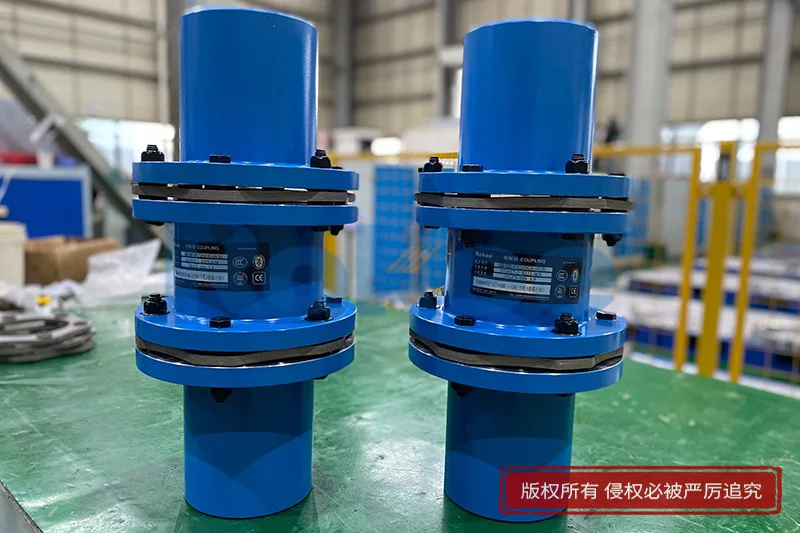

JS GRID COUPLING

Rokee is a well-known JS GRID COUPLING supplier from china, the page show cases of JS GRID COUPLING, provide customized services based on user's drawings, and supporting exports.

JS GRID COUPLING is an advanced mechanical transmission connection device that achieves flexible connection between shafts through a unique snake shaped spring structure. Widely used in various industrial fields, it is highly praised for its excellent performance and reliability. Compared with traditional couplings, JS GRID COUPLINGs use snake shaped springs made of special alloy steel as elastic elements, and achieve a perfect balance between transmission efficiency and vibration reduction performance through precise mechanical processing and heat treatment processes.

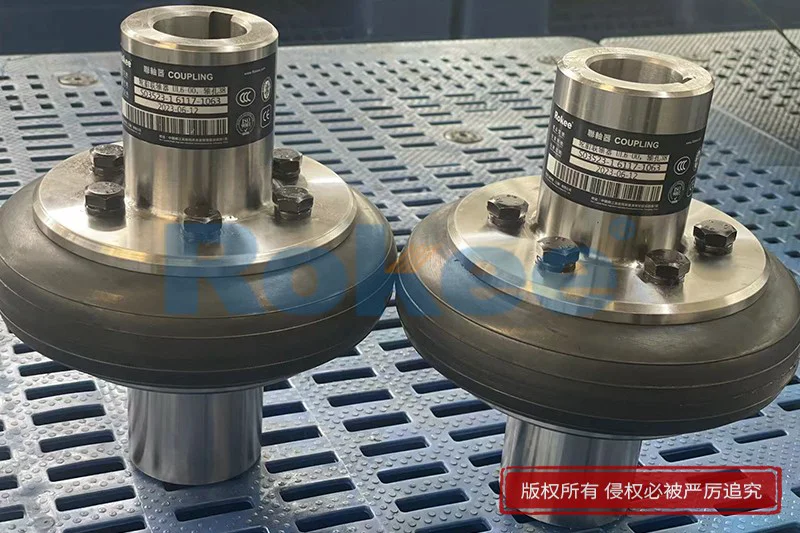

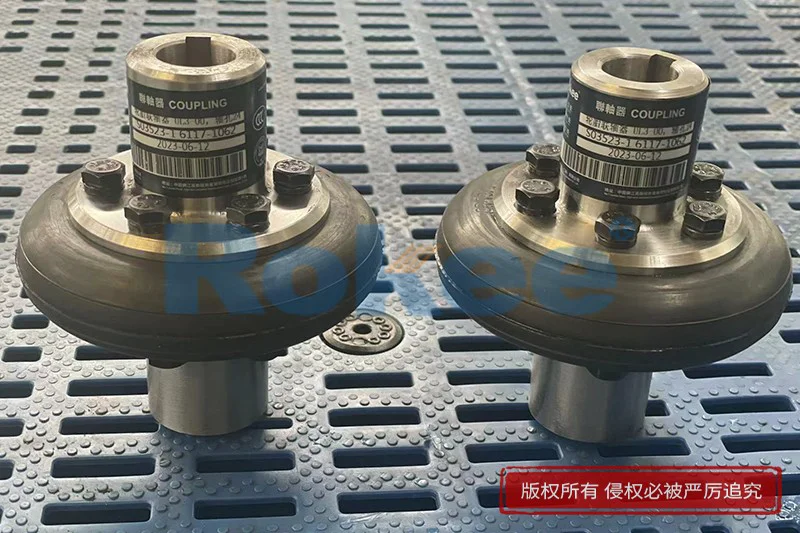

The JS GRID COUPLING consists of the following key components:

Serpentine spring element: made of high-strength alloy steel and subjected to special heat treatment process, it has excellent elasticity and fatigue life. The springs are arranged in a three-dimensional serpentine pattern and can absorb vibrations and impacts in multiple directions.

Coupling hub: usually made of high-strength cast iron or alloy steel material, with an inner hole that matches the shaft, and a special tooth groove structure designed on the outer edge that matches the spring.

Protective cover: protects the internal spring from external environmental influences and prevents lubricant leakage.

Lubrication system: Some high-end models are equipped with automatic lubrication devices to ensure lubrication effectiveness during long-term operation.

When the driving shaft rotates, the serpentine spring is driven to deform through the teeth of the hub, and the spring then transmits power to the driven hub. The uniqueness of this design lies in:

Three dimensional elastic deformation: Springs can not only deform radially and axially, but also achieve a certain degree of angular deflection, forming a true three-dimensional flexible connection.

Progressive stiffness: As the torque increases, the deformation of the spring increases, and the stiffness also increases, forming a nonlinear torque deformation characteristic.

Multi point contact stress distribution: The serpentine design distributes contact stress at multiple points, significantly reducing local stress concentration and extending service life.

Performance advantages and technical features

Excellent vibration damping performance

The vibration absorption capacity of JS GRID COUPLING is 40-60% higher than that of ordinary spring coupling, specifically manifested in:

Can reduce the vibration amplitude of the transmission system by more than 70%

Effectively suppress high-frequency vibration and instantaneous impact

Reduce vibration damage to bearings and gearboxesSuperb compensation capability

Axial compensation: up to ± 5mm maximum

Radial compensation: up to 1.5mm maximum

Angle compensation: up to 1.5 ° maximum

Three types of compensation can exist simultaneously and interact with each otherOther significant advantages

High transmission efficiency: up to 98-99.5%, with minimal energy loss

Easy maintenance: adopting modular design, replacing the spring does not require disassembling the entire coupling

Long lifespan: The service life can reach more than 10 years under standard operating conditions

Strong environmental adaptability: stable performance within the temperature range of -40 ℃ to+150 ℃

Selection considerations

Torque demand: including rated torque and peak torque

Shaft diameter size: Ensure matching with equipment shaft

Environmental conditions: temperature, humidity, corrosiveness, etc

Installation space: radial and axial space limitations

Dynamic characteristics: system inertia, critical speed, etc

Application field

Heavy Industry Applications

Transmission system of steel rolling mill

Mining crushing equipment

Large scale compressor unit

Ship propulsion systemenergy sector

Wind turbine

Hydroelectric power generation unit

Gas turbine connection

Oil drilling platform equipmentprecision machinery

CNC machine spindle connection

Precision testing equipment

Semiconductor manufacturing equipment

Medical imaging equipment

Key points for installation and maintenance

Professional installation steps

Alignment check: Use a laser alignment instrument to ensure that the alignment accuracy of the two axes is within 0.05mm

Cleaning treatment: Thoroughly clean the contact surface between the shaft and coupling

Hot installation method: For interference fit, it is recommended to use induction heating method for installation

Bolt tightening: Use a torque wrench to gradually tighten in diagonal order

Lubrication treatment: Inject specified lubricating grease during initial installationMaintenance and upkeep standards

Regular inspection: Check the wear and lubrication status of the spring every 3-6 months

Lubrication cycle: Supplement lubricating grease every 2000 working hours under normal operating conditions

Wear monitoring: Use a dedicated thickness gauge to check for changes in spring thickness

Vibration analysis: It is recommended to conduct a vibration spectrum analysis once a year

The JS GRID COUPLING with its unique design and excellent performance, has become an indispensable key component in modern industrial transmission systems. With the continuous advancement of technology, it will continue to play an important role in various industrial fields, providing more reliable and efficient transmission solutions for equipment.

With excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the product selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc.

« JS GRID COUPLING » Post Date: 2025/12/11 , https://www.rokeecoupling.net/cases/js-grid-coupling.html

Other Cases

Stainless Steel Double Diaphragm Coupling

Stainless Steel Double Diaphragm Coupling Cardan Shaft of 4000mm Plate Main Mill

Cardan Shaft of 4000mm Plate Main Mill Claw Type Flexible Couplings

Claw Type Flexible Couplings RODA Curved Tooth Coupling

RODA Curved Tooth Coupling ZL Flexible Pin Tooth Coupling

ZL Flexible Pin Tooth Coupling Star-shaped Elastic Coupling

Star-shaped Elastic Coupling Jaw Flexible Coupling With Brake Disc

Jaw Flexible Coupling With Brake Disc UL6 Rubber Tyre Coupling

UL6 Rubber Tyre Coupling Universal Joint Couplings For Steel Mills

Universal Joint Couplings For Steel Mills UL3 Rubber Tire Coupling

UL3 Rubber Tire Coupling