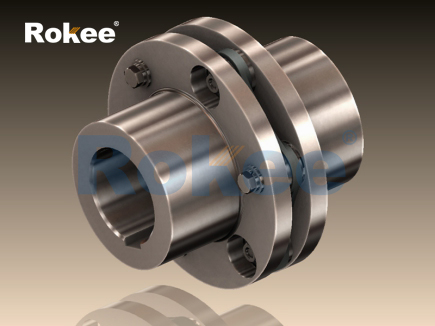

Rokee is a well-known high-quality supplier of Laminated Membrane Couplings and technical services in China, customize laminated membrane couplings according to user drawings, alternatively, if the user provides laminated membrane couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Laminated membrane coupling is a precision mechanical transmission device that connects shafts through flexible metal diaphragm components. As a widely used type of coupling in modern industry, it exhibits excellent adaptability under various harsh working conditions with its unique structural characteristics and outstanding performance. It is widely used in wind power generation, petrochemical industry, ship propulsion, compressor system and other fields, and has become one of the preferred solutions for high-precision and reliable transmission connection.

The core of a laminated membrane coupling lies in its intricate metal diaphragm assembly design, typically consisting of the following main components:

Metal diaphragm group: composed of multiple high elasticity stainless steel thin sheets stacked together, with a thickness usually between 0.2-1.0mm. It is made into a corrugated or flat shape through a special forming process, which is a key component for transmitting torque and absorbing deviation.

Wheel hub assembly: consists of two wheels installed on the drive shaft and the driven shaft respectively, usually made of high-strength alloy steel and precision machined to ensure installation accuracy.

Intermediate shaft (some models): Used to connect the diaphragm groups at both ends in long-distance transmission, the length can be adjusted as needed.

Connecting bolts: High strength fasteners that ensure reliable connections between components, typically designed with anti loosening features.

Compared to traditional types such as gear couplings and elastic couplings, laminated membrane couplings have several significant advantages:

Backless transmission: Direct contact between metals ensures zero backlash, especially suitable for situations requiring precise positioning

Maintenance free design: No lubrication required, reducing maintenance costs and downtime

High torsional stiffness: The metal diaphragm provides extremely high torsional stiffness, ensuring precise phase control

Long service life: High quality stainless steel materials can be used for more than 10 years under normal working conditions

Environmental adaptability: high temperature resistance, corrosion resistance, working temperature range can reach -50 ℃ to+300 ℃

Lightweight: Compared to gear couplings with the same torque capacity, the weight can be reduced by 30-50%

Laminated membrane couplings achieve multiple functions through the elastic deformation of metal diaphragms:

Torque transmission: The driving torque is transmitted from one hub to another hub through the shear force of the diaphragm

Deviation compensation:

Axial deviation: absorbed through the tensile/compressive deformation of the diaphragm

Radial deviation: compensated by the bending deformation of the diaphragm

Angular deviation: adapted through the conical deformation of the membrane

Vibration damping: The elastic properties of the diaphragm can effectively filter high-frequency vibrations

Electrical insulation: Diaphragm made of non-conductive materials can provide electrical isolation between shafts

It is worth noting that the compensation capability of a single membrane is limited, and a multi-layer membrane stacking design is usually used to enhance the compensation capability without significantly reducing the torsional stiffness.

According to the structure and application requirements, laminated membrane couplings can be divided into several main types:

Single membrane type:

The simplest structure and lowest cost

Limited compensation capability, mainly used in small deviation situations

Typical applications: small pumps, compressors

Double membrane type:

Two sets of membranes are connected through an intermediate shaft

Enhanced bias compensation capability

Typical applications: Medium sized wind turbines, generator sets

Multi membrane type:

Three or more membrane combinations

Maximum compensation capability, high torque density

Typical applications: ship propulsion, large compressors

Special structural type:

Equipped with safety shear device: overload protection function

Insulation type: Electrical isolation version

Airtight type: used in vacuum or high-pressure environments

The correct selection of laminated membrane couplings requires consideration of multiple key factors:

Torque parameters:

Rated torque: calculated based on driving power and speed

Peak torque: considering starting and impact loads

Safety factor: usually taken as 1.5-3.0

Deviation requirements:

Axial deviation: generally allowed 0.5-5mm

Radial deviation: usually 0.2-3mm

Angular deviation: commonly 0.5 ° -3 °

Environmental factors:

temperature range

corrosive medium

Explosion-proof requirements

Dynamic characteristics:

critical speed

Torsional vibration frequency

Unbalanced response

Installation restrictions:

spatial dimensions

Axis end distance

Dismantling requirements

Installation points:

Ensure that the axis alignment accuracy is within the allowable range of the coupling

Use specialized tools for installation and avoid knocking

Tighten the bolts step by step according to the specified torque value

Check the axial preload (if applicable)

Perform static and low-speed dynamic balance checks

Maintenance suggestion:

Regularly check the tightening status of bolts

Monitor whether the membrane has cracks or permanent deformation

Check the alignment of the shaft, especially after foundation settlement

Record vibration data and analyze trend changes

Establish a preventive maintenance plan

Energy industry:

Gas turbine generator set

Wind power gearbox connection

Main pump drive for nuclear power plant

Petrochemical industry:

Large compressor drive

Pump set transmission system

Offshore platform equipment

Shipbuilding industry:

Main propulsion system

shaft generator

Servo drive

Industrial manufacturing:

Rolling mill transmission

Papermaking machinery

precision machine tool

As an important component of modern mechanical transmission systems, membrane couplings will continue to drive industrial equipment towards higher efficiency, reliability, and intelligence through technological advancements. With the application of new materials and processes, the performance boundaries of membrane couplings will continue to expand in the future.

« Laminated Membrane Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/laminated-membrane-couplings.html