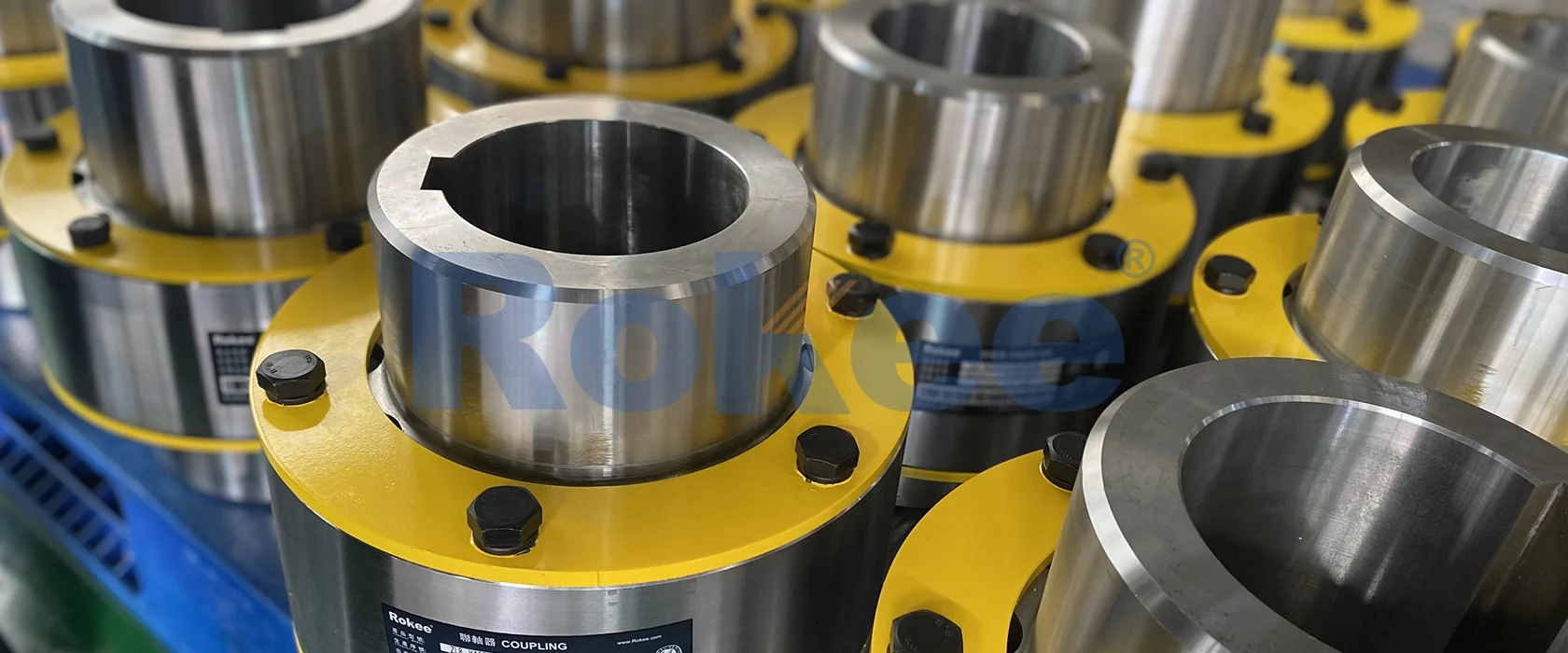

Rokee is a well-known high-quality supplier of Pin Bush Couplings and technical services in China, customize pin bush couplings according to user drawings, alternatively, if the user provides pin bush couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex ecosystem of mechanical power transmission, couplings are indispensable components that establish a reliable connection between rotating shafts, enabling efficient torque transfer while accommodating inevitable misalignments and absorbing operational shocks. Among the various coupling configurations available, the pin bush coupling (also known as pin and bushing coupling) has earned widespread recognition for its simplicity, cost-effectiveness, and versatility. Designed to balance performance and practicality, this type of flexible coupling is extensively utilized in numerous industrial sectors where moderate torque transmission and misalignment compensation are required. This article provides a comprehensive exploration of pin bush couplings, covering their structural composition, working principles, key performance characteristics, industrial applications, maintenance practices, and emerging development trends, aiming to offer a detailed understanding of their role in modern mechanical systems.

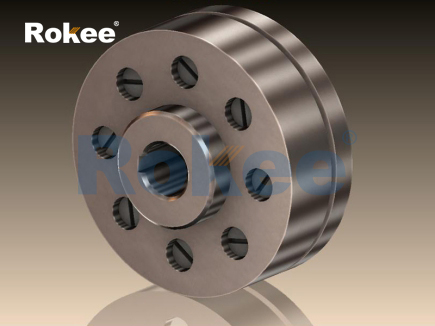

Pin bush couplings are classified as flexible couplings, characterized by a relatively simple yet robust design that facilitates torque transmission while allowing for limited misalignment. The core structure of a typical pin bush coupling consists of five primary components: two flanges, a set of pins, a corresponding set of bushings, split pins (or cotter pins), and rubber or elastomeric sleeves. Each component plays a distinct role in ensuring the coupling’s overall functionality and reliability.

The two flanges are the foundational elements of the coupling, each designed to be rigidly attached to the end of the two shafts that need to be connected. Flange attachment is typically achieved through keyway connections, where a metal key fits into grooves on both the shaft and the flange hub, ensuring a secure torque transfer interface. Alternatively, some flanges may use shrink-fit or bolted connections depending on the specific application requirements, such as shaft diameter and torque load. The flanges are usually fabricated from high-strength materials such as cast iron, steel, or aluminum alloy, selected based on factors like operating environment, load capacity, and weight constraints.

The pins are cylindrical components that extend from one of the flanges, evenly spaced along the circumference of the flange to ensure balanced torque distribution. The number and diameter of the pins are key design parameters that directly influence the coupling’s torque-carrying capacity. For example, couplings designed for high-torque applications will feature a greater number of larger-diameter pins. The pins are typically made from hardened steel to withstand the shear forces and wear associated with torque transmission.

The bushings, also referred to as sleeves or rubber elements, are the critical flexible components of the pin bush coupling. They are designed to fit over the pins, creating a flexible interface between the two flanges. The bushings are usually made from elastomeric materials such as natural rubber, neoprene, nitrile rubber, or polyurethane. These materials exhibit excellent elasticity, which allows the coupling to accommodate misalignments and absorb vibrations. The bushing design may vary, with some featuring a solid cylindrical shape and others incorporating grooves or ribs to enhance flexibility and vibration damping capabilities. In some configurations, the bushings are press-fitted into the holes of the second flange, creating a secure yet flexible connection between the two flanges via the pins.

Split pins or cotter pins are used to secure the pins in place, preventing axial movement of the pins during operation. These small but essential components are inserted through holes drilled at the end of the pins, ensuring that the pins remain engaged with the bushings and flanges even under dynamic load conditions. Finally, some pin bush couplings may include additional components such as grease nipples for lubrication, although this is more common in heavy-duty applications where reducing friction between the pins and bushings is critical for prolonging service life.

The operational principle of pin bush couplings revolves around the interaction between the rigid pins and flexible bushings, which enables torque transmission while accommodating misalignments and absorbing vibrations. When torque is applied to the input shaft, it is transferred to the corresponding flange, which in turn drives the pins attached to it. The pins engage with the bushings, which are secured to the output flange, and the torque is transmitted through this pin-bushing interface to the output flange and ultimately to the output shaft.

A key aspect of the working principle is the role of the elastomeric bushings in providing flexibility. Unlike rigid couplings, which require near-perfect shaft alignment, the elastic nature of the bushings allows the pin bush coupling to accommodate three main types of misalignment: angular misalignment, parallel misalignment, and axial misalignment. Angular misalignment occurs when the axes of the two shafts intersect at an angle, and the bushings’ flexibility allows the pins to pivot slightly relative to the bushings, compensating for this angular offset. Typically, pin bush couplings can accommodate angular misalignments of up to 1.5 to 2 degrees, depending on the bushing material and design.

Parallel misalignment, which involves a lateral offset between the two shaft axes, is compensated for by the radial flexibility of the bushings. As the input flange rotates, the pins move within the bushings, allowing for a small amount of lateral displacement between the two flanges. The maximum parallel misalignment capacity of a pin bush coupling is usually in the range of 0.5 to 2 mm, again depending on the specific design and material of the bushings. Axial misalignment, which refers to relative axial movement of the two shafts, is absorbed by the compression and expansion of the elastomeric bushings along the axial direction.

Another important function of the bushings is vibration damping. During operation, rotating machinery generates vibrations that can be transmitted through the shafts to other components, leading to increased wear, noise, and reduced equipment lifespan. The elastomeric bushings in pin bush couplings act as vibration isolators, absorbing and dissipating vibrational energy due to their viscoelastic properties. This not only reduces noise levels but also protects the connected machinery from the harmful effects of vibration. Additionally, the bushings help to mitigate shock loads, such as those caused by sudden starts or stops, by absorbing the impact and distributing the load evenly across the pins.

Pin bush couplings offer a range of performance characteristics and advantages that make them a popular choice for many industrial applications. One of the most significant advantages is their simplicity of design. Unlike more complex coupling types such as gear couplings or disc couplings, pin bush couplings have a straightforward structure with fewer components, making them easy to manufacture, install, and maintain. This simplicity also contributes to their cost-effectiveness, as they are typically more affordable than other flexible coupling options, especially for low to moderate torque applications.

Another key advantage is their versatility in accommodating misalignments. As discussed earlier, pin bush couplings can handle angular, parallel, and axial misalignments, making them suitable for a wide range of machinery where perfect shaft alignment is difficult to achieve or maintain. This is particularly beneficial in applications where thermal expansion of shafts, installation errors, or structural deflection may cause misalignment over time.

The vibration damping and shock absorption capabilities of pin bush couplings are also notable. The elastomeric bushings effectively reduce vibration transmission, improving the overall stability and lifespan of the connected machinery. This makes them ideal for use with electric motors, pumps, compressors, and other equipment that generates significant vibrations during operation. Additionally, the ability to absorb shock loads helps to protect the shafts and other components from damage caused by sudden changes in load or speed.

Pin bush couplings also exhibit good torque transmission capacity for their size and cost. While they are not designed for extremely high-torque applications like some gear couplings, they are well-suited for moderate torque loads, which covers a large number of industrial applications. The even distribution of torque across multiple pins ensures that the load is not concentrated on a single component, reducing the risk of premature failure.

Another advantage is their easy maintenance and replacement. The simple design means that inspecting the coupling for wear or damage is straightforward. When the bushings wear out, they can be easily replaced without disassembling the entire shaft system, which saves time and labor costs. The pins and flanges, being made from durable materials, typically have a long service life, further reducing maintenance requirements and downtime.

Finally, pin bush couplings are suitable for a wide range of operating environments. The choice of bushing material can be tailored to the environment: for example, nitrile rubber bushings are resistant to oil and chemicals, making them suitable for use in industrial settings where oil contamination is common, while neoprene bushings offer good resistance to weathering and ozone, making them ideal for outdoor applications.

Due to their unique combination of simplicity, cost-effectiveness, and versatility, pin bush couplings find applications in a diverse range of industries and machinery types. One of the most common application areas is pump and compressor systems. Pumps and compressors are widely used in industries such as water treatment, oil and gas, chemical processing, and manufacturing. These machines often experience misalignment due to thermal expansion and installation variations, and the pin bush coupling’s ability to accommodate misalignments and absorb vibrations makes it an ideal choice for connecting the motor to the pump or compressor shaft. For example, in centrifugal pumps, pin bush couplings ensure efficient torque transmission while protecting the pump’s bearings from the vibrations generated by the motor.

The electric motor industry is another major user of pin bush couplings. Electric motors are used to power a wide range of machinery, and the coupling between the motor and the driven equipment is critical for ensuring efficient operation. Pin bush couplings are commonly used with induction motors, synchronous motors, and DC motors, providing a flexible connection that compensates for misalignment and reduces vibration transmission. This is particularly important in applications where the motor and driven equipment are mounted on separate bases, increasing the likelihood of misalignment.

In the agricultural machinery sector, pin bush couplings are used in equipment such as tractors, harvesters, and irrigation pumps. Agricultural machinery operates in harsh and uneven terrain, leading to frequent misalignments and shock loads. The robust design and vibration damping capabilities of pin bush couplings make them well-suited for these applications. For example, in tractor PTO (Power Take-Off) systems, pin bush couplings connect the tractor’s engine to various implements such as plows and harvesters, ensuring reliable torque transmission even under dynamic load conditions.

The material handling industry also relies heavily on pin bush couplings. Conveyors, belt drives, and bucket elevators, which are used to transport materials in factories, mines, and warehouses, often use pin bush couplings to connect the drive motor to the conveyor shaft. These couplings accommodate the misalignments that may occur due to the long length of conveyor systems and absorb the vibrations generated by the movement of materials. Additionally, their easy maintenance makes them ideal for use in material handling applications where downtime must be minimized.

Other notable applications of pin bush couplings include textile machinery (such as spinning frames and looms), printing machinery, paper mills, and automotive auxiliary systems (such as water pumps and alternators). In each of these applications, the coupling’s ability to provide a flexible, reliable, and cost-effective connection between shafts makes it an essential component. For example, in textile mills, the high-speed operation of spinning frames generates significant vibrations, and pin bush couplings help to dampen these vibrations, ensuring smooth operation and reducing wear on the machinery.

Proper maintenance is essential for ensuring the long service life and reliable operation of pin bush couplings. The maintenance requirements of these couplings are relatively simple, thanks to their straightforward design, but regular inspection and upkeep are still critical to prevent premature failure and avoid costly downtime.

The primary maintenance task for pin bush couplings is regular inspection of the bushings. The elastomeric bushings are the most wear-prone components of the coupling, as they are subjected to continuous compression, shear, and friction during operation. Over time, the bushings can become worn, cracked, or hardened, reducing their flexibility and vibration damping capabilities. Inspections should be conducted periodically to check for signs of bushing wear, such as excessive play between the pins and bushings, cracks in the bushing material, or leakage of rubber particles. If any of these signs are detected, the bushings should be replaced immediately to prevent further damage to the pins, flanges, or connected shafts.

Lubrication is another important maintenance consideration, particularly for heavy-duty pin bush couplings. While the elastomeric bushings themselves do not require lubrication, the pins and the holes in the flanges where the bushings are installed may need periodic lubrication to reduce friction and wear. Grease is the most commonly used lubricant for this purpose, and grease nipples are often provided on the flanges to facilitate easy lubrication. It is important to use the correct type of grease, as specified by the coupling manufacturer, to ensure compatibility with the bushing material and operating conditions.

Shaft alignment checks should also be performed regularly. While pin bush couplings can accommodate misalignments, excessive or prolonged misalignment can accelerate bushing wear and increase stress on the pins and flanges. Shaft alignment can be checked using simple tools such as dial indicators or more advanced laser alignment systems. If misalignment exceeds the coupling’s capacity, corrective action should be taken, such as adjusting the position of the motor or driven equipment.

Inspection of pins and flanges is also necessary. The pins should be checked for signs of bending, wear, or corrosion, and the flanges should be inspected for cracks, deformation, or loose fasteners. Loose flange bolts or keyway connections can lead to excessive vibration and misalignment, so all fasteners should be checked periodically and tightened to the recommended torque values. If any pins or flanges are found to be damaged, they should be replaced to ensure the coupling’s structural integrity.

Common troubleshooting issues with pin bush couplings include excessive vibration, abnormal noise, and reduced torque transmission. Excessive vibration is often a sign of worn bushings, misalignment, or loose fasteners. Abnormal noise, such as squeaking or rattling, may indicate that the bushings are worn or that the pins are loose. Reduced torque transmission can be caused by sheared pins, worn bushings, or a damaged keyway connection. In most cases, these issues can be resolved by replacing worn components, realigning the shafts, or tightening loose fasteners.

As industrial machinery becomes more advanced, with increasing demands for higher efficiency, longer service life, and reduced environmental impact, the design and development of pin bush couplings are also evolving. Several key trends are shaping the future of these couplings, driven by advancements in materials science, manufacturing technology, and industrial automation.

One of the most significant trends is the development of advanced bushing materials. Traditional elastomeric materials such as natural rubber and neoprene are being replaced with high-performance materials like polyurethane, silicone rubber, and composite elastomers. These advanced materials offer superior properties such as higher wear resistance, better temperature stability, improved chemical resistance, and longer service life. For example, polyurethane bushings exhibit excellent abrasion resistance and can withstand higher temperatures than traditional rubber bushings, making them suitable for more demanding applications. Additionally, the use of nanocomposite materials, which incorporate nanoparticles into the elastomeric matrix, is being explored to further enhance the mechanical properties of bushings, such as strength and flexibility.

Another trend is the adoption of additive manufacturing (3D printing) technology for coupling components. 3D printing allows for the production of complex flange and bushing designs that are difficult or impossible to achieve with traditional manufacturing processes. For example, 3D-printed flanges can be designed with integrated lightweight structures, reducing the overall weight of the coupling without compromising strength. Additionally, 3D printing enables the production of custom bushings with tailored geometries to optimize flexibility and vibration damping for specific applications. This technology also allows for faster prototyping and shorter lead times, making it easier for manufacturers to develop and test new coupling designs.

The integration of smart monitoring technologies into pin bush couplings is another emerging trend. With the growing focus on predictive maintenance in industrial settings, manufacturers are developing smart couplings equipped with sensors that can monitor key operating parameters such as temperature, vibration, and wear. These sensors transmit real-time data to a central monitoring system, allowing maintenance personnel to detect potential issues before they lead to coupling failure. For example, a vibration sensor can detect increased vibration caused by worn bushings, alerting maintenance teams to replace the bushings before they fail completely. This predictive maintenance approach reduces downtime, improves equipment reliability, and lowers maintenance costs.

There is also a growing emphasis on energy efficiency in coupling design. By optimizing the geometry of the pins and bushings, reducing friction, and using lightweight materials, manufacturers are able to reduce the energy losses associated with torque transmission. This is particularly important in the context of global efforts to reduce energy consumption and carbon emissions. Additionally, the development of low-friction bushings, which require less lubrication, is helping to reduce the environmental impact of couplings by minimizing lubricant usage and waste.

Finally, the trend toward customization is becoming more prevalent in the pin bush coupling market. As industries become more specialized, there is a growing demand for couplings that are tailored to the unique requirements of specific applications. Manufacturers are increasingly offering custom design solutions, where the coupling’s dimensions, material selection, and bushing properties are optimized for a particular machine or operating environment. This includes couplings designed for extreme temperatures, high-speed applications, or corrosive environments.

Pin bush couplings occupy a vital position in the field of mechanical power transmission, offering a simple, cost-effective, and versatile solution for connecting rotating shafts. Their unique design, which combines rigid flanges and pins with flexible elastomeric bushings, enables them to transmit torque efficiently while accommodating misalignments and absorbing vibrations. These characteristics make them suitable for a wide range of industrial applications, from pumps and compressors to agricultural machinery and material handling systems.

Proper maintenance, including regular inspection of bushings, lubrication, and shaft alignment checks, is critical for ensuring the long service life and reliable operation of pin bush couplings. By following recommended maintenance practices, industrial operators can minimize downtime and maximize the performance of their machinery.

Looking to the future, advancements in materials science, additive manufacturing, and smart technologies are expected to further enhance the performance and capabilities of pin bush couplings. The development of advanced bushing materials, 3D-printed components, and smart monitoring systems will enable these couplings to meet the evolving demands of modern industrial machinery, including higher efficiency, longer service life, and improved reliability. As such, pin bush couplings will continue to be a preferred choice for many industrial applications, playing a key role in ensuring the smooth and efficient operation of rotating equipment across various sectors.

« Pin Bush Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/pin-bush-couplings.html