Rokee is a well-known high-quality supplier of Membrane Couplings and technical services in China, customize membrane couplings according to user drawings, alternatively, if the user provides membrane couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Membrane coupling is a high-performance flexible coupling widely used in modern industrial machinery transmission systems. It uses one or more specially designed metal diaphragms as elastic elements to achieve power transmission and displacement compensation between two axes. Compared with traditional couplings, membrane couplings have become the preferred transmission components in many industrial application fields due to their unique structural characteristics and excellent mechanical performance.

The core working principle of membrane couplings is based on the principle of elastic deformation. When power is transmitted from the drive shaft, it is achieved through the elastic deformation of the diaphragm:

Torque transmission: The diaphragm undergoes elastic deformation under the action of torque, transmitting rotational power to the driven shaft

Displacement compensation: The diaphragm can compensate for axial, radial, and angular displacements

Vibration absorption: The elastic properties of the diaphragm can absorb and buffer vibrations in the transmission system

This working principle enables the membrane coupling to effectively solve various alignment deviation problems that traditional rigid couplings cannot overcome without reducing transmission efficiency.

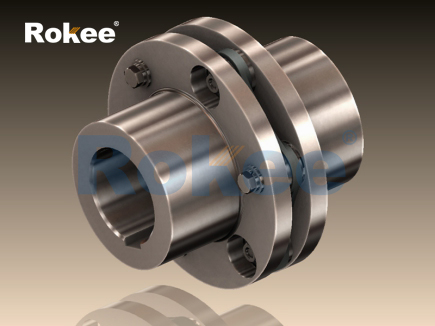

A typical membrane coupling is mainly composed of the following components:

Metal diaphragm group: usually made of stainless steel or other high-strength alloys, it is the core component of the coupling

Wheel hub: a metal component that connects the ends of a shaft, typically made of high-strength cast iron or steel materials

Intermediate section: The intermediate component connecting the two wheel hubs, with a length that can be adjusted as needed

Connecting bolt: used to fix the diaphragm to the wheel hub or intermediate section

Protective cover: a protective device equipped on some models to protect the membrane from external environmental influences

The design of membrane usually adopts porous structure or corrugated shape to optimize its elastic performance and fatigue life.

According to the structure and application requirements, membrane couplings can be divided into various types:

Single diaphragm type: suitable for applications with smaller torque and displacement compensation

Double membrane type: with better displacement compensation capability, suitable for situations with large deviations

Multi diaphragm type: used for high-power transmission, providing higher torque capacity

Axial insertion type: special design for easy installation and disassembly

Flange connection type: suitable for heavy-duty connection of large equipment

In addition, it can be divided into parallel membrane type, corrugated membrane type, and spiral membrane type according to the shape of the membrane.

Membrane couplings have several outstanding technical features:

High torque transmission capability: Modern membrane couplings can transmit up to millions of Newton meters of torque

Accurate centering compensation:

Axial displacement compensation: usually up to ± 0.5-5mm

Radial displacement compensation: usually up to 0.2-3mm

Angular displacement compensation: usually up to 0.5 ° -3 °

Zero backlash transmission: ensuring the implementation of high-precision motion control

Maintenance free design: No lubrication required, reducing maintenance costs

High speed capability: Well balanced membrane couplings can reach tens of thousands of revolutions per minute

Excellent fatigue resistance: High quality membranes can withstand more than 10 ^ 7 cycles of cyclic loading

Membrane couplings are widely used for their excellent performance in:

Power generation equipment: steam turbines, gas turbines, wind turbines, etc

Petrochemical industry: compressors, pumps, mixing equipment, etc

Shipbuilding industry: main propulsion system, auxiliary power system

Metallurgical industry: rolling mills, fans, pump sets, etc

Paper Machinery: Various Roller Transmission Systems

Precision machinery: high-precision equipment such as CNC machine tools and robots

Aerospace: Aircraft Engine Auxiliary Transmission System

In the field of wind power generation, membrane couplings have become the mainstream choice, with a market share of over 70%.

The correct selection is crucial for ensuring the performance and service life of the coupling, with main considerations including:

Torque demand: including rated torque and peak torque

Speed range: working speed and critical speed

Displacement compensation requirements: expected axial, radial, and angular deviations

Environmental conditions: temperature, humidity, corrosive media, etc

Space limitations: Install space size constraints

Dynamic characteristics: requirements for torsional stiffness, inertia, etc

Standard certification: industry-specific requirements (such as API, ATEX, etc.)

When selecting, it is recommended to leave a safety margin of 15-20% and consider possible system upgrade requirements in the future.

Installation points:

Ensure that the shaft end is clean and undamaged

Use specialized tools for alignment and control deviations within the allowable range

Tighten the bolts according to the specified torque value

Avoid forced installation that may cause pre deformation of the diaphragm

Maintenance suggestion:

Regularly inspect the membrane for cracks or plastic deformation

Monitor the tightening status of bolts

Check the operating temperature of the coupling

Record vibration data and analyze the trend of changes

Although membrane couplings are designed to be maintenance free, regular inspections can significantly extend their service life.

Compared with traditional types such as gear couplings and elastic couplings, membrane couplings have significant advantages:

Compared to gear couplings:

No lubrication required

Easy maintenance

No tooth surface wear problem

More suitable for high-speed applications

Compared with elastic couplings:

higher accuracy

Longer service life

Better temperature adaptability

Greater displacement compensation capability

Compared to universal couplings:

A smoother transmission

Smaller vibrations

higher efficiency

A simpler structure

Laminated membrane couplings are particularly suitable for applications that require high reliability, long lifespan, and low maintenance.

As an important component in the field of modern mechanical transmission, membrane couplings have gained widespread recognition for their excellent performance and reliability. With the advancement of materials science and manufacturing technology, the application scope of membrane couplings will be further expanded, and their performance will continue to improve. Correctly selecting, installing, and maintaining membrane couplings can not only ensure the stable operation of the transmission system, but also significantly reduce the total lifecycle cost, providing solid guarantees for the efficient operation of industrial equipment.

« Membrane Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/membrane-couplings.html