Rokee is a well-known high-quality supplier of Shim Pack Couplings and technical services in China, customize shim pack couplings according to user drawings, alternatively, if the user provides shim pack couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Shim pack coupling is a high-performance flexible coupling that compensates for the relative displacement between two connected shafts through the elastic deformation of one or more sets of metal diaphragms. Shim pack couplings with their unique performance advantages, have been widely used in industrial fields such as aviation, shipbuilding, power, and petrochemicals.

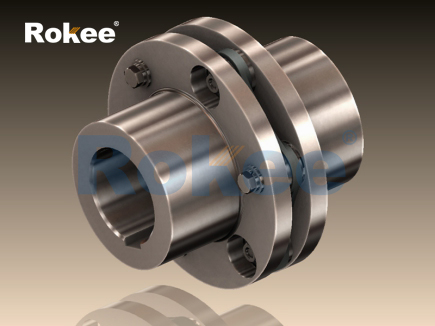

Compared with traditional gear couplings or rubber elastic couplings, shim pack couplings have significant characteristics such as no wear, no maintenance, and high reliability. The core component is a thin-walled diaphragm group made of high-strength stainless steel, which can adapt to axial, radial, and angular deviations while transmitting torque through precise pre tensioning installation.

Wheel hub components: usually made of high-strength alloy steel, directly connected to the drive shaft and the driven shaft

Diaphragm group: an elastic element composed of multiple stainless steel sheets, which is the core component of a coupling

Intermediate shaft: Some models are designed with an intermediate shaft to increase compensation capability

Connecting bolts: high-precision fasteners to ensure reliable connection of various components

Single piece diaphragm: simple structure, suitable for small torque transmission

Multi piece membrane: Improving load-bearing capacity and compensation capability through multi-layer stacking

Corrugated membrane: special corrugated design enhances elastic deformation ability

Fan shaped membrane: segmented design reduces stress concentration

Torque transmission: transmitting power through the shear action of the diaphragm group

Deviation compensation: Diaphragm deformation absorbs axial, radial, and angular displacements

Vibration damping: The elasticity of the diaphragm can partially absorb and isolate vibrations

High torque transmission capability: large torque transmission per unit weight

Zero backlash: ensuring transmission accuracy, suitable for precision transmission

Maintenance free: No worn parts, long service life

High speed adaptability: excellent dynamic balance performance

Corrosion resistance: Stainless steel diaphragm is suitable for harsh environments

Wide temperature adaptability: the working temperature range can reach -50 ℃ to 300 ℃

Classified by structure

Single membrane type: simple structure, limited compensation capability

Double membrane type: enhances angular and radial compensation capability

Multi membrane type: used for high-power and high-precision applications

Type with intermediate shaft: suitable for long-distance transmission

Classified by connection method

Flange connection type

Clamping type

Keyway connection type

Spline connection type

Rated torque: the maximum torque that the coupling can continuously operate at

Maximum torque: the peak torque that can be sustained in the short term

Speed range: allowable working speed range

Deviation compensation capability:

Axial displacement: usually 0.2-5mm

Radial displacement: usually 0.1-3mm

Angular displacement: usually 0.5 ° -3 °

Power and torque requirements of the transmission system

Possible types and sizes of deviations in the shaft system

Working environment conditions (temperature, corrosiveness, etc.)

Installation space restrictions

Dynamic performance requirements (such as critical speed)

Ensure that the shaft end is clean and free of burrs

Using the correct method for centering (laser centering is recommended)

Install bolts according to the prescribed tightening torque

To avoid pre deformation of the membrane caused by forced assembly

Check the tightening status of bolts

Observe the membrane for cracks or deformation

Monitor changes in vibration conditions

Check the status of the seals (if any)

Energy industry: Steam turbines, generators, compressors

Shipbuilding industry: propulsion systems, auxiliary machinery

Petrochemical industry: pump sets, fans, compressors

Aerospace: Engine Accessories Transmission

Precision machinery: CNC machine tools, measuring equipment

As an important component of modern mechanical transmission systems, shim pack couplings will continue to drive industrial equipment towards high efficiency, reliability, and intelligence through their technological development. With the application of new materials and processes, the performance boundary of shim couplings will continue to expand to meet more demanding industrial application requirements.

« Shim Pack Couplings » Post Date: 2024/4/23 , https://www.rokeecoupling.net/tags/shim-pack-couplings.html