-

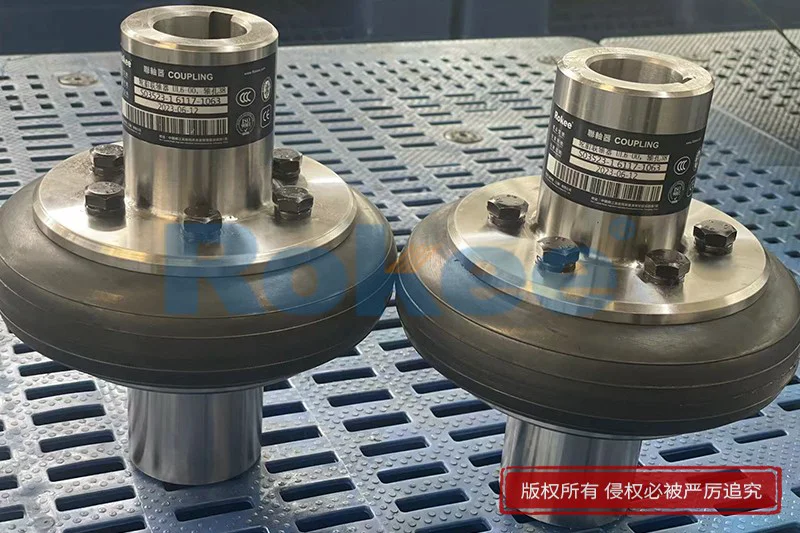

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.View More -

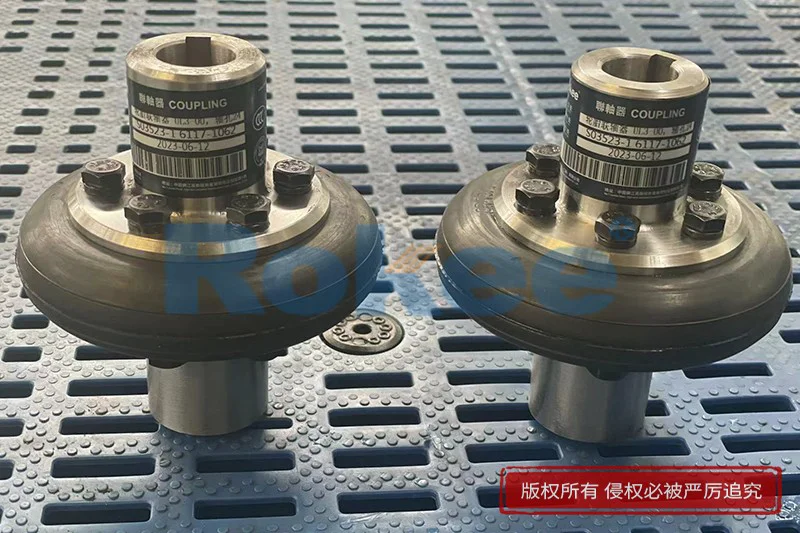

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body.View More -

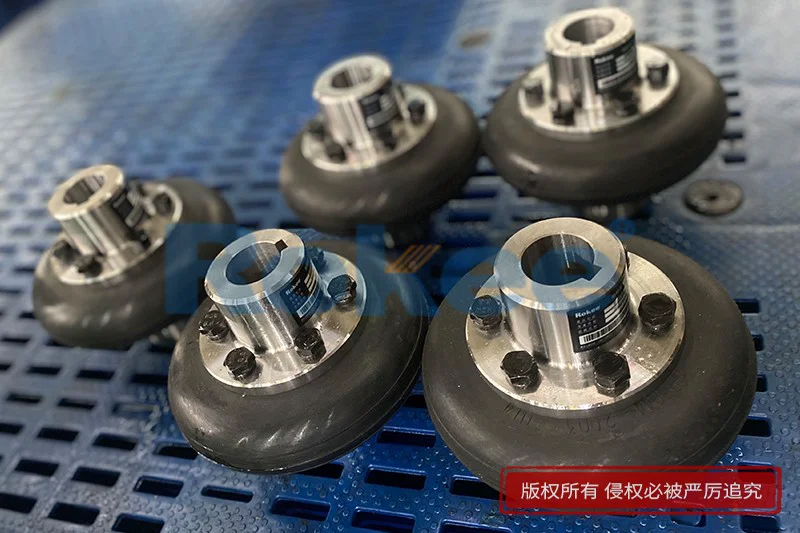

LLB Tyre Coupling

The LLB Tyre Coupling is formed by fixing two halves of the coupling and the tire body together through bolts. The shaft hole type can be Y type, J1 type, and Z1 type. It has good shock absorption and excellent inter axle offset compensation performance.View More

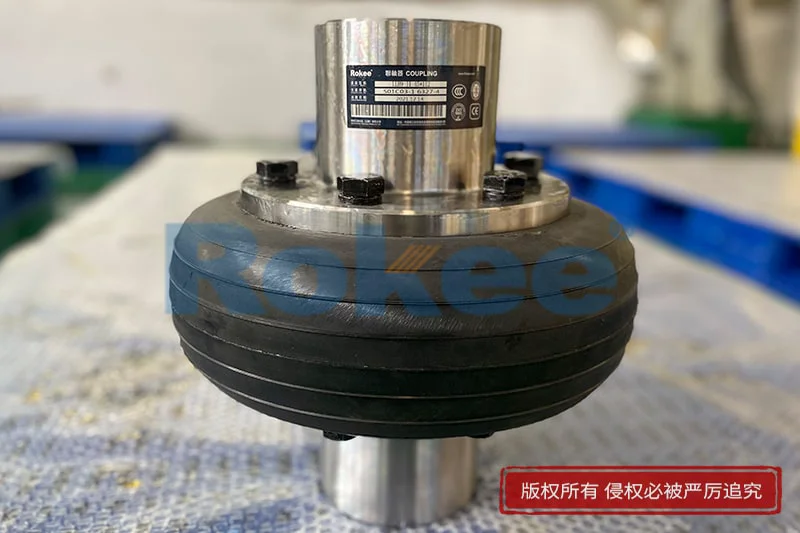

Tire coupling is an elastic coupling known for its unique rubber or polyurethane elastomer components, playing an important role in mechanical transmission systems. The core design of this coupling is to clamp a ring-shaped rubber element between two metal flanges, resembling a tire, hence the name.

During the power transmission process, the driving shaft transmits torque to the elastic tire element through one side flange, and then outputs it to the driven shaft through the other side flange. This design cleverly utilizes the deformation ability of elastic materials to compensate for various deviations between shaft systems, including radial displacement, angular deviation, and axial displacement. Elastic components deform when subjected to force, absorbing impact and vibration while maintaining transmission continuity through their restoring force.

After years of development, modern tyre couplings have formed various structural variants, but the basic constituent elements remain consistent:

- Metal flange components: usually made of cast iron or steel, precision machined to ensure installation accuracy, surface treatment may include galvanizing or spraying to prevent corrosion.

- Elastic components: Made from special rubber blends such as NBR, CR, or polyurethane, combined with a metal skeleton through a special vulcanization process, they have excellent fatigue resistance. Elastic bodies are often designed with reinforced cord layers to increase torsional stiffness.

- Connecting bolt group: High strength bolts combined with anti loosening devices ensure that they will not loosen under dynamic loads.

According to structural differences, elastic tyre couplings are mainly divided into:

- Standard type: single tire structure, suitable for general working conditions

- Double tire type: Two elastic elements are arranged back-to-back, doubling the torque capacity

- With intermediate section: adding intermediate shaft section to compensate for greater axial displacement

- Quick release: Designed with a special interface for quick replacement of elastomers

The high-performance composite rubber tyre coupling that has emerged in recent years combines the advantages of traditional tire couplings and grid couplings, using a combination of multiple layers of elastic bodies with different hardness to achieve more accurate vibration control.

Flexible tire couplings demonstrate outstanding performance in various aspects in the field of mechanical transmission:

- Excellent shock absorption capability: The high damping characteristics of rubber components can absorb up to 30% of vibration energy, significantly reducing the risk of resonance in the transmission system. Experimental data shows that compared to rigid couplings, tire couplings can reduce the vibration amplitude of the system by 40-60%.

- Comprehensive compensation capability: A single compact unit can simultaneously compensate for:

Radial deviation: usually up to 0.5-3mm

Angular deviation: generally allowed 1-3 °

Axial displacement: 2-8mm is allowed depending on the model - Overload protection function: When the torque exceeds the design value, the elastic body will slip first instead of causing equipment damage, providing mechanical safety for the system. Some advanced models are also designed with visual overload indicators.

- Electrical insulation characteristics: The natural insulation properties of rubber materials can block shaft current, prevent bearing electrical corrosion, and are particularly suitable for variable frequency motor drive systems.

- Easy maintenance: The replacement of elastomers usually only requires loosening the bolts, without the need to move the equipment body, greatly reducing downtime. Modern design adopts a modular concept to make spare parts management more efficient.

The correct selection of flexible tyre couplings requires consideration of multidimensional technical parameters:

- Torque characteristics:

Rated torque Tn: maximum torque allowed for continuous operation

Maximum torque Tmax: short-term peak allowable value (usually 2-3 times Tn)

Starting torque: instantaneous load during motor starting needs to be considered - Stiffness parameter:

Torsional stiffness: affecting the response characteristics of the system

Radial stiffness: determines the ability to compensate for deviations

Axial stiffness: affecting axial displacement absorption performance - Environmental adaptability:

Temperature range: ordinary rubber -20 ℃~+80 ℃, special formula can reach -40 ℃~+120 ℃

Medium resistance: Select corresponding materials for environments such as oil stains and chemicals

IP protection level: dustproof and waterproof performance should be considered for outdoor or humid environments

Beyond the traditional industrial transmission field, tyre shaft couplings are demonstrating their value in more emerging scenarios:

- In the field of new energy:

Wind turbine generator set: used for connecting the gearbox and generator to solve the deviation problem caused by tower swing

Electric vehicle drive system: providing vibration isolation between the motor and the reducer - Intelligent manufacturing:

Industrial robot joint transmission: Precision tire coupling achieves small deviation compensation

CNC machine tool feed system: reducing high-frequency vibration transmitted by servo motors - Special equipment:

Ship propulsion system: seawater corrosion resistant design

Mining Machinery: Super Strong Impact Resistant Version

Oil drilling and production equipment: explosion-proof structure - Infrastructure:

Large scale water pump unit: solving the alignment problem caused by foundation settlement

Air conditioning refrigeration unit: reducing noise transmission

Correct installation is the key to ensuring the performance of elastic tire couplings:

- Summary of installation steps:

Clean the shaft neck and coupling inner hole, check the fit size

Use hot installation method (heating temperature usually does not exceed 120 ℃) or hydraulic tools for installation, and hammering is strictly prohibited

Use a laser alignment instrument to ensure that the deviation is within the allowable range (generally required to be ≤ 0.05mm)

Tighten the bolts step by step in diagonal order, and strictly follow the torque values specified in the manual

Recheck the bolt tightening status after 24 hours of initial operation - Maintenance strategy:

Daily inspection: visually inspect the aging and cracking of rubber parts

Regular maintenance: Check bolt torque and alignment status every 3-6 months

Status monitoring: using vibration analysis technology to evaluate the health status of the coupling - Common troubleshooting:

Abnormal vibration: First, check the alignment condition, and then evaluate the change in elastic hardness

Rubber cracking: may be caused by ozone aging or overload, environmental conditions and load conditions need to be checked

Loose bolts: Anti loosening agents should be used and re tightened according to specifications

As a classic solution in the field of mechanical transmission, elastic tyre couplings continue to play an irreplaceable role in various industrial scenarios due to their unique elastic advantages. With the advancement of materials science and manufacturing technology, modern elastic rubber tire couplings have developed into high-tech products that not only meet basic transmission needs, but also provide value-added vibration control and protection functions for the entire transmission system. Proper selection, installation, and maintenance of flexible tire couplings can significantly improve equipment reliability, extend service life, and reduce overall operating costs. In the future, the introduction of intelligent and adaptive technologies will bring new vitality to this traditional product and continue to create value for the industrial transmission field.

Cases of Tyre Couplings

-

UL6 Rubber Tyre Coupling

UL6 Rubber Tyre Coupling -

UL3 Rubber Tire Coupling

UL3 Rubber Tire Coupling -

UL Tire Flexible Coupling

UL Tire Flexible Coupling -

LLB Elastic Tire Coupling

LLB Elastic Tire Coupling -

LLB7 Flexible Tire Coupling

LLB7 Flexible Tire Coupling -

LLB9 Tyre Type Coupling

LLB9 Tyre Type Coupling

Related Articles

- 2024-09-04Specifications of Tyre Type Coupling

- 2024-08-28Tire Shaft Coupling Calculation

- 2024-08-07Tire Shaft Coupling Design

- 2024-08-07Torque of Tyre Type Coupling

- 2024-07-09High Quality Tyre Type Couplings

- 2024-07-09Tire Shaft Coupling Models

- 2024-06-18Tire Shaft Coupling Price

- 2024-06-17Tyre Type Couplings Supply

- 2024-06-17Tire Shaft Coupling Standard Sizes

- 2024-06-11Tire Shaft Coupling Brands

- 2024-06-11Uses of Tyre Type Coupling

- 2024-06-08Tyre Type Couplings Wholesale

- 2024-06-08Tire Shaft Coupling Assembly Drawing

- 2024-06-07Tire Shaft Coupling On Sales

- 2024-06-07Tyre Type Couplings Company

- 2024-06-06High Quality Tire Shaft Couplings

- 2024-06-06Installation of Tire Shaft Coupling

- 2024-06-06High Performance Tire Shaft Couplings

- 2024-06-06Grease of Tire Shaft Coupling

- 2024-06-06Gap Chart of Tire Shaft Couplings