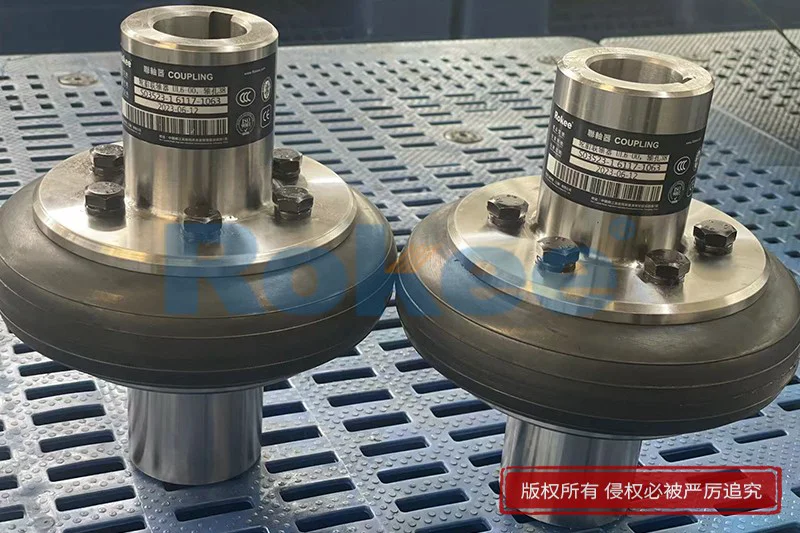

Rokee is a well-known high-quality supplier of Tyre Couplings and technical services in China, customize tyre couplings according to user drawings, alternatively, if the user provides tyre couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Tyre coupling is a high-performance coupling with elastic elements, named after its main structure resembling a tire. Since its emergence in the mid-20th century, this type of coupling has become an indispensable key component in modern mechanical transmission systems due to its unique performance advantages, and is widely used in various industrial fields.

Tire body: usually made of high-strength rubber or polyurethane material, in the shape of a circular tire, and is the main elastic element

Metal flange: a metal component connected to both sides of the tire body, used to connect with the drive shaft and the driven shaft

Tightening bolt: a high-strength bolt component that securely connects a flange to a tire body

Protective cover: a protective device equipped on some models to prevent external foreign objects from damaging the tire body

The working principle is based on the principle of elastic deformation: when there is relative displacement between the two axes, the tire body absorbs vibration and compensates for deviation through its own elastic deformation, while transmitting torque and rotational motion.

Excellent vibration damping performance: capable of effectively absorbing and isolating mechanical vibrations, reducing system noise

Large angle compensation capability: can simultaneously compensate for axial, radial, and angular deviations, with a maximum compensation angle of 5-10 degrees

No lubrication design: No need to add lubricating oil regularly, easy to maintain

High elasticity memory: able to quickly restore its original state after withstanding impact loads

Insulation performance: Rubber material has electrical insulation properties, which can prevent current conduction

Lightweight design: significantly reduced weight compared to metal couplings

Torque range: typically ranging from a few Newton meters to tens of thousands of Newton meters

Speed range: up to 10000rpm (depending on the specific model)

Working temperature: -40 ℃ to+100 ℃ (special materials can reach higher temperatures)

Elastic hardness: usually adjustable between 50-90 Shore A

Service life: up to 5-10 years under normal operating conditions

Shipbuilding industry: ship propulsion system, servo system

Power generation equipment: diesel generator set, steam turbine generator set

Metallurgical machinery: rolling mill, continuous casting machine

Mining machinery: crushers, ball mills

Petrochemical industry: Compressor and pump equipment

Rail Transit: Locomotive Transmission System

Transmitting torque: Calculate and determine the maximum torque required by the system

Speed requirement: Consider the working speed range

Deviation compensation requirement: Evaluate the possible types and quantities of deviations in the shaft system

Environmental conditions: temperature, humidity, corrosive media, etc

Space limitations: Install space size constraints

Dynamic characteristics: whether special vibration reduction requirements are needed

Ensure that the two axes are aligned within the allowable range

Tighten the bolts according to the specified torque value

Avoid using impact tools for installation

Check the gap between the coupling and adjacent components

Regularly inspect the elastomer for cracks and signs of aging

Check the tightening status of bolts

Clean the surface of the coupling, remove oil stains and foreign objects

Record the operating status and establish maintenance records

As an efficient and reliable transmission component, tyre couplings will continue to evolve with the advancement of industrial technology and demonstrate their value in more fields, providing smoother and more reliable power transmission solutions for mechanical equipment.

« Tyre Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/tyre-couplings.html