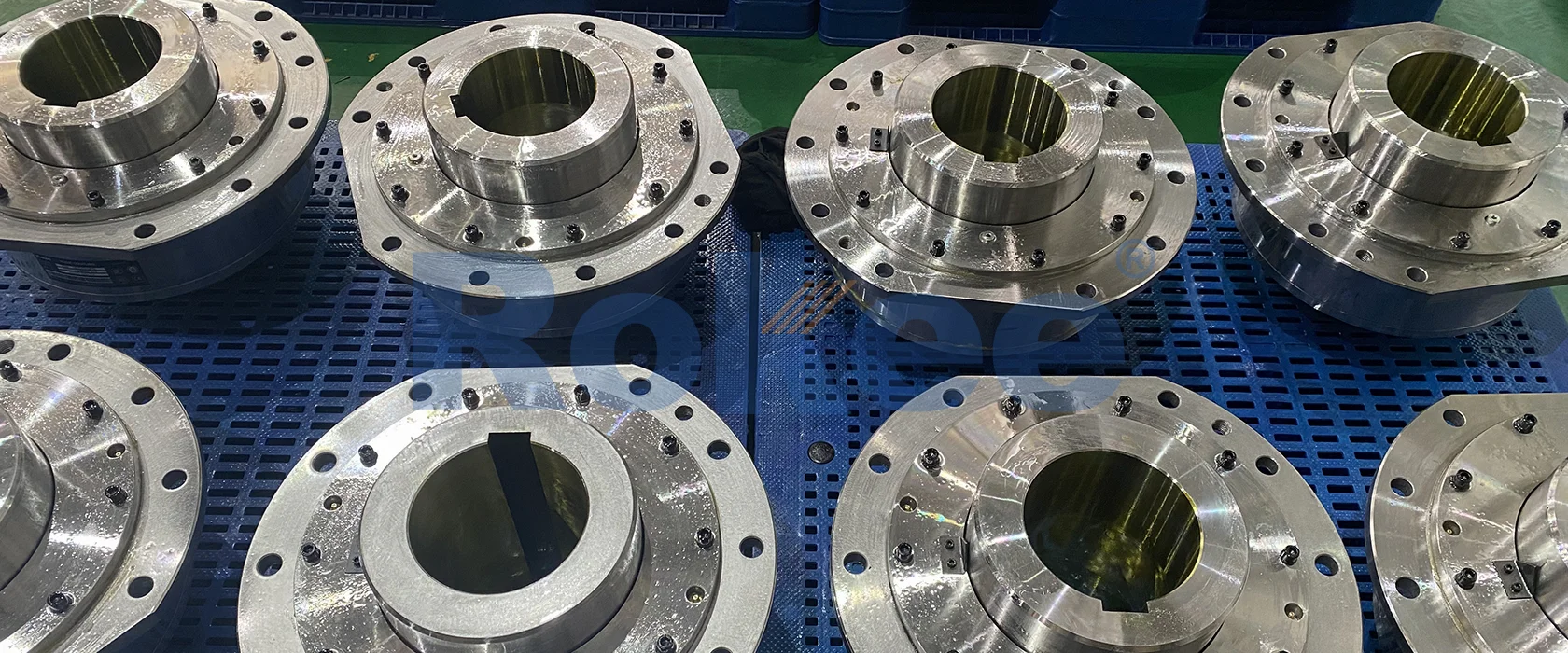

Rokee is a well-known high-quality supplier of Barrel Couplings and technical services in China, customize barrel couplings according to user drawings, alternatively, if the user provides barrel couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Barrel coupling is a mechanical transmission device specifically designed for drum type equipment, mainly used to connect the power transmission between the drive motor and the drum shaft. This type of coupling plays a crucial role in various types of equipment such as coilers, hoists, winches, and cranes, effectively compensating for axial, radial, and angular deviations while withstanding large torque loads.

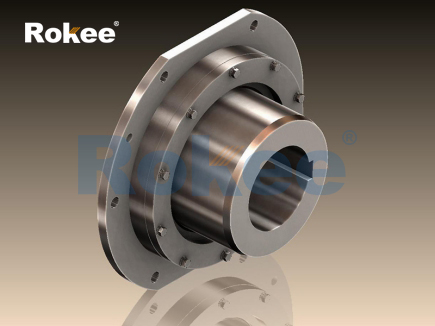

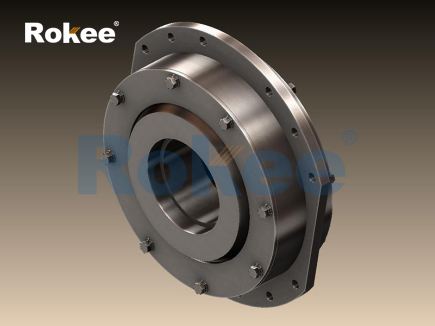

Specially designed for drum type equipment with a compact structure

Has excellent overload resistance and fatigue life

Can adapt to the unique working environment and working conditions requirements of drum equipment

Easy maintenance and long service life

Gear type barrel coupling

The gear type barrel coupling adopts an internal and external gear meshing structure and has the following characteristics:

High torque transmission capacity, up to several million Newton meters

Allow for larger axial displacement compensation (± 15mm)

Can adapt to a certain angular deviation (usually ≤ 1.5 °)

Widely used in heavy-duty cranes, port equipment and other occasions

Cross axis barrel coupling

The characteristics of the cross axis structure include:

Using cross axis and bearing components to achieve multi-directional compensation

Simple structure and easy maintenance

Suitable for medium torque transmission scenarios

Widely used in metallurgy and mining machinery

Elastic barrel coupling

The elastic coupling variant has unique advantages:

Built in elastic components to cushion vibrations and impacts

Reduce transmission system noise

Protect the drive motor from the impact of sudden load changes

Commonly used in precision winding equipment such as paper and film production lines

Magnetic barrel coupling

Innovative magnetic coupling features:

Non contact transmission, zero wear

Absolute sealing, suitable for special environments

No lubrication required, extremely low maintenance cost

Widely used in industries with high cleanliness requirements such as chemical and food industries

Rated torque: the maximum torque value that the coupling can transmit continuously during operation

Peak torque: the maximum overload torque that can be sustained in a short period of time

Speed range: allowable operating speed range

Compensation capability:

Axial compensation amount (usually 5-20mm)

Radial compensation amount (generally 2-10mm)

Angular compensation amount (0.5 ° -3 °)

Moment of inertia: a key parameter affecting the acceleration performance of a system

Working temperature range: -30 ℃ to+120 ℃

Selection considerations

Equipment types: cranes, rolling mills, paper machines, and other different equipment with varying requirements

Installation space: The outer diameter and length of the coupling need to match the equipment space

Environmental conditions: Temperature, humidity, corrosiveness, and other environmental factors affect material selection

Maintenance cycle: Select the corresponding structure based on maintainability requirements

Calculation and selection steps

Determine the rated torque and peak torque required to be transmitted by the equipment

Measure the available installation space size

Evaluate the required deviation compensation amount

Consider the requirements of environmental factors for materials

Choose the appropriate type and specification of coupling

Correct installation process

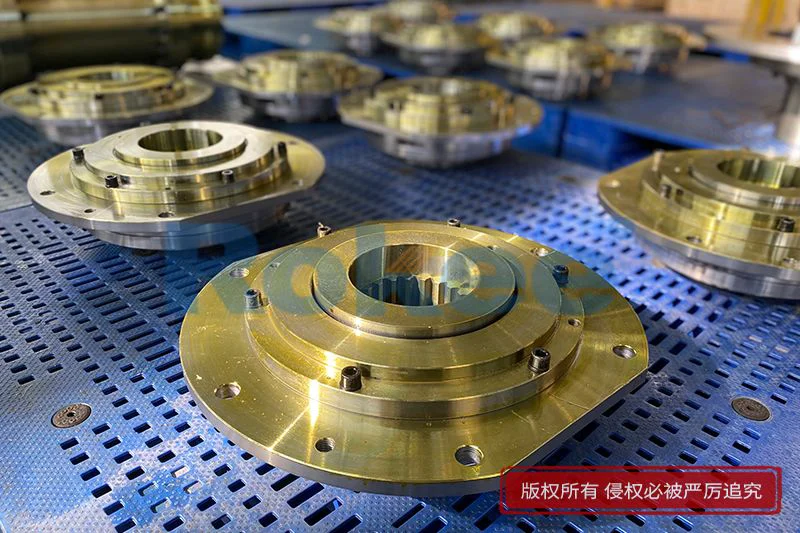

Clean all mating surfaces, remove burrs and dirt

Check the alignment of the shaft and adjust it if necessary

Use specialized tools for installation to avoid knocking

Tighten the connecting bolts according to the manufacturer's recommended torque values

Perform manual turning inspection after installation is completed

Key points of daily maintenance

Lubrication management: Regularly replenish or replace designated lubricating grease (gear type)

Alignment check: Check the alignment of the axis once every quarter

Wear monitoring: Pay attention to abnormal vibration and noise signals

Tightening inspection: Regularly check the tightening status of all connecting bolts

Application of Port Cranes

In large port container cranes, the barrel coupling must meet the following requirements:

High torque transmission (over 200000 Nm)

Long term continuous work reliability

Corrosion resistance to seawater

Easy to maintain design

Hot rolling mills in the steel industry

Characteristics of the coupling of the coiling machine in the hot rolling production line:

High temperature resistance (up to 200 ℃)

Anti impact load capacity

Quick design changes reduce downtime

Wind turbine

Requirements for coupling of wind turbine pitch system:

High precision angle transmission

Resistance to extreme temperature changes

Long life maintenance free design

In the realm of mechanical power transmission, couplings serve as critical intermediaries that connect rotating shafts, enabling torque transfer while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse range of coupling technologies available, barrel couplings stand out for their unique design characteristics and ability to perform reliably in high-demand industrial environments. Unlike conventional couplings that rely on gear teeth or flexible discs for power transmission, barrel couplings utilize a specialized configuration of cylindrical rollers and toothed components to achieve efficient torque transfer, exceptional misalignment compensation, and extended service life.

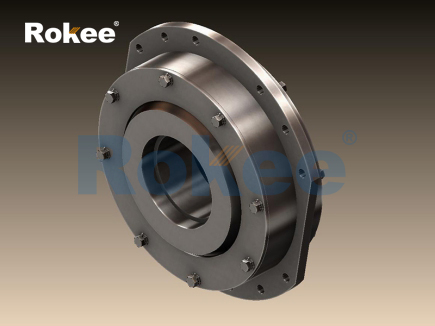

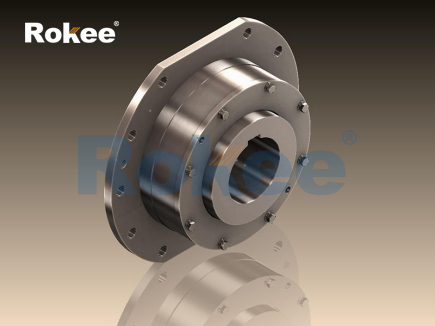

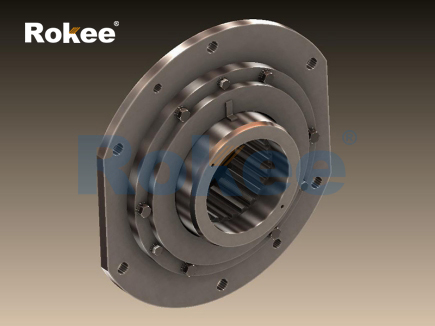

At the core of a barrel coupling’s functionality lies its distinctive structural design, which is engineered to balance torsional rigidity with flexibility. A typical barrel coupling consists of three primary components: a sleeve with internal semicircular toothing, a hub with matching external semicircular toothing, and a series of hardened steel cylindrical barrels inserted into the cavities formed by the interlocking toothing of the sleeve and hub. The semicircular toothing on both the sleeve and hub is precision-machined to ensure a perfect fit with the cylindrical barrels, which act as the primary torque-transmitting elements. This design differs significantly from gear couplings, which rely on meshing gear teeth to transfer torque, and instead uses line contact between the barrels and the toothed surfaces to distribute loads evenly. The cylindrical barrels, often treated with surface hardening processes to enhance wear resistance, rotate within the toothed cavities as the shafts turn, enabling smooth power transmission even when minor misalignments are present.

Complementing these core components are additional features that enhance the coupling’s performance and durability. Sealing covers equipped with specialized lip seals are integrated to protect the internal components from contamination by dust, debris, and moisture, while also retaining lubrication. Proper lubrication is critical for minimizing friction between the barrels and toothed surfaces, reducing wear, and preventing overheating during operation. Two double-lamina elastic rings are typically mounted on the hub, one on each side of the toothing, to limit the axial displacement of the barrels and maintain their optimal position within the coupling. The outer cover often incorporates a wear indicator, a valuable maintenance tool that allows operators to monitor internal wear without disassembling the coupling. This indicator moves relative to marked positions on the hub as wear occurs, providing a visual reference for when inspection or replacement may be necessary. This design feature addresses a key limitation of many alternative couplings, which require disassembly to assess wear, leading to increased downtime and maintenance costs.

The working principle of a barrel coupling revolves around its ability to transmit torque while compensating for axial, angular, and radial misalignments between connected shafts. Torque transmission begins when rotational force is applied to either the hub or the sleeve. This force is transferred through the cylindrical barrels, which engage with the semicircular toothing of both components. The line contact between the barrels and the toothed surfaces ensures that torque is distributed evenly across multiple points, reducing contact stress and minimizing wear. Unlike rigid couplings, which require precise alignment and can transmit harmful bending moments to shafts and bearings, barrel couplings act as articulated joints, allowing a degree of relative movement between the connected shafts. This flexibility is particularly valuable in industrial applications where installation inaccuracies, structural deformation, or thermal expansion can lead to shaft misalignment.

Angular misalignment compensation is achieved through the curved profile of the semicircular toothing and the cylindrical shape of the barrels. As the hub and sleeve rotate at slightly different angles, the barrels roll within the toothed cavities, adapting to the misalignment without generating excessive stress. Axial misalignment, or relative movement along the shaft’s axis, is accommodated by the elastic rings and the design of the toothed surfaces, which allow the barrels to shift position within acceptable limits. The amount of misalignment a barrel coupling can compensate for varies depending on its size and design, but many models can handle angular misalignments up to several degrees and axial displacements of a few millimeters. This level of flexibility is crucial for protecting sensitive components such as gearboxes, motors, and bearings, which can suffer premature failure if subjected to excessive misalignment-induced stress. By isolating these components from harmful bending moments, barrel couplings extend the overall service life of the mechanical system and reduce the risk of unplanned downtime.

One of the key performance advantages of barrel couplings is their ability to withstand high radial loads and transmit large torque values without compromising structural integrity. The use of hardened steel for the barrels and toothed components ensures that the coupling can handle the demands of heavy-duty applications, such as those found in crane hoisting mechanisms, steel mills, and mining equipment. The even distribution of torque across multiple barrels reduces the risk of localized stress concentrations, which can lead to component failure in high-torque scenarios. Additionally, the torsional rigidity of barrel couplings is well-balanced with their flexibility, ensuring that power is transmitted efficiently without excessive backlash or torsional deflection. This balance is particularly important in applications where precise speed control and torque delivery are critical, such as conveyor systems and precision manufacturing equipment.

When compared to alternative coupling technologies, barrel couplings offer several distinct advantages. Gear couplings, for example, are known for their high torque capacity but have limited misalignment compensation capabilities and require frequent lubrication and maintenance. They also suffer from higher bending stress wear, which can reduce their service life in applications with significant misalignment. Jaw couplings, while simple and low-maintenance, have lower torque capacity and are unsuitable for heavy-duty applications. Disc couplings offer high-speed capabilities and no backlash but have limited misalignment tolerance and are more susceptible to damage from radial loads. Barrel couplings, by contrast, combine the high torque capacity of gear couplings with the misalignment compensation capabilities of flexible couplings, while also offering easier maintenance through their integrated wear indicators. Their ability to tolerate greater wear without a significant decrease in operating capacity further distinguishes them from alternatives, making them a cost-effective choice for long-term operation.

The versatility of barrel couplings makes them suitable for a wide range of industrial applications, with particular prominence in sectors that require reliable performance in heavy-duty and high-misalignment scenarios. One of the most common applications is in crane and hoisting mechanisms, where barrel couplings are used to connect the cable drum to the gearbox output shaft. In these systems, precise torque transmission is essential for lifting and lowering heavy loads, while misalignment compensation is critical due to the dynamic forces and structural movements inherent in crane operation. Without a flexible coupling, the rigid connection between the gearbox and cable drum would transmit bending moments to the gearbox output shaft, leading to fatigue, wear, and potential shaft breakage. Barrel couplings eliminate this risk by acting as articulated joints, making the connection statically determinate and protecting the gearbox and other components.

Steel mills represent another key application area for barrel couplings, where they are used in various processes such as rolling mills, winches, and conveying systems. The harsh operating environment of steel mills, characterized by high temperatures, dust, and heavy loads, demands couplings that are durable, resistant to contamination, and capable of withstanding extreme conditions. Barrel couplings’ robust construction, sealed design, and ability to handle high torque and radial loads make them well-suited for these applications. They are also used in stackers and reclaimers, equipment used for handling bulk materials such as coal and ore, where reliable torque transmission and misalignment compensation are essential for continuous operation.

Other notable applications include wind energy systems, where barrel couplings are used in wind turbine drivetrains to connect the rotor to the gearbox or generator. The dynamic nature of wind energy production, with varying wind speeds and directional changes, creates significant misalignment challenges that barrel couplings are well-equipped to handle. Their ability to transmit large torques efficiently also makes them suitable for this application, where maximizing energy output is critical. In the marine industry, barrel couplings are used in ship propulsion systems and deck machinery, where they must withstand corrosive saltwater environments and heavy loads. The sealed design of barrel couplings helps protect internal components from corrosion, while their robust construction ensures reliable performance in harsh marine conditions.

Proper installation and maintenance are essential for maximizing the performance and service life of barrel couplings. The installation process begins with ensuring that the connected shafts are aligned as accurately as possible, even though the coupling can compensate for misalignments. Poor initial alignment can increase wear on the barrels and toothed surfaces, reducing the coupling’s service life. The coupling should be assembled in a clean environment to prevent contamination of internal components, and all fasteners should be tightened to the recommended torque specifications. Before operation, the coupling must be filled with the appropriate lubricant, as specified by the manufacturer, to ensure smooth operation and reduce wear. The type of lubricant selected depends on the operating conditions, including temperature, load, and speed, and should be chosen to provide optimal protection against friction and corrosion.

Regular maintenance is critical for monitoring wear and ensuring the coupling remains in optimal condition. The integrated wear indicator should be checked periodically to assess internal wear. If the indicator shows that wear has exceeded acceptable limits, the coupling should be inspected further, and worn components such as barrels or toothed surfaces should be replaced. Lubrication levels should be checked regularly, and the lubricant should be replaced at recommended intervals to prevent degradation. Seals should be inspected for damage or leaks, as compromised seals can lead to contamination and premature wear. In addition, the coupling should be visually inspected for signs of damage, such as cracks, deformation, or excessive corrosion, which could indicate a potential failure. Any damaged components should be replaced immediately to avoid further damage to the coupling or connected equipment.

Storage and handling practices also play a role in maintaining the integrity of barrel couplings. Couplings should be stored in a dry, dustproof environment with a relative humidity below 50% to prevent corrosion. They should be protected from collisions and other physical damage during transportation and storage. If a coupling is stored for an extended period, long-term protection measures such as corrosion inhibitors may be necessary. When handling the coupling, care should be taken to avoid damaging the toothed surfaces, barrels, or seals, as even minor damage can affect performance.

Advancements in materials and manufacturing technologies have led to continuous improvements in barrel coupling design and performance. One notable trend is the use of high-strength alloys and engineered materials for the hub, sleeve, and barrels. These materials offer enhanced durability, corrosion resistance, and wear resistance compared to traditional steels, making them suitable for use in more extreme operating environments. For example, the use of stainless steel or alloy steel with specialized heat treatments can increase the coupling’s resistance to corrosion and fatigue, extending its service life in marine or chemical processing applications.

Another area of innovation is the optimization of the semicircular toothing profile and barrel design. Advanced finite element analysis (FEA) tools are used to simulate the performance of barrel couplings under various load conditions, allowing engineers to refine the toothing profile to reduce contact stress and improve torque transmission efficiency. These simulations help identify potential stress concentrations and optimize the design to distribute loads more evenly, further enhancing the coupling’s durability. The use of precision machining technologies, such as computer numerical control (CNC) machining, ensures that the toothed surfaces and barrels are manufactured to extremely tight tolerances, improving the fit and performance of the coupling.

The integration of smart technologies into barrel couplings is an emerging trend that holds significant potential for improving maintenance and operational efficiency. Embedded sensors can be used to monitor parameters such as temperature, vibration, and wear in real time, providing valuable data to operators. This data enables predictive maintenance, allowing operators to address potential issues before they lead to equipment failure. For example, vibration sensors can detect abnormal wear patterns, while temperature sensors can alert operators to overheating caused by insufficient lubrication. Smart wear indicators, which transmit data wirelessly to a central monitoring system, eliminate the need for manual inspections and provide continuous wear monitoring, reducing downtime and maintenance costs.

Environmental considerations are also driving advancements in barrel coupling design. The development of more efficient sealing technologies reduces lubricant leakage, minimizing environmental impact. Additionally, the use of recyclable materials and the design of couplings for easier disassembly and recycling are becoming increasingly important as industries strive to reduce their carbon footprint. Manufacturers are also focusing on developing maintenance-free or low-maintenance barrel couplings, which reduce the need for lubricant replacement and component replacement, further minimizing environmental impact and operational costs.

Despite their many advantages, barrel couplings face certain challenges and limitations. One of the primary challenges is the high cost of precision manufacturing, which can make them more expensive than some alternative coupling technologies. However, this higher initial cost is often offset by their longer service life, lower maintenance requirements, and reduced downtime, making them a cost-effective choice for many applications. Another limitation is their performance in extreme temperature environments. While advancements in materials have improved their temperature tolerance, extremely high or low temperatures can still affect the performance of lubricants and materials, requiring specialized designs for such applications.

Competition from alternative coupling technologies is another factor that influences the adoption of barrel couplings. As manufacturers continue to improve the performance of gear couplings, disc couplings, and other alternatives, barrel couplings must maintain their competitive edge through ongoing innovation. However, their unique combination of high torque capacity, misalignment compensation, and ease of maintenance ensures that they remain the preferred choice for many heavy-duty industrial applications.

Looking to the future, the demand for barrel couplings is expected to grow as industries such as manufacturing, construction, and renewable energy continue to expand. The increasing focus on industrial automation and the need for reliable, efficient power transmission systems will drive the adoption of advanced barrel coupling technologies. The integration of smart features and the development of more durable, environmentally friendly designs will further enhance their appeal. As engineers continue to push the boundaries of material science and manufacturing technology, barrel couplings will evolve to meet the changing needs of industrial applications, solidifying their position as a critical component in mechanical power transmission systems.

In conclusion, barrel couplings offer a unique combination of torque transmission efficiency, misalignment compensation, and durability that makes them indispensable in a wide range of industrial applications. Their specialized design, which utilizes cylindrical barrels and semicircular toothing, provides a balance of torsional rigidity and flexibility that protects sensitive equipment and extends service life. From crane hoisting mechanisms to wind energy systems, barrel couplings play a vital role in ensuring reliable, efficient operation in some of the most demanding environments. Proper installation, maintenance, and handling practices are essential for maximizing their performance, while ongoing advancements in materials, manufacturing, and smart technologies continue to enhance their capabilities. As industries continue to evolve and demand higher levels of performance and efficiency, barrel couplings will remain a key technology in mechanical power transmission, adapting to meet the challenges of the future.

« Barrel Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/barrel-couplings.html