Rokee is a well-known high-quality supplier of Flexible Gear Couplings and technical services in China, customize flexible gear couplings according to user drawings, alternatively, if the user provides flexible gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

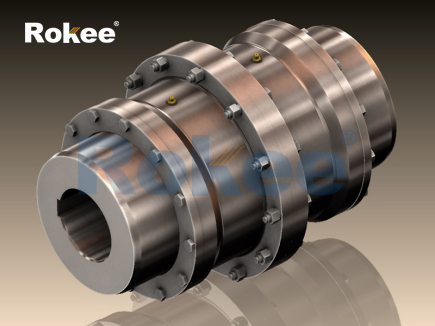

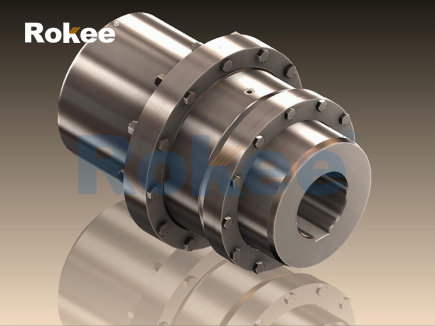

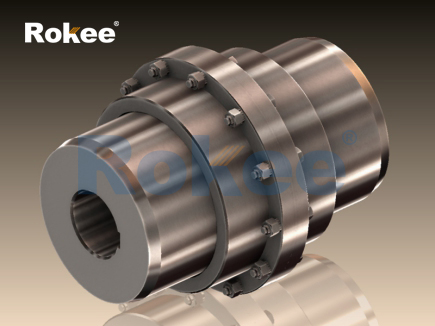

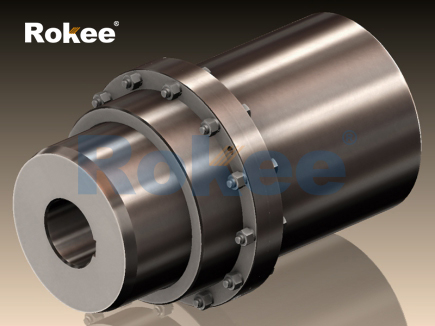

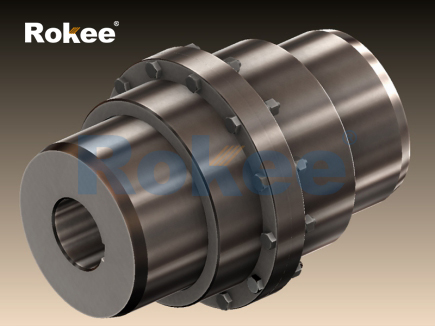

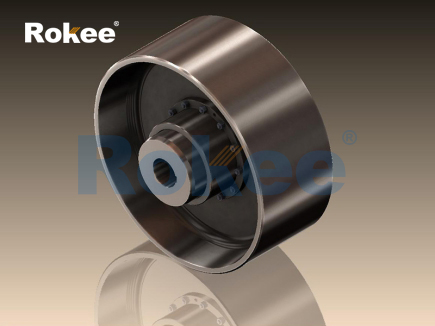

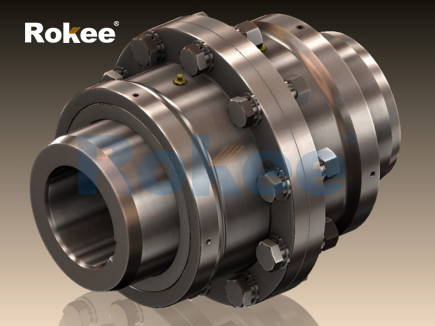

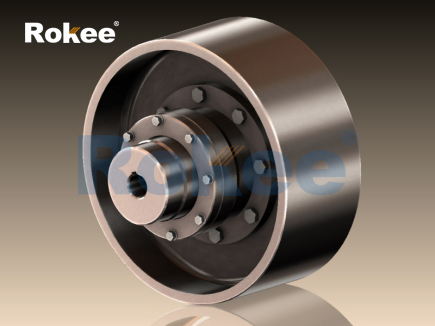

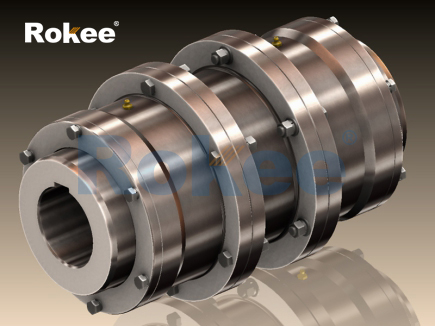

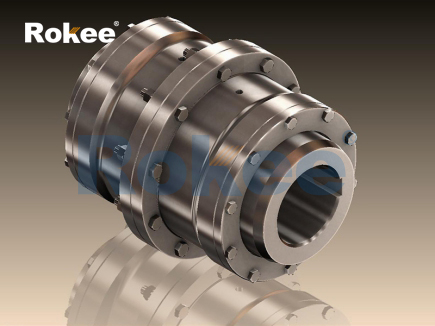

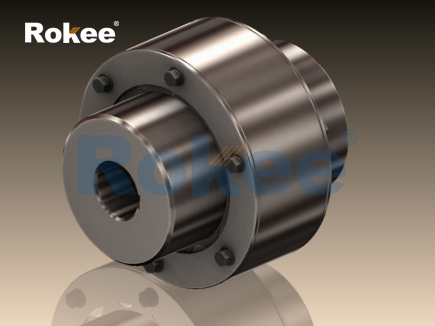

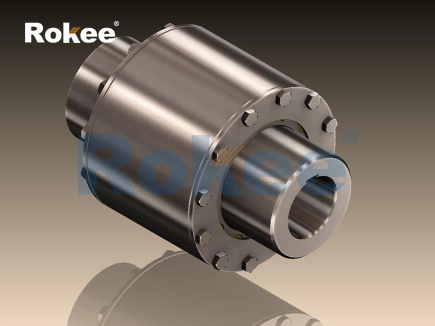

Flexible gear coupling is a high-performance coupling device that transmits torque through gear meshing. It combines the high torque characteristics of traditional gear transmission with the compensation capability of elastic couplings. This type of coupling consists of two wheel hubs with external teeth and two sleeves with internal teeth. It transmits power through the meshing of the internal and external teeth, and has certain compensation capabilities in the axial, radial, and angular directions.

Wheel hub components: usually forged alloy steel parts with precision machined outer teeth

Sleeve component: a ring-shaped component with internal teeth that meshes with the external teeth of the wheel hub

Sealing system: prevents lubricant leakage and contamination from entering

Lubrication system: including lubrication oil passage and oil storage chamber

When the drive shaft rotates, torque is transmitted to the driven shaft through the meshing of the outer teeth of the hub and the inner teeth of the sleeve. The special tooth profile design between the inner and outer teeth allows for relative displacement within a certain range, thereby compensating for axis deviation.

High torque density: The ability to transmit torque per unit size is superior to most types of couplings

Multi directional compensation capability: can simultaneously compensate for axial displacement (± 5-15mm), radial displacement (0.5-3mm), and angular deviation (0.5 ° -2 °)

Vibration damping characteristics: absorb vibration through oil film damping between tooth surfaces

Long life design: High quality materials and precision machining ensure long-term reliable operation

Compared with traditional rigid couplings, flexible toothed couplings can significantly reduce the additional load caused by centering errors; Compared with elastic couplings, it has higher torque transmission capacity and longer service life.

Heavy industry: rolling mills, mining machinery, large compressors

Energy sector: Steam turbine generator sets, wind power generation equipment

Shipbuilding industry: propulsion shaft system

Petrochemical industry: large pump sets, compressors

Paper Machinery: Large Drum Drive System

Transmission torque demand (rated torque and peak torque)

speed range

Shaft diameter size

Compensation requirements

Environmental conditions (temperature, corrosiveness, etc.)

Ensure that the shaft end clearance meets the manufacturer's requirements

Use specialized tools for installation to avoid hammering

The initial centering error should be controlled within 50% of the coupling compensation capacity

Lubricate according to specifications and ensure sufficient lubrication before the first operation

Regularly check the lubrication condition (every 3-6 months)

Monitoring temperature rise (under normal operating conditions, the temperature rise does not exceed 30 ℃ of the ambient temperature)

Regularly check the sealing condition

Abnormal vibration: usually caused by poor alignment or wear, requiring re alignment or replacement of components

Lubrication failure: manifested as overheating and abnormal noise, lubricant needs to be replaced

Tooth wear: Check the lubrication system and evaluate the remaining life of the coupling

As a key component of modern mechanical transmission systems, the development of flexible gear couplings will continue to drive industrial equipment towards higher efficiency and reliability. The correct selection, installation, and maintenance of flexible gear couplings are of great significance for ensuring the long-term stable operation of equipment.

« Flexible Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/flexible-gear-couplings.html