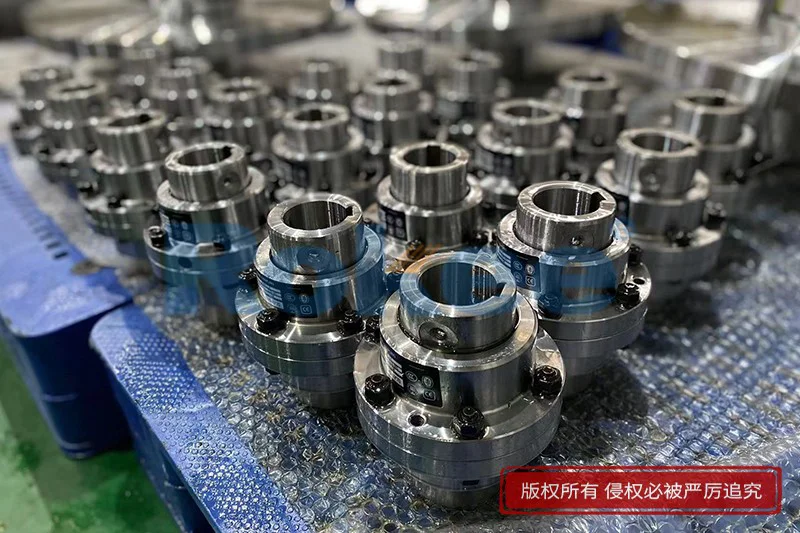

Rokee is a well-known high-quality supplier of Tooth Couplings and technical services in China, customize tooth couplings according to user drawings, alternatively, if the user provides tooth couplings parameters, we can select the model and design drawings for you, support wholesale and export.

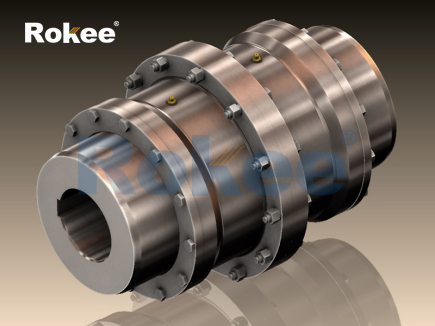

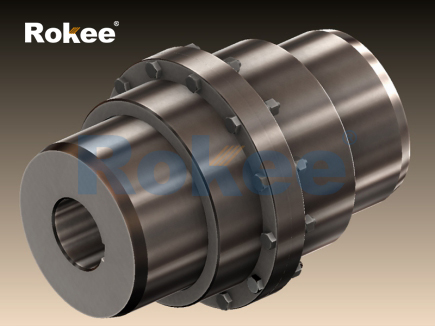

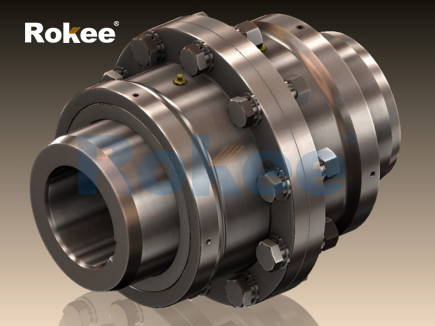

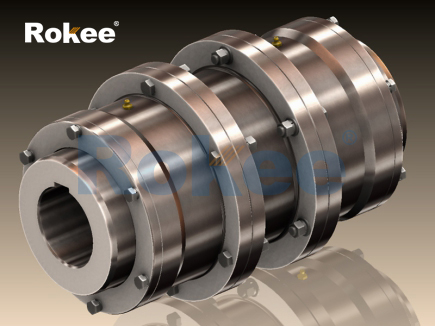

Tooth coupling is a flexible coupling widely used in industrial machinery transmission systems, which achieves power transmission through the meshing of internal and external gears, while allowing for a certain relative displacement between the two shafts. This type of coupling is also known as a tooth coupling or sleeve coupling due to its structural characteristics.

Internal gear ring: usually directly connected to the equipment shaft, with an internal gear structure

External gear sleeve: sleeve on the outside of the internal gear ring, with external gears

Sealing device: prevents lubricant leakage and contamination from entering

Lubrication system: including lubrication structures such as oil holes and oil grooves

Involute tooth profile: ensuring smooth transmission of torque

Drum shaped tooth design: improving compensation capability

Special tooth surface treatment: enhances wear resistance and service life

The tooth coupling transmits torque through the meshing of internal and external gears, and its unique design allows for the following compensation capabilities:

Angular deviation compensation: usually up to 1 ° -1.5 °

Radial deviation compensation: ranging from 0.5-6mm

Axial displacement compensation: 5-20mm range

Comprehensive displacement compensation: capable of compensating for multiple deviations simultaneously

Tooth couplings are particularly suitable for heavy-duty and high-speed working conditions, with a maximum speed of over 10000rpm and a torque transmission range from tens of Newton meters to millions of Newton meters.

High torque transmission capability: large torque transmission per unit volume

Excellent compensation performance: can simultaneously compensate for multiple deviations

Long service life: high-quality materials with good lubrication

Easy to maintain: Most designs are maintenance free or require periodic lubrication

Smooth operation: reduce vibration and noise transmission

Metallurgical industry: heavy equipment such as rolling mills and continuous casting machines

Mining machinery: crushers, ball mills, etc

Power industry: connection of steam turbine and generator

Shipbuilding industry: propulsion system shaft connection

Petrochemical industry: Compressor and pump equipment

Transmitting torque demand

speed range

Compensation requirements

Working environment conditions

Installation space restrictions

Ensure that the axis alignment is within the allowable range

Apply pre tightening force correctly

Lubrication system installed in place

Perform necessary dynamic balancing

Regularly check the lubrication condition

Monitor vibration and noise changes

Check the integrity of the seal

Tooth wear: Check lubrication and replace if necessary

Abnormal vibration: realign or check balance

High temperature: Check lubrication and load conditions

Tooth couplings occupy an important position in the field of industrial transmission due to their excellent performance and reliability. With the continuous advancement of technology, their application scope and performance level will continue to improve.

In the complex network of mechanical transmission systems, tooth couplings stand out as indispensable components that bridge rotating shafts to transfer torque while accommodating misalignments. These mechanical devices have evolved over decades to meet the rigorous demands of various industrial applications, from heavy-duty mining equipment to high-speed turbomachinery. Their ability to combine high torque-bearing capacity with structural compactness makes them a preferred choice in scenarios where reliability and efficiency are paramount. Unlike flexible couplings that rely on elastic elements, tooth couplings operate as movable rigid couplings, leveraging the meshing of internal and external teeth to achieve power transmission. This design principle endows them with unique characteristics that balance stiffness and adaptability, enabling seamless operation even under challenging operating conditions such as variable loads, temperature fluctuations, and axial or radial displacements.

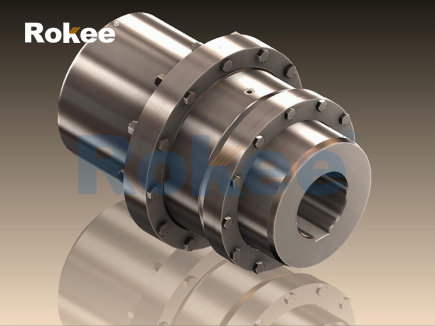

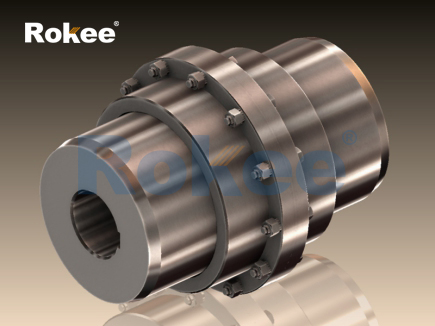

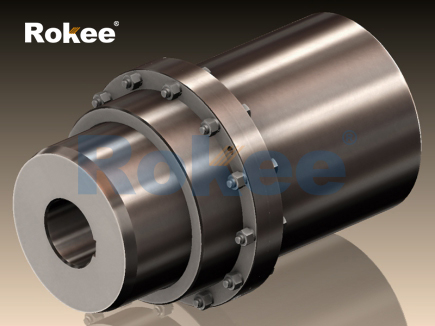

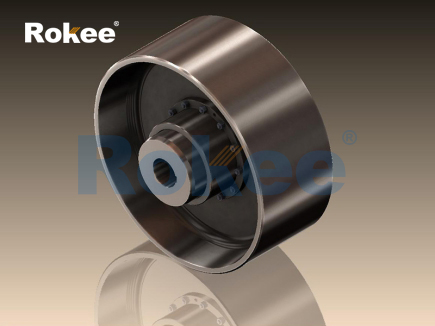

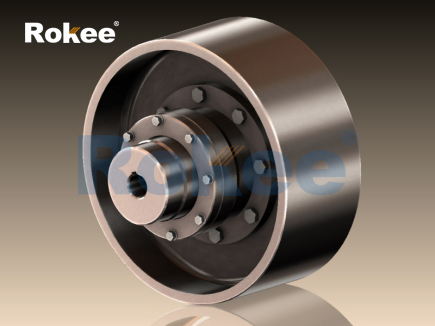

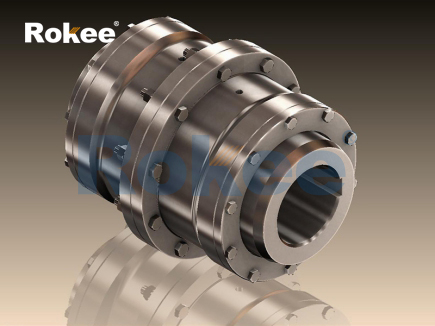

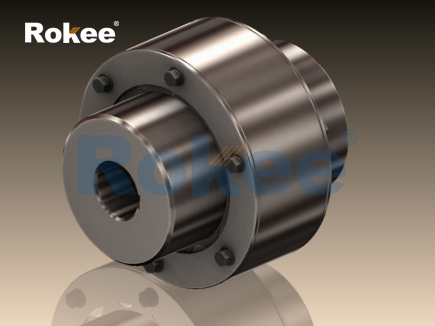

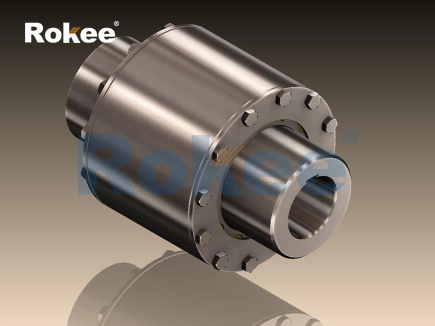

The fundamental structure of a tooth coupling comprises several key components that work in tandem to ensure efficient torque transfer and misalignment compensation. At the core of the assembly are internal gear rings and external tooth sleeves, which form the meshing pair responsible for power transmission. The internal gear ring features precision-machined internal teeth that engage with the external teeth of the sleeve, creating a positive drive connection. Depending on the application requirements, the external tooth sleeve can be designed with either straight or crowned (drum-shaped) teeth, each offering distinct performance attributes. Complementing these core components are end caps and sealing devices, which play critical roles in protecting the meshing teeth from contaminants and maintaining proper lubrication. In smaller-sized couplings, the end cap and internal gear ring may be integrated into a single unit to optimize structural compactness, reducing radial space requirements and simplifying installation in confined areas.

The operational principle of tooth couplings revolves around three primary functions: torque transmission, misalignment compensation, and lubrication management. When the driving shaft rotates, torque is transmitted to the external tooth sleeve through a key connection or interference fit. The meshing of the external teeth with the internal gear ring then transfers this torque to the driven shaft, ensuring synchronized rotation of the connected components. A defining feature of tooth couplings is their ability to compensate for relative displacements between the two shafts, including axial, radial, and angular misalignments. This compensation is achieved through the periodic axial sliding of the tooth surfaces as the shafts move relative to each other. For crowned tooth designs, the spherical tooth profile enhances this capability by distributing contact stress more evenly across the tooth width, eliminating the edge loading that plagues straight tooth couplings. Proper lubrication is essential to minimize friction and wear between the meshing teeth, as the relative sliding motion inherently generates frictional forces that can degrade performance over time. Sealing devices prevent lubricant leakage and block the ingress of dust, debris, and corrosive substances, preserving the integrity of the meshing surfaces and extending the coupling's service life.

Tooth couplings are classified primarily based on the tooth profile of the external sleeve, with straight tooth and crowned tooth designs representing the two main categories. Straight tooth couplings feature teeth with linear axial profiles, similar to standard involute cylindrical gears. Their meshing mechanism relies on increased tooth backlash to compensate for shaft misalignments, but this design limits their displacement capacity and leads to uneven load distribution, particularly under angular misalignment. As a result, straight tooth couplings are gradually being phased out in most modern applications, retained only in specialized scenarios where misalignments are minimal and cost constraints are prohibitive. Crowned tooth couplings, by contrast, have emerged as the dominant design in industrial settings due to their superior performance characteristics. The external teeth of these couplings are machined with a spherical profile, with the center of the sphere aligned with the gear axis. This curved tooth design allows for a larger contact area and more uniform stress distribution, enabling the coupling to accommodate angular displacements of up to 6 degrees (with a recommended operating range of 1.5 to 2.5 degrees) and increasing torque transmission capacity by 15% to 30% compared to straight tooth alternatives. Some specialized crowned tooth designs incorporate additional features such as telescoping sleeves or enhanced lubrication channels to address extreme operating conditions, further expanding their application scope.

Material selection is a critical aspect of tooth coupling design, as it directly influences load-bearing capacity, durability, and resistance to environmental factors. The most commonly used materials include high-strength alloy steels, which offer an optimal balance of strength, toughness, and wear resistance. One widely adopted alloy steel is a chromium-molybdenum variant that exhibits excellent hardenability, minimal quenching distortion, and no significant temper brittleness. When subjected to quenching and tempering followed by surface hardening, this material achieves a surface hardness of 50 to 55 HRC, combined with a tough core that resists impact loads. For medium-load applications where cost efficiency is a priority, high-quality carbon steel forgings are often employed. These components undergo tempering treatment to enhance mechanical properties, achieving a hardness range of 220 to 250 HB. In extreme environments involving high temperatures, corrosion, or chemical exposure, specialized alloys such as nickel-chromium-molybdenum steels are utilized. These materials can be carburized and quenched to attain surface hardness levels of 58 to 62 HRC while maintaining core toughness (30 to 35 HRC), ensuring reliable performance in harsh conditions. For corrosive environments like chemical processing plants or marine applications, stainless steel variants may be selected to prevent rust and material degradation, though this comes with a trade-off in terms of cost and weight.

The manufacturing process of tooth couplings demands strict precision to ensure optimal meshing performance and structural integrity. The production workflow typically begins with forging, which refines the grain structure of the material and enhances its mechanical properties compared to cast components. Forging is followed by heat treatment processes tailored to the selected material, such as quenching and tempering for alloy steels or carburizing for high-wear applications. These heat treatments are critical for achieving the desired hardness, toughness, and fatigue resistance. The tooth profiles are then machined using precision methods such as hobbing, shaping, or grinding. Hobbing is commonly used for initial tooth cutting, while grinding is employed for high-precision applications to achieve tight tolerances and smooth surface finishes. The spherical profile of crowned teeth requires specialized machining techniques to ensure the correct curvature and alignment with the gear axis. After machining, the components undergo rigorous inspection to verify dimensional accuracy, tooth profile integrity, and surface quality. Dynamic balancing is another essential step for couplings used in high-speed applications, as unbalanced components can generate vibrations that reduce efficiency and accelerate wear in the entire transmission system. The assembly process involves fitting the external tooth sleeves with the internal gear rings, installing end caps and seals, and applying the appropriate lubricant to ensure smooth initial operation.

Tooth couplings find widespread application across a diverse range of industries, each presenting unique operating challenges that the coupling must address. In the metallurgical industry, they are used in rolling mills, conveyor rollers, and other equipment subjected to heavy shock loads and frequent thermal expansions. The high torque capacity and misalignment compensation of crowned tooth couplings make them ideal for these applications, as they can accommodate the axial and radial displacements caused by temperature variations in the rolling process. In mining operations, tooth couplings are employed in crushers, ball mills, and conveyor systems, where they must withstand high loads, dusty environments, and intermittent operation. Enhanced sealing designs are critical in these settings to prevent dust and abrasive particles from entering the meshing teeth and causing premature wear. The hoisting and transportation industry, including bridge cranes and port machinery, relies on tooth couplings for their high reliability and ability to handle variable loads. Regular lubrication and maintenance are essential here to ensure consistent performance in safety-critical applications.

The petroleum and chemical industry presents unique challenges due to the presence of corrosive media, high temperatures, and pressure fluctuations. Tooth couplings used in compressors, pumps, and agitators in this sector are often constructed from corrosion-resistant materials and equipped with robust sealing systems to prevent lubricant contamination and component degradation. In the power generation industry, both thermal and hydroelectric power plants utilize tooth couplings in turbine-generator sets, where high rotational speeds and precision alignment are required. These couplings undergo strict dynamic balancing to ensure smooth operation at speeds exceeding several thousand revolutions per minute. The marine industry also relies on tooth couplings for ship propulsion systems, where compact design and resistance to saltwater corrosion are essential. Specialized marine-grade materials and sealing solutions are employed to extend service life in this harsh environment. Even in high-speed rail traction systems, crowned tooth couplings play a vital role in connecting traction motors to gearboxes, where they must compensate for misalignments while transmitting high torque at elevated speeds, ensuring the reliability and safety of the entire rail system.

Lubrication and maintenance are critical factors in maximizing the service life and performance of tooth couplings. The relative sliding between meshing teeth generates friction and heat, which can lead to wear, pitting, and glue together if not properly managed. Two primary lubrication methods are employed: grease lubrication and forced oil lubrication. Grease lubrication is suitable for medium-speed, medium-load applications and offers simplicity and cost-effectiveness. Lithium-based greases with appropriate viscosity grades are commonly used, as they provide good adhesion to tooth surfaces and resistance to oxidation. For high-speed, high-load, or high-temperature applications, forced thin-oil lubrication systems are preferred. These systems deliver a continuous supply of lubricating oil to the meshing teeth, reducing friction to a fraction of that experienced with grease lubrication (typically 10% or less) and dissipating heat more effectively. The choice of lubricant depends on operating parameters such as speed, load, temperature, and environmental conditions. For example, high-temperature applications require lubricants with excellent thermal stability, while corrosive environments may necessitate specialized additives to prevent rust and degradation.

Regular maintenance practices are essential to detect potential issues before they escalate into catastrophic failures. Routine inspections should include checking lubricant levels and condition, inspecting seals for leaks, and measuring tooth wear and meshing clearance. Lubricant should be replaced at specified intervals, with the frequency determined by operating conditions—more frequent replacement is necessary in harsh or high-load environments. Seal replacement is recommended at the first sign of leakage to prevent lubricant loss and contamination. Tooth wear can be measured using specialized tools to assess meshing clearance; excessive clearance indicates significant wear and may require component replacement to avoid further damage. Bolt preload should also be checked regularly, as loose bolts can lead to misalignment, vibration, and eventual coupling failure. In addition to routine maintenance, periodic alignment checks using laser alignment tools are critical to ensure that shaft misalignments remain within acceptable limits. Proper alignment minimizes edge loading and uneven wear, extending the coupling's service life and reducing stress on adjacent components such as bearings and shafts.

Despite their robust design, tooth couplings are susceptible to various failure modes, most of which are attributed to improper installation, lubrication, or operation. Lubrication failure is one of the most common causes, occurring when lubricant levels are insufficient, the wrong type of lubricant is used, or the lubricant degrades over time. This leads to increased friction between meshing teeth, resulting in wear, pitting, gluing, or even tooth breakage. Installation errors, such as excessive misalignment beyond the coupling's compensation capacity or poor shaft alignment, can cause localized contact on the tooth surfaces, generating additional bending moments and axial forces. These forces lead to uneven wear, stress concentration at the tooth roots, and ultimately, component failure. Manufacturing defects, though less common, can also contribute to premature failure. These include material inconsistencies, improper heat treatment leading to insufficient hardness or toughness, and machining errors resulting in uneven meshing clearance or incorrect tooth profiles.

Operational factors such as overloading and frequent start-stop cycles also impact coupling durability. Overloading causes contact stresses to exceed the material's design limits, leading to plastic deformation, fatigue cracks, and tooth breakage. Frequent start-stop operations subject the teeth to repeated impact loads, accelerating fatigue damage and reducing service life. High-speed operation without adequate heat dissipation can cause lubricant degradation and tooth surface gluing, particularly in couplings with inadequate lubrication systems. Environmental factors such as dust, moisture, and corrosive substances can exacerbate wear and corrosion, especially if seals are compromised. Addressing these failure modes requires a proactive approach, including proper installation, regular maintenance, and adherence to operating limits. When failures occur, root cause analysis should be conducted to identify the underlying issue—whether it be lubrication, alignment, material, or operational—and implement corrective measures to prevent recurrence.

Advancements in design and analysis techniques have significantly improved the performance and reliability of tooth couplings in recent years. Finite Element Analysis (FEA) has become a valuable tool in the design process, enabling engineers to simulate the stress distribution, contact patterns, and dynamic behavior of coupling components under various operating conditions. FEA models can accurately predict tooth root bending stresses, contact pressures, and deformation characteristics, allowing for optimized tooth profiles and structural designs. For example, FEA simulations of crowned teeth help determine the optimal curvature to minimize stress concentration and maximize misalignment compensation. Multi-field coupling analysis, which considers the interaction of mechanical, thermal, and fluid fields, provides a more comprehensive understanding of coupling behavior in complex工况 (operating conditions) such as high-speed, high-temperature environments. This analysis helps identify potential issues such as thermal expansion-induced misalignments or lubricant film breakdown, enabling the development of more robust designs.

Topology optimization and parametric design methods are also being employed to enhance coupling performance while reducing weight and material usage. These techniques allow engineers to optimize the structural layout of components, removing material from non-critical areas while maintaining strength and stiffness. The result is lighter couplings that offer improved dynamic performance and energy efficiency, particularly beneficial in high-speed applications where weight reduction translates to reduced inertial forces. Advances in material science have led to the development of new alloys and surface treatment technologies that further enhance coupling durability. For example, advanced carburizing processes can achieve higher surface hardness with improved depth uniformity, while ceramic coatings or diamond-like carbon (DLC) films can reduce friction and wear in high-performance applications. These material innovations extend service life and enable tooth couplings to operate in increasingly harsh environments.

The future of tooth coupling technology is shaped by the evolving demands of industrial applications, including the need for higher efficiency, greater reliability, and enhanced environmental sustainability. As industries continue to pursue higher operating speeds and loads, tooth couplings will need to be designed with even greater precision and durability. The integration of smart monitoring technologies, such as embedded sensors to detect vibration, temperature, and wear, is expected to become more prevalent. These sensors will enable predictive maintenance, allowing operators to identify potential issues before they cause failure and optimize maintenance schedules to minimize downtime. The development of standardized design guidelines and testing procedures will also contribute to improved product consistency and interchangeability, addressing a current challenge in the industry where variations in design and manufacturing can lead to compatibility issues.

In terms of environmental sustainability, there is a growing focus on reducing the environmental impact of manufacturing processes and extending the service life of components. This includes the use of recycled materials where feasible, the development of more energy-efficient manufacturing techniques, and the design of couplings that are easier to repair and reuse. The optimization of lubrication systems to reduce lubricant consumption and minimize leakage will also play a role in enhancing sustainability. For specialized applications such as renewable energy systems (e.g., wind turbines), tooth couplings will continue to be adapted to meet unique requirements, such as low noise operation, high reliability in variable wind conditions, and resistance to outdoor environmental factors.

In conclusion, tooth couplings represent a critical component in mechanical transmission systems, offering a unique combination of high torque capacity, structural compactness, and misalignment compensation. Their design, materials, and manufacturing processes have evolved significantly to meet the demands of diverse industrial applications, from heavy-duty mining equipment to high-speed turbomachinery. Proper lubrication, maintenance, and installation are essential to ensuring their reliable performance and extending service life, while advancements in design analysis and material science continue to push the boundaries of their capabilities. As industries evolve and demand higher efficiency and reliability, tooth couplings will remain a vital technology, adapting to new challenges through innovation and continuous improvement. Their versatility and robustness ensure that they will continue to play a central role in powering industrial operations for years to come.

The ongoing research and development in tooth coupling technology are focused on addressing current limitations and unlocking new capabilities. This includes the refinement of tooth profiles to further improve stress distribution and misalignment compensation, the development of advanced materials to withstand extreme conditions, and the integration of smart technologies for real-time monitoring and predictive maintenance. As these innovations are implemented, tooth couplings will become even more reliable, efficient, and adaptable, solidifying their position as a cornerstone of modern mechanical transmission systems. Whether in traditional industrial settings or emerging technologies, tooth couplings will continue to be essential for connecting rotating shafts and transferring power with precision and reliability.

Another area of ongoing development is the optimization of coupling designs for specific applications, such as electric vehicles and renewable energy systems. Electric vehicles require compact, high-efficiency couplings that can handle the instant torque delivery of electric motors, while wind turbines demand couplings that can withstand variable loads and harsh outdoor conditions. Customized designs tailored to these applications will continue to emerge, incorporating specialized features such as enhanced damping, improved sealing, and lightweight materials. Additionally, the push for global standardization will facilitate the interchangeability of components across different manufacturers and regions, reducing costs and simplifying maintenance for end-users.

Ultimately, the success of tooth couplings lies in their ability to balance performance, reliability, and cost-effectiveness. As technology advances and industrial needs evolve, tooth couplings will continue to be refined and adapted, ensuring that they remain a trusted solution for mechanical power transmission. Their enduring relevance is a testament to their robust design and the critical role they play in keeping industrial systems running smoothly and efficiently.

« Tooth Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/tooth-couplings.html