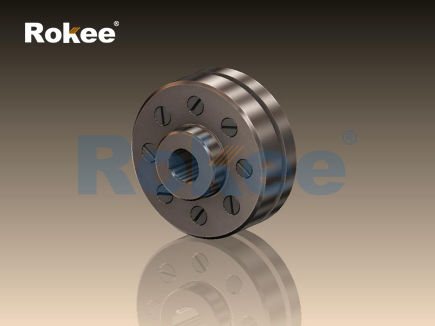

Rokee is a well-known high-quality supplier of Flexible Couplings and technical services in China, customize flexible couplings according to user drawings, alternatively, if the user provides flexible couplings parameters, we can select the model and design drawings for you, support wholesale and export.

A flexible coupling is a mechanical connection device that can transmit torque between two shafts while allowing for a certain degree of axial, radial, and angular misalignment. Unlike rigid couplings, flexible couplings can absorb and compensate for misalignment, vibration, and impact loads in the shaft system through their elastic elements or structural design, thereby protecting the transmission system from damage. Flexible couplings are widely used in various industrial fields, including wind power generation, ship propulsion, petrochemicals, machine tool manufacturing, etc. They are essential key components in modern mechanical transmission systems.

Elastic element flexible coupling

Rubber elastic coupling: using rubber components to provide elastic deformation ability, with good vibration reduction performance

Polyurethane coupling: made of polyurethane material, with high elasticity and wear resistance

Metal spring coupling: using spiral springs or diaphragm springs as elastic elements, suitable for high-precision applications

Non metallic flexible coupling

Tire type coupling: structurally similar to a tire, with large angle compensation capability

Bellows coupling: using metal or plastic bellows structure, suitable for precision transmission

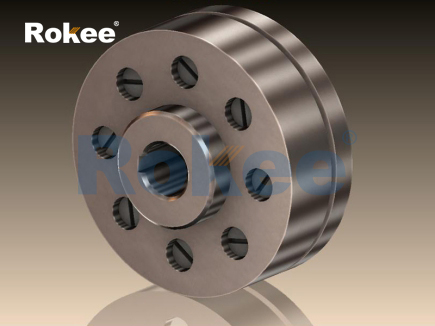

Metal flexible coupling

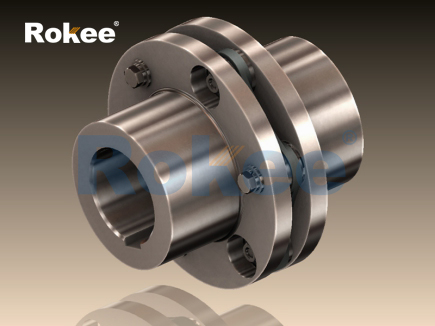

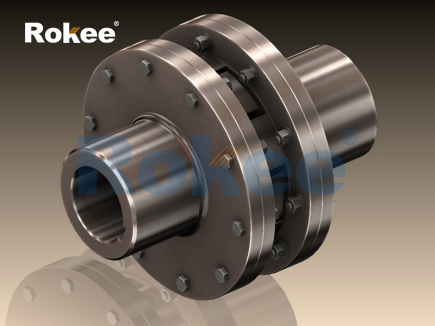

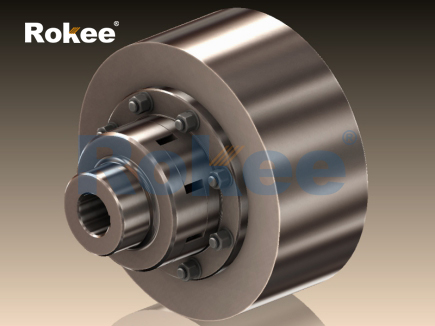

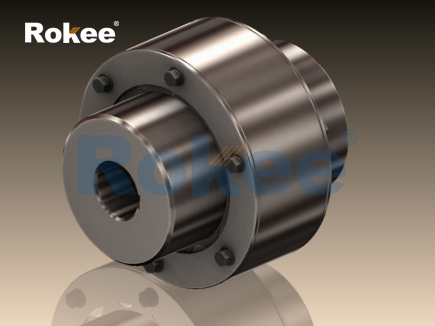

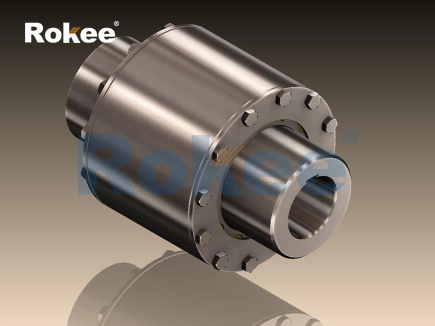

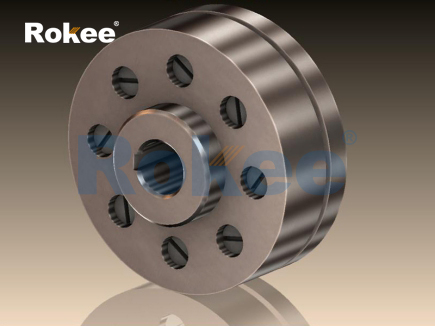

Diaphragm coupling: composed of multiple layers of metal diaphragms, it has high torque transmission capability and good misalignment compensation performance

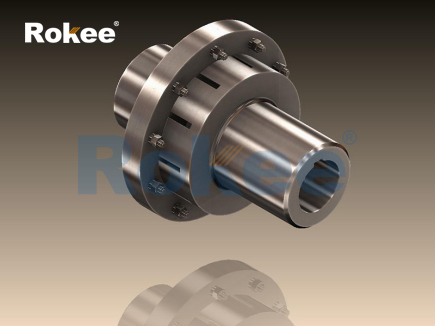

Gear coupling: transmits torque through gear meshing, allowing for certain angles and radial offsets

Universal joint: adopting a cross shaft or ball cage structure, it can achieve large angle transmission

Flexible couplings achieve the following key functions through their special structural design:

Torque transmission: effectively transmitting the rotational motion and torque of the drive shaft to the driven shaft

Misalignment compensation: Absorb and compensate for axial, radial, and angular deviations generated during the installation or operation of the shaft system

Vibration damping: Absorbing and attenuating vibrations and impacts in the transmission system through elastic elements

Overload protection: Some types of devices can be protected by slipping or disconnecting during overload

Rated torque: the maximum torque value that the coupling can continuously transmit

Maximum torque: the maximum torque that can be sustained in a short period of time

Speed range: allowable operating speed range

Compensation capability for misalignment: maximum allowable deviation in axial, radial, and angular directions

Torsional stiffness: the ability to resist torsional deformation

Inertia moment: mass distribution characteristics of rotating components

Working temperature range: the temperature limit that the coupling material can withstand

Service life: the expected service life under specific operating conditions

Application scenario: Clearly define the equipment and environment for which the coupling will be used

Transmission power and speed: Calculate the required torque and speed range

Axis misalignment: Evaluate expected axial, radial, and angular deviations

Space limitations: Consider size constraints for installation space

Environmental conditions: temperature, humidity, corrosiveness and other environmental factors

Maintenance requirements: Is regular lubrication or maintenance necessary

Cost factor: Choosing the best cost-effectiveness within the budget range

Ensure proper support and positioning at the shaft end

Align and adjust according to the steps recommended by the manufacturer

Use appropriate tools to avoid damaging coupling components

Check if the torque of all fasteners meets the requirements

For types that require lubrication, ensure to use the correct lubricant

Regularly check the alignment status of the coupling

Monitor changes in vibration and noise levels

Check for signs of wear or aging on the elastic components

Lubricate according to the recommended cycle (if applicable)

Record operational data for predictive maintenance

Wind power generation: used to connect the generator and gearbox, compensating for the misalignment caused by tower deformation

Ship propulsion: transmitting power between the main engine and propeller shaft, absorbing hull deformation

Steel industry: used for heavy equipment such as rolling mills to withstand high torque and impact loads

Machine tool manufacturing: ensuring the positioning accuracy of precision transmission systems

Petrochemical industry: providing reliable connections in equipment such as pumps and compressors

With the continuous development of industrial technology, flexible couplings will continue to develop towards high performance, high reliability, and intelligence, providing more comprehensive solutions for various mechanical transmission systems.

In the complex network of mechanical power transmission systems, flexible couplings stand as indispensable components that bridge rotating shafts while addressing inherent challenges such as misalignment, vibration, and shock loads. Unlike rigid couplings, which require precise alignment and offer no flexibility, flexible couplings are engineered to accommodate relative movements between connected shafts without compromising torque transmission efficiency. This unique capability makes them a cornerstone in numerous industries, from automotive and aerospace to manufacturing and renewable energy, where reliable power transfer and equipment protection are paramount. The role of flexible couplings extends beyond mere connection; they act as buffers, dampeners, and compensators, enhancing the longevity of machinery, improving operational comfort, and optimizing overall system performance. As industrial technologies evolve toward higher efficiency, automation, and sustainability, the design, materials, and applications of flexible couplings continue to advance, adapting to new operational demands and environmental constraints.

At its core, a flexible coupling is a mechanical device designed to join two shafts—typically a driving shaft (connected to a motor or engine) and a driven shaft (connected to a pump, fan, conveyor, or other equipment)—while permitting angular, parallel, or axial misalignment between them. Misalignment is a common issue in rotating machinery, arising from factors such as installation errors, thermal expansion, structural settlement, or wear over time. Rigid couplings, which maintain a fixed connection, transfer these misalignment-induced stresses directly to the shafts, bearings, and other components, leading to premature wear, increased vibration, and potential catastrophic failure. Flexible couplings mitigate this risk by incorporating a flexible element that absorbs or compensates for misalignment, reducing stress on adjacent components and ensuring smooth power transmission. Additionally, these couplings dampen vibrations generated by rotating equipment, minimizing noise pollution and improving operator comfort—a critical consideration in both industrial and mobile applications. The ability to absorb shock loads, such as those caused by sudden starts, stops, or load fluctuations, further enhances the durability of the entire drive system, reducing maintenance costs and downtime.

The classification of flexible couplings is primarily based on their design principles and the materials used in their flexible elements, resulting in a diverse range of types tailored to specific application requirements. Elastomeric couplings, one of the most widely used categories, utilize elastomeric materials—such as rubber, polyurethane, or synthetic composites—as the flexible medium. These couplings typically consist of two metal hubs with protruding jaws or pins that engage with an elastomeric insert or sleeve. The elastomeric element deforms under load to accommodate misalignment, absorb vibrations, and cushion shock impacts. A key advantage of elastomeric couplings is their low maintenance requirement, as they do not require lubrication and feature a simple, cost-effective design. However, their performance is limited by temperature resistance; extreme heat or cold can degrade the elastomer, reducing its flexibility and service life. They are well-suited for general industrial applications, including pumps, fans, compressors, and conveyor systems, where moderate torque and misalignment demands are common.

Metallic flexible couplings, by contrast, rely on metal components—such as corrugated discs, diaphragms, or grids—to provide flexibility while maintaining high torsional stiffness. Disc couplings, for example, use thin, flat or corrugated metal discs bolted between two hubs. These discs flex to accommodate angular and axial misalignment without backlash, making them ideal for high-precision, high-speed applications. Since they have no contact between moving parts, disc couplings require no lubrication and exhibit minimal wear, ensuring long service life even in harsh environments. Grid couplings, another metallic type, feature a steel grid that fits into serrated hubs, transmitting torque while allowing for angular and parallel misalignment. The grid acts as a shock absorber, reducing vibration and accommodating moderate misalignment, but it requires periodic lubrication to prevent corrosion and wear. Metallic couplings are preferred in applications such as aerospace, marine propulsion, turbines, and CNC machinery, where high torque, precision, and resistance to extreme temperatures and chemicals are essential.

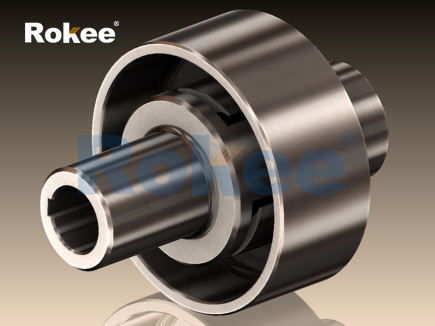

Oldham couplings represent a specialized type of flexible coupling designed to handle significant parallel misalignment between shafts. Comprising two hubs with perpendicular slots and a central sliding disc, Oldham couplings transmit torque through the disc, which slides within the slots to compensate for parallel offset. This design ensures constant velocity transmission without backlash, making them suitable for precision systems such as stepper motors, encoders, robotics, and packaging machines. Some Oldham couplings feature electrically insulating central discs, providing additional protection in applications where electrical isolation between shafts is required. However, their ability to accommodate angular or axial misalignment is limited, and the sliding disc may experience wear over time, necessitating periodic inspection and replacement. Universal joint couplings, often referred to as U-joints, are another specialized type that enables power transmission at variable angles. Consisting of two yokes connected by a cross-shaped pivot, U-joints are commonly used in automotive drivelines, agricultural machinery, and industrial equipment where shafts operate at non-parallel angles. While they excel at angular misalignment, U-joints can introduce vibration at high speeds if not properly balanced, and they require lubrication to maintain performance.

The selection of materials for flexible couplings is a critical design consideration that directly impacts performance, durability, and suitability for specific operating environments. For elastomeric elements, the choice of material depends on factors such as temperature range, chemical exposure, and load requirements. Rubber-based elastomers offer excellent vibration damping but are susceptible to oil and chemical degradation, while polyurethane exhibits higher wear resistance and durability, making it suitable for heavier loads. Synthetic composites, such as fiber-reinforced polymers, combine lightweight properties with enhanced strength and temperature resistance, expanding the application range of elastomeric couplings. Metal components of couplings are typically manufactured from steel, stainless steel, or aluminum alloys. Steel provides high torque capacity and durability, making it ideal for heavy-duty applications, while stainless steel offers corrosion resistance for use in humid, chemical, or marine environments. Aluminum alloys are preferred for lightweight applications, such as aerospace or portable machinery, where weight reduction is a priority without compromising structural integrity.

The manufacturing process of flexible couplings involves a series of precision steps to ensure dimensional accuracy, structural integrity, and consistent performance. The process typically begins with design and engineering, where parameters such as torque capacity, misalignment tolerance, speed rating, and environmental conditions are analyzed to determine the optimal design and materials. Material preparation follows, with metal components undergoing cutting, forging, or casting to achieve the desired shape. Precision machining—including turning, milling, and drilling—refines the dimensions of hubs, discs, and other metal parts, ensuring tight tolerances for proper fit and function. Elastomeric elements are produced through molding or extrusion processes, with careful control of temperature and pressure to achieve the required mechanical properties. Assembly involves joining the flexible element with the metal components, often using press-fitting, bolting, or bonding techniques. Quality control and testing are integral to the manufacturing process, with inspections for dimensional accuracy, material integrity, and performance under load. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, may be used to detect hidden defects in metal components, while functional testing verifies torque transmission, misalignment accommodation, and vibration damping capabilities.

Flexible couplings find applications across a vast spectrum of industries, each with unique operational demands that influence the choice of coupling type and design. In the automotive industry, they are used in drivelines, steering systems, and engine mounts to absorb vibrations, accommodate misalignment, and improve ride comfort. In electric and hybrid vehicles, flexible couplings play a crucial role in connecting electric motors to transmissions, addressing the higher torque densities and quieter operation requirements of these systems. The aerospace sector relies on high-precision metallic couplings for engine connections, control systems, and aircraft components, where weight, reliability, and resistance to extreme temperatures and pressure are critical. Flexible couplings in aerospace applications must meet stringent performance standards to ensure safety and durability in harsh flight conditions.

The renewable energy sector, particularly wind power, utilizes flexible couplings in turbine systems to connect the rotor to the gearbox and generator. These couplings must accommodate misalignment caused by wind-induced loads, absorb vibrations, and transmit high torque while withstanding outdoor environmental conditions, such as temperature fluctuations, humidity, and corrosion. In solar power systems, flexible couplings are used in tracking mechanisms to ensure precise movement of solar panels, optimizing energy capture. The manufacturing industry depends heavily on flexible couplings for automated machinery, conveyor systems, and robotic arms, where reliable power transmission and precision alignment are essential for maintaining productivity. Industrial robots, in particular, require couplings that offer high torsional stiffness and minimal backlash to ensure accurate positioning and movement.

Proper installation and maintenance are critical to maximizing the service life and performance of flexible couplings, as improper handling is a leading cause of coupling failure and machinery downtime. Installation begins with ensuring proper shaft preparation, including cleaning, deburring, and verifying shaft diameter and keyway dimensions to ensure a secure fit with the coupling hubs. Alignment of the driving and driven shafts is one of the most important installation steps; even minor misalignment beyond the coupling’s tolerance can lead to increased vibration, premature wear, and component failure. Alignment can be performed using tools such as dial indicators, laser alignment systems, or optical instruments, with adjustments made to the equipment mounts to achieve the required precision. It is also essential to follow proper torque specifications when fastening coupling bolts to avoid over-tightening, which can damage the flexible element or hubs, or under-tightening, which can result in slippage and wear.

Maintenance practices for flexible couplings vary by type but generally include regular inspection, cleaning, and replacement of worn components. Elastomeric couplings should be inspected for signs of elastomer degradation, such as cracking, hardening, or swelling, which indicate the need for replacement. Metallic couplings, such as grid couplings, require periodic lubrication to prevent corrosion and wear of moving parts, with lubricant type and frequency determined by operating conditions. Oldham couplings need inspection of the central disc for wear or damage, as excessive wear can compromise alignment and torque transmission. Regular vibration monitoring is also a valuable maintenance tool, as increased vibration levels can indicate misalignment, worn components, or other issues before they lead to catastrophic failure. Predictive maintenance technologies, such as real-time data analytics and condition monitoring systems, are increasingly being used to track coupling performance, enabling proactive maintenance and minimizing unplanned downtime.

Failure of flexible couplings can result from a variety of factors, including improper selection, installation errors, inadequate maintenance, and operational overloads. Improper selection—such as choosing a coupling with insufficient torque capacity or misalignment tolerance—can lead to premature wear or sudden failure. Oversized couplings, while seemingly more durable, can increase radial loads on shafts and bearings if misalignment exists, leading to accelerated wear. Installation errors, such as poor alignment, incorrect torque application, or improper shaft fit, are among the most common causes of coupling failure. Environmental factors, such as extreme temperatures, chemical exposure, or moisture, can degrade coupling materials, reducing their performance and service life. For example, elastomeric elements may degrade when exposed to oils, solvents, or ultraviolet radiation, while metal components can corrode in humid or chemical-rich environments. Operational factors, such as frequent starts and stops, shock loads, or excessive speed, can induce fatigue in coupling components, leading to cracks, deformation, or failure over time.

Troubleshooting coupling failures involves identifying the root cause through visual inspection, vibration analysis, and performance testing. Common failure symptoms include excessive vibration, noise (such as squealing, grinding, or clicking), reduced torque transmission, and visible damage to coupling components. Excessive vibration may indicate misalignment, worn elastomeric elements, or unbalanced shafts, requiring realignment, component replacement, or balancing. Noise from metallic couplings may signal worn or insufficiently lubricated parts, while elastomeric couplings may emit noise when the flexible element is damaged or degraded. Visible damage, such as cracked discs, worn grids, or swollen elastomers, clearly indicates the need for component replacement. In some cases, failure may be attributed to systemic issues, such as excessive torque or load fluctuations, requiring a reevaluation of the coupling selection or operational parameters.

The evolution of flexible coupling technology is closely tied to broader industrial trends, including the shift toward automation, electrification, and sustainability. As manufacturing facilities adopt Industry 4.0 technologies, flexible couplings are being integrated into smart systems with real-time monitoring capabilities, enabling predictive maintenance and optimizing performance. The rise of electric and hybrid vehicles has driven demand for couplings that can handle higher torque densities, operate quietly, and accommodate the unique misalignment and vibration characteristics of electric motors. In the renewable energy sector, the push for higher efficiency wind turbines and solar tracking systems has led to the development of specialized couplings with enhanced durability, corrosion resistance, and misalignment accommodation.

Advancements in materials science are also shaping the future of flexible couplings. The development of high-performance elastomers and composites offers improved temperature resistance, chemical stability, and durability, expanding the application range of elastomeric couplings. Metal matrix composites, which combine the strength of metals with the lightweight properties of polymers, are being explored for high-performance applications, such as aerospace and racing, where weight reduction and strength are critical. Additive manufacturing, or 3D printing, is emerging as a viable method for producing custom coupling components, enabling rapid prototyping, complex designs, and on-demand production of specialized parts. This technology allows for the creation of couplings with optimized geometries for enhanced flexibility, torque transmission, and vibration damping, tailored to specific application needs.

Sustainability is another key driver of innovation in flexible coupling design and manufacturing. There is a growing emphasis on using eco-friendly materials, such as recycled metals and biodegradable elastomers, to reduce environmental impact. Manufacturers are also optimizing production processes to minimize waste, energy consumption, and carbon emissions. Additionally, the design of couplings for longer service life and easier recyclability is becoming a priority, aligning with global efforts to promote circular economy practices. The integration of energy-efficient features, such as low-friction designs and optimized torque transmission, further contributes to sustainability by reducing overall energy consumption in mechanical systems.

In conclusion, flexible couplings are essential components in mechanical power transmission systems, providing the critical functions of connecting shafts, accommodating misalignment, damping vibrations, and absorbing shock loads. Their diverse range of types, materials, and designs makes them suitable for applications across industries, from general manufacturing to aerospace and renewable energy. Proper selection, installation, and maintenance are essential to ensuring their performance and longevity, while ongoing technological advancements continue to enhance their capabilities, efficiency, and sustainability. As industrial systems become more complex, automated, and environmentally conscious, flexible couplings will remain a vital part of ensuring reliable, efficient, and durable power transmission, adapting to new challenges and opportunities in the global marketplace. The future of flexible couplings lies in the integration of smart technologies, advanced materials, and sustainable practices, further solidifying their role as indispensable components in modern mechanical systems.

« Flexible Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/flexible-couplings.html