool, creating a tight interference fit. For smaller couplings or applications with lower torque requirements, mechanical pressing or hydraulic methods may be used, although these methods carry a higher risk of damaging the mating surfaces if not performed correctly.

Once installed, it is crucial to check the alignment of the coupling using precision tools such as dial indicators or laser alignment systems. Misalignment beyond the coupling’s compensation capacity can lead to excessive stress on the diaphragms, resulting in fatigue failure. Angular misalignment, in particular, is a common cause of diaphragm damage, as it creates alternating bending stresses in the metal sheets. Most diaphragm couplings can compensate for angular displacements between 1.5° and 2.5°, depending on the design and material. After the initial installation, the coupling should be run for a test cycle, and all bolts should be inspected and retightened if necessary. This process should be repeated for several operating cycles to ensure that no loosening occurs, as loose bolts can cause uneven torque distribution and damage the diaphragms.

Regular maintenance and inspection are essential to ensure the long-term performance of diaphragm couplings. Unlike lubricated couplings, diaphragm couplings require minimal maintenance, but periodic checks can help identify potential issues before they lead to failure. During operation, the coupling should be monitored for unusual noises, vibrations, or temperature increases, which may indicate misalignment, bolt loosening, or diaphragm damage. It is also recommended to inspect the diaphragms for signs of wear, such as cracks around the bolt holes or deformation of the metal sheets. To prevent fretting wear between the diaphragm layers, a solid lubricant such as molybdenum disulfide can be applied to the mating surfaces, or the diaphragms can be treated with a wear-resistant coating. This reduces friction between the layers during flexing, extending the diaphragm’s lifespan.

Despite their robust design, diaphragm couplings can experience failure if not properly selected, installed, or maintained. The most common failure modes include fatigue cracking, torsional overload, and misalignment-induced damage. Fatigue cracking is often caused by repeated cyclic loading, such as torque fluctuations or continuous misalignment. This type of failure typically manifests as cracks around the bolt holes or along the stress relief grooves of the diaphragms. In cases where torque fluctuations are excessive, the alternating stresses can exceed the diaphragm’s fatigue strength, leading to progressive cracking and eventual failure. Torsional overload, on the other hand, occurs when the coupling is subjected to torque exceeding its rated capacity, resulting in sudden fracture of the diaphragms. This type of failure is often caused by unexpected load spikes, equipment malfunctions, or improper selection of the coupling.

Misalignment-induced damage is another common failure mode, occurring when the coupling is installed with misalignment beyond its compensation range. This creates excessive bending and shear stresses in the diaphragms, leading to premature fatigue failure. The location of the cracks can often indicate the type of misalignment: cracks near the bolt holes typically point to angular misalignment, while cracks along the diaphragm’s edges may indicate radial or axial misalignment. To prevent these failures, it is essential to select the correct coupling size and design based on the application’s torque requirements, misalignment levels, and operating conditions. Additionally, proper installation and alignment, as well as regular monitoring of the coupling’s performance, can significantly reduce the risk of failure.

Advancements in material science and manufacturing technology have continued to improve the performance and capabilities of diaphragm couplings. The use of carbon fiber composite materials (CFRP) in diaphragm construction is one such innovation, offering higher strength-to-weight ratios and improved flexibility compared to traditional metal diaphragms. CFRP diaphragms can transmit higher torques while providing enhanced axial displacement compensation, making them suitable for high-performance applications such as racing engines and advanced aerospace systems. Experimental testing has shown that CFRP sine-wave curved diaphragms can transmit torques of up to 7.5 kN·m and compensate for axial displacements of 4 mm, outperforming traditional stainless steel diaphragms in certain applications. Additionally, the use of finite element analysis (FEA) in diaphragm design has allowed engineers to optimize the shape, thickness, and stress distribution of the diaphragms, reducing weight while improving fatigue resistance.

Electron beam welding has also played a crucial role in the manufacturing of diaphragm couplings, enabling precise, high-strength welds between the diaphragms and the spool piece. This welding method produces minimal heat-affected zones, preserving the material’s mechanical properties and ensuring consistent performance across the coupling. The use of computer numerical control (CNC) machining has further enhanced the precision of diaphragm manufacturing, allowing for complex contour designs and tight tolerances that optimize flexibility and torque transmission. These technological advancements have expanded the range of applications for diaphragm couplings, making them suitable for increasingly demanding environments and performance requirements.

When comparing diaphragm couplings to other types of couplings, their unique combination of advantages becomes evident. Unlike gear couplings, which require regular lubrication and are prone to noise and vibration, diaphragm couplings operate without lubrication, produce minimal noise, and offer better vibration damping. Gear couplings are generally more robust and can withstand higher torque loads, but they are heavier, more complex to install, and less suitable for high-speed applications. Claw couplings, which use rubber or polyurethane elastic elements, offer good vibration absorption and are more cost-effective, but they have lower temperature and corrosion resistance and are not suitable for high-precision or harsh environment applications. Disc couplings, which are similar in design to diaphragm couplings, are more compact but offer lower flexibility and misalignment compensation capabilities.

The selection of the appropriate coupling type depends on a variety of factors, including torque requirements, rotational speed, misalignment levels, environmental conditions, and precision needs. Diaphragm couplings are often the preferred choice for applications that require high precision, high speed, corrosion resistance, and minimal maintenance. Their ability to operate reliably in harsh environments, combined with their efficient torque transmission and misalignment compensation capabilities, makes them an essential component in modern mechanical power transmission systems.

In conclusion, diaphragm couplings represent a sophisticated and reliable solution for mechanical power transmission, offering a unique balance of efficiency, flexibility, and durability. Their design, which leverages the elastic deformation of metal diaphragms, eliminates the need for lubrication, reduces maintenance requirements, and allows for operation in a wide range of harsh environments. From energy production and chemical processing to high-precision manufacturing and aerospace applications, diaphragm couplings play a critical role in ensuring the reliable and efficient operation of modern machinery. As material science and manufacturing technologies continue to advance, diaphragm couplings are likely to become even more versatile and capable, meeting the evolving demands of industrial applications worldwide. Proper selection, installation, and maintenance of diaphragm couplings are essential to maximizing their performance and lifespan, ensuring that they continue to deliver reliable service in even the most demanding conditions.

« Diaphragm Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/diaphragm-couplings.html