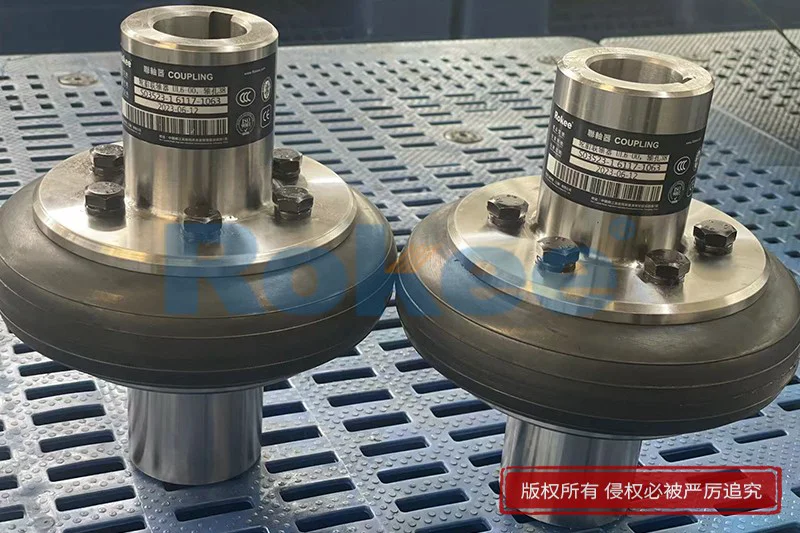

Rokee is a well-known high-quality supplier of Tire Couplings and technical services in China, customize tire couplings according to user drawings, alternatively, if the user provides tire couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Tire coupling is an elastic coupling that uses tire shaped elastic elements made of rubber or polyurethane to achieve shaft to shaft connection. It occupies an important position in the industrial transmission field due to its excellent vibration reduction, buffering, and compensation capabilities. This type of coupling is particularly suitable for transmission systems that require absorption of vibrations, compensation for deviations, and isolation of impacts.

Elastic tire body: made of high-strength rubber or polyurethane material, in the shape of a circular tire, and is the core component of a coupling

Metal pressure plate: usually two pieces, clamped and fixed to the tire body by bolts

Connecting flange: a metal component connected to the drive shaft and the driven shaft

Tightening bolts: used to connect and secure the entire component

The tire coupling achieves its function through the deformation ability of the elastic tire body: when the driving shaft rotates, torque is transmitted to the driven shaft through the elastic deformation of the tire body, while absorbing vibration and compensating for deviations. The elastic properties of the tire body enable it to withstand small deviations in radial, axial, and angular directions without affecting transmission efficiency.

Excellent vibration damping performance: can absorb up to 70% of vibration energy, significantly reducing equipment noise

Multi directional compensation capability:

Radial deviation compensation: ± 0.5-3mm

Axial deviation compensation: ± 1-5mm

Angular deviation compensation: 1 ° -3 °

Electrical insulation characteristics: Rubber material provides good insulation performance, preventing current conduction

Maintenance free design: No lubrication required, reducing maintenance costs

Overload protection: In the event of overload, the tires will slip, ensuring the safety of the equipment

Torque demand: Calculate maximum working torque and peak torque

Speed range: Consider the influence of centrifugal force on rubber components

Environmental conditions: temperature, chemicals, UV radiation, etc

Deviation type and magnitude: Determine the required compensation capability

Space limitations: Installation size and weight requirements

Rubber aging and cracking: manifested as surface cracking and hardening

Excessive wear: Decreased torque transmission capability

Permanent deformation: loss of rebound ability

Loose bolts: causing abnormal vibration

Regularly check the condition of rubber parts (every 6 months)

Monitoring operating temperature (abnormal temperature rise warning)

Check the tightening torque of bolts (every 1000 operating hours)

Avoid contact with oils and solvents

Tire couplings play an irreplaceable role in modern industrial transmission systems due to their unique design and excellent performance. With the advancement of materials science and manufacturing technology, tire couplings will continue to develop towards high performance, intelligence, and environmental protection, providing more reliable transmission solutions for various mechanical equipment.

In the complex network of industrial transmission systems, components that ensure smooth power transfer while safeguarding equipment integrity are indispensable. Among these, the tire coupling stands out as a versatile and reliable flexible coupling, widely integrated into diverse mechanical setups across sectors such as metallurgy, mining, petroleum, chemical engineering, and manufacturing. Its unique design, which combines structural robustness with elastic adaptability, addresses two critical challenges in mechanical transmission: compensating for shaft misalignment and dampening shock loads. Unlike rigid couplings that demand precise alignment and offer little to no vibration absorption, tire couplings leverage a flexible tire-shaped element to bridge the gap between driving and driven shafts, balancing torque transmission efficiency with equipment protection.

At its core, a tire coupling consists of three fundamental components: two half-couplings and a flexible tire-shaped element. The half-couplings, typically fabricated from high-strength metals, serve as the connection points between the coupling and the respective shafts of the driving and driven machinery. These components are precision-machined to ensure dimensional accuracy, as their ability to maintain a secure fit with the shafts directly impacts torque transmission reliability. The material choice for half-couplings is dictated by the operational demands of the application—common options include carbon steel, alloy steel, and in some cases, lightweight aluminum alloys for scenarios where reducing rotational inertia is a priority. Carbon steel offers an optimal balance of strength and cost-effectiveness for general industrial use, while alloy steel is preferred for heavy-duty applications requiring enhanced durability under high torque and impact loads. Aluminum alloys, though less robust than steel, are utilized in high-speed systems where minimizing mass reduces stress on bearings and other transmission components. The half-couplings feature flanged ends that interface with the tire element, with connection methods typically falling into two categories: bolted connection and vulcanized bonding.

Bolted connections are favored for their ease of installation and maintenance. In this configuration, the tire element is secured to the flanges of the half-couplings using bolts and pressure plates, creating a firm yet detachable bond. This design allows for straightforward replacement of the tire element when wear or damage occurs, minimizing downtime and maintenance costs. Vulcanized bonding, by contrast, involves integrating the tire element with metal plates (embedded within the tire’s ends) through a heat and pressure treatment process that creates a permanent, seamless bond. This method enhances the overall structural integrity of the coupling, as the absence of detachable fasteners eliminates the risk of bolt loosening or slippage under high torque. However, vulcanized couplings require complete replacement of the entire assembly if the tire element fails, making them more suitable for applications where long-term reliability is prioritized over ease of maintenance. The choice between these connection methods depends on the specific operational requirements, including maintenance frequency, torque levels, and downtime tolerance.

The tire-shaped elastic element is the defining feature of the coupling, responsible for its flexibility, shock absorption, and misalignment compensation capabilities. This component is typically manufactured from rubber or rubber composites reinforced with fiber fabrics or metal cords, with material formulation tailored to the application’s environmental and operational conditions. Natural rubber, known for its excellent elasticity and resilience, is commonly used in general-purpose applications with moderate temperature ranges and low chemical exposure. However, for harsh environments involving high temperatures, corrosive substances, or dynamic stress cycles, synthetic rubbers such as polyurethane-modified rubber, hydrogenated nitrile rubber, and ethylene-propylene-diene monomer (EPDM) rubber are preferred. These synthetic materials offer superior resistance to oxidation, ozone aging, tearing, and chemical degradation, ensuring prolonged service life under demanding conditions.

The performance of the tire element is further enhanced through advanced material engineering techniques. Reinforcement systems play a critical role in improving the mechanical properties of the rubber without compromising its elasticity. Nano-scale fillers such as fumed silica and specially treated carbon black are incorporated into the rubber compound to boost tensile strength, abrasion resistance, and dimensional stability. These fillers create a dense network within the rubber matrix, distributing stress evenly across the tire element and preventing localized damage. The vulcanization process is also optimized to ensure a uniform cross-linked network, which enhances the rubber’s elasticity across a wide temperature range and reduces the risk of permanent deformation under repeated stress. Additionally, composite antioxidants are added to the formulation to counteract the effects of heat and cyclic deformation, slowing down oxidative aging and extending the element’s service life. Internal reinforcement cords, typically made from high-strength polyester or steel, are integrated into the tire element to provide structural support. These cords are arranged in a cross-angle pattern, balancing radial stiffness with axial and angular flexibility, allowing the coupling to compensate for misalignment while maintaining torque transmission capacity.

The working principle of a tire coupling revolves around the elastic deformation of the tire element. When the driving shaft rotates, torque is transmitted to the adjacent half-coupling, which in turn transfers the force to the tire element. The tire element deforms elastically under this torque, converting the rotational force into motion that drives the second half-coupling and the driven shaft. A key advantage of this design is its ability to compensate for various types of shaft misalignment, including axial, radial, and angular displacement. Axial misalignment occurs when the shafts move along their longitudinal axes, a common issue in systems where thermal expansion causes dimensional changes. Radial misalignment arises when the shafts are offset parallel to each other, while angular misalignment refers to shafts that are not collinear, forming a slight angle between their axes. The tire element’s flexibility allows it to accommodate these displacements by deforming correspondingly, eliminating the need for perfect shaft alignment and reducing stress on bearings, gears, and other transmission components.

In typical industrial applications, tire couplings can compensate for axial displacements ranging from ±5mm to ±10mm, radial displacements between 0.5mm and 1.5mm, and angular displacements of 1.5° to 3°. This level of compensation capability makes them highly adaptable to installations where precise alignment is difficult to achieve or maintain, such as large-scale machinery with heavy frames that may deflect under load. Beyond misalignment compensation, the tire element’s elastic properties enable effective shock absorption and vibration damping. During motor startup, load changes, or equipment shutdowns, the transmission system experiences sudden torque spikes and vibrations that can damage sensitive components. The tire element acts as a buffer, absorbing these shock loads and dissipating vibrational energy through internal friction, reducing the impact on the driving and driven machinery. This damping effect not only protects equipment but also reduces operational noise, creating a safer and more comfortable working environment.

The performance characteristics of tire couplings are shaped by their structural design and material selection, making them well-suited for a wide range of industrial applications. One of their most notable attributes is their high torque transmission capacity, which spans from tens of Newton-meters to tens of thousands of Newton-meters. This versatility allows them to be used in both light-duty equipment such as pumps and fans, and heavy-duty machinery including crushers, ball mills, and rolling mills. The torque capacity is determined by factors such as the size of the tire element, the strength of the half-couplings, and the material properties of the elastic component. By optimizing these factors, tire couplings can reliably transmit power even under peak load conditions, ensuring consistent equipment performance.

Another key performance feature is the coupling’s temperature adaptability. Most standard tire couplings operate effectively within a temperature range of -20℃ to 80℃, making them suitable for indoor and outdoor applications in moderate climates. For extreme temperature environments, specialized rubber compounds can be used to extend this range, with some formulations capable of withstanding temperatures as low as -40℃ or as high as 120℃. The rubber material’s inherent resistance to mild corrosion also allows tire couplings to be used in environments with small amounts of chemical contaminants, such as industrial facilities with minor oil or chemical spills. However, prolonged exposure to strong corrosive substances should be avoided, as this can degrade the rubber and compromise the coupling’s performance.

While standard tire couplings meet the needs of most general industrial applications, certain specialized scenarios demand customized solutions to address unique operational challenges. High elastic customization, in particular, has emerged as a critical approach for optimizing coupling performance in extreme conditions such as high-vibration environments, heavy shock loads, or precise synchronization requirements. Customization is not merely a matter of adjusting the size or thickness of the tire element; it involves a systematic engineering process that integrates material science, structural analysis, and load simulation to create a coupling tailored to the specific dynamic load profile of the application.

Material customization is a core aspect of high-elasticity tire coupling design. In applications with frequent torque spikes, such as ball mills and crushers, standard rubber compounds may suffer from premature cracking or permanent deformation due to excessive heat generation and cyclic stress. To address this, specialized rubber formulations are developed by blending synthetic rubbers with reinforcing agents and additives to achieve a balance of high elasticity and damping capacity. For example, polyurethane-modified rubber combined with natural rubber offers enhanced tear resistance and dynamic ozone aging performance, while optimized vulcanization systems ensure the rubber maintains its elasticity across a wide temperature range. In one application involving a large cement plant’s ball mill, a customized high-elasticity tire coupling replaced a standard model, resulting in a 15% reduction in startup current peaks and a 30% decrease in vibration intensity. The customized tire element showed no signs of cracking or deformation after 18 months of continuous operation, doubling the service life of the original coupling.

Structural optimization is another key component of customization. The traditional uniform cross-section design of tire elements can lead to stress concentration in certain areas, increasing the risk of early failure under cyclic loads. Customized designs address this by adopting non-uniform cross-sections, such as convex or wavy profiles, which distribute stress more evenly across the tire element. The arrangement of internal reinforcement cords is also optimized, with cross-angle adjustments that enhance radial support while allowing greater axial and angular compensation. Finite element analysis (FEA) is commonly used to simulate the coupling’s performance under various load conditions, enabling engineers to design a non-linear stiffness curve. This curve features low initial stiffness to absorb minor shocks and compensate for small misalignments, with stiffness increasing gradually as deformation grows to limit excessive movement and protect equipment. This “intelligent flexibility” ensures the coupling adapts to changing load conditions without compromising reliability.

Customization also extends to the half-couplings and connection components. In high-speed applications, lightweight aluminum alloy flanges are used to reduce rotational inertia, minimizing stress on the transmission system. Specialized surface treatments, such as friction-enhancing coatings, are applied to the contact surfaces between the half-couplings and the tire element to prevent slippage under high torque. For applications requiring precise synchronization, such as multi-motor driven paper machinery, couplings are designed with extremely low and consistent torsional stiffness to accommodate minor output variations between motors while maintaining synchronization. This level of customization ensures the coupling integrates seamlessly with the equipment, optimizing performance and extending service life.

The versatility of tire couplings is reflected in their wide range of applications across diverse industrial sectors. In the metallurgy industry, they are used in rolling mills, coking equipment, and blast furnace systems, where they compensate for misalignment caused by thermal expansion and absorb shocks from material processing. Rolling mills, in particular, benefit from the coupling’s ability to dampen torsional vibrations, which can affect the quality of the finished metal products. In the mining industry, tire couplings are integrated into crushers, ball mills, and conveyor systems, where they withstand heavy shock loads from ore processing and compensate for misalignment due to the large size and weight of the equipment. Crushers, which experience sudden torque spikes when processing large ore chunks, rely on the coupling’s shock absorption capabilities to protect downstream components such as gearboxes and motors.

The petroleum and chemical industries utilize tire couplings in pumps, compressors, and mixers, where they operate in harsh environments involving high temperatures, pressure, and potential chemical exposure. The corrosion resistance of synthetic rubber compounds ensures the couplings maintain performance in these conditions, while their vibration damping reduces noise and protects precision components. In the power generation sector, tire couplings are used in boiler feed pumps, fans, and generators, where reliable torque transmission and vibration control are critical for efficient power production. They also find applications in transportation equipment, such as port cranes and conveyor systems, where they compensate for structural deformation and wind-induced misalignment, ensuring smooth and safe operation.

The selection of a tire coupling for a specific application requires careful consideration of several key factors to ensure optimal performance and reliability. The primary consideration is the operating torque, with the coupling’s allowable torque capacity exceeding the maximum torque generated by the equipment to accommodate peak loads. The operating speed is also critical, as excessive rotational speeds can cause premature wear of the tire element due to centrifugal forces. Engineers must also evaluate the expected shaft misalignment, selecting a coupling with sufficient compensation capacity to handle axial, radial, and angular displacements. Environmental factors, such as temperature, humidity, and chemical exposure, dictate the choice of rubber compound, with specialized formulations required for extreme conditions. Installation space constraints may also influence the coupling’s size and design, with compact models available for applications with limited clearance.

Proper installation and maintenance are essential to maximizing the service life of tire couplings and ensuring safe operation. During installation, the shafts should be aligned as accurately as possible within the coupling’s compensation range to minimize stress on the tire element. The half-couplings must be securely fastened to the shafts using appropriate keys or shrink fits, with bolted connections torqued to the recommended specifications to prevent loosening. Regular inspection is critical for early detection of potential issues, with visual checks for cracks, bulging, or wear on the tire element. Operators should also monitor for unusual vibrations or noise, which may indicate misalignment, bolt loosening, or tire element degradation. In bolted couplings, the bolts and pressure plates should be inspected periodically for tightness, while vulcanized couplings require careful monitoring of the bond between the tire element and the half-couplings.

Common faults in tire couplings include tire element degradation, bolt loosening, shaft misalignment, and imbalance. Tire element wear or cracking is typically caused by excessive stress, temperature extremes, or chemical exposure, requiring replacement of the element or the entire coupling in the case of vulcanized designs. Bolt loosening can lead to slippage and increased vibration, with retightening or replacement of worn bolts recommended. Shaft misalignment, if excessive, can accelerate tire element wear and damage bearings, necessitating realignment of the shafts. Imbalance, caused by uneven mass distribution in the coupling or connected components, generates centrifugal forces that increase vibration and stress, requiring balancing procedures to correct. Regular lubrication of the half-coupling shafts and keys is also important to prevent corrosion and ensure smooth operation, though tire couplings themselves do not require lubrication due to their rubber elements.

When comparing tire couplings to other types of couplings, their unique combination of flexibility, shock absorption, and misalignment compensation sets them apart from rigid and semi-rigid alternatives. Gear couplings, for example, offer high torque capacity and durability but lack effective vibration damping and require precise alignment and regular lubrication. They are more suitable for heavy-duty applications where misalignment is minimal and vibration is not a major concern. Chain couplings, similar to gear couplings, provide high torque transmission but have limited misalignment compensation and generate more noise due to the meshing of chains and sprockets. Disc couplings offer excellent misalignment compensation and are suitable for high-speed applications but have lower shock absorption capabilities and are more sensitive to overloads.

Jaw couplings, which use elastomeric spiders to connect two jaws, offer moderate vibration damping and misalignment compensation but have lower torque capacity compared to tire couplings, making them suitable for light to medium-duty applications. Universal joints are designed for high angular misalignment but are less effective at damping vibrations and require regular maintenance. Tire couplings outperform these alternatives in applications requiring both misalignment compensation and shock absorption, offering a balance of performance, reliability, and low maintenance. Their ability to operate without lubrication and their relatively simple design also contribute to lower operational costs compared to gear and chain couplings.

Despite their numerous advantages, tire couplings have certain limitations that must be considered. They are less suitable for high-speed applications where centrifugal forces can degrade the rubber element, and their temperature and chemical resistance, while superior to some elastomeric couplings, is still limited compared to metal couplings. The tire element is also susceptible to aging over time, requiring periodic replacement to maintain performance. However, these limitations are often outweighed by their benefits in most industrial scenarios, making them a preferred choice for applications involving vibration, shock loads, and misalignment.

The evolution of tire coupling technology continues to be driven by advancements in material science and engineering design. Ongoing research into new rubber compounds and reinforcement materials aims to enhance the coupling’s temperature resistance, durability, and torque capacity. The integration of advanced simulation tools, such as FEA and computational fluid dynamics (CFD), allows for more precise optimization of structural designs, improving performance and reducing the risk of failure. The development of smart monitoring systems, which use sensors to track vibration, temperature, and stress levels, is also enabling predictive maintenance, allowing operators to address potential issues before they lead to equipment downtime.

In conclusion, tire couplings play a vital role in modern industrial transmission systems, offering a unique combination of flexibility, shock absorption, and misalignment compensation. Their design, which integrates robust half-couplings with a versatile elastic tire element, ensures reliable torque transmission while protecting equipment from damage caused by vibrations and misalignment. Through material customization and structural optimization, tire couplings can be tailored to meet the demands of extreme applications, from heavy-duty mining equipment to precision manufacturing systems. Proper selection, installation, and maintenance are essential to maximizing their service life and performance, while ongoing technological advancements continue to expand their capabilities. As industries evolve and demand more efficient and reliable transmission solutions, tire couplings will remain a cornerstone of mechanical design, adapting to new challenges and contributing to the smooth and safe operation of industrial machinery worldwide.

The widespread adoption of tire couplings across diverse sectors is a testament to their versatility and effectiveness. In manufacturing facilities, they ensure the smooth operation of production lines, reducing downtime and improving productivity. In energy production, they contribute to the efficient generation of power by maintaining reliable transmission between turbines, generators, and auxiliary equipment. In mining and construction, they withstand the harsh conditions of heavy machinery, extending equipment life and reducing maintenance costs. As environmental regulations become more stringent, the role of tire couplings in reducing energy consumption and noise pollution is also gaining importance, making them an essential component of sustainable industrial practices.

Looking ahead, the future of tire couplings will be shaped by the need for higher performance, greater durability, and smarter monitoring. Advances in nanotechnology may lead to the development of rubber compounds with unprecedented strength and resistance to extreme conditions, while additive manufacturing techniques could enable the production of complex, customized half-couplings with optimized weight and performance. The integration of IoT (Internet of Things) technology into tire couplings will allow for real-time monitoring of operational parameters, enabling predictive maintenance and further reducing downtime. As industries continue to push the boundaries of performance and efficiency, tire couplings will evolve to meet these demands, solidifying their position as a critical component in industrial transmission systems for years to come.

« Tire Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/tire-couplings.html