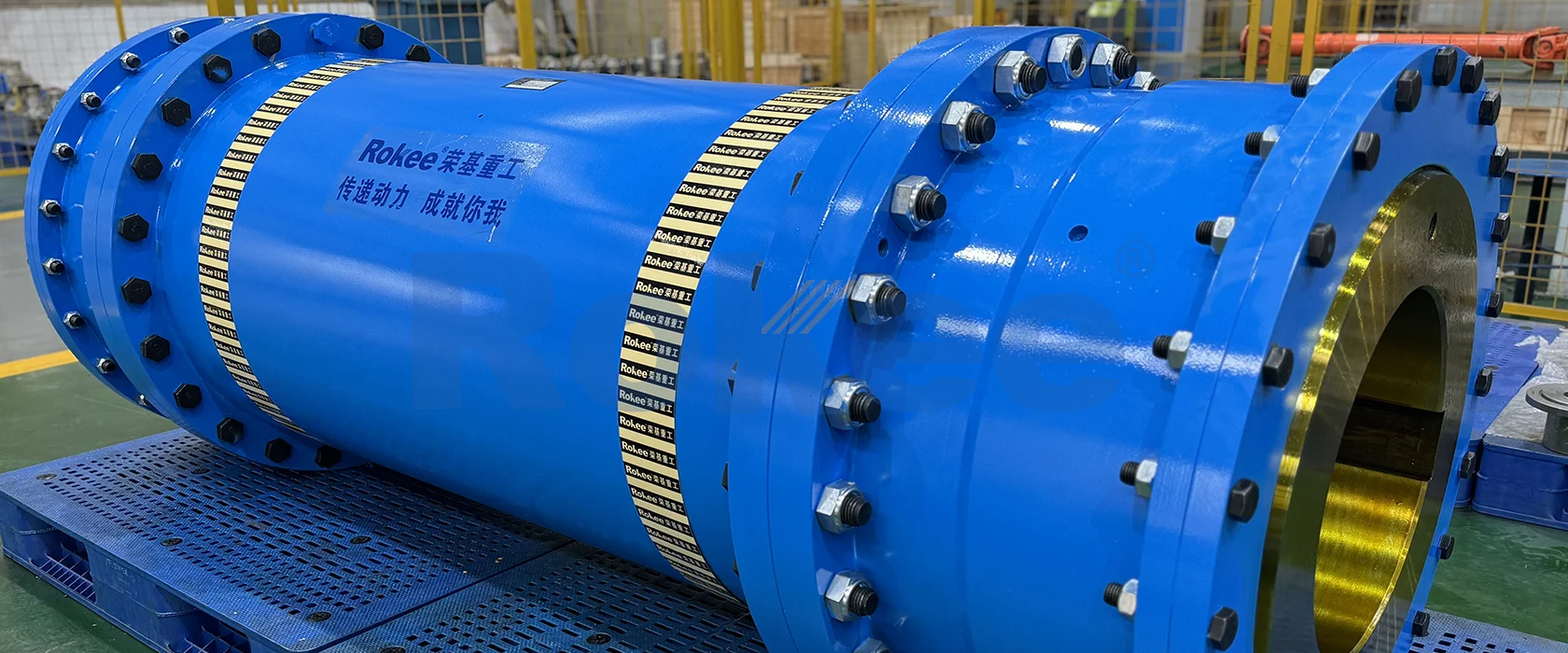

Rokee is a well-known high-quality supplier of Gear Couplings and technical services in China, customize gear couplings according to user drawings, alternatively, if the user provides gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

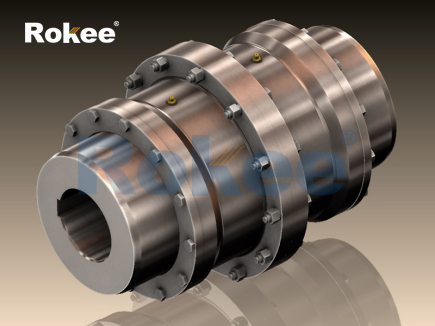

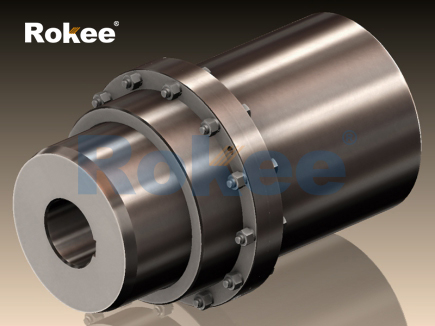

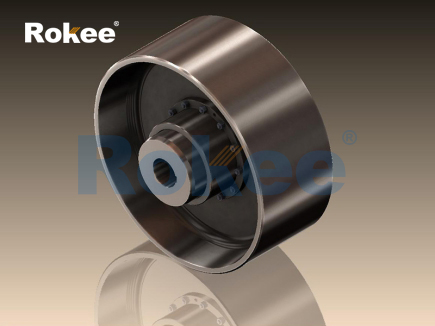

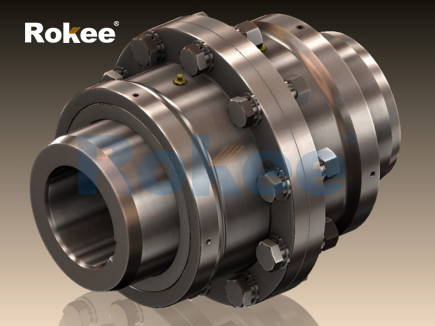

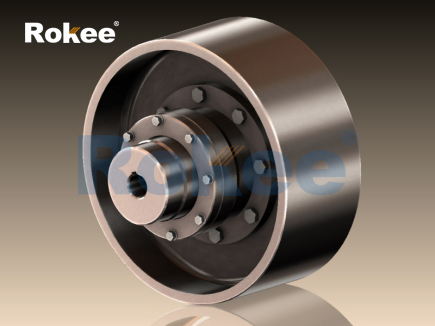

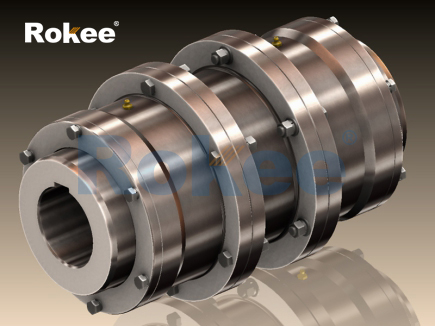

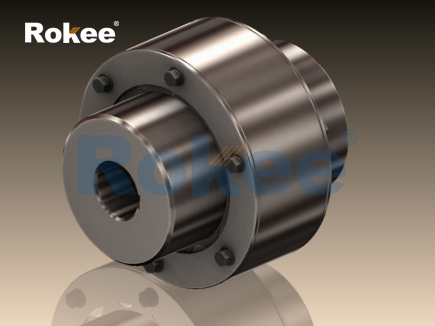

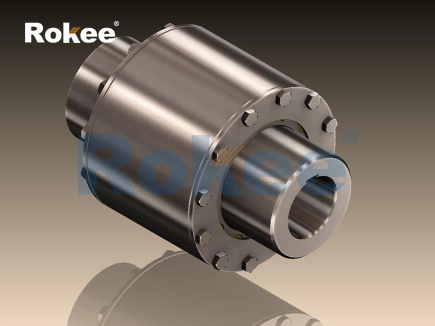

Gear coupling is a flexible coupling that transmits torque through the meshing of internal and external gears, playing a key role in modern mechanical transmission systems. This type of coupling consists of two half couplings with external teeth and two sleeves with internal teeth. Power transmission is achieved through precise meshing of gears, while allowing for a certain degree of axial, radial, and angular displacement.

Compared to other types of couplings, gear couplings have significant characteristics such as high load-bearing capacity, strong compensation capacity, and high transmission efficiency. They are widely used in heavy industrial fields such as metallurgy, mining, shipbuilding, and power generation. Typical application scenarios include the main drive of rolling mills, large blowers, and ship propulsion systems, which require high transmission accuracy and reliability.

Main component analysis

The core components of a toothed coupling include:

External gear shaft sleeve: usually directly connected to the driving shaft or driven shaft, with involute tooth profile machined on the outer surface

Internal gear ring: fixed at the other end, with an inner hole machined with a tooth profile that matches the outer teeth

Sealing device: prevents grease leakage and contamination from entering, commonly including labyrinth seals and rubber seals

Lubrication system: including oil nozzle, oil passage, and oil storage chamber, ensuring sufficient lubrication of the gear meshing surface

Material selection criteria

The material selection of gear couplings directly affects their service life and load-bearing capacity:

Gear parts are usually made of alloy structural steels such as 42CrMo and 35CrMo, which have undergone quenching and tempering treatment and tooth surface quenching

Large couplings may use cast steel materials such as ZG310-570

Stainless steel or special alloy materials can be used under special working conditions

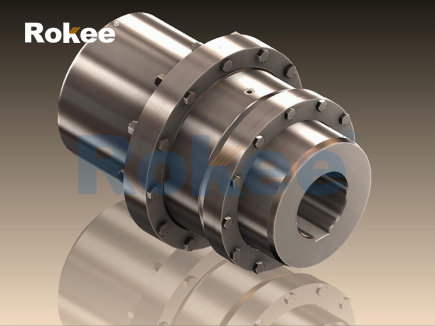

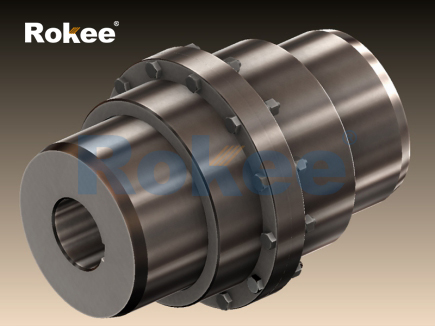

Typical structural form

According to different application requirements, gear couplings have developed various structural variants:

GCLD type: Extended toothed coupling with intermediate shaft

WGP type: Gear coupling with brake wheel

NGCL type: Nylon internal gear ring gear coupling with buffering and vibration reduction characteristics

Power transmission mechanism

The gear coupling transmits torque through the meshing of internal and external gears, and its working principle can be summarized as follows:

The active shaft drives the outer gear shaft sleeve to rotate

The meshing between the outer and inner teeth transmits torque to the inner ring gear

Internal gear ring drives synchronous rotation of driven shaft

In the case of misalignment, the gear pair can slide relative to each other to compensate for the deviation

Compensation Capability Analysis

The unique advantage of the toothed coupling lies in its excellent deviation compensation capability:

Radial deviation: generally compensated for 0.4-6.3mm

Angular deviation: A deviation angle of 0.5 ° -1.5 ° is usually allowed

Axial displacement: The design allows for an axial displacement of 2-10mm

Force characteristics

The gear meshing process mainly bears the following loads:

Tangential force: generated by torque transmission

Radial force: caused by deviation compensation

Impact load: generated during startup, braking, or sudden load changes

Tooth contact stress: a key factor affecting gear life

Core performance parameters

Rated torque: ranging from tens of Newton meters to millions of Newton meters

Maximum speed: usually not exceeding 4000rpm, high-speed models can reach 10000rpm

Transmission efficiency: up to 98% -99.5%

Service life: up to 3-5 years under normal operating conditions

Comparison of technological advantages

Compared with traditional couplings, gear couplings have:

Higher load-bearing capacity: greater torque transmission per unit volume

Better compensation performance: simultaneously compensating for multiple biases

More stable operation: less vibration in gear meshing transmission

Longer lifespan: Slow wear under good lubrication conditions

Special performance variants

Improved gear coupling developed to meet special needs:

Damping gear coupling: with built-in elastic elements, it has vibration reduction function

Safety gear coupling: equipped with overload protection device

High temperature resistant gear coupling: using special materials and lubrication methods

Key elements of selection

When choosing a gear coupling, the following factors should be considered:

Transmission torque magnitude and variation characteristics

Shaft diameter size and connection method

Operating speed range

Environmental conditions (temperature, humidity, corrosiveness, etc.)

Allowable installation deviation values

Maintenance convenience requirements

Installation technical requirements

Proper installation is crucial for the performance of gear couplings:

Check the alignment of the shaft and ensure that the deviation is within the allowable range

Clean the mating surface, remove burrs and oil stains

When using hot or hydraulic assembly, the temperature should not exceed 120 ℃

The fastening bolts should be tightened symmetrically and evenly according to the specified torque

After installation, manually rotate and check if it is flexible and unobstructed

Common installation errors and their impacts

Poor alignment: leading to increased vibration and intensified tooth surface wear

Improper axial clearance: affecting compensation capability or generating axial force

Insufficient lubrication: causing early wear and adhesive failure

Improper fastening: may cause looseness or damage to the mating surface

Daily inspection points

Vibration and noise monitoring

Temperature rise inspection (generally not exceeding 70 ℃)

Observation of sealing condition

Confirmation of bolt tightening status

Lubrication Management Standards

The lubrication management of gear couplings includes:

Lubricant selection: NLGI 1 # or 2 # extreme pressure lithium grease is usually used

Lubrication cycle: usually supplemented once every 500-2000 working hours

Oil injection control: Fill the inner cavity with 1/2-2/3 space

Lubricant replacement: Replace thoroughly at least once a year

Typical fault handling

Common faults and solutions:

Abnormal vibration: Check the alignment and recalibrate

Excessive temperature: Add lubricating grease or check the load condition

Oil leakage: Replace the seal or adjust the seal clearance

Tooth wear: Repair or replace the coupling as appropriate

Metallurgical industry: main drive for rolling mills and straightening machines

Power industry: shaft connection of steam turbine generator set

Ship Engineering: Power Transmission between Main Engine and Propulsion

Petrochemical industry: Transmission connections for large compressors and pump units

Comparison with elastic couplings

Advantages: Greater load-bearing capacity, stronger compensation capability, and longer lifespan

Disadvantages: High manufacturing cost, requiring regular lubrication, poor buffering and vibration reduction performance

Comparison with diaphragm couplings

Advantages: Able to withstand larger deviations and have stronger impact resistance

Disadvantages: Large axial size, slightly inferior high-speed performance

Comparison with universal joint couplings

Advantages: smoother transmission, higher efficiency, no need for phase adjustment

Disadvantages: Small angle compensation capability and more complex structure

As a key component in the industrial transmission field, the technical level and reliability of the gear coupling directly affect the performance of the entire mechanical system. With the development of materials science, manufacturing processes, and intelligent monitoring technology, gear couplings will continue to evolve, providing more efficient and reliable power transmission solutions for modern industry. Proper selection, installation, and maintenance are key to ensuring optimal performance, and users should give them full attention during the application process.

In the complex network of industrial transmission systems, gear couplings stand out as indispensable mechanical components, engineered to connect two rotating shafts for efficient torque transfer while accommodating various forms of misalignment. Their unique combination of high torsional stiffness, robust load-bearing capacity, and flexibility makes them a preferred choice across a wide spectrum of heavy-duty and precision applications. Unlike other coupling types that may prioritize either rigidity or flexibility, gear couplings strike a delicate balance between these two attributes, enabling them to perform reliably in harsh operating environments where stability, durability, and efficiency are paramount.

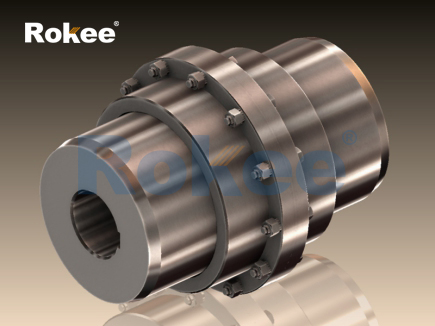

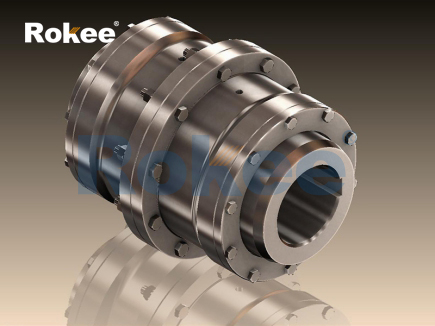

At the core of a gear coupling lies a sophisticated structural design that facilitates both torque transmission and misalignment compensation. Typically classified as rigid-flexible couplings, they primarily consist of two external gear hubs, an internal gear sleeve (or two internal gear rings), sealing devices, connecting bolts, and a lubrication system. The external gear hubs are mounted on the respective shafts of the driving and driven machinery, usually via keyway connections to ensure a secure fit and prevent relative rotation between the hub and the shaft. These hubs feature precision-machined external teeth that mesh seamlessly with the internal teeth of the sleeve or rings. The internal gear component serves as the connecting medium, enveloping the external gear hubs and transmitting torque through the meshing of teeth. A key structural variation is the distinction between straight-tooth and drum-tooth designs, with the latter being more prevalent in industrial applications due to its enhanced misalignment compensation capabilities. The drum-shaped external teeth, with their spherical center aligned along the gear axis, allow for relative sliding between tooth surfaces when misalignment occurs, reducing stress concentrations and minimizing wear.

Sealing devices are critical components of gear couplings, designed to prevent the leakage of lubricants and the ingress of external contaminants such as dust, dirt, and moisture. These seals, often constructed from durable elastomeric materials or metal gaskets, form a tight barrier around the gear meshing area, safeguarding the internal components from corrosion and premature wear. Connecting bolts are used to fasten the internal gear sleeve to the hubs, ensuring that the coupling remains intact under high torque and rotational forces. The bolts must be tightened evenly and to the appropriate torque specifications to maintain structural integrity and avoid uneven load distribution. The lubrication system, which may include oil holes, oil passages, and grease chambers, is essential for reducing friction between meshing teeth, dissipating heat generated during operation, and extending the service life of the coupling. Proper lubrication ensures smooth meshing, minimizes tooth surface wear, and prevents galling or seizing, even under high-speed and high-torque conditions.

The working principle of a gear coupling revolves around the efficient transfer of torque through gear meshing while accommodating axial, radial, and angular misalignment between the connected shafts. When the driving shaft rotates, it imparts rotational force to the external gear hub mounted on it. This force is then transmitted to the internal gear sleeve via the meshing teeth, which in turn drives the external gear hub on the driven shaft, causing it to rotate synchronously. The design of the gear teeth plays a pivotal role in enabling misalignment compensation. In drum-tooth configurations, the curved tooth profile allows for slight axial movement, radial offset, and angular deflection between the shafts without generating excessive additional loads or compromising torque transmission efficiency. The tooth flank clearance, which is carefully calibrated during manufacturing, provides the necessary space for relative movement between the teeth, ensuring that misalignment does not result in binding or excessive wear. This ability to compensate for misalignment is particularly valuable in industrial settings where precise shaft alignment is difficult to achieve or maintain, such as in large-scale machinery subjected to thermal expansion, structural deformation, or dynamic loads.

Material selection is a critical factor in determining the performance, durability, and application range of gear couplings. The choice of materials depends on various factors, including the expected torque load, rotational speed, operating temperature, environmental conditions (such as corrosion or humidity), and wear resistance requirements. High-strength alloy steels are the most commonly used materials for the external gear hubs and internal gear sleeves due to their excellent mechanical properties, including high tensile strength, toughness, and wear resistance. Common alloy steels include those containing chromium, molybdenum, and nickel, which enhance the material's hardenability and resistance to fatigue. For example, certain alloy steels can be heat-treated to achieve a high surface hardness while maintaining a tough core, making them ideal for withstanding the high contact stresses generated during gear meshing.

In addition to alloy steels, some gear coupling designs incorporate non-metallic components, such as nylon inner gear rings, to achieve specific performance characteristics. These nylon components, often made from high-strength materials like MC nylon or nylon 66, offer self-lubricating properties, vibration damping capabilities, and corrosion resistance. They are particularly suitable for applications where maintenance requirements need to be minimized or where noise reduction is a priority. However, non-metallic components may have lower torque capacity and temperature resistance compared to metallic ones, limiting their use in heavy-duty, high-temperature environments. For applications exposed to corrosive environments, such as marine or chemical processing facilities, gear couplings may be constructed from corrosion-resistant alloys or undergo surface treatments like galvanization, chrome plating, or nitriding to enhance their resistance to rust and chemical attack.

Manufacturing processes for gear couplings are highly precise, requiring advanced machining and heat treatment techniques to ensure dimensional accuracy, surface quality, and mechanical performance. The production process typically begins with forging or casting the raw material into the rough shape of the hubs and sleeves. Forging is preferred for high-performance couplings as it refines the grain structure of the metal, improving strength and toughness compared to casting. After forging, the components undergo rough machining to remove excess material and achieve approximate dimensions. Precision machining follows, using computer numerical control (CNC) lathes, milling machines, and gear hobbing or shaping machines to create the gear teeth and other critical features. The gear teeth are machined to tight tolerances to ensure smooth meshing and optimal torque transmission. The surface finish of the teeth is also carefully controlled, with processes like grinding or honing used to achieve the required smoothness and reduce friction.

Heat treatment is a vital step in the manufacturing process, as it enhances the mechanical properties of the metal components. Common heat treatment processes include quenching, tempering, carburizing, and nitriding. Quenching involves heating the metal to a high temperature and then rapidly cooling it to harden the surface, while tempering reduces brittleness and improves toughness by reheating the quenched material to a lower temperature. Carburizing is used to increase the carbon content of the surface layer, allowing for a harder surface while maintaining a tough core, which is particularly beneficial for gear teeth subjected to high contact stresses. Nitriding is a surface hardening process that introduces nitrogen into the metal surface, improving wear resistance and corrosion resistance without significantly altering the core properties. These heat treatment processes are carefully controlled to ensure consistent results, with parameters such as temperature, heating rate, and cooling rate precisely monitored to avoid material defects like cracks or distortion.

The performance characteristics of gear couplings are a direct result of their structural design, material selection, and manufacturing processes. One of the most notable attributes is their high torque capacity, which enables them to transmit large amounts of power efficiently. This makes them ideal for heavy-duty applications such as rolling mills, crushers, and turbines, where substantial torque needs to be transferred between shafts. Gear couplings also exhibit high torsional stiffness, meaning they experience minimal angular deflection under load, ensuring precise torque transmission and maintaining synchronization between the driving and driven shafts. This stiffness is particularly important in precision machinery where positional accuracy is critical.

Another key performance feature is their ability to accommodate multiple types of misalignment. Axial misalignment, which occurs when the shafts move along their longitudinal axis, is compensated for by the drum tooth design and tooth flank clearance. Radial misalignment, caused by a offset between the shaft centers, is accommodated by the curved tooth profile, which allows the teeth to mesh evenly despite the offset. Angular misalignment, where the shafts are not perfectly parallel, is also compensated for by the drum teeth, which can tilt relative to each other without binding. The degree of misalignment that a gear coupling can accommodate depends on factors such as the tooth design, size, and material, but typical values range from a few tenths of a millimeter for radial misalignment to several degrees for angular misalignment.

Gear couplings also offer excellent durability and long service life when properly maintained. The use of high-strength materials and robust heat treatment processes ensures that they can withstand the rigors of continuous operation in harsh industrial environments. Their compact design is another advantage, as it allows them to be installed in spaces where other types of couplings may not fit. Despite their compact size, they deliver high power density, making them a cost-effective solution for many industrial applications. However, gear couplings do have some limitations. They require regular lubrication to prevent wear and overheating, and they can generate noise at high speeds, particularly if misalignment is excessive or lubrication is inadequate. They are also less suitable for extremely high-speed applications without proper balancing, as unbalanced components can cause vibration and premature failure.

The versatility of gear couplings is reflected in their wide range of applications across various industries. In the metallurgical and mining sectors, they are extensively used in rolling mills, crushers, ball mills, and conveyors. Rolling mills, which require the transmission of high torque to shape metal into sheets, bars, or rails, rely on gear couplings to handle the heavy loads and compensate for the misalignment caused by thermal expansion of the rolls. Crushers and ball mills, which operate under harsh conditions with high impact loads and vibration, benefit from the durability and misalignment compensation capabilities of gear couplings, ensuring reliable operation and minimizing downtime. In the mining industry, where equipment is often subjected to dust, moisture, and heavy loads, gear couplings provide the necessary robustness to withstand these conditions.

The power generation industry is another major user of gear couplings, particularly in thermal power plants, nuclear power plants, and wind energy systems. In thermal and nuclear power plants, gear couplings connect turbines to generators, transmitting enormous amounts of power while accommodating the misalignment caused by thermal expansion of the shafts and structural components. The high-temperature resistance and high torque capacity of gear couplings make them suitable for these applications, where reliability is critical to ensuring continuous power supply. In wind energy systems, gear couplings connect the gearbox to the generator, withstanding the alternating loads and variable speeds inherent in wind power generation. Their durability and ability to compensate for misalignment ensure the long-term stability of wind turbines, which are often located in remote areas with limited access for maintenance.

The oil and gas industry relies on gear couplings for a variety of applications, including pumps, compressors, and reactor. These components operate in corrosive environments, often exposed to hydrocarbons, saltwater, and harsh chemicals, making corrosion resistance a key requirement. Gear couplings used in this industry are typically constructed from corrosion-resistant alloys or undergo specialized surface treatments to protect against degradation. They must also withstand high pressures and temperatures, as well as the dynamic loads generated by pumps and compressors during operation. In marine and offshore applications, gear couplings are used in ship propulsion systems and offshore platform equipment, where they must compensate for hull deformation and withstand the corrosive effects of saltwater and salt spray. The multiple sealing structures and anticorrosion treatments of these couplings ensure their performance in these demanding environments.

General mechanical manufacturing also benefits from the use of gear couplings in equipment such as cranes, conveyors, and pumps. Cranes, which require precise torque control and frequent start-stop, rely on gear couplings to handle the dynamic loads and compensate for misalignment between the motor and the lifting mechanism. Conveyors, used in factories, mines, and ports to transport materials, use gear couplings to transmit power efficiently while accommodating the misalignment caused by the long length of the conveyor system. Pumps, which are used in a wide range of applications from water supply to chemical processing, benefit from the high efficiency and durability of gear couplings, ensuring reliable operation and minimizing energy consumption.

Proper installation and maintenance are essential to ensuring the optimal performance and long service life of gear couplings. The installation process begins with a thorough inspection of all components to check for signs of damage, wear, or defects. Any burrs, nicks, or debris on the shaft ends must be removed to ensure a proper fit between the hub and the shaft. The shafts must be carefully aligned using appropriate tools such as laser alignment devices to minimize misalignment, as excessive misalignment can lead to premature wear and failure. The coupling components should be lubricated with the recommended lubricant before installation to ease assembly and prevent corrosion. Once installed, the connecting bolts must be tightened evenly to the specified torque to ensure a secure connection and even load distribution.

Regular maintenance practices include periodic inspections, lubrication, and alignment checks. Visual inspections should be conducted to monitor for signs of wear, cracks, deformation, or corrosion on the coupling components. The lubrication status should be checked regularly, with lubricant replaced if it becomes discolored, dried out, or contaminated with impurities. The frequency of lubrication depends on the operating conditions, but it is typically recommended to replenish lubricant every three to six months for most applications. Alignment checks should be performed periodically to ensure that the shafts remain within the allowable misalignment limits, as thermal expansion, structural deformation, or bolt loosening can cause misalignment over time. Vibration and temperature monitoring can also be used to detect potential issues early, with abnormal vibration or overheating indicating possible misalignment, lubrication problems, or component wear.

Fault diagnosis is an important aspect of maintenance, as early detection of issues can prevent costly downtime and component failure. Abnormal vibration is a common indicator of problems such as misalignment, unbalanced components, or worn teeth. Vibration analysis tools can be used to measure vibration amplitude and frequency, helping to identify the root cause of the issue. Overheating can be caused by poor lubrication, excessive friction, or misalignment, and can be detected using infrared thermal imagers or temperature sensors. If wear or damage is detected, repairs or component replacement may be necessary. Lightly worn tooth surfaces can sometimes be repaired by grinding, while severe damage may require replacing the inner or outer gear rings. Connecting bolts that become loose should be retightened to the specified torque, and any damaged seals should be replaced to prevent lubricant leakage and contamination.

The design and performance of gear couplings continue to evolve in response to the changing needs of industrial applications. One emerging trend is the integration of smart technologies, such as sensors and monitoring systems, into gear couplings to enable real-time monitoring of performance parameters. These smart couplings can detect vibration, temperature, torque, and misalignment, transmitting data to a central control system for analysis. This allows for predictive maintenance, where potential issues are identified before they lead to failure, minimizing downtime and improving operational efficiency.

Advancements in material science are also driving improvements in gear coupling performance. The development of new high-strength alloys and composite materials is enabling the creation of couplings with higher torque capacity, improved wear resistance, and enhanced corrosion resistance. These materials also allow for the design of more compact and lightweight couplings, which is particularly beneficial in applications where space and weight are critical factors. Improvements in manufacturing processes, such as additive manufacturing, are also opening up new possibilities for gear coupling design, allowing for the creation of complex geometries that optimize performance and reduce weight.

Another trend is the focus on energy efficiency, with manufacturers designing gear couplings to minimize power loss during torque transmission. This is achieved through optimized gear tooth profiles, reduced friction, and improved lubrication systems. Energy-efficient gear couplings not only reduce energy consumption but also generate less heat, improving overall system efficiency and reducing maintenance requirements. In addition, there is a growing emphasis on sustainability, with manufacturers exploring the use of recyclable materials and environmentally friendly lubricants in gear coupling production.

In conclusion, gear couplings play a critical role in modern industrial transmission systems, offering a unique combination of high torque capacity, torsional stiffness, and misalignment compensation. Their robust design, diverse material options, and precise manufacturing processes make them suitable for a wide range of applications across industries such as metallurgy, mining, power generation, oil and gas, marine, and general manufacturing. Proper installation, maintenance, and fault diagnosis are essential to maximizing their performance and service life, while ongoing advancements in technology and material science continue to enhance their capabilities. As industrial operations become increasingly complex and demanding, gear couplings will remain a vital component, enabling efficient, reliable, and sustainable power transmission in a wide variety of applications. Their ability to adapt to changing operating conditions and meet evolving performance requirements ensures that they will continue to be a preferred choice for industrial engineers and operators for years to come.

« Gear Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/gear-couplings.html