Rokee is a well-known high-quality supplier of Flexible Bush Couplings and technical services in China, customize flexible bush couplings according to user drawings, alternatively, if the user provides flexible bush couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Flexible Bush Coupling is a widely used type of elastic coupling in mechanical transmission systems, which achieves flexible connection between shafts by introducing elastic elements into the coupling structure. Compared with rigid couplings, Flexible Bush Couplings can effectively compensate for radial, axial, and angular deviations between two shafts, while also having advantages such as buffering, vibration absorption, and noise reduction.

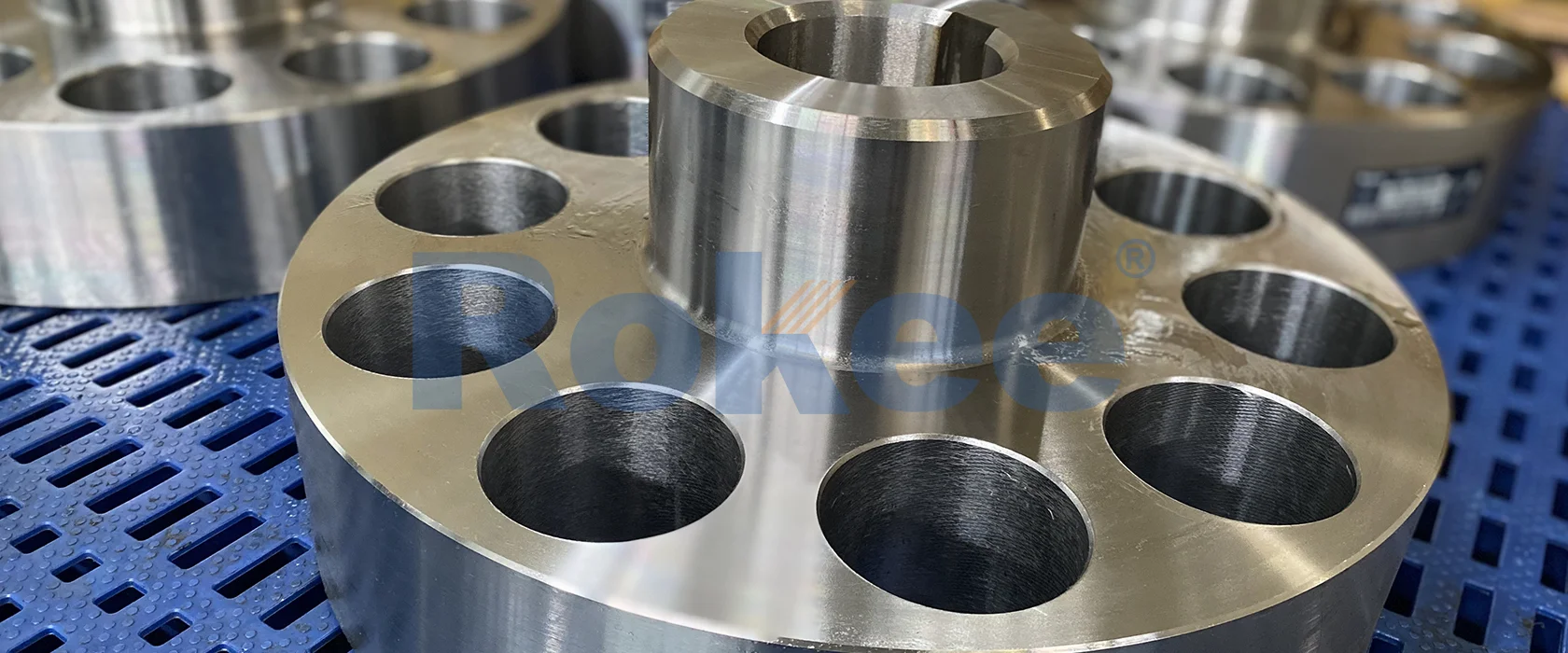

Half coupling: usually made of steel or cast iron, divided into two parts: the active end and the passive end, connected to the equipment shaft by bolts or other means.

Elastic sleeve: a core component made of rubber, polyurethane or other elastic materials, with different hardness levels to adapt to different working conditions.

Connecting components: including bolts, pins, etc., used to fix the elastic sleeve and transmit torque.

Protective cover (some models): used to protect internal components, prevent dust from entering and grease leakage.

The Flexible Bush Coupling achieves the following functions through the deformation of the elastic sleeve:

Torque transmission: Power is transmitted from the drive shaft to the driven shaft through an elastic sleeve

Deviation compensation: The flexibility of the elastic sleeve allows for a certain degree of axial, radial, and angular deviation

Vibration absorption: Elastic materials can absorb and buffer impacts and vibrations in transmission systems

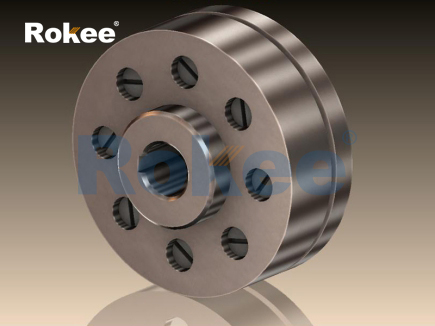

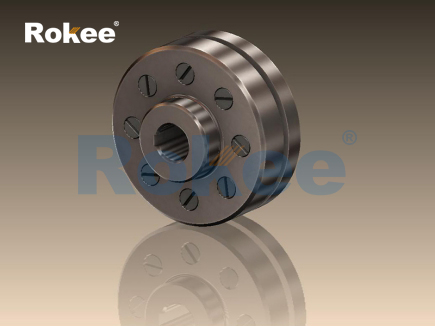

Standard type Flexible Bush Coupling: the most common type, suitable for general industrial applications

Flange type Flexible Bush Coupling: with a larger contact area, suitable for high torque applications

Flexible Bush Coupling with brake wheel: integrated braking function, used for equipment that requires rapid braking

Maintenance free type: using special materials and design, no need for regular lubrication

Rated torque: ranging from a few Newton meters to tens of thousands of Newton meters

Allowable deviation:

Radial deviation: usually 0.1-0.3mm

Axial deviation: 1-5mm

Angular deviation: 0.5 ° -1.5 °

Maximum speed: Depending on the model, it can reach over 10000rpm

Working temperature range: -40 ℃ to+100 ℃ (depending on the elastic material)

Determine the application scenario: consider load characteristics, environmental conditions, etc

Calculate required torque: Consider working torque and peak torque

Determine shaft diameter and spacing: match equipment interface

Consider the need for deviation compensation: choose the appropriate model based on installation accuracy

Environmental factors: the impact of temperature, humidity, corrosiveness, etc. on materials

Installation steps:

Clean the contact surface between the shaft and coupling

Use hot installation or hydraulic method to avoid hammering

Use specialized tools to ensure alignment accuracy

Gradually and evenly tighten the connecting bolts

Daily maintenance:

Regularly check the wear of the elastic sleeve

Check the tightening status of bolts

Clean the surface of the coupling

Supplement lubricating grease according to the prescribed cycle (non maintenance free type)

Common troubleshooting:

Abnormal vibration: check the alignment and elastic sleeve status

Overheating: Check lubrication and load status

Abnormal noise: Check for loose or damaged components

General mechanical equipment: pumps, fans, compressors, etc

Material conveying equipment: conveyors, elevators, etc

Power generation equipment: generators, turbines, etc

Construction machinery: excavators, cranes, etc

Shipbuilding industry: propulsion systems, auxiliary equipment, etc

Advantages:

Simple structure and low cost

Easy to maintain (especially maintenance free models)

Good buffering and vibration reduction performance

Can compensate for multiple types of deviations

Limitations:

Limited compensation capability, not suitable for large deviation situations

Elastic materials will age and need to be replaced regularly

Performance may decrease in high temperature or corrosive environments

Flexible Bush Couplings play an important role in the industrial transmission field due to their excellent cost-effectiveness and reliable performance. Proper selection, installation, and maintenance of Flexible Bush Couplings can significantly improve the efficiency and service life of the transmission system.

« Flexible Bush Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/flexible-bush-couplings.html