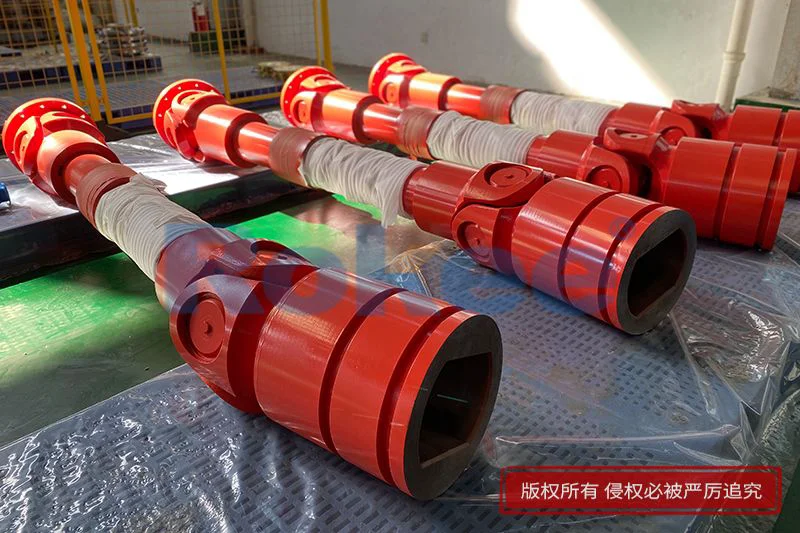

Rokee is a well-known high-quality supplier of Industrial Cardan Shafts and technical services in China, customize industrial cardan shafts according to user drawings, alternatively, if the user provides industrial cardan shafts parameters, we can select the model and design drawings for you, support wholesale and export.

Industrial cardan shaft is a mechanical device used to connect two non overlapping transmission shafts and achieve power transmission. As a core component in modern mechanical transmission systems, it can compensate for angular deviation, radial displacement, and axial displacement between shafts, ensuring the smoothness and reliability of power transmission.

Compared with ordinary couplings, cardan shafts have unique advantages: they allow for significant angular deviations (usually up to 15 ° -45 °) between the connected shafts during operation, while still efficiently transmitting torque. This characteristic makes it widely used in many industrial fields, from automotive transmission systems to heavy machinery, from precision instruments to aerospace equipment.

Cross shaft assembly: composed of a cross shaft and four needle roller bearings, it is the core moving component of the cardan shaft, responsible for compensating for angle changes.

Flange fork: There are usually two, which connect the driving shaft and the driven shaft respectively, and are connected to each other through a cross shaft.

Bearing cover and seal: protect needle roller bearings from contamination, maintain lubrication, and extend service life.

Spline sleeve (some models): allows axial displacement compensation, commonly used in long wheelbase transmission systems.

Balance block (high-speed application): used to balance the centrifugal force generated during rotation and reduce vibration.

The working principle of the cardan shaft is based on the geometric characteristics of the cardan shaft. When the driving shaft rotates, torque is transmitted to the driven shaft through the cross shaft. Due to the fact that the cross axis can freely swing in two planes, even if there is an angular deviation between the two axes, the continuity of torque transmission can still be maintained.

It is worth noting that when a single cardan shaft transmits torque, the angular velocity of the driven shaft is not constant, but exhibits periodic fluctuations. This fluctuation is directly proportional to the angle between the two axes. To eliminate this speed fluctuation, a dual cardan shaft arrangement is often used in industrial applications. By correctly arranging the phases of the two cardan shafts, the speed fluctuation can be completely cancelled out, achieving constant speed transmission.

Cross axis cardan shaft

The most common type has a simple structure, strong load-bearing capacity, and allows for an angle deviation of 15 ° -45 °. Widely used in automotive transmission shafts, rolling mills, and other applications.

Ball cage constant velocity cardan shaft

By adopting a spherical raceway and cage structure, true constant speed transmission can be achieved with slightly smaller angle compensation capability (generally ≤ 22 °). Mainly used for the drive shaft of front wheel drive vehicles.

Trident cardan shaft

Composed of three pin shafts and a specially shaped fork, it has a large angle compensation ability, low vibration, and is commonly used in ship propulsion systems.

Double cardan shaft

Connect two single cardan shafts through an intermediate shaft to achieve long-distance transmission and large angle compensation while maintaining constant speed characteristics.

Heavy duty cardan shaft

Specially designed for heavy machinery such as metallurgy and mining, with a load-bearing capacity of millions of Newton meters, using special materials and lubrication systems.

Transmission torque: Calculate the required torque capacity based on the driving power and speed, and consider the starting torque and impact load.

Speed range: cardan shafts with different structures have their applicable speed ranges, and dynamic balance requirements need to be considered for high-speed applications.

Angle compensation requirements: including working angle and installation angle, the larger the angle, the shorter the lifespan.

Environmental conditions: Temperature, humidity, corrosive media and other environmental factors affect the selection of materials and seals.

Space limitations: The size constraints of the installation space may determine the structural form of the coupling.

Maintenance requirements: lubrication method (grease lubrication or oil lubrication), re lubrication cycle and other maintenance factors.

Automotive industry: transmission shaft, steering system, four-wheel drive system, etc.

Metallurgical machinery: the main transmission system of rolling mills, straightening machines, and continuous casting equipment.

Construction machinery: power transmission for excavators, cranes, and concrete pump trucks.

Shipbuilding industry: power transmission for propulsion shaft systems and deck machinery.

Energy equipment: wind turbine pitch system, turbine speed control mechanism.

Aerospace: Helicopter rotor transmission, flight control system.

Precision Machinery: Machine Tool Rotary Workbench, Robot Joint Transmission.

Ensure that the alignment error of the two axes is within the allowable range, even if the cardan shaft can compensate for the deviation, good alignment can still extend the service life

For the arrangement of dual cardan shafts, it should be ensured that the two cardan shafts are in the same plane and the fork phase is correct

The fastening bolts must be tightened to the specified torque and anti loosening measures must be taken

After installation, manually rotate to check for interference or abnormal resistance

Regularly check the lubrication condition and supplement or replace lubricating grease according to the instructions

Monitoring operating temperature, abnormal temperature rise often indicates malfunction

Regularly check the sealing condition to prevent contaminants from entering the bearings

Pay attention to abnormal vibrations or noise and promptly investigate the cause

For critical equipment, it is recommended to use condition monitoring technology for predictive maintenance

As the fundamental component of mechanical transmission, cardan shafts will continue to make breakthroughs in reliability, efficiency, and intelligence, providing more outstanding power transmission solutions for modern industrial equipment.

Industrial cardan shafts, also known as universal shafts, stand as indispensable mechanical components in modern power transmission systems, designed to transfer torque and rotational motion between non-collinear shafts. Their ability to accommodate angular misalignment, axial movement, and radial deflection makes them vital across a spectrum of industrial sectors, where seamless power transfer under dynamic conditions is critical. Unlike rigid connectors that require precise alignment, cardan shafts leverage articulated joints to maintain rotational continuity even when the driving and driven shafts are offset, a feature that has solidified their position as a cornerstone of heavy machinery, automotive drivetrains, and specialized industrial equipment. The evolution of these components has been shaped by advancements in materials science, manufacturing technologies, and engineering design, transforming them from simple mechanical linkages into high-performance systems optimized for efficiency, durability, and adaptability to extreme operating conditions.

At the core of a cardan shaft’s functionality lies its structural composition, which typically includes two universal joints (U-joints) connected by a central shaft, often referred to as the propeller shaft or drive shaft. The universal joints, the most critical elements of the assembly, enable angular movement through a cross-shaped component—known as a cross shaft or spider—that connects two yokes. Each yoke is attached to either the driving or driven shaft, and the cross shaft is fitted with bearings to facilitate smooth rotation and bending. This configuration allows the cardan shaft to compensate for angular misalignment ranging from 5° to 45°, depending on the design and application requirements. In some cases, double cardan shafts are employed, incorporating an intermediate shaft and additional universal joints to eliminate speed fluctuations inherent in single-joint designs, making them suitable for long-distance transmission and high-precision applications. The central shaft, meanwhile, is engineered to withstand torsional stress and shear forces, with its diameter, length, and material composition tailored to the torque demands of the specific application.

The working principle of an industrial cardan shaft is rooted in mechanical geometry and dynamics, focusing on the seamless transfer of rotational motion despite misalignment. When the driving shaft rotates, it imparts motion to the attached yoke, which in turn rotates the cross shaft. The cross shaft then transfers this rotation to the opposing yoke, which drives the driven shaft. The bearings within the universal joints reduce friction during this process, ensuring that motion is transmitted efficiently with minimal energy loss. A key characteristic of this mechanism is its ability to accommodate multiple types of misalignment simultaneously—angular, axial, and radial—making it ideal for equipment where thermal expansion, vibration, or installation errors may cause shifts in shaft position. For instance, in rolling mills, where rollers undergo frequent adjustment to accommodate different material thicknesses, cardan shafts compensate for the resulting angular deviations, ensuring consistent power delivery to the roll system. Similarly, in construction machinery such as excavators, the shafts adapt to the articulation of the boom and slewing mechanism, maintaining torque transfer during dynamic movement.

Material selection plays a pivotal role in determining the performance, durability, and lifespan of industrial cardan shafts, with different materials chosen based on the application’s torque requirements, operating environment, and weight constraints. Traditional cardan shafts are predominantly fabricated from high-strength steel alloys, which offer exceptional torsional rigidity, impact resistance, and durability under heavy loads. These steels are often heat-treated to enhance their mechanical properties, ensuring they can withstand the repetitive stress cycles and high torque encountered in heavy-duty applications such as mining, metallurgy, and construction. In recent years, advancements in materials science have led to the adoption of lightweight alternatives, including high-grade aluminum and carbon fiber-reinforced polymers (CFRPs). Aluminum shafts offer a significant weight reduction compared to steel, which translates to lower inertia, improved fuel efficiency, and reduced wear on associated components—advantages particularly valuable in automotive and aerospace applications. Carbon fiber composites, meanwhile, provide an optimal balance of strength and weight, with torsional stiffness comparable to steel but at a fraction of the weight, making them suitable for high-speed, high-performance applications where weight minimization is critical.

The manufacturing process of industrial cardan shafts is a precision-driven endeavor that combines traditional machining techniques with advanced technologies to ensure dimensional accuracy and structural integrity. The production of the central shaft typically involves forging or rolling to achieve the desired shape and mechanical properties, followed by turning, milling, and grinding to achieve precise dimensions and surface finish. Forging enhances the grain structure of the material, improving its strength and resistance to fatigue failure, a common concern in components subjected to repetitive stress. The universal joints and yokes are manufactured using precision casting or machining processes, with the cross shaft and bearings requiring tight tolerances to ensure smooth operation. In modern manufacturing facilities, computer numerical control (CNC) machines are used to achieve high levels of accuracy, reducing human error and ensuring consistency across production runs. Additionally, simulation-driven design tools are employed to optimize the shaft’s geometry, predicting stress distribution and identifying potential weak points before production, which helps minimize the risk of failure and reduces development time.

Industrial cardan shafts find application across a diverse range of sectors, each with unique requirements that drive specific design adaptations. In the automotive industry, they are a critical component of drivetrains, connecting the gearbox to the drive axle in rear-wheel and four-wheel-drive vehicles. In these applications, the shafts must accommodate the vertical movement of the wheels caused by road irregularities, while transmitting high torque efficiently. Lightweight materials are increasingly used in automotive cardan shafts to improve fuel efficiency and reduce emissions, aligning with global efforts to enhance vehicle sustainability. The construction machinery sector relies heavily on cardan shafts for equipment such as excavators, cranes, loaders, and bulldozers, where they transfer power from the engine to hydraulic systems and traction components. These shafts must withstand extreme loads, vibration, and harsh environmental conditions, including dust, moisture, and temperature fluctuations, requiring robust construction and durable materials.

The metallurgical and steel industry represents another key application area for industrial cardan shafts, where they are used in rolling mills, furnaces, and conveyor systems. Rolling mills, in particular, demand cardan shafts with exceptional torque-bearing capacity and angular compensation capabilities, as they transmit power to the rolls that shape metal into sheets, bars, and other forms. The shafts in these applications must operate reliably under high temperatures and heavy loads, with minimal maintenance downtime to ensure continuous production. The paper and pulp industry also utilizes cardan shafts in machinery such as paper machines and pulp digesters, where they transfer power to rollers and agitators. In these environments, corrosion resistance is a critical consideration, leading to the use of stainless steel or corrosion-resistant coatings to protect against moisture and chemical exposure.

Other notable application sectors include agriculture, aerospace, mining, and renewable energy. In agricultural machinery, cardan shafts connect tractors to implements such as plows, harvesters, and sprayers, accommodating the varying angles and positions of the implements during operation. Aerospace applications require high-precision cardan shafts for use in helicopter rotor systems and aircraft engines, where they must meet stringent performance and safety standards, with minimal weight and maximum reliability. The mining industry relies on heavy-duty cardan shafts for equipment such as crushers, conveyors, and drilling rigs, where they operate under extreme loads and abrasive conditions. In the renewable energy sector, particularly in wind turbines, cardan shafts are used to transfer power from the rotor to the generator, accommodating the misalignment caused by wind-induced vibration and thermal expansion.

Despite their robust design and versatility, industrial cardan shafts are susceptible to a range of issues that can affect their performance and lifespan, with proper maintenance and installation critical to mitigating these risks. Misalignment is one of the most common problems, occurring when the driving and driven shafts are not perfectly aligned during installation or when shifts occur due to equipment vibration or thermal expansion. Excessive misalignment places additional stress on the universal joints and bearings, leading to premature wear, vibration, and noise, and can ultimately result in component failure. To address this, regular alignment checks using precision tools are essential, along with the use of adjustable mounts to correct misalignment as needed.

Fatigue failure is another significant concern for industrial cardan shafts, caused by repetitive stress cycles that lead to the formation and propagation of microscopic cracks in the material. This type of failure is often the result of overloading, improper design, or the use of low-quality materials. Factors such as excessive torque, vibration, and temperature fluctuations can accelerate fatigue, reducing the shaft’s lifespan. To prevent fatigue failure, it is critical to select shafts designed for the specific torque requirements of the application, ensure proper installation, and conduct regular inspections to detect cracks early. Non-destructive testing methods such as ultrasonic testing or magnetic particle inspection are commonly used to identify hidden defects before they lead to catastrophic failure.

Universal joint wear is a common issue that affects cardan shaft performance, primarily caused by insufficient lubrication, excessive load, or misalignment. The bearings within the U-joints are particularly prone to wear, as they are subjected to high levels of friction during operation. Lack of proper lubrication leads to increased friction and heat, accelerating wear and potentially causing the bearings to seize. Regular lubrication with high-quality lubricants tailored to the operating environment is essential to minimize wear and extend the life of the universal joints. Additionally, periodic inspection of the U-joints for signs of wear, such as play or noise, allows for timely replacement before further damage occurs.

Corrosion is a significant challenge for cardan shafts operating in harsh environments, such as marine, offshore, or chemical processing applications, where exposure to saltwater, acids, or other corrosive substances can weaken the material. Corrosion leads to pitting, cracking, and loss of structural integrity, reducing the shaft’s load-bearing capacity and increasing the risk of failure. To mitigate corrosion, manufacturers use corrosion-resistant materials such as stainless steel or apply protective coatings such as galvanization, powder coating, or chemical plating. Regular cleaning and maintenance to remove corrosive substances from the shaft’s surface also help extend its lifespan.

Balancing issues can also impact the performance of industrial cardan shafts, particularly in high-speed applications. Imbalanced shafts generate excessive vibration, which not only reduces efficiency but also places additional stress on associated components, leading to premature wear and failure. Balancing is typically performed during the manufacturing process using specialized equipment to ensure that the shaft rotates uniformly, with minimal vibration. However, imbalance can occur over time due to wear, damage, or the addition of attachments, requiring periodic rebalancing to maintain performance.

The industrial cardan shaft sector is continuously evolving, driven by technological advancements, changing industry requirements, and global trends toward efficiency, sustainability, and automation. One of the most prominent trends is the integration of smart technologies, such as sensor arrays and predictive maintenance systems, into cardan shaft designs. Sensors embedded within the universal joints or central shaft monitor parameters such as load distribution, vibration, temperature, and wear, providing real-time data on the component’s condition. This data is analyzed using predictive maintenance algorithms to forecast potential failures, allowing for proactive maintenance and minimizing unplanned downtime. This digital transformation is particularly valuable in industries such as manufacturing and mining, where equipment downtime can result in significant productivity losses and financial costs.

Another key trend is the shift toward lightweight and high-performance materials, driven by the need to improve energy efficiency and reduce environmental impact. Carbon fiber composites and advanced aluminum alloys are increasingly replacing traditional steel in applications where weight reduction is critical, such as automotive and aerospace. These materials not only reduce the shaft’s weight but also offer improved corrosion resistance and fatigue life, enhancing overall performance. Additionally, advancements in material processing techniques, such as additive manufacturing, are enabling the production of complex, optimized cardan shaft components that were previously difficult or impossible to manufacture using traditional methods. Additive manufacturing allows for the creation of intricate geometries that improve stress distribution and reduce weight, while also enabling rapid prototyping and customization.

The growing adoption of electric and hybrid vehicles is also shaping the development of industrial cardan shafts, with manufacturers designing specialized shafts to meet the unique requirements of these powertrains. Electric vehicles (EVs) have different torque characteristics compared to internal combustion engine vehicles, requiring cardan shafts with higher torque density and lower inertia. Additionally, the compact design of EV drivetrains demands smaller, more efficient cardan shafts that can fit within limited space. Hybrid vehicles, which combine electric motors with internal combustion engines, require shafts that can accommodate the dynamic switching between power sources, further driving innovation in design and materials.

Regulatory changes and environmental standards are also influencing the industrial cardan shaft market, with stricter emissions and energy efficiency requirements pushing manufacturers to develop more efficient components. In the automotive and industrial sectors, governments worldwide are implementing regulations to reduce carbon emissions, driving the adoption of lightweight materials and efficient power transmission systems. Cardan shafts play a role in meeting these standards by reducing energy loss during power transfer and enabling the use of more efficient drivetrains. Additionally, regulations governing workplace safety and equipment reliability are leading to the development of cardan shafts with enhanced safety features, such as fail-safe designs that prevent catastrophic failure in the event of component damage.

Global supply chain dynamics are also impacting the industrial cardan shaft sector, with manufacturers adapting to changes in raw material availability, transportation costs, and regional demand. The volatility of raw material prices, particularly for steel and aluminum, has led manufacturers to explore alternative materials and optimize production processes to reduce costs. Additionally, the shift toward regional manufacturing to minimize transportation costs and improve supply chain resilience is leading to the establishment of production facilities in key markets, such as Asia-Pacific, North America, and Europe. Asia-Pacific, in particular, is emerging as a major hub for cardan shaft production, driven by the growth of the automotive and manufacturing sectors in countries such as China, India, and Japan.

The future of industrial cardan shafts is likely to be characterized by further integration of smart technologies, advancements in materials science, and a focus on customization and sustainability. As industries continue to embrace automation and Industry 4.0, cardan shafts will become an integral part of connected systems, with real-time data integration enabling predictive maintenance, remote monitoring, and optimized performance. The development of new materials, such as advanced composites and metal matrix composites, will further enhance the strength, durability, and efficiency of cardan shafts, opening up new applications in extreme environments and high-performance systems.

Customization will also play an increasingly important role, with manufacturers offering tailored cardan shaft solutions to meet the specific requirements of individual applications. This includes custom designs for unique torque, misalignment, and space constraints, as well as specialized materials and coatings for harsh environments. Additionally, the focus on sustainability will drive the development of recyclable cardan shafts and production processes that minimize waste and energy consumption, aligning with global efforts to achieve a circular economy.

In conclusion, industrial cardan shafts are essential components in modern power transmission systems, with their ability to accommodate misalignment and transmit torque efficiently making them indispensable across a wide range of industries. From traditional steel designs used in heavy machinery to advanced composite shafts for high-performance applications, their evolution has been driven by a commitment to improving efficiency, durability, and adaptability. As technology continues to advance, cardan shafts will evolve to meet the changing needs of industries, integrating smart features, lightweight materials, and sustainable designs to remain at the forefront of power transmission innovation. Proper maintenance, installation, and material selection will continue to be critical to ensuring their reliable performance, while ongoing research and development will unlock new possibilities for their application in the future.

The role of industrial cardan shafts in supporting global industrialization and technological progress cannot be overstated. They are the unsung workhorses of manufacturing, construction, automotive, and aerospace industries, enabling the smooth operation of equipment that powers economies worldwide. As industries continue to push the boundaries of performance and efficiency, the industrial cardan shaft will remain a key enabler of innovation, adapting to new challenges and opportunities to drive progress in the mechanical engineering sector.

« Industrial Cardan Shafts » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/industrial-cardan-shafts.html