-

SWC-BH Cardan Shaft

SWC-BH Standard Telescopic Welded Universal Joint CouplingView More -

SWC-CH Cardan Shaft

SWC-CH Long Telescopic Welded Universal Joint CouplingView More -

SWC-DH Cardan Shaft

SWC-DH Short Telescopic Welded Universal Joint CouplingView More -

SWC-WD Cardan Shaft

SWC-WD Non-telescopic Short Universal Joint CouplingView More -

SWC-WH Cardan Shaft

SWC-WH Non-telescopic Welded Universal Joint CouplingView More -

SWP-A Cardan Shaft

SWP-A Has A Telescopic Long Cross Universal Joint CouplingView More -

SWP-B Cardan Shaft

SWP-B Has A Telescopic Short Cross Universal Joint CouplingView More -

SWP-C Cardan Shaft

SWP-C Non-telescopic Short Cross Universal Joint CouplingView More -

SWP-D Cardan Shaft

SWP-D Non-telescopic Long Cross Universal Joint CouplingView More

Cardan shaft is a key component widely used in mechanical transmission systems, which can achieve reliable torque transmission even when the two axis lines do not coincide (there is an angle). Unlike ordinary couplings, the unique feature of universal couplings is that they allow the two connected shafts to swing relative to each other within a certain angle range, while maintaining the continuity of power transmission. This characteristic makes it an indispensable transmission component in many industrial applications, especially suitable for situations that require compensation for axis offset or angle changes.

The standard universal joint coupling mainly consists of the following key components:

- Cross shaft: It is the core component of a universal joint, shaped like a cross, with bearings installed at all four ends

- Bearing components: usually using needle roller bearings or sliding bearings, installed at the end of the cross shaft

- Fork shaped joint: Two Y-shaped connectors, respectively connected to the driving shaft and the driven shaft

- Flange or spline connection: used to fixedly connect the coupling with the drive shaft and the driven shaft

- Lubrication system: including oil nozzles and sealing devices to ensure long-term reliable operation of bearings

There are various variants of modern universal couplings in design, such as double cross shaft structure, ball cage structure, etc., to meet different application requirements.

The working principle of universal shaft coupling is based on the rotation and swing characteristics of the cross axis:

- When the active shaft rotates, it drives the fork joint connected to it to rotate

- The fork shaped joint transmits rotational motion to another fork shaped joint through a cross axis

- The driven fork joint then transmits the motion to the driven shaft

- The cross axis can freely swing with the change of the angle between the two axes during rotation

It is worth noting that the single cross axis universal joint will generate periodic speed fluctuations (uneven output shaft speed) during the transmission process, which will intensify with the increase of the angle between the two shafts. To eliminate this problem, a dual universal joint arrangement is often used in practical applications, which achieves uniform speed transmission through phase adjustment.

According to their structure and application characteristics, universal couplings can be divided into the following main types:

- Cross axis universal joint coupling:

The most common basic types

Simple structure and low manufacturing cost

The allowable angle deviation is usually 15 ° -25 ° - Ball cage universal joint coupling:

Adopting a spherical structure design

The transmission is smoother and the vibration is smaller

Allowable angle up to 45 °

Widely used in automotive drive systems - Double cross axis universal joint coupling:

Composed of two cross axis structures connected in series

Can eliminate speed fluctuations

Suitable for high-power transmission applications - Flexible universal joint coupling:

Replacing metal cross shafts with elastic components

Absorbable vibration and impact

Suitable for precision transmission systems - Constant speed universal joint coupling:

Special design ensures constant input and output speed

Widely used in front wheel drive systems for automobiles

When choosing a cardan shaft coupling, the following key parameters need to be considered:

- Torque Capacity: The maximum torque that the coupling can transmit (Nm)

- Speed range: maximum allowable operating speed (rpm)

- Angle compensation capability: maximum allowable angle between two axes (°)

- Axial displacement compensation: allowable axial displacement (mm)

- Radial displacement compensation: allowable radial offset (mm)

- Working temperature range: the ambient temperature at which the coupling can work normally

- Inertia moment: an important parameter that affects the dynamic response characteristics of a system

- Weight: Especially important for high-speed applications

These parameters need to be matched and selected according to specific application scenarios to ensure the reliability and efficiency of the transmission system.

Cardan shafts are widely used in various industrial fields due to their unique performance advantages

- Automotive industry: transmission shaft connection, steering system, four-wheel drive system.

- Construction machinery: excavators, loaders, cranes.

- Steel metallurgy: rolling mill drive, continuous casting equipment, rolling mill adjustment device.

- Shipbuilding industry: propulsion systems, servo drive, deck machinery.

- Energy equipment: wind turbines, water turbines, gas turbines.

- Aerospace: Flight control system, engine transmission, landing gear mechanism.

- Industrial robots: Joint transmission, end effector, rotating platform.

The correct selection of universal joint requires consideration of the following factors:

- Application environment: including temperature, humidity, corrosiveness, etc

- Load characteristics: constant load, impulse load, or periodic load

- Motion parameters: speed, angle deviation, displacement compensation requirements

- Space limitations: Installation space size and shape restrictions

- Maintenance requirements: lubrication cycle, expected service life

- Cost factor: Balance between initial cost and maintenance cost

The selection process generally includes:

- Determine application requirements and operating conditions

- Calculate the required torque and speed

- Evaluate angle and displacement compensation requirements

- Consider environmental factors and special requirements

- Choose the appropriate type and specification of coupling

- Verify the rationality of the selection and make necessary adjustments

Proper installation and maintenance are crucial for the performance and lifespan of cardan shaft couplings

- Installation points:

Ensure that the two axes are aligned within the allowable deviation range

Follow the manufacturer's instructions for pre lubrication

Use appropriate tools to avoid violent installation

Check if all fasteners are tightened to the specified torque

After installation, manually rotate and check for any abnormal resistance - Maintenance suggestion:

Regularly check the coupling for any abnormal noise or vibration

Perform lubrication and maintenance according to the recommended cycle

Monitor the status of seals to prevent lubricant leakage

Regularly check the wear of bearings

Pay attention to the temperature changes of the coupling

Establish maintenance records and track usage status - Common faults and troubleshooting methods:

Abnormal vibration: check alignment and bearing wear

Overheating: Check lubrication and load conditions

Increased noise: Check for worn or loose components

Oil leakage: Replace the seal or check the oil seal

As a classic component in the field of mechanical transmission, cardan couplings are constantly expanding their application boundaries through material, process, and design innovation while maintaining their basic principles, meeting the increasingly high performance requirements of modern industry for transmission systems. By comparison, it can be seen that universal couplings have significant advantages in angle compensation, especially suitable for transmission situations where there is a large angle between the axis lines.

As a key component in mechanical transmission systems, universal joint couplings play an irreplaceable role in many industrial fields due to their unique angle compensation capability and reliable torque transmission performance. From automotive transmission systems to heavy machinery, from precision instruments to aerospace equipment, the application of universal couplings is ubiquitous. With the advancement of materials science and manufacturing technology, modern universal shafts are developing towards higher performance, longer lifespan, and greater intelligence, providing more comprehensive solutions for various complex transmission needs. The correct selection, installation, and maintenance of universal shaft couplings are of great significance for ensuring the reliability, efficiency, and service life of the entire transmission system.

Cases of Cardan Shaft

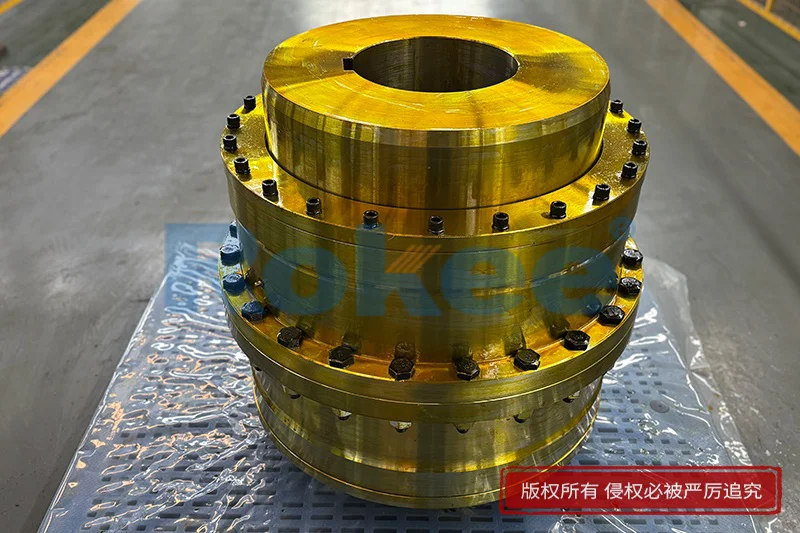

RODA Universal Gear Coupling

RODA Universal Gear Coupling Scalable Universal Joint Couplings

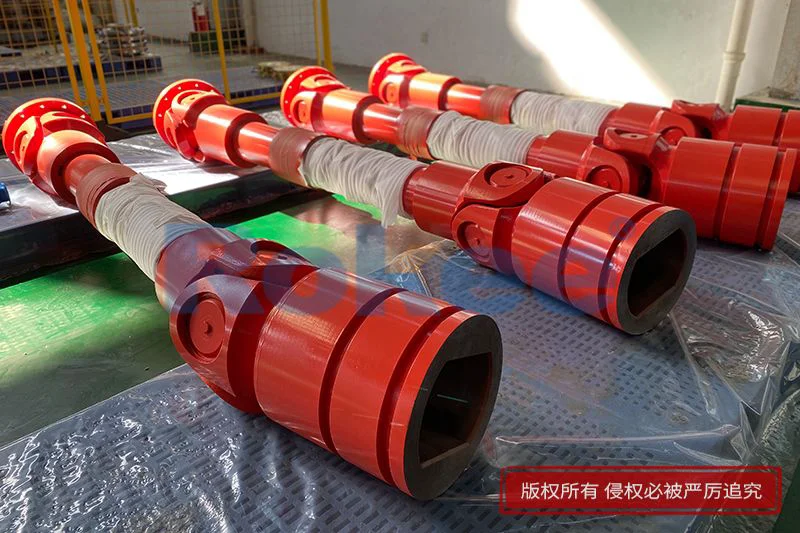

Scalable Universal Joint Couplings Double Universal Joint Coupling

Double Universal Joint Coupling Telescopic Universal Joint Drive Shaft

Telescopic Universal Joint Drive Shaft Long Type Universal Drive Shaft

Long Type Universal Drive Shaft Short Telescopic Cardan Shaft

Short Telescopic Cardan Shaft

Related Articles

- 2025-12-01Cardan Shaft Coupling For Edge Bonding Machine

- 2025-12-01Universal Shaft Joint For Metallurgical Machinery

- 2025-12-01Cross Type Universal Joint For Blender

- 2025-12-01Universal Cross Joint For CNC Machine

- 2025-12-01Universal Joint For Veneer Reeling Machine

- 2025-12-01Universal Shaft For Electric Motor

- 2025-12-01Universal Joint Shaft For Steel Mill

- 2025-12-01Universal Joint Coupling For Steering Gear Box

- 2025-12-01Universal Cross Joint Coupling For Vibrating Screen

- 2025-12-01Universal Joint Shaft Coupling For Bridge Crane

- 2025-12-01Universal Shaft Coupling For Roll Squeezer

- 2025-12-01Telescopic Universal Joint For Water Pump

- 2025-12-01Universal Coupling For Rotavator

- 2025-12-01Cross Cardan Shaft For Borehole Pump

- 2025-09-04Cross Cardan Shaft For Reducer

- 2025-09-04Universal Coupling For CNC Machine

- 2025-09-04Telescopic Universal Joint For Petroleum Machinery

- 2025-09-04Universal Shaft Coupling For Roller Bed

- 2025-09-04Universal Joint Shaft Coupling For Thread Roller

- 2025-09-04Universal Cross Joint Coupling For Screw Rolling Machine