Rokee is a well-known high-quality supplier of Jaw Couplings and technical services in China, customize jaw couplings according to user drawings, alternatively, if the user provides jaw couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Jaw coupling is a rigid coupling widely used in mechanical transmission systems, which occupies an important position in industrial production due to its simple structure, high torque transmission, and easy installation.

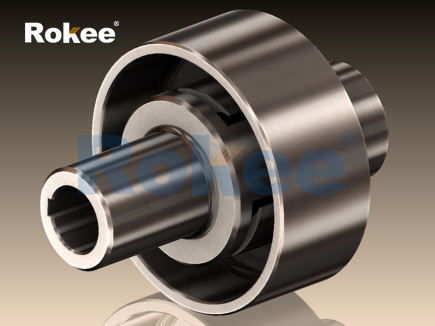

The basic structure of a jaw coupling consists of two half couplings with claws and an elastic element in the middle:

Claw shaped flange: usually arranged in a star or claw shape, with a quantity of generally 3-8

Elastic element: made of materials such as polyurethane, rubber, or nylon

Connectors: including fastening devices such as bolts, nuts, etc

The working principle is that the claws of two half couplings interlock with each other, and an elastic element is clamped in the middle, which can absorb certain vibrations and impacts while transmitting torque.

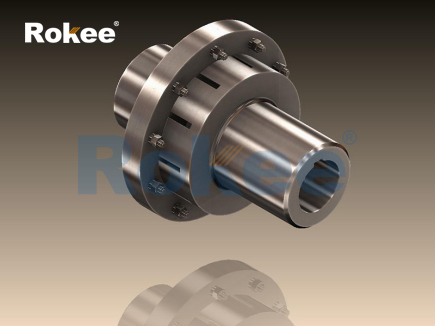

Standard jaw coupling

The most common type, suitable for general industrial applications, with moderate torque transmission capacity.

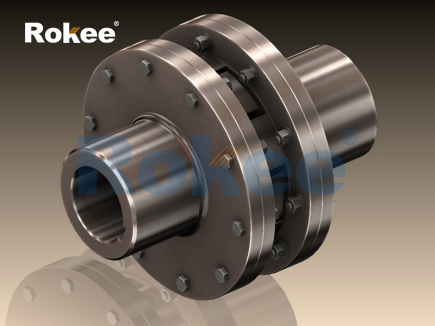

Heavy duty jaw coupling

Adopting high-strength materials and thickened design, suitable for high torque applications such as mining machinery and heavy equipment.

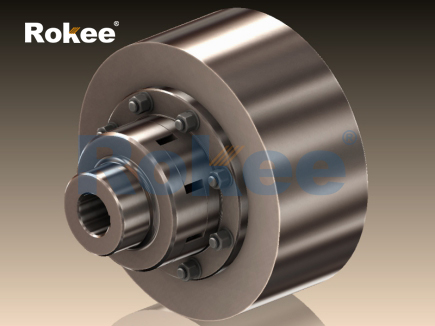

Micro jaw coupling

Specially designed for precision instruments and small equipment, with small size but high precision.

Corrosion resistant jaw coupling

Made of stainless steel or special coating, suitable for corrosive environments such as chemical and marine environments.

High torque transmission capability: Modern jaw couplings can transmit torque ranging from a few Newton meters to tens of thousands of Newton meters

Good buffering performance: can absorb about 5-15% of vibration and impact

No lubrication required: easy maintenance, low operating costs

Axial compensation capability: allows for a certain axial displacement (usually 0.5-3mm)

Easy installation: The requirements for alignment are relatively low, and the installation tolerance is large

Long lifespan: High quality products can have a service life of 5-10 years

When choosing a jaw coupling, the following factors should be considered:

Transmitting torque magnitude

speed range

Shaft diameter size

Working environment (temperature, humidity, corrosiveness, etc.)

Compensation capability required

Installation space restrictions

Installation steps:

Check the fit dimensions of the shaft and coupling

Clean the mating surface

Installation of alignment (it is recommended to use a laser alignment device)

Tighten the bolts to the specified torque

Maintenance points:

Regularly check the wear of elastic components

Observe for any abnormal vibrations or noise

Check if the fasteners are loose

The inspection cycle should be shortened in harsh environments

Industrial manufacturing: machine tools, pumps, fans, etc

Energy sector: generator sets, wind turbines

Transportation: Ship propulsion systems, railway vehicles

Mining machinery: crushers, conveying equipment

Agricultural machinery: tractors, harvesters

Food processing: packaging machinery, conveyor belts

« Jaw Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/jaw-couplings.html