Rokee is a well-known high-quality supplier of Brake Drum Gear Couplings and technical services in China, customize brake drum gear couplings according to user drawings, alternatively, if the user provides brake drum gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

The brake drum gear coupling is an advanced mechanical transmission device that integrates braking function. It combines traditional drum gear couplings with braking systems and demonstrates unique advantages in the field of transmission. This type of coupling not only has excellent torque transmission capability and angle compensation performance, but also can achieve rapid braking when needed, and is widely used in various heavy machinery and precision equipment that require precise braking. In modern industrial transmission systems, brake drum gear couplings have become the preferred transmission components in fields such as metallurgical equipment, mining machinery, lifting equipment, and ship propulsion systems. Its outstanding performance meets the strict requirements of high torque transmission, reliable braking, and long lifespan in these application scenarios.

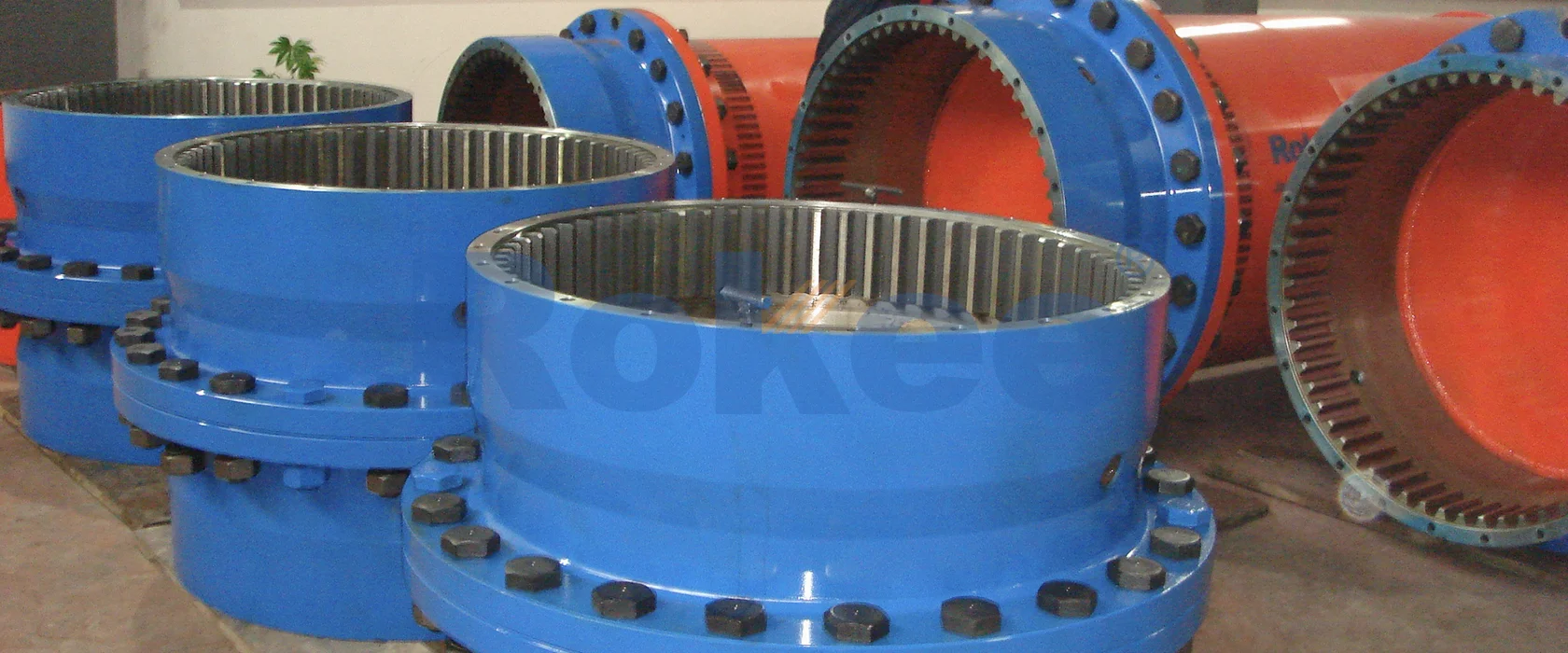

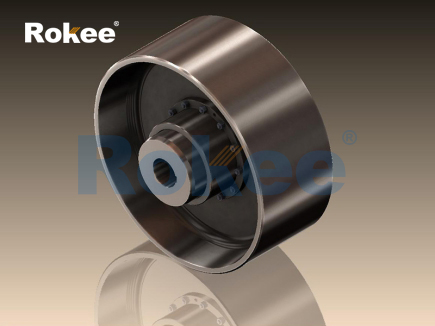

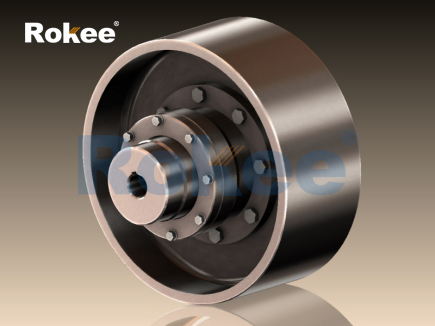

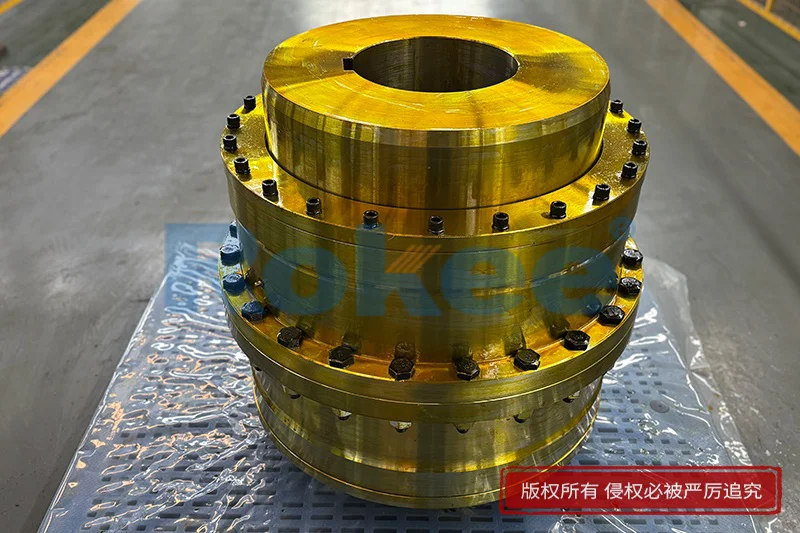

Drum gear coupling body: including inner gear ring and outer gear sleeve, adopting a special drum shaped gear design, and the gear surface is precision machined and hardened

Brake drum component: usually made of cast iron or steel cylinder, designed as an integral part of the coupling, with a special surface treatment to improve the friction coefficient

Braking mechanism: including brake shoes, brake pads, brake springs, and brake cylinders/hydraulic cylinders and other components

Sealing system: It is crucial to prevent lubricant leakage and external contaminants from entering, especially under harsh working conditions

In the transmission state, the torque of the electric motor or engine is transmitted to the driven shaft through the meshing of the coupling teeth. The special design of drum shaped teeth allows for a certain range of axial, radial, and angular offsets, effectively compensating for installation errors and displacement during operation.

When braking is required, the control system triggers the action of the braking mechanism, and the brake shoe presses against the inner surface of the brake drum under the action of the cylinder or spring, achieving rapid braking through friction torque. Advanced brake drum gear couplings are usually equipped with automatic brake clearance adjustment devices to ensure the stability of braking performance.

Transmission performance characteristics

High torque transmission capacity: Optimized tooth design and material selection increase torque transmission capacity by 30-50% compared to ordinary couplings

Excellent compensation capability: The drum tooth design allows for angular deviation of ± 1 °~± 1.5 ° and radial deviation of 0.5-3mm (depending on specifications)

Smooth transmission: The involute profile ensures smooth transmission, reduces vibration and noise

Braking performance advantages

Quick response: The braking action time can be controlled within 0.1-0.3 seconds to meet emergency braking needs

High braking torque: The combination of special friction materials can achieve a braking torque of 150-200% of the rated torque

Wear resistant and durable: The brake pads are made of composite materials, with a service life of millions of braking cycles

Comprehensive technological advantages

Compact integrated design: saves installation space, simplifies system structure

Maintenance free or low maintenance: Most adopt a lifetime lubrication design, with automatic compensation for brake component wear

High reliability: Dual protection design, even if the braking system fails, the coupling can still maintain its transmission function

Load characteristics: Consider peak torque, continuous working torque, and possible impact loads

Speed range: Ensure that the coupling does not resonate at the highest speed

Installation conditions: Evaluate shaft alignment and allowable deviation range

Braking requirements: Determine the necessary braking torque and response speed according to safety standards

Environmental factors: Consider the impact of temperature, humidity, dust, etc. on braking performance

Maintenance conditions: Select the appropriate coupling type for the maintenance cycle

Heavy industry sector

In the metallurgical industry, brake drum shaped gear couplings are widely used in equipment such as rolling mills and straightening machines. Their excellent braking performance ensures rapid shutdown in emergency situations and protects valuable equipment. After adopting this type of coupling in a large hot rolling plant, the equipment failure rate decreased by 40% and the maintenance interval was extended by three times.

Lifting and transportation machinery

Port cranes, bridge cranes and other equipment have extremely high requirements for braking performance. The application of brake drum shaped gear coupling in lifting mechanism solves the problems of brake vibration and rapid wear of brake lining in traditional braking systems. Actual application data shows that the braking stability has been improved by 60%, and the lining life has been extended by 2-3 times.

Ship propulsion system

The ship propulsion system requires the transmission device to have good compensation capability and reliable braking function. The gear coupling with integrated brake drum performs well in marine applications, especially maintaining stable performance in harsh sea conditions. After adopting a certain type of ocean going cargo ship, the shaft vibration was reduced by 35% and the emergency braking distance was shortened by 28%.

Other special applications

Mining machinery: elevators, crushers, etc

Wind power equipment: yaw braking system

Special vehicles: Heavy engineering machinery transmission system

Installation specifications

Alignment adjustment: use the laser alignment instrument to ensure that the shaft alignment is within the allowable range. Even if the drum gear coupling has the compensation ability, good alignment can still extend the service life

Bolt tightening: Cross tighten in steps according to the torque values provided by the manufacturer, using a torque wrench to ensure accuracy

Lubrication inspection: Confirm that the type and amount of lubricant added meet the requirements

Brake system debugging: adjust brake clearance, test brake response time and braking torque

maintenance

Regular inspection: Check the wear of the tooth surface and the thickness of the brake lining every 3-6 months

Lubrication management: Replace or supplement lubricants according to recommended cycles, using designated grades

Braking performance monitoring: Regular testing of braking response time and braking distance

Wear and tear parts replacement: When the remaining thickness of the brake lining is less than 2mm, it should be replaced in a timely manner

With the advancement of industry and the development of high-end equipment manufacturing, brake drum gear couplings will continue to develop towards high performance, intelligence, and environmental protection, providing more reliable solutions for various mechanical transmission systems.

« Brake Drum Gear Couplings » Post Date: 2024/4/23 , https://www.rokeecoupling.net/tags/brake-drum-gear-couplings.html