-

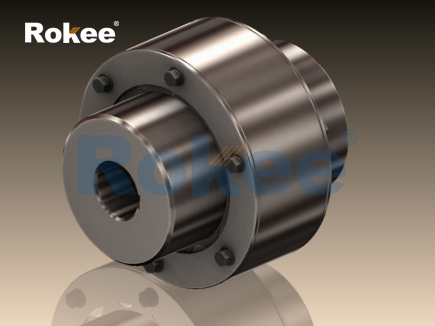

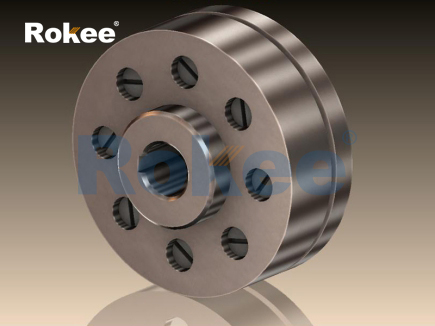

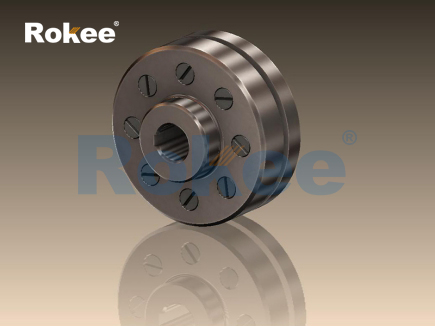

LZ/ZL Flexible Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

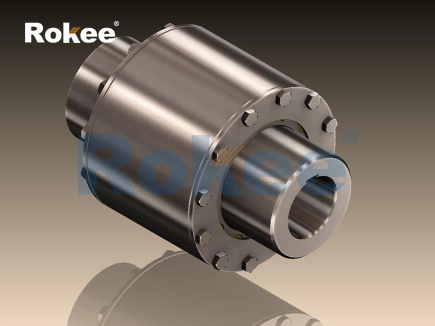

LZD/ZLD Flexible Pin Gear Coupling

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

LZZ/ZLL Flexible Pin Gear Coupling

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

LXZ/HLL Flexible Pin Coupling

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

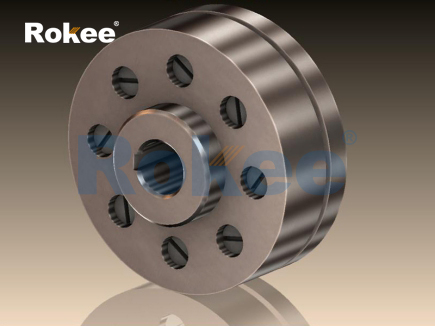

LT/TL Pin Bush Couping

LT Pin Bush Couping is the basic form of this series of couplings.View More -

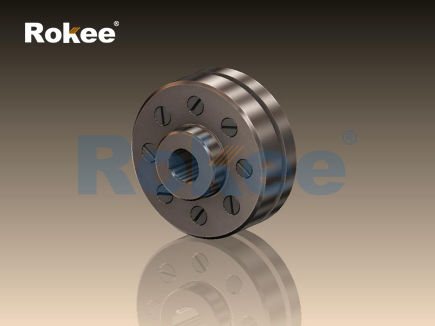

LTZ/TLL Pin Bush Couping

LTZ/TLL Pin Bush Couping is designed with a brake wheel, suitable for situations where braking is required.View More

Elastic pin coupling is a flexible coupling device widely used in mechanical transmission systems. It connects two shafts through specially designed elastic elements (pins) and compensates for various deviations between the shafts. Flexible pin coupling can effectively absorb vibrations, alleviate impacts, and allow for a certain degree of axial, radial, and angular displacement while transmitting torque.

Compared with traditional rigid couplings, elastic pin couplings have obvious advantages: they can not only transmit power, but also reduce system vibration and noise, extend equipment service life, and are particularly suitable for transmission systems with misalignment.

Structure and working principle of flexible pin coupling

- Basic structural composition

A typical elastic pin coupling consists of the following key components:

Half couplings (usually two): installed on the drive shaft and driven shaft respectively

Elastic pin: the core elastic element that connects two half couplings

Baffle or pressure plate: fix the position of the column pin

Nuts and washers: used for fastening - Unique Design of Elastic Column Pin

Elastic column pins, as core components, are usually made of high-strength engineering plastics (such as polyurethane) or rubber materials, with special geometric design:

The column part may be designed with grooves or ripples to enhance elasticity

The end usually has flanges or flanges for fixing

Material selection considers wear resistance, fatigue resistance, and temperature adaptability - Detailed explanation of working principle

When power is transmitted from the drive shaft:

The torque is transmitted to the elastic column pin through the first half coupling

Elastic pins absorb some impact and vibration through deformation

The deformed column pin transmits power to the second half coupling

Throughout the entire process, elastic deformation allows for a certain relative displacement between the two axes

Common classification methods

- Classified by elastic element material:

Rubber column pin coupling: with good damping characteristics

Polyurethane column pin coupling: Strong wear resistance and high load-bearing capacity

Nylon column pin coupling: suitable for light load and high-speed applications - Classified by structural form:

Standard type elastic pin coupling

Elastic column pin coupling with brake wheel

Flange type elastic pin coupling

Intermediate shaft type elastic pin coupling

Industrial applications

- Pump equipment:

Centrifugal pumps, plunger pumps, etc

Solving the problem of aligning the pump shaft and motor shaft - Fan system:

Centrifugal fan, axial flow fan

Absorb the vibration caused by the impeller - Construction Machinery:

Crane and excavator transmission system

Adapt to shaft deviation under harsh working conditions

The elastic sleeve pin coupling as an efficient power transmission device, has shown significant technological progress in the field of mechanical transmission in recent years. Pin bush coupling mainly consists of two half couplings and a set of column pins with elastic sleeves. The connection and compensation between the two shafts are achieved through the deformation of the elastic elements.

Modern bush pin couplings use composite polymer materials to manufacture elastic sleeves. Compared with traditional rubber materials, the new polyurethane elastomer has higher fatigue resistance and longer service life. The latest design adopts an asymmetric elastic sleeve structure, which can automatically adjust the stiffness characteristics at different speeds to achieve the best power transmission efficiency.

Core technological innovations include:

- Intelligent damping system: Built in sensors can monitor torque changes in real time

- Modular column pin design: easy to quickly replace damaged parts

- Self lubricating structure: reduces maintenance requirements and extends service life

The elastic pin and bush coupling exhibits multiple outstanding performances:

- Excellent vibration damping performance: can absorb up to 85% of vibration energy, protecting the transmission system

- Significant angle compensation capability: allowing axis deviation of 0.5 ° -3 °

- Wide temperature adaptability: The working temperature range is extended to -40 ℃ to 120 ℃

- High torque density: Increased torque transmission per unit volume by over 30%

Compared to gear couplings or diaphragm couplings, pin bushed couplings have significant advantages such as easy installation, low maintenance costs, and no need for lubrication.

Scientific selection is the key to ensuring the performance of couplings:

- Torque calculation: Consider peak torque and working torque, increase safety factor by 15-20%

- Speed matching: shall not exceed 80% of the rated speed of the coupling

- Environmental factors: Evaluate the effects of temperature, humidity, and chemical media

- Size limitation: Consider installation space and shaft end distance

In terms of maintenance, it is recommended to adopt a predictive maintenance strategy:

- Check the wear of the elastic sleeve every 6 months

- Use an infrared thermometer to monitor the working temperature

- Establish a vibration database for trend analysis

- Using a state monitoring system to achieve real-time diagnosis

Cases of Pin & Bush Couplings

-

TL Column Pin Flexible Coupling

TL Column Pin Flexible Coupling -

LX Pin Flexible Coupling

LX Pin Flexible Coupling -

ZL Flexible Pin Tooth Coupling

ZL Flexible Pin Tooth Coupling -

LT15 Elastic Sleeve Pin Coupling

LT15 Elastic Sleeve Pin Coupling -

TL Pin Coupling Hub

TL Pin Coupling Hub -

TL Pin Bush Flexible Coupling

TL Pin Bush Flexible Coupling

Related Articles

- 2025-12-01Telescoping Driveshaft For Rotavator

- 2025-12-01Bush Type Coupling Models

- 2025-12-01Efficiency of Bush Pin Type Couplings

- 2025-12-01Grease of Bushed Pin Type Coupling

- 2025-12-01Tagging of Bushed Pin Flexible Coupling

- 2025-12-01Lubrication of Pin Type Flexible Coupling

- 2025-12-01Catalogue of Pin Type Couplings

- 2025-12-01Custom Bush Pin Type Flexible Coupling

- 2025-12-01Pin Bush Type Couplings Supply

- 2025-12-01Components of Pin And Bushing Coupling

- 2025-12-01High Quality Pin And Bush Type Couplings

- 2025-12-01Bushed Couplings Picture

- 2025-09-05Bush Pin Type Flexible Couplings Drawing

- 2025-09-05Procurement of Pin Type Couplings

- 2025-09-05Parts of Pin Type Flexible Coupling

- 2025-09-05Working Principle of Bushed Pin Flexible Couplings

- 2025-09-05Torque of Bushed Pin Type Coupling

- 2025-09-05Exploded View of Bush Pin Type Couplings

- 2025-09-05Bushed Pin Type Flexible Coupling Assembly Drawing

- 2025-09-05Bush Type Coupling Standard Sizes