Rokee is a well-known high-quality supplier of Toothed Couplings and technical services in China, customize toothed couplings according to user drawings, alternatively, if the user provides toothed couplings parameters, we can select the model and design drawings for you, support wholesale and export.

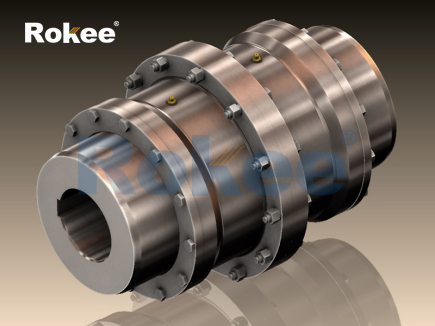

Toothed Coupling is a commonly used connecting device in mechanical transmission systems, which transmits torque and motion through gear meshing. This type of coupling is widely used in heavy-duty and high-speed transmission systems due to its excellent load-bearing capacity and good compensation performance. Compared with other types of couplings, the most significant feature of Toothed Couplings is their ability to transmit large torque while compensating for radial, axial, and angular deviations between the two shafts.

External gear sleeve: usually connected to the drive shaft or driven shaft, with precise involute tooth profile machined on the inner surface

Internal gear ring: used in conjunction with external gear sleeve, with corresponding tooth profile machined on the outer surface

Intermediate connector: used in some structures to connect two internal gear rings

Sealing device: prevents grease leakage and contamination from entering

Lubrication system: including lubrication structures such as oil holes and oil grooves

In terms of material selection, high-quality alloy steel is the first choice for manufacturing Toothed Couplings, commonly including 42CrMo, 35CrMo, etc. After quenching and tempering heat treatment, the tooth surface hardness can reach HRC50-60. For special working conditions, stainless steel or surface hardening treatment can also be used.

The working principle of the Toothed Coupling is based on the principle of gear meshing transmission. When the driving shaft rotates, torque is transmitted to the driven shaft through the contact between the outer gear sleeve and the inner gear ring. During the transmission process, there is a slight gap between the teeth, allowing for a certain relative displacement between the two shafts.

Capable of withstanding extremely high radial, axial, and angular loads

Compensating for shaft deviation through tooth sliding

Has good buffering and vibration reduction performance

The transmission efficiency can usually reach 98% -99.5%

It is worth noting that the compensation capability of a toothed coupling is closely related to its tooth profile design. The tooth profile of modern optimized design allows for angular deviation of 0.5 ° -1.5 ° and radial deviation of 0.1-0.3mm without affecting transmission accuracy.

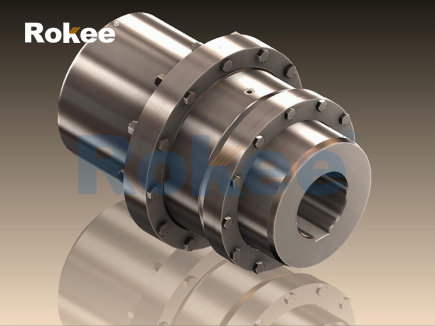

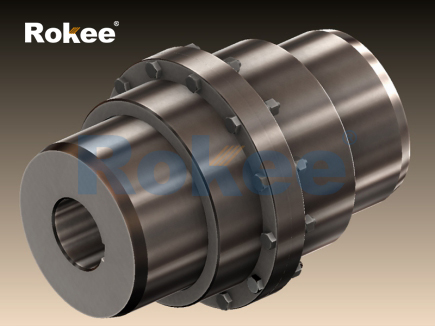

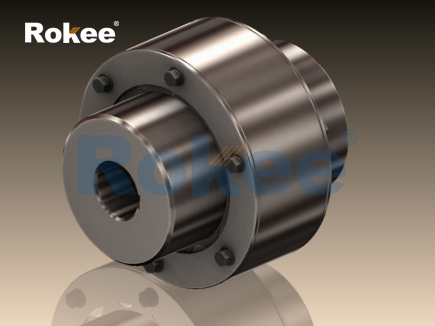

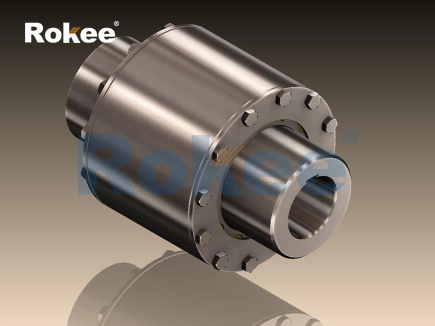

Standard Toothed Coupling: the most basic form, consisting of two outer gear sleeves and one inner gear ring

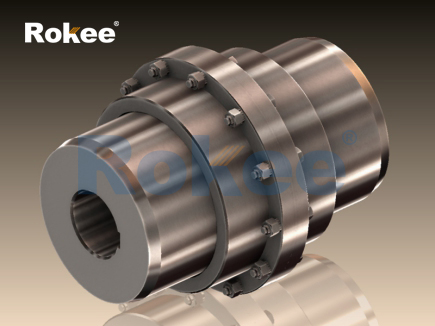

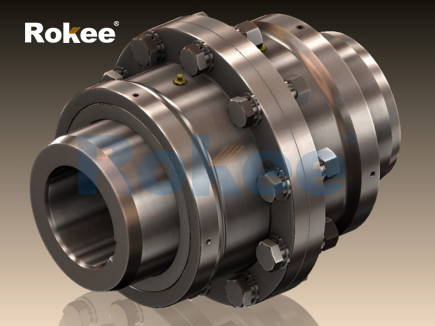

Drum shaped Toothed Coupling: The tooth surface is drum shaped, with stronger compensation capability

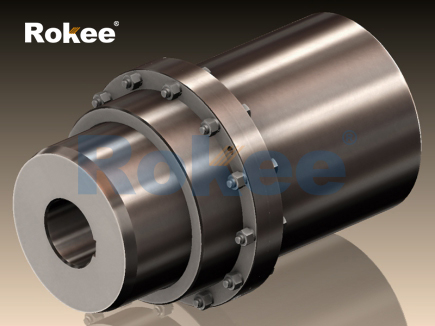

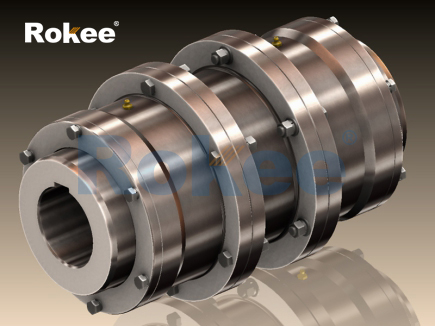

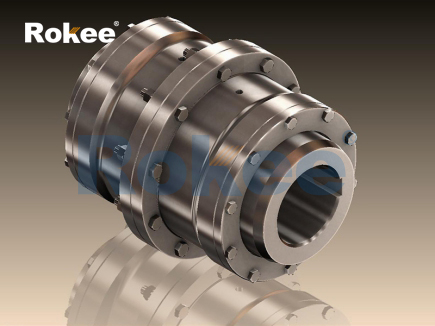

Double toothed coupling: equipped with two inner gear rings, further enhancing compensation capability

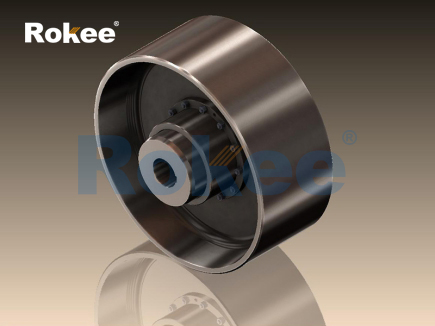

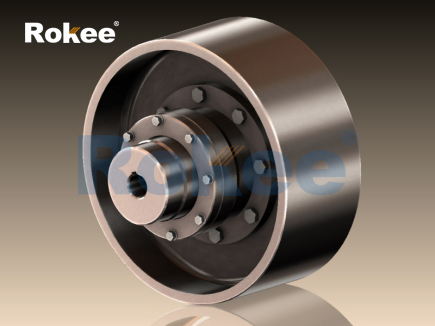

Flange type Toothed Coupling: connected by flanges for easy installation and disassembly

Compact Toothed Coupling: small in size, suitable for space limited applications

Among them, drum shaped Toothed Couplings are widely used in heavy industries such as metallurgy, mining, and shipbuilding due to their excellent comprehensive performance. Its drum shaped tooth design makes the contact stress distribution more uniform and significantly improves the service life.

Metallurgical industry: heavy equipment such as rolling mills and continuous casting machines

Mining machinery: crushers, ball mills, elevators

Shipbuilding industry: propulsion shaft connection

Energy industry: generator sets, wind turbines

Petrochemical equipment: compressors, pump sets

Construction Machinery: Crane, Excavator Transmission System

In the field of wind power, more and more large megawatt level wind turbines are adopting high-performance Toothed Couplings, which can effectively compensate for shaft deviation caused by tower deformation and foundation settlement, while bearing huge alternating loads.

Before installation, check the alignment of the shaft and control it within the allowable deviation range

Clean all mating surfaces, remove burrs and dirt

Tighten the bolts according to the prescribed tightening torque

Use specialized tools for installation to avoid direct hammering

Check if the axial clearance meets the design requirements

Regularly check the lubrication condition and maintain sufficient and clean lubricating grease

Monitor vibration and noise changes during operation

Regularly check the condition of the seals to prevent leakage

Establish operational files to record temperature and vibration data

Experience has shown that poor lubrication is the main cause of early failure of Toothed Couplings, so special attention should be paid to the maintenance of the lubrication system.

Transferred power and speed

Shaft diameter size

Installation space restrictions

Types and sizes of deviations that need to be compensated for

Environmental conditions (temperature, humidity, corrosiveness, etc.)

Accessibility and frequency of maintenance

For overloaded applications, it is recommended to choose a design with a safety factor of not less than 2.0; In high-speed situations, the dynamic balance level needs to be considered, generally requiring a G6.3 level or higher.

Abnormal noise: usually caused by insufficient lubrication or poor alignment, the lubrication condition and shaft alignment should be checked

Overheating: Possible due to overload or poor lubrication, load and lubrication conditions need to be verified

Tooth wear: Check for hard particles entering the meshing area or lubricant contamination

Increased vibration: It may be due to unbalanced coupling or loose foundation, requiring rebalancing or tightening

Leakage: The seal is damaged and should be replaced in a timely manner

Regular status monitoring can effectively prevent these issues and avoid losses caused by unexpected shutdowns.

As a key component of mechanical transmission systems, the performance of Toothed Couplings directly affects the operational reliability and efficiency of the entire equipment. With the advancement of materials science, manufacturing technology, and design methods, modern Toothed Couplings are able to meet increasingly demanding working conditions. The correct selection, installation, and maintenance of Toothed Couplings are of great significance for ensuring long-term stable operation of equipment. In the future, intelligence and green environmental protection will become the main directions for the development of Toothed Coupling technology.

A toothed coupling is a type of movable rigid coupling widely utilized in industrial transmission systems, designed to transmit torque and rotational motion between two shafts while accommodating certain relative displacements. Its core operational mechanism relies on the meshing of internal and external gears, a design that endows it with exceptional load-bearing capacity and structural compactness. Unlike flexible couplings that rely on elastic elements for torque transmission and displacement compensation, toothed couplings achieve power transfer through direct gear engagement, making them particularly suitable for heavy-duty, high-torque applications where reliability and efficiency are paramount. The versatility of toothed couplings allows their integration into a wide range of industrial equipment, spanning from metallurgical rolling mills and mining crushers to marine propulsion systems and gas turbines, underscoring their indispensable role in modern mechanical engineering.

The fundamental structure of a toothed coupling consists of several key components that work in tandem to ensure stable transmission and displacement compensation. At the heart of the assembly are internal gear rings and external gear sleeves, both featuring the same number of teeth to enable precise meshing. The external gear sleeve is typically mounted on the shaft end via a key connection, while the internal gear ring is paired with the external sleeve to form a torque-transmitting interface. Additional components include end caps, sealing devices, and fasteners such as bolts. End caps serve to secure internal parts and prevent axial displacement, while sealing devices play a critical role in maintaining lubrication integrity by blocking the ingress of contaminants and preventing lubricant leakage. In smaller-sized toothed couplings, the end cap and internal gear ring may be integrated into a single unit to optimize structural compactness and reduce assembly complexity. The design of each component is meticulously engineered to withstand the mechanical stresses of torque transmission, minimize wear, and accommodate the relative movements between shafts.

Toothed couplings are primarily classified into two main categories based on the profile of the external gear teeth: straight tooth and drum tooth couplings. Straight tooth couplings feature external gear sleeves with linear tooth profiles, where the indexing circle and root circle are straight lines. This design allows for basic compensation of relative displacements between shafts by virtue of increased backlash between the internal and external teeth. However, the displacement compensation capability of straight tooth couplings is inherently limited, particularly in terms of angular displacement. As a result, they are gradually being phased out in new projects and are mostly confined to legacy equipment or light-load applications where shaft alignment can be maintained with high precision. The simplicity of their design translates to lower manufacturing costs, but their performance limitations make them less suitable for modern industrial environments characterized by dynamic loads and misalignment challenges.

Drum tooth couplings represent a significant advancement over straight tooth designs, incorporating a curved tooth profile that enhances both load-bearing capacity and displacement compensation. The external gear sleeve of a drum tooth coupling has its tooth tips processed into an arc shape, with the tooth blank formed into a spherical surface whose center lies on the gear axis. This three-dimensional curved tooth design fundamentally improves the meshing characteristics between the internal and external gears. Unlike straight tooth couplings, which experience edge contact under misalignment conditions, drum tooth couplings distribute the load across a larger tooth surface area, eliminating edge compression and reducing stress concentration. This structural innovation results in a 15-30% higher load-bearing capacity compared to straight tooth counterparts. Additionally, drum tooth couplings offer superior angular displacement compensation, with an allowable angular displacement of up to 1°30′—a 50% improvement over the 1° limit of straight tooth couplings. The external gear sleeve often features a trumpet-shaped tooth end, facilitating easy assembly and disassembly by guiding the meshing of internal and external teeth during installation.

Beyond the two primary types, specialized variations of toothed couplings have been developed to address specific application requirements. Nylon internal gear couplings, for instance, utilize glass fiber-reinforced nylon composite materials for the internal gear sleeve, offering inherent vibration damping and corrosion resistance properties. These couplings operate effectively within a temperature range of -40℃ to 120℃ and exhibit a low wear resistance coefficient of 0.12 under dry friction conditions. Their nominal torque coverage spans from 40 N·m to 3150 N·m, making them suitable for light to medium-load applications such as water pumps and hydraulic systems. A key advantage of nylon internal gear couplings is their lubrication-free operation, which reduces maintenance requirements and operational costs. Elastic pin toothed couplings integrate nylon pins as buffer elements, leveraging the material's elastic modulus of 3.2 GPa to absorb up to 15% of impact loads—reducing vibration by 60% compared to rigid couplings. These couplings offer axial compensation of ±0.7 mm and are commonly employed in economical applications like conveyors and fans, where vibration mitigation and cost-effectiveness are critical.

The material selection and manufacturing processes of toothed couplings directly influence their performance, durability, and suitability for specific operating conditions. The external gear sleeves and internal gear rings are typically fabricated from high-strength steels to withstand the high contact stresses and torque loads encountered during operation. For heavy-duty applications, alloy steels such as 42CrMo are preferred for the external gear sleeves, undergoing quenching and tempering heat treatment to achieve a hardness range of HRC 28-32 and a tensile strength of at least 900 MPa. This heat treatment process balances hardness and toughness, ensuring resistance to both wear and impact. Internal gear rings may be manufactured from cast steel such as ZG310-570, subjected to normalizing and tempering to attain a yield strength of 310 MPa or higher. The tooth surfaces, which are subjected to the highest levels of wear and stress, are often treated with carburizing and quenching using materials like 20CrMnTi, resulting in a surface hardness of HRC 58-62—enhancing wear resistance by 50% compared to untreated surfaces.

Precision manufacturing processes are essential to ensure the optimal performance of toothed couplings. The gear teeth are typically machined using hobbing and shaping processes, followed by precision grinding to achieve tight dimensional tolerances and smooth surface finishes. This meticulous machining ensures uniform meshing backlash between internal and external teeth, minimizing vibration and noise during operation. For high-speed applications such as gas turbines, toothed couplings undergo dynamic balancing to meet strict precision standards (e.g., G2.5 grade), which prevents excessive vibration at rotational speeds exceeding 4000 rpm. The sealing devices are manufactured from wear-resistant materials such as oil-resistant rubber or fluororubber, tailored to the operating environment—fluororubber being preferred for corrosive or high-temperature conditions due to its superior chemical stability. The integration of these materials and processes results in toothed couplings that can operate reliably for over 100,000 hours when properly maintained.

The working principle of toothed couplings revolves around the meshing of internal and external gears to transmit torque while accommodating relative displacements between shafts. When the driving shaft rotates, torque is transferred to the external gear sleeve via a key connection. The external gear then engages with the internal gear ring, converting the rotational motion of the driving shaft into torque that drives the driven shaft. This meshing action is not only efficient but also allows for a degree of flexibility in shaft alignment. As the two shafts experience relative displacements—whether radial, axial, or angular—the tooth surfaces of the internal and external gears undergo periodic axial sliding. This sliding motion enables the coupling to compensate for misalignment without compromising torque transmission, a feature that distinguishes toothed couplings from rigid couplings, which require precise alignment to avoid catastrophic failure.

Lubrication and sealing are critical factors that determine the service life and operational efficiency of toothed couplings. The periodic axial sliding between meshing teeth inevitably causes wear and power loss, making effective lubrication essential to reduce friction and protect tooth surfaces. The choice of lubricant depends on the operating conditions, including load, speed, and temperature. For most industrial applications, lithium-based grease (NLGI 2 grade) is employed due to its excellent adhesion, temperature stability, and wear-reducing properties. In high-speed or heavy-duty applications, forced thin oil lubrication systems are often utilized to ensure continuous lubricant supply and heat dissipation. These systems circulate lubricating oil through the coupling, removing heat generated by friction and preventing tooth surface glue—a phenomenon where excessive heat causes metal surfaces to fuse together.

Sealing devices complement lubrication systems by preventing lubricant leakage and blocking the entry of contaminants such as dust, dirt, and moisture. A well-designed sealing system maintains the integrity of the lubricating film, extending the service life of the coupling by reducing tooth wear and corrosion. The sealing arrangement typically consists of lip seals or mechanical seals mounted on the end caps, creating a closed cavity around the meshing gears. In harsh environments such as chemical plants or mining sites, where corrosive substances or abrasive particles are present, enhanced sealing solutions with stainless steel components and fluororubber seals are employed to ensure durability. Regular inspection of seals is crucial to detect leaks early, as inadequate sealing can lead to lubricant loss, accelerated wear, and premature coupling failure.

Toothed couplings find application across a diverse range of industries, each presenting unique operational challenges that the coupling's design addresses. In the metallurgical industry, they are extensively used in rolling mills, where they connect motors, reducers, and work rolls. The high torque density and displacement compensation capability of drum tooth couplings make them ideal for this application, as rolling mills operate under heavy loads and experience significant thermal expansion of shafts—requiring axial compensation of up to ±5 mm. The ability to withstand repeated start-stop cycles and impact loads ensures reliable performance in this demanding environment. In the mining industry, toothed couplings are employed in crushers, ball mills, and conveyor systems, where they must operate in dusty, vibration-prone conditions. The robust construction and effective sealing of these couplings prevent contamination, while their load-bearing capacity accommodates the high torque requirements of mining equipment.

Marine propulsion systems rely on toothed couplings to connect engines to propeller shafts, demanding high reliability and resistance to corrosion from saltwater. Stainless steel components and specialized sealing systems are used to protect against corrosion, while the coupling's displacement compensation capability accommodates the misalignment caused by hull flexure during operation. Gas turbines and other high-speed rotating machinery utilize precision-balanced toothed couplings to transmit torque at rotational speeds exceeding 6000 rpm. These couplings undergo rigorous dynamic balancing to minimize vibration, which could otherwise compromise the integrity of the turbine system. In the chemical and petrochemical industries, toothed couplings are employed in pump sets and compressors, where they must resist corrosive media and maintain seal integrity to prevent fluid leakage. Stainless steel and corrosion-resistant alloys are commonly used in these applications to ensure long-term reliability.

The installation of toothed couplings requires careful attention to detail to ensure optimal performance and longevity. Prior to installation, all components must be thoroughly inspected for damage, wear, or dimensional deviations from design specifications. This includes verifying the dimensions of the shaft and gear sleeve to ensure compatibility with the coupling components. Proper shaft alignment is critical, as misalignment beyond the coupling's compensation range can lead to excessive stress, vibration, and premature failure. Laser alignment tools are recommended for achieving precise coaxiality, reducing radial and angular deviations to within acceptable limits. For drum tooth couplings, additional considerations include accounting for thermal expansion of shafts during operation, which may require reserve axial clearance to prevent binding.

During installation, the gear surfaces should be cleaned to remove any contaminants, burrs, or machining residues that could interfere with meshing or cause premature wear. The application of a thin layer of lubricant to the tooth surfaces facilitates initial meshing and reduces friction during the break-in period. Fasteners such as bolts should be tightened to the specified torque to ensure secure connection of components, preventing loosening during operation. It is also important to verify the functionality of the sealing system, ensuring that there are no leaks and that the lubricant is properly retained within the coupling cavity. For split-type couplings, the two halves should be aligned correctly to ensure uniform meshing of gears, avoiding localized stress concentrations.

Regular maintenance and inspection are essential to maximize the service life of toothed couplings and prevent unexpected failures. Routine maintenance activities include periodic lubricant replacement, seal inspection, and wear assessment of gear teeth. The frequency of lubricant replacement depends on operating conditions—heavy-load or high-temperature applications require more frequent changes to maintain lubricant performance. When replacing lubricant, the coupling cavity should be thoroughly cleaned to remove old grease, contaminants, and wear debris. Seals should be inspected for cracks, deformation, or wear, as damaged seals can lead to lubricant leakage and contamination. Fasteners should be checked regularly for tightness, as vibration during operation can cause bolts to loosen over time.

Wear assessment of the gear teeth involves inspecting for signs of pitting, spalling, scoring, or plastic deformation. Pitting and spalling are typically caused by fatigue due to repeated contact stresses, while scoring results from inadequate lubrication or the presence of abrasive particles. Plastic deformation may occur under excessive load or impact. If wear exceeds acceptable limits, the affected components should be replaced to prevent further damage to the coupling or connected equipment. Temperature monitoring is another important maintenance practice, as abnormal temperature rise can indicate issues such as inadequate lubrication, misalignment, or overload. Regular vibration analysis can also detect early signs of wear or misalignment, allowing for corrective action before catastrophic failure occurs.

Despite their robust design, toothed couplings can experience failure due to various factors, including lubrication issues, installation errors, design defects, and operational overload. Lubrication failure is one of the most common causes, occurring when the lubricant is insufficient, degraded, or improperly selected. Insufficient lubrication leads to dry friction between tooth surfaces, resulting in accelerated wear, scoring, and ultimately glue. Degraded lubricant loses its ability to form a protective film, while the use of a lubricant with incorrect viscosity can lead to oil film rupture under load. To mitigate this, it is essential to follow recommended lubrication practices, including the use of the correct lubricant type and regular replacement.

Installation errors, such as excessive misalignment or improper torque application to fasteners, can also lead to coupling failure. Misalignment beyond the coupling's compensation range causes localized contact between teeth, generating additional bending moments and axial forces that result in uneven wear, noise, and eventually tooth breakage. Improperly tightened bolts may loosen during operation, leading to component displacement and uneven load distribution. The use of precision alignment tools and adherence to torque specifications during installation can prevent these issues. Design and manufacturing defects, such as inadequate material selection, improper heat treatment, or poor machining precision, can compromise the coupling's structural integrity. Insufficient tooth surface hardness, uneven meshing gap, or incorrect tooth profile design all contribute to premature failure, emphasizing the importance of quality control during manufacturing.

Operational factors, including overload and frequent start-stop cycles, can also shorten the service life of toothed couplings. Overloading causes contact stresses to exceed the material's yield strength, leading to plastic deformation, tooth fatigue, and breakage. Frequent start-stop cycles subject the coupling to repeated impact loads, accelerating fatigue damage to the gear teeth and fasteners. In high-speed applications, inadequate heat dissipation can cause excessive temperature rise, leading to lubricant degradation and tooth surface damage. Proper load management, including avoiding prolonged overload and minimizing unnecessary start-stop cycles, can extend coupling life.

The selection of a suitable toothed coupling requires careful consideration of several key factors, including nominal torque, operating speed, shaft dimensions, displacement requirements, and environmental conditions. The nominal torque of the coupling must be sufficient to accommodate the maximum torque generated by the equipment, including transient loads during startup and braking. A safety margin is typically applied to account for unexpected overloads, ensuring the coupling can withstand peak loads without failure. The operating speed must not exceed the coupling's allowable speed, which is determined by factors such as material strength, dynamic balancing, and heat dissipation capacity. For high-speed applications, precision-balanced couplings with enhanced lubrication systems are necessary to maintain stability.

Shaft dimensions, including diameter and length, must be compatible with the coupling's shaft hole specifications to ensure a secure fit. The coupling's displacement compensation capability must match the expected misalignment between shafts, which may result from thermal expansion, structural flexure, or installation errors. Environmental conditions such as temperature, humidity, and the presence of corrosive or abrasive substances influence material and seal selection. High-temperature environments require heat-resistant materials and lubricants, while corrosive environments demand stainless steel components and chemical-resistant seals. For applications with strict noise requirements, drum tooth couplings are preferred due to their smoother meshing action and lower noise levels compared to straight tooth designs.

Advancements in materials science and manufacturing technology continue to drive improvements in toothed coupling performance. The development of advanced alloy steels and surface treatment technologies has enhanced wear resistance and fatigue strength, allowing couplings to operate under higher loads and speeds. Composite materials, such as glass fiber-reinforced nylon and carbon fiber-reinforced polymers, are being increasingly used in specialized applications to reduce weight, improve corrosion resistance, and enhance vibration damping. Precision manufacturing techniques, including computer numerical control (CNC) machining and 3D printing, have enabled tighter dimensional tolerances and more complex tooth profiles, optimizing meshing efficiency and displacement compensation.

Innovations in lubrication and sealing systems have also contributed to improved coupling reliability. The development of long-life lubricants with enhanced thermal stability and wear-reducing additives has extended maintenance intervals, reducing operational costs. Advanced sealing technologies, such as magnetic seals and labyrinth seals, offer superior protection against contamination and lubricant leakage, making toothed couplings suitable for even harsher operating environments. The integration of condition monitoring sensors, such as temperature and vibration sensors, into toothed couplings allows for real-time monitoring of operational status, enabling predictive maintenance and reducing unplanned downtime.

In conclusion, toothed couplings represent a critical component in modern industrial transmission systems, offering a unique combination of high torque density, displacement compensation capability, and structural reliability. Their design, materials, and performance characteristics make them indispensable in a wide range of applications, from heavy-duty metallurgical and mining equipment to high-speed gas turbines and marine propulsion systems. Proper selection, installation, lubrication, and maintenance are essential to maximize their service life and ensure optimal performance. As technology continues to advance, toothed couplings are likely to become even more efficient, durable, and adaptable, meeting the evolving demands of industrial machinery and contributing to the overall productivity and reliability of mechanical systems worldwide. The ongoing refinement of their design and manufacturing processes will further solidify their position as a preferred choice for torque transmission in challenging operating conditions.

« Toothed Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/toothed-couplings.html