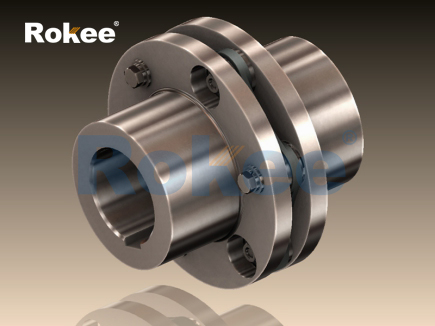

Rokee is a well-known high-quality supplier of Disc Couplings and technical services in China, customize disc couplings according to user drawings, alternatively, if the user provides disc couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Disc coupling is a high-performance flexible coupling that compensates for the relative displacement between two shafts through the elastic deformation of one or more sets of metal discs. The core of this coupling lies in its unique structural design - a thin and high-strength metal disk group that can adapt to axial, radial, and angular deviations while transmitting torque.

The working principle is based on the theory of elastic deformation: when the driving shaft rotates, torque is transmitted to the first set of disks through bolts, and the disks produce slight twisting deformation to transmit power to the intermediate piece, which is then transmitted to the driven shaft through the second set of disks. Throughout the entire process, the elastic deformation of the metal disk effectively absorbs and compensates for various misalignment situations between the shaft systems, while maintaining extremely high torsional stiffness.

Disc couplings typically consist of the following key components:

Metal disk group: usually made of stainless steel or high-strength alloy steel, with a thickness of 0.25-3mm, and subjected to special heat treatment process to improve fatigue life. Each set of disks contains 2-6 independent disks arranged in a staggered pattern to enhance flexibility.

Wheel hub components: precision machined aluminum alloy or steel parts that are connected to the shaft through interference fit or cone sleeve structure, and the surface is usually hardened to improve wear resistance.

Intermediate shaft sleeve: a transitional component used to connect two sets of disks, the length can be adjusted as needed, and the material selection considers the balance of weight and strength.

High strength connecting bolts: use 12.9 grade or higher alloy steel bolts, with precise control of pre tightening force to ensure connection reliability.

Performance characteristics and advantages of disc couplings

High precision transmission: The torsional stiffness can reach 5000-15000 Nm/rad, and the transmission error is less than 0.05 °, making it particularly suitable for precision equipment such as CNC machine tools and robots.

Excellent compensation capability:

Axial displacement: ± 0.5-3mm

Radial displacement: 0.2-1.5mm

Angular deviation: ± 0.5 ° -3 °

Maintenance free design: No sliding parts, no need for lubrication, and the service life usually exceeds 50000 hours.

Excellent dynamic performance: high critical speed (up to 50000 RPM or more), low vibration, and low noise.

Lightweight: Compared to gear couplings, it reduces weight by 30-50% and lowers rotational inertia.

Application fields of disc couplings

High end manufacturing equipment:

Five axis linkage machining center spindle connection

Precision Grinding Machine Transmission System

Semiconductor manufacturing equipment positioning mechanism

Energy sector:

Gas turbine generator set

Large scale compressor unit

Wind power variable pitch system

Installation specifications:

Using laser alignment instrument to ensure axis alignment accuracy ≤ 0.05mm

Use a torque wrench to tighten the bolts in stages in a cross pattern

Perform dynamic balance verification, residual unbalance ≤ 1g · mm/kg

Maintenance points:

Check the fatigue cracks on the surface of the disc every 2000 hours of operation (penetrant testing can be used)

Regularly check the pre tightening force of bolts (attenuation not exceeding 10%)

Avoid overload operation (instantaneous overload not exceeding 300% of rated torque)

With the development of industry, disc couplings are continuously evolving towards intelligence, lightweight, and high performance, demonstrating irreplaceable technological advantages in the field of precision transmission. Proper selection and use of disc couplings can significantly improve the reliability, accuracy, and energy efficiency performance of mechanical systems.

« Disc Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/disc-couplings.html