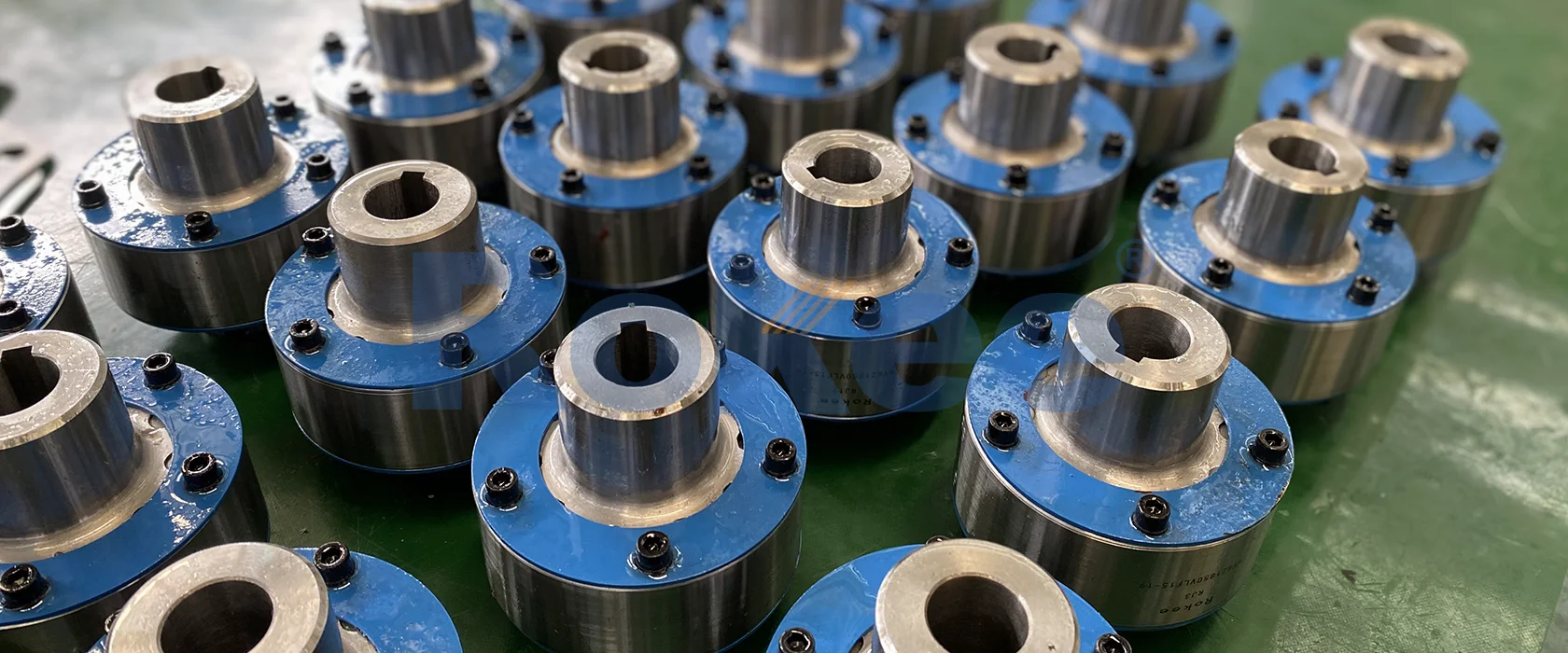

Rokee is a well-known high-quality supplier of Elastic Couplings and technical services in China, customize elastic couplings according to user drawings, alternatively, if the user provides elastic couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Elastic coupling as a core component in mechanical transmission systems, is a mechanical device that can connect two shafts and allow for a certain relative displacement while transmitting motion and power. Compared with rigid couplings, elastic couplings can not only transmit torque through their unique elastic elements, but also effectively compensate for various alignment deviations between shaft systems, buffer vibration impacts, and improve the dynamic performance of the entire transmission system.

In modern industrial applications, elastic couplings have become the preferred solution for solving complex shaft connection problems. From precision instruments to heavy machinery, from low-speed high torque to high-speed rotating equipment, elastic couplings are widely used in various industrial fields such as wind power, metallurgy, shipbuilding, petrochemicals, machine tools, pumps, etc. due to their excellent performance.

The core function of an elastic coupling is based on its unique principle of elastic deformation. When power is transmitted from the driving shaft to the driven shaft, the elastic elements in the coupling undergo controllable elastic deformation, which can effectively absorb and alleviate the impact of various adverse factors on the transmission system.

Radial compensation: allows for a certain degree of parallel offset between the two axis lines

Angular compensation: allows for a certain degree of angular deviation between two axes

Axial compensation: allows for a certain displacement of the two axes along the axis direction

In addition, elastic couplings can absorb vibration energy through the damping characteristics of elastic elements, reduce the resonance peak of the system, and protect equipment from damage caused by impact loads. This design concept of "using softness to overcome rigidity" greatly improves the smoothness and reliability of the transmission system while maintaining efficient power transmission.

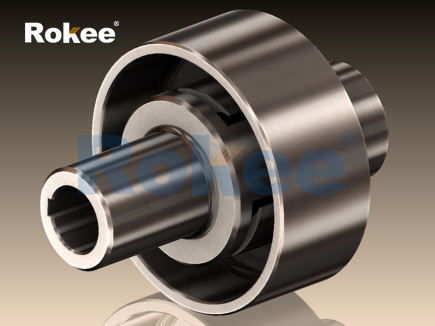

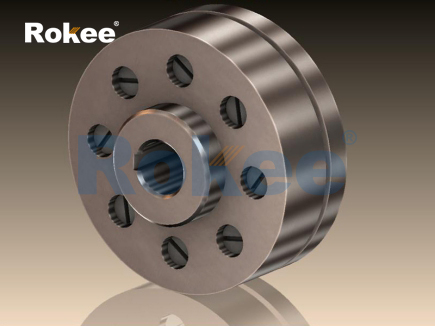

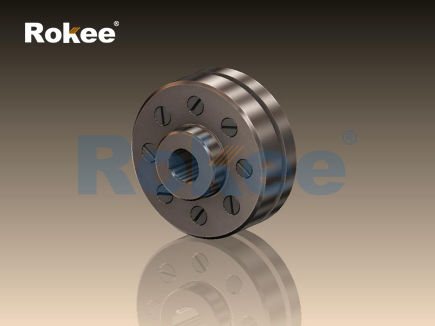

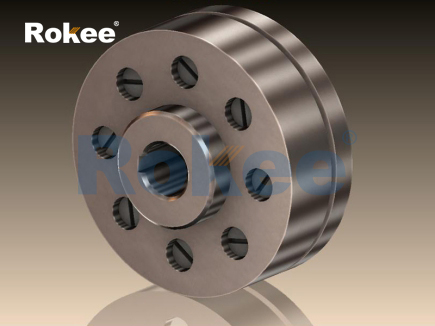

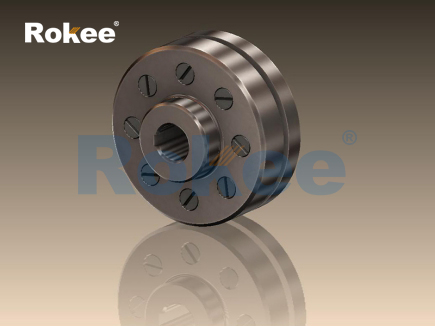

Bushed pin coupling

This is one of the most common types of elastic couplings, which uses rubber or polyurethane elastic sleeves as cushioning elements. Its structure is simple, cost-effective, and suitable for general industrial transmission applications. The hardness of the elastic sleeve can be adjusted according to the load requirements to achieve different elastic characteristics and torque transmission capabilities.

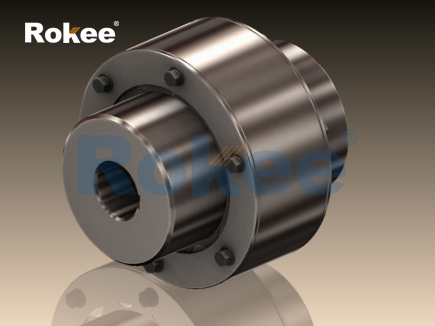

Plum coupling

Using star shaped plum blossom shaped elastomers as connectors, it has a large angular and radial compensation capability. This design makes the stress distribution of the coupling more uniform when subjected to misalignment, extending its service life. The plum blossom shaped coupling is particularly suitable for situations with significant installation errors or the possibility of foundation settlement.

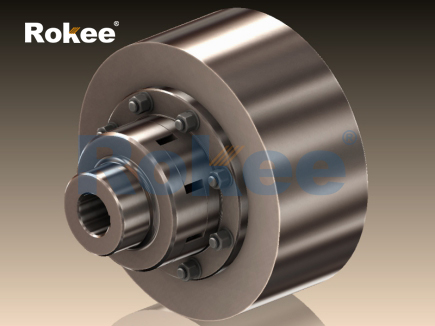

Tire coupling

Composed of rubber tire like elastic elements and two half couplings, it has excellent shock absorption and noise reduction performance. Its unique structure can absorb displacement deviations in multiple directions, and is commonly used in applications such as ship propulsion systems and large wind turbines that require high shock absorption.

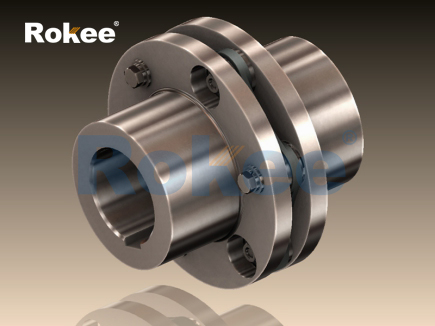

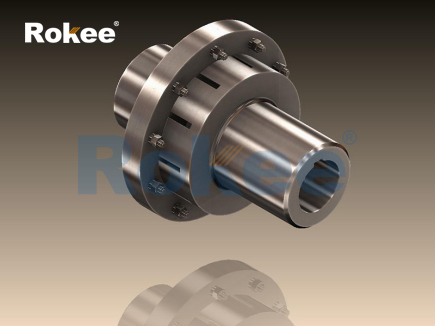

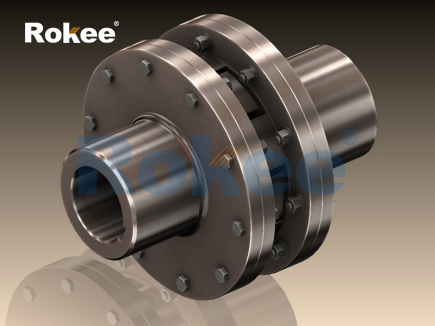

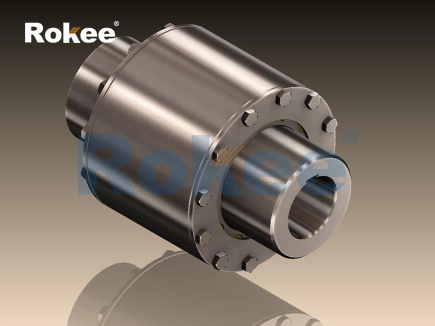

Diaphragm coupling

Using multi-layer metal film groups as elastic components, it has the characteristics of zero backlash and high stiffness. This type of coupling does not require lubrication, is easy to maintain, and is particularly suitable for high-speed transmission applications such as turbomachinery, centrifugal compressors, etc.

Serpentine spring coupling

Using a specially shaped snake shaped spring as an elastic element, it combines high elasticity and high strength. Its unique "spring pack" structure can effectively balance load distribution and is suitable for heavy-duty and impact load applications, such as steel mills, crushers, and other heavy equipment.

Rated torque: The maximum torque value that the coupling can continuously transmit is the primary basis for selection

Maximum torque: The instantaneous overload capacity that a coupling can withstand, typically 2-3 times the rated torque

Speed range: The safe operating speed range of the coupling, and special attention should be paid to high-speed applications

Compensation capability: including radial, angular, and axial displacement compensation amounts

Stiffness characteristics: torsional stiffness affects the dynamic response and resonance frequency of the system

Environmental adaptability: including special requirements such as temperature range, corrosion resistance, dust and water resistance

Service life: a durability index closely related to working conditions and load characteristics

Determine application requirements: Analyze basic information such as equipment type, power characteristics, and working environment

Calculate load parameters: accurately calculate normal operating torque, peak torque, and speed range

Evaluate alignment conditions: measure or estimate various alignment deviations that may exist in the shaft system

Consider environmental factors: assess the impact of temperature, humidity, corrosive media, and other environmental factors

Select appropriate type: Choose the most suitable coupling structure based on the above factors

Determine specific specifications: Refer to the performance curve and technical parameters provided by the manufacturer to determine the specifications

Verify installation space: Ensure that the coupling size matches the available installation space

In special application scenarios, such as high-precision CNC machine tools or aerospace equipment, more professional performance indicators such as transmission accuracy and dynamic response characteristics of couplings need to be considered.

Accurate alignment: Although elastic couplings have compensation capabilities, good initial alignment can significantly extend their service life

Avoid forced installation: It is not allowed to install the coupling by violent means such as hammering

Correct tightening: Tighten the connecting bolts according to the specified torque value, avoiding over tightening or over loosening

Protecting elastic components: preventing the elastic body from being cut or chemically corroded during installation

Regular inspection: Establish a regular inspection system to monitor the condition of the coupling

Observation of anomalies: Pay attention to abnormal phenomena such as vibration, noise, temperature, etc

Elastic replacement: timely replacement of aging and cracked elastic components

Lubrication management: Maintain appropriate lubrication status for the types of couplings that require lubrication

Record analysis: Establish maintenance records to document the operational status and replacement history of the coupling

Wind turbine generator: Large diaphragm coupling connects the gearbox and generator to compensate for deviations caused by tower deformation

Petrochemical industry: corrosion-resistant elastic couplings are used for pump and compressor transmission, adapting to harsh environments

Steel rolling mill: Heavy duty serpentine spring coupling withstands huge impact loads

Ship propulsion system: tire type coupling effectively isolates the vibration of the main engine and protects the propulsion shaft system

CNC machine tool: high-precision diaphragm coupling ensures transmission accuracy and dynamic response

Rail transit: Elastic couplings are used to connect traction motors and gearboxes, improving operational stability

As an indispensable key component in modern mechanical transmission, the technological progress of elastic couplings directly affects the performance and reliability of the entire mechanical system. With the continuous emergence of new materials and processes, elastic couplings will play a more important role in a wider range of fields.

« Elastic Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/elastic-couplings.html