SWC Cardan Shaft Coupling

Rokee is a well-known SWC Cardan Shaft Coupling supplier from china, the page show cases of SWC Cardan Shaft Coupling, provide customized services based on user's drawings, and supporting exports.

SWC Cardan Shaft Coupling is a key connecting device widely used in modern mechanical transmission systems, and belongs to a standard model of cross axis Cardan Shaft Coupling. This type of coupling is an ideal choice for connecting different axis transmission components due to its excellent compensation capability and high transmission efficiency.

The main features of SWC Cardan Shaft include:

Can compensate for large angular deviations between two axes (generally up to 15 ° -25 °)

Allow for certain radial and axial displacements

Transmission efficiency up to 98% -99.9%

High load-bearing capacity and compact structure

Easy maintenance and long service life

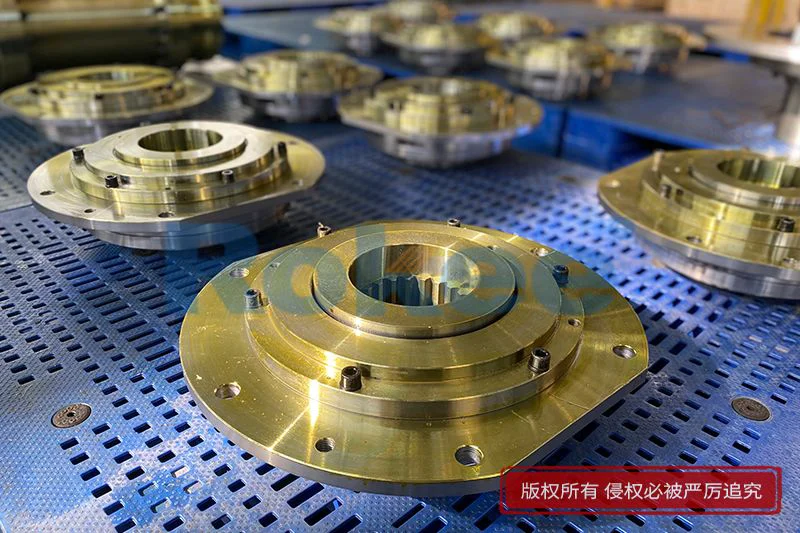

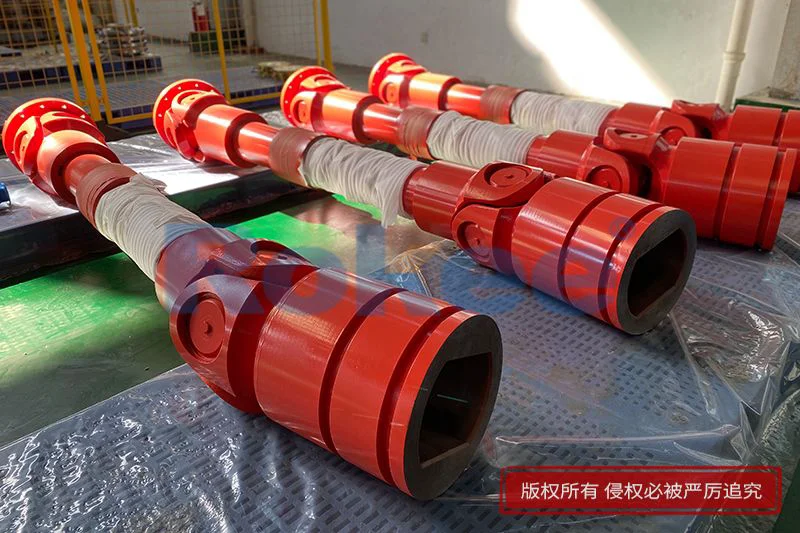

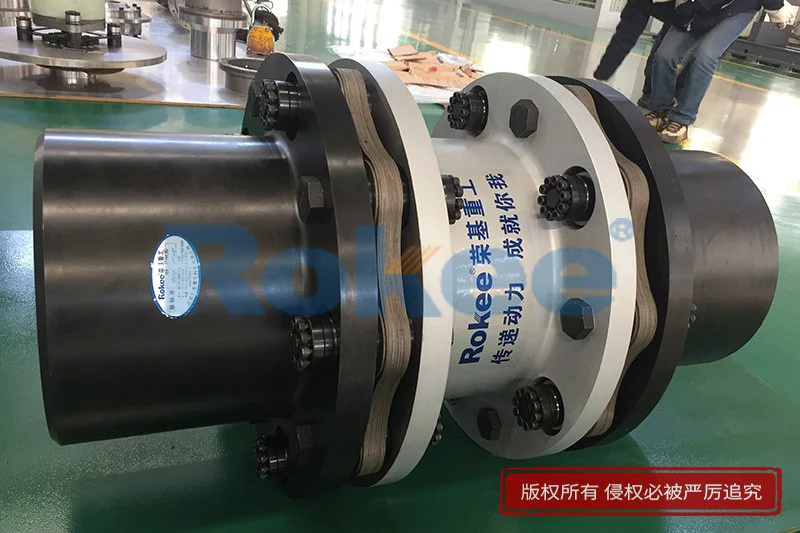

The SWC Cardan Coupling mainly consists of the following core components:

Cross shaft assembly: composed of a cross shaft, needle roller bearings, and bearing seats, it is the core component for achieving universal transmission. The cross shaft is forged from high-quality alloy steel and has extremely high strength and wear resistance after heat treatment.

Flange fork: Generally made of QT400-15 ductile iron or 42CrMo alloy steel, it has excellent mechanical properties.

Spline sleeve and spline shaft: used to connect transmission components at both ends, can be designed as telescopic or fixed according to needs.

Sealing device: High performance sealing components are used to prevent grease leakage and contamination from entering.

Safety protection device: Some models are equipped with protective covers to ensure safe operation.

The SWC Coupling achieves power transmission between non collinear shafts through a cross axis structure. Its working principle is based on the following characteristics:

Angle compensation principle: When there is an angle between the two axes, the active axis decomposes the rotational motion into two perpendicular plane swings through the cross axis, and then synthesizes them onto the driven axis to achieve variable angle transmission.

Speed fluctuation and elimination: Single cross axis Cardan Shaft Couplings can generate speed fluctuations during transmission, so in practical applications, double Cardan Shaft Coupling arrangements (i.e. one SWC coupling at each end) are often used to eliminate speed fluctuations through phase angle arrangements.

Displacement compensation: The telescopic spline structure can compensate for axial displacement, while the cross axis structure can compensate for radial and angular displacement.

Common Model Series

SWC-BH type: standard type, flange connection

SWC-BF type: flange connection, without bearing seat

SWC-WH type: non retractable type

SWC-WS Type: Small and Lightweight Design

SWC-CH type: heavy-duty design with high load-bearing capacity

SWC universal joint couplings are widely used in applications that require large angle compensation and high torque transmission, mainly including:

Metallurgical equipment: rolling mills, continuous casting machines, straightening machines, etc

Mining machinery: crushers, ball mills, conveying equipment, etc

Construction machinery: cranes, excavators, concrete pump trucks, etc

Shipbuilding industry: propulsion shaft system, deck machinery, etc

Petrochemical industry: pump sets, compressors, mixing equipment, etc

Power generation equipment: connection of steam turbine and generator set

Paper making machinery: transmission connections for various rollers

Advantages and characteristics of SWC Cardan Shaft Coupling

Efficient transmission: transmission efficiency up to 98% -99.9%, with minimal energy loss

Large angle compensation: Compared to other types of couplings, it can compensate for larger axis deviations

Compact structure: Under the same torque, the volume is smaller than other types of couplings

Easy maintenance: Long lubrication cycle, usually replenished with lubricating grease every 6 months

Long life design: Key components are made of special materials and heat treatment processes, ensuring a long service life

High standardization: easy to replace and repair

The correct selection of SWC Cardan Shaft Coupling requires consideration of the following factors:

Transmission torque: Select the appropriate model based on the maximum working torque of the equipment

Speed range: Ensure that the allowable speed of the coupling is higher than the working speed

Axis deviation: including angular deviation, radial deviation, and axial deviation

Working environment: environmental factors such as temperature, humidity, corrosiveness, etc

Installation space: The external dimensions of the coupling need to adapt to the installation space

Special requirements: such as explosion-proof, waterproof, high temperature resistance and other special requirements

Installation precautions

Ensure that the alignment error of the two axes is within the allowable range

The flange connection bolts need to be tightened symmetrically and evenly according to the specified torque

Models with expansion splines require appropriate expansion allowance to be reserved

Before the initial operation, an appropriate amount of lubricating grease should be added

Key points of maintenance and upkeep

Regularly check the operation status of the coupling, pay attention to abnormal vibration and noise

Supplement lubricating grease according to the prescribed lubrication cycle (usually once every 6 months)

Regularly check if fasteners are loose

Rust prevention measures should be taken during long-term disuse

SWC Cardan Shaft Coupling as a key component in modern mechanical transmission systems, plays an irreplaceable role in many industrial fields with its unique angle compensation capability and efficient power transmission characteristics. With the advancement of materials science and manufacturing technology, SWC universal couplings will continue to develop towards higher performance, longer lifespan, and greater intelligence, providing more reliable connection solutions for industrial equipment. The correct selection, installation, and maintenance of SWC universal shaft couplings are of great significance for ensuring long-term stable operation of equipment and improving production efficiency.

With excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc.

« SWC Cardan Shaft Coupling » Post Date: 2024/4/25 , https://www.rokeecoupling.net/cases/swc-cardan-shaft-coupling.html

Other Cases

Large Universal Joint Coupling

Large Universal Joint Coupling WJ Spherical Roller Coupling For Drum

WJ Spherical Roller Coupling For Drum LK Elastic Block Coupling

LK Elastic Block Coupling Large Tooth Coupling

Large Tooth Coupling Telescopic Universal Joint Drive Shaft

Telescopic Universal Joint Drive Shaft Large Heave-duty Steel Laminae Coupling

Large Heave-duty Steel Laminae Coupling Internal Spline Drive Shaft

Internal Spline Drive Shaft RLAT Diaphragm Coupling With Super-long Wheelbase

RLAT Diaphragm Coupling With Super-long Wheelbase Long Type Universal Drive Shaft

Long Type Universal Drive Shaft Internal & External Gear Coupling

Internal & External Gear Coupling