Rokee is a well-known high-quality supplier of Telescoping Driveshafts and technical services in China, customize telescoping driveshafts according to user drawings, alternatively, if the user provides telescoping driveshafts parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex landscape of mechanical power transmission, the need to transfer torque and rotational motion between components that experience relative axial displacement is a common challenge across numerous industries. From automotive vehicles navigating uneven terrain to industrial machinery with moving parts, traditional fixed-length driveshafts often fail to accommodate the dynamic axial movement required in such systems. This is where the telescoping driveshaft—also known as a sliding or extensible driveshaft—emerges as a specialized and indispensable solution. Engineered to transmit torque while allowing significant axial elongation and compression, telescoping driveshafts combine the core functionality of standard driveshafts with the flexibility to adapt to changing distances between power sources and driven components. This article provides a comprehensive exploration of telescoping driveshafts, covering their fundamental design and functionality, key types, diverse industrial and automotive applications, critical design considerations, and best practices for maintenance, offering valuable insights into this vital mechanical component.

At its essence, a telescoping driveshaft is a power transmission component designed to transfer rotational torque from an input shaft (e.g., from an engine or motor) to an output shaft (e.g., to a differential or gearbox) while accommodating axial movement between the two shafts. Unlike fixed-length driveshafts, which maintain a constant length and are only suitable for applications with fixed distances between components, telescoping driveshafts feature a modular, sliding structure that enables them to extend or contract along their central axis. This axial flexibility is the defining characteristic of telescoping driveshafts, making them ideal for systems where the relative position of the input and output components changes dynamically during operation.

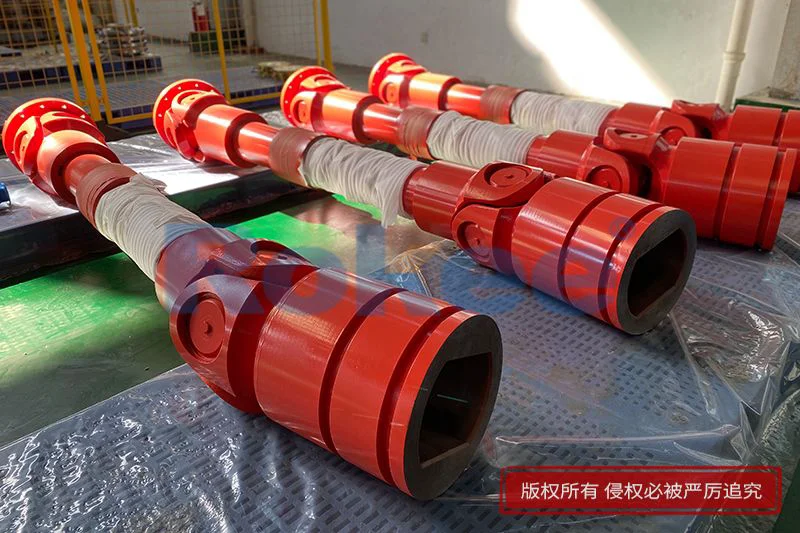

The basic structure of a telescoping driveshaft typically consists of two primary components: an outer tube (female section) and an inner shaft (male section) that slides concentrically within the outer tube. To ensure efficient torque transmission while facilitating smooth axial movement, the interface between the outer tube and inner shaft is equipped with a splined connection. Splines are ridges or grooves machined into the surface of the inner shaft and the inner surface of the outer tube, creating a precise interlocking mechanism. This splined connection prevents relative rotation between the two sections while allowing them to move freely along the axial direction. In some designs, particularly those requiring higher torque capacity or smoother operation, the splined interface may be supplemented with roller bearings or bushings to reduce friction and wear during sliding and rotational motion.

In addition to the core telescoping sections, most telescoping driveshafts incorporate universal joints (UJs) or constant velocity (CV) joints at one or both ends. These joints serve a critical purpose: accommodating angular misalignment between the input and output shafts, which is often present alongside axial movement in dynamic systems. For example, in a rear-wheel-drive vehicle, the rear axle moves up and down relative to the transmission as the vehicle travels over bumps or uneven terrain. This movement creates both axial displacement (requiring the driveshaft to telescope) and angular misalignment (requiring UJs or CV joints to maintain torque transmission). The combination of telescoping sections and universal joints makes the driveshaft a versatile component capable of handling multiple types of misalignment simultaneously.

The functionality of a telescoping driveshaft is rooted in its ability to balance two competing requirements: rigid torque transmission and flexible axial movement. When torque is applied to the input end, the splined connection transfers this torque from the inner shaft to the outer shaft (or vice versa) without slippage, ensuring that rotational motion is efficiently transmitted to the output component. At the same time, as the distance between the input and output shafts changes, the inner shaft slides smoothly within the outer tube, maintaining the connection and torque transmission without imposing excessive stress on the driveshaft or adjacent components. This balance of rigidity and flexibility is what distinguishes telescoping driveshafts from other types of power transmission components.

Telescoping driveshafts are available in several distinct types, each designed to meet specific application requirements related to torque capacity, axial movement range, operating speed, environmental conditions, and angular misalignment tolerance. The primary classification of telescoping driveshafts is based on the design of their splined connection, the type of universal joints used, and their structural configuration. Below are the most common types, along with their unique characteristics and typical use cases.

1. Splined Telescoping Driveshafts (Slip-in-Spline Design)

The splined telescoping driveshaft is the most common and straightforward type, characterized by a direct splined connection between the inner shaft and outer tube. The splines are typically straight (parallel to the shaft axis) or helical (angled relative to the axis). Straight splines are simpler to manufacture and are suitable for applications with moderate torque requirements and low to moderate operating speeds. They provide reliable torque transmission but may generate more friction during axial sliding compared to other designs. Helical splines, on the other hand, offer several advantages: they distribute torque more evenly across the spline surface, reduce stress concentrations, and enable smoother axial movement due to the angled contact between the splines. This makes helical splined driveshafts ideal for high-torque, high-speed applications, such as heavy-duty trucks, construction machinery, and industrial gearboxes.

In some splined telescoping driveshaft designs, the splined interface is lubricated with grease or oil to minimize friction and wear. Seals are often installed at the junction of the inner and outer sections to prevent lubricant leakage and protect the splines from contamination by dust, dirt, or moisture. This lubrication and sealing are critical for extending the service life of the driveshaft, especially in harsh operating environments.

2. Ball Spline Telescoping Driveshafts

For applications requiring extremely smooth axial movement and high precision, ball spline telescoping driveshafts are the preferred choice. Unlike traditional splined driveshafts, which rely on direct contact between the splines of the inner and outer sections, ball spline designs incorporate a series of steel balls that roll between the splines. These balls are contained within a cage that maintains their position and ensures even distribution across the spline surface. The rolling contact between the balls and splines significantly reduces friction compared to sliding contact, enabling smoother axial movement with minimal resistance.

Ball spline telescoping driveshafts are capable of transmitting high torque while accommodating large axial strokes, making them suitable for applications such as industrial robots, machine tools, and precision automation systems. They also offer superior positional accuracy and repeatability, which is critical in applications where precise control of axial movement is required. However, ball spline designs are more complex and expensive to manufacture than traditional splined driveshafts, limiting their use to applications where the benefits of smooth operation and precision justify the higher cost.

3. Telescoping Driveshafts with CV Joints

Many telescoping driveshafts, particularly those used in automotive and high-performance applications, are equipped with constant velocity (CV) joints instead of traditional universal joints. CV joints are designed to transmit torque at a constant angular velocity, even when the shafts are misaligned at large angles. This eliminates the velocity fluctuation that is inherent in traditional UJs, resulting in smoother power transmission, reduced vibration, and lower noise levels.

Telescoping driveshafts with CV joints are commonly used in front-wheel-drive vehicles, all-wheel-drive vehicles, and high-performance racing cars. In these applications, the driveshaft must accommodate both axial movement (due to suspension travel) and large angular misalignment (due to steering or suspension geometry). The combination of telescoping splines and CV joints ensures that torque is transmitted efficiently and smoothly, even under extreme operating conditions. Some advanced designs also incorporate a sliding CV joint, which integrates the telescoping function directly into the CV joint itself, eliminating the need for a separate splined section and reducing the overall length and complexity of the driveshaft.

4. Heavy-Duty Telescoping Driveshafts

Heavy-duty telescoping driveshafts are engineered to handle extremely high torque loads and large axial movement ranges, making them suitable for heavy machinery such as construction equipment (excavators, bulldozers, cranes), agricultural machinery (tractors, combines), and industrial equipment (conveyors, mining machinery). These driveshafts feature robust construction, with thick-walled outer tubes, high-strength alloy steel inner shafts, and large-diameter splines to withstand the rigors of heavy-duty operation.

To enhance durability, heavy-duty telescoping driveshafts often incorporate additional features such as heat-treated splines for increased wear resistance, reinforced universal joints with large bearings, and protective boots or covers to shield the splined interface from harsh environmental conditions (e.g., dirt, rocks, moisture, and chemicals). Some designs also include vibration damping components to reduce noise and vibration, improving operator comfort and reducing stress on adjacent machinery components.

Telescoping driveshafts are utilized across a wide range of industries and applications, where their unique ability to transmit torque while accommodating axial movement makes them irreplaceable. From everyday automotive vehicles to specialized industrial machinery, these components play a critical role in ensuring the reliable and efficient operation of power transmission systems. Below are the key application areas where telescoping driveshafts are most commonly used.

1. Automotive Industry

The automotive industry is one of the largest consumers of telescoping driveshafts, with applications in rear-wheel-drive (RWD), four-wheel-drive (4WD), and all-wheel-drive (AWD) vehicles, as well as some front-wheel-drive (FWD) vehicles. In RWD vehicles, the telescoping driveshaft connects the transmission to the rear differential. As the vehicle travels over uneven terrain, the rear axle moves up and down relative to the transmission, causing the distance between the two components to change. The telescoping driveshaft extends and contracts to accommodate this movement, while universal joints or CV joints handle the associated angular misalignment. In 4WD and AWD vehicles, telescoping driveshafts are also used in the transfer case and front axle assemblies, where they must accommodate both axial movement and angular misalignment between the various components of the drivetrain.

High-performance and racing vehicles often use specialized telescoping driveshafts with CV joints to ensure smooth power transmission at high speeds and during aggressive maneuvering. These driveshafts are typically made from lightweight materials such as aluminum or carbon fiber composites to reduce rotational mass, improving acceleration and overall vehicle performance.

2. Construction and Heavy Machinery

Construction equipment such as excavators, bulldozers, cranes, and loaders relies heavily on telescoping driveshafts to transmit power between moving components. For example, in an excavator, the telescoping driveshaft connects the engine to the hydraulic pump and the transmission to the tracks. As the excavator's arm moves up, down, and around, the distance between the engine and the driven components changes, requiring the driveshaft to telescope. Similarly, in a crane, the telescoping boom requires a driveshaft that can extend and contract as the boom is extended or retracted, transmitting power to the winch and other components.

These applications demand heavy-duty telescoping driveshafts capable of withstanding high torque loads, extreme environmental conditions (e.g., dust, dirt, moisture, and temperature fluctuations), and frequent axial movement. The driveshafts used in construction machinery are often designed with reinforced splines, large bearings, and protective covers to ensure long-term reliability in these harsh operating environments.

3. Agricultural Machinery

Agricultural machinery, such as tractors, combines, harvesters, and sprayers, operates in challenging, uneven terrain where axial movement between components is common. Telescoping driveshafts are used in these machines to connect the engine to the transmission, the transmission to the wheels or tracks, and the power take-off (PTO) shaft to various implements (e.g., plows, mowers, balers, and seeders). The PTO shaft, in particular, often features a telescoping design to accommodate the changing distance between the tractor and the implement as the tractor moves over uneven ground.

Agricultural telescoping driveshafts must be durable enough to withstand the high torque loads associated with farm implements, as well as resistant to corrosion from moisture, chemicals (e.g., fertilizers and pesticides), and debris (e.g., dirt, straw, and crop residues). Many agricultural driveshafts also include safety features such as shield guards to prevent entanglement with clothing or body parts.

4. Industrial Manufacturing and Automation

In industrial manufacturing facilities, telescoping driveshafts are used in a variety of equipment, including conveyors, robotic arms, machine tools, and packaging machinery. Conveyors, for example, often use telescoping driveshafts to connect the drive motor to the conveyor rollers, accommodating the axial movement that occurs as the conveyor belt stretches or as the frame expands and contracts due to temperature changes. Robotic arms and automation systems use precision telescoping driveshafts (often with ball splines) to transmit torque to the joints of the robot, enabling smooth, precise movement of the arm while accommodating the axial displacement of the joints.

Machine tools such as lathes, milling machines, and grinders also use telescoping driveshafts in their spindle drives and feed mechanisms, where they must transmit high torque with high precision while accommodating the axial movement of the cutting tools. These driveshafts are typically made from high-strength, wear-resistant materials and are precision-machined to ensure accurate torque transmission and smooth operation.

5. Marine and Offshore Applications

Marine vessels, such as ships, boats, and offshore platforms, use telescoping driveshafts in their propulsion systems and auxiliary equipment. In the propulsion system, the telescoping driveshaft connects the engine to the propeller shaft, accommodating the axial movement that occurs due to the flexure of the vessel's hull and the thermal expansion and contraction of the shafts. This ensures that torque is transmitted efficiently to the propeller, even as the relative position of the engine and propeller changes.

Marine telescoping driveshafts must be corrosion-resistant to withstand the harsh saltwater environment, and they are often made from stainless steel or other corrosion-resistant alloys. They may also include sealed bearings and lubrication systems to prevent water ingress and protect the splined interface from wear. Offshore platforms use similar telescoping driveshafts in their drilling equipment, winches, and other machinery, where they must accommodate axial movement and withstand the extreme environmental conditions of the offshore environment.

Designing or selecting a telescoping driveshaft for a specific application requires careful consideration of several key factors to ensure optimal performance, reliability, and longevity. These factors include torque capacity, axial movement range, angular misalignment tolerance, operating speed, environmental conditions, material selection, and cost. Below is a detailed discussion of each of these critical design considerations.

1. Torque Capacity

Torque capacity is the maximum amount of torque that a telescoping driveshaft can transmit without failing or suffering permanent damage. This is the most critical design parameter, as selecting a driveshaft with insufficient torque capacity will lead to premature failure, potentially causing damage to other components in the power transmission system. The torque capacity of a telescoping driveshaft depends on several factors, including the diameter and material of the inner and outer shafts, the design and size of the splined connection, and the type of universal joints or CV joints used.

When determining the required torque capacity, engineers must consider not only the nominal operating torque of the application but also any peak torque loads that may occur during start-up, acceleration, or overload conditions. A safety factor is typically applied to the calculated torque requirement to ensure that the driveshaft can handle unexpected torque spikes. For heavy-duty applications, this safety factor may be as high as 2.5 to 3.0, while for light-duty applications, a safety factor of 1.5 to 2.0 may be sufficient.

2. Axial Movement Range

The axial movement range (also known as the stroke length) is the maximum distance that the telescoping driveshaft can extend or contract along its axis. This parameter is determined by the application's requirements, specifically the maximum change in distance between the input and output shafts during operation. It is critical to select a driveshaft with an axial movement range that exceeds the maximum expected displacement in the application, as insufficient stroke length will cause the driveshaft to bottom out (reach the end of its extension or contraction) during operation, leading to excessive stress, damage, or failure.

The axial movement range of a telescoping driveshaft is determined by the length of the splined interface between the inner and outer shafts. A longer splined section provides a larger stroke length but also increases the overall length and weight of the driveshaft. Engineers must balance the required stroke length with the space constraints of the application to ensure that the driveshaft fits within the available envelope.

3. Angular Misalignment Tolerance

Angular misalignment tolerance refers to the maximum angle at which the input and output shafts can be misaligned relative to each other while the driveshaft still transmits torque efficiently. This parameter is determined by the type of universal joints or CV joints used in the driveshaft design. Traditional universal joints can typically accommodate angular misalignment of up to 30 degrees, while CV joints can handle much larger angles (up to 70 degrees or more) and transmit torque at a constant velocity.

When selecting a telescoping driveshaft, it is important to match the angular misalignment tolerance of the driveshaft to the requirements of the application. Applications with large angular misalignment (e.g., automotive steering systems, robotic arms) require driveshafts with CV joints, while applications with moderate misalignment (e.g., industrial conveyors, agricultural PTO shafts) may use driveshafts with traditional universal joints. Failure to account for angular misalignment can lead to increased wear, vibration, noise, and reduced service life of the driveshaft.

4. Operating Speed

Operating speed (measured in revolutions per minute, RPM) is another critical design consideration, as it affects the dynamic performance of the telescoping driveshaft. At high speeds, the driveshaft is subject to centrifugal forces, which can cause vibration, imbalance, and fatigue failure if not properly designed. The maximum operating speed of a telescoping driveshaft is determined by several factors, including the diameter and material of the shafts, the balance of the driveshaft assembly, and the type of bearings used in the universal joints or CV joints.

High-speed applications (e.g., automotive racing, high-performance industrial machinery) require telescoping driveshafts that are precision-balanced to minimize vibration. Lightweight materials such as aluminum or carbon fiber composites are often used in these applications to reduce rotational mass, which helps to reduce centrifugal forces and improve balance. Additionally, high-speed bearings with low friction and high precision are required to ensure smooth operation at elevated RPMs.

5. Environmental Conditions

The environmental conditions in which the telescoping driveshaft operates have a significant impact on its performance and service life. Factors such as temperature, humidity, corrosion, dust, dirt, moisture, and chemicals must be considered when selecting the material, lubrication, and sealing of the driveshaft.

For high-temperature applications (e.g., near engines or furnaces), driveshafts made from heat-resistant materials such as high-temperature alloys or stainless steel are required. In corrosive environments (e.g., marine, chemical processing, agricultural), corrosion-resistant materials and protective coatings are essential to prevent rust and degradation. Sealed bearings and lubrication systems are also critical in these environments to prevent contamination of the splined interface and bearings by moisture, dust, or chemicals. In dusty or dirty environments (e.g., construction, mining), protective boots or covers can be used to shield the driveshaft from debris, reducing wear and extending service life.

6. Material Selection

The selection of materials for a telescoping driveshaft is critical to its performance, durability, and cost. The most common materials used for telescoping driveshafts include carbon steel, alloy steel, aluminum, and carbon fiber composites. Carbon steel is widely used for light-duty and medium-duty applications due to its low cost and good strength. Alloy steel (e.g., 4140, 4340) is used for heavy-duty applications, as it offers higher strength, toughness, and wear resistance than carbon steel.

Aluminum is used in applications where weight reduction is a priority (e.g., automotive racing, aerospace), as it is lighter than steel while still offering good strength. Carbon fiber composites are the lightest and strongest material option, making them ideal for high-performance applications where weight reduction and high strength are critical. However, carbon fiber composites are also the most expensive, limiting their use to specialized applications.

The splined interface and universal joints or CV joints are typically made from high-strength, wear-resistant materials such as heat-treated alloy steel or stainless steel. Bearings used in the joints may be made from steel, ceramic, or other materials, depending on the application's speed and load requirements.

7. Cost

Cost is always a consideration in engineering design, and telescoping driveshafts are available at a wide range of price points, depending on their design, material, and performance characteristics. Simple splined telescoping driveshafts made from carbon steel are the most economical option, making them suitable for light-duty and non-critical applications. Heavy-duty driveshafts made from alloy steel, or precision driveshafts made from aluminum or carbon fiber composites, are more expensive but offer superior performance and durability.

When selecting a telescoping driveshaft, engineers must balance cost with performance requirements and the criticality of the application. For non-critical applications with moderate requirements, a lower-cost carbon steel driveshaft may be sufficient. For critical applications where reliability and performance are paramount (e.g., automotive safety systems, heavy machinery), a higher-cost, high-performance driveshaft is justified.

Proper maintenance is essential to ensure the long-term performance, reliability, and safety of telescoping driveshafts. Regular maintenance can help to prevent premature failure, reduce downtime, and extend the service life of the driveshaft and the associated power transmission components. The key maintenance practices for telescoping driveshafts include lubrication, inspection, alignment checks, and replacement of worn components. Below is a detailed overview of each of these practices.

1. Lubrication

Lubrication is the most important maintenance task for telescoping driveshafts, as it reduces friction between the splined interface and the bearings in the universal joints or CV joints, prevents wear, and protects against corrosion. The type of lubricant used depends on the application's operating conditions, such as temperature, speed, and environmental conditions. Common lubricants for telescoping driveshafts include grease (for most applications) and oil (for high-speed or high-temperature applications).

The lubricant should be applied regularly according to the manufacturer's recommendations, which typically range from every 500 to 2000 operating hours for grease-lubricated driveshafts. It is important to ensure that the lubricant reaches all moving parts of the driveshaft, including the splined interface, bearings, and joints. Sealed driveshafts may require less frequent lubrication, but the seals should be checked regularly to ensure they are intact and preventing lubricant leakage. In corrosive or dusty environments, more frequent lubrication may be necessary to prevent contamination of the lubricant and wear of the driveshaft components.

2. Inspection

Regular inspection of telescoping driveshafts is critical to identifying potential issues before they lead to failure. Inspections should be performed at regular intervals (e.g., monthly, quarterly, or annually, depending on the application) and should include a visual examination of the driveshaft components, as well as functional tests to check for excessive play, noise, or vibration.

Key items to inspect include: the splined interface for signs of wear, corrosion, or damage (e.g., chipped splines, excessive clearance); the universal joints or CV joints for excessive play, noise, or leakage of lubricant; the seals and boots for cracks, tears, or damage (which can allow contamination of the driveshaft components); and the fasteners (e.g., bolts, nuts, clamps) for tightness. In addition, the driveshaft should be checked for balance, as an unbalanced driveshaft can cause vibration and premature wear.

In applications where the driveshaft is exposed to harsh environmental conditions (e.g., construction, marine), more frequent inspections are recommended. Any signs of wear, damage, or abnormal operation should be addressed immediately to prevent further damage to the driveshaft or other components.

3. Alignment Checks

Proper alignment of the input and output shafts is critical for the performance and longevity of telescoping driveshafts. Misalignment beyond the driveshaft's tolerance can cause increased wear on the splined interface and joints, vibration, noise, and premature failure. Regular alignment checks should be performed to ensure that the shafts are aligned within the driveshaft's specified limits.

Alignment checks can be performed using simple tools such as a straightedge and feeler gauge for basic applications, or more precise tools such as laser alignment systems for high-precision applications. The alignment should be checked both when the system is at rest and during operation (if possible), as dynamic conditions can cause changes in alignment. If misalignment is detected, the shafts should be adjusted or the mounts should be repaired to correct the alignment.

4. Replacement of Worn Components

Over time, the components of a telescoping driveshaft (such as the splined interface, bearings, joints, seals, and boots) will wear out and need to be replaced. Worn components should be replaced as soon as they are detected to prevent further damage to the driveshaft and the associated power transmission system. When replacing components, it is important to use parts that are compatible with the original driveshaft design to ensure proper fit and performance.

In some cases, it may be more cost-effective to replace the entire driveshaft rather than individual components, especially if multiple components are worn or damaged. For example, if the splined interface is severely worn and the universal joints are also failing, replacing the entire driveshaft may be more economical than replacing each component separately. Additionally, replacing the driveshaft ensures that all components are matched and functioning properly together.

Telescoping driveshafts are essential components in power transmission systems that require torque transmission between components with dynamic axial movement. Their unique design, which combines a telescoping splined section with universal joints or CV joints, enables them to accommodate both axial displacement and angular misalignment, making them versatile and indispensable across a wide range of industries. From automotive vehicles and construction machinery to agricultural equipment and industrial automation systems, telescoping driveshafts play a critical role in ensuring the reliable and efficient operation of mechanical systems.

When designing or selecting a telescoping driveshaft, engineers must carefully consider key factors such as torque capacity, axial movement range, angular misalignment tolerance, operating speed, environmental conditions, material selection, and cost. By matching the driveshaft's characteristics to the specific requirements of the application, they can ensure optimal performance and longevity. Proper maintenance, including regular lubrication, inspection, alignment checks, and replacement of worn components, is also essential to extend the service life of the driveshaft and prevent premature failure.

As technology continues to advance, telescoping driveshafts are likely to become even more efficient, lightweight, and durable. Advances in materials science, such as the development of new high-strength, lightweight composites, will enable the design of driveshafts that offer superior performance while reducing weight and improving fuel efficiency. Additionally, the integration of sensors and monitoring systems into telescoping driveshafts may enable real-time monitoring of their performance, allowing for predictive maintenance and further reducing downtime.

In summary, telescoping driveshafts are a critical innovation in power transmission technology, providing the flexibility and reliability needed to meet the demands of dynamic mechanical systems. By understanding their design, functionality, applications, and maintenance requirements, engineers and technicians can select and use these components effectively, ensuring the reliable and efficient operation of the systems they power.

« Telescoping Driveshafts » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/telescoping-driveshafts.html