-

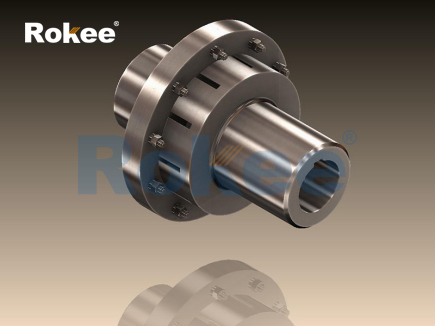

LM/ML Plum Blossom Coupling

LM/ML Plum Blossom Coupling is the basic form of this series of couplings.View More -

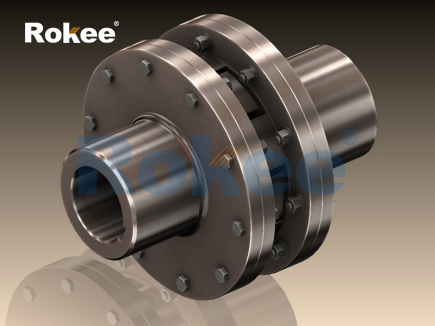

LMD/MLZ Plum Blossom Coupling

LMD/MLZ Plum Blossom Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

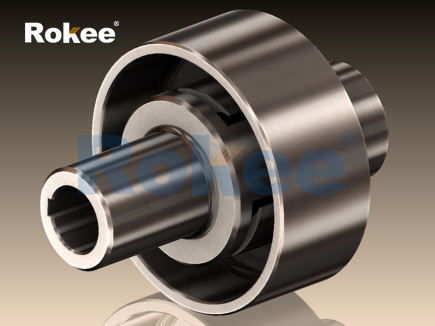

LMS/MLS Plum Blossom Coupling

LMS/MLS Plum Blossom Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

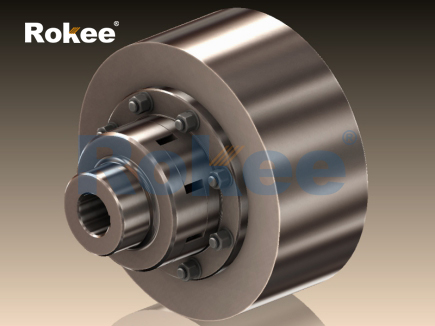

LMZ-I/MLL-I Plum Blossom Coupling

LMZ-I/MLL-I Plum Blossom Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Plum Blossom Coupling

LMZ-II/MLL-II Plum Blossom Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Plum Blossom Coupling

LMPK/MLPK Plum Blossom Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

Plum blossom coupling is a widely used elastic coupling, named after its core elastic element in a plum blossom shape. The plum coupling plays an important role in connecting and buffering mechanical transmission systems through its unique structural design, and is an indispensable transmission component in modern industrial equipment.

The claw coupling mainly consists of the following parts:

- Two metal shaft sleeves: usually made of high-quality steel or aluminum alloy, the surface is precision machined to ensure a tight fit with the shaft

- Plum shaped elastomer: a core component located between two shaft sleeves, made of highly elastic materials such as polyurethane and rubber

- Compression device: used to fix the elastic body and ensure the integrity of the coupling

The structural design of the jaw flex coupling enables it to adapt to a certain degree of axial, radial, and angular deviations, while effectively absorbing vibrations and impacts.

The plum blossom coupling transmits torque and compensates for shaft deviation through the deformation of the elastic body

- Torque transmission: The drive side shaft sleeve transmits torque to the driven side by compressing the "petals" of the elastic body

- Deviation compensation: The flexibility of the elastic body allows for a certain degree of parallelism, misalignment, and axial displacement between the two axes

- Vibration reduction function: The damping characteristics of the elastomer can absorb and reduce vibrations and impacts in the transmission system

Main performance advantages of claw coupling

- Excellent damping and buffering performance: can reduce system vibration by 30-50%

- Good misalignment compensation capability: typically allows for an angle deviation of 0.5 ° -1 ° and a radial deviation of 0.2-0.5mm

- Gapless transmission: ensuring precise torque transmission

- Maintenance free design: No lubrication required, reducing maintenance costs

- Electrical insulation performance: effectively isolates current conduction between two axes

According to the different types of elastomers, plum couplings are mainly divided into the following categories:

- Standard plum blossom coupling: made of polyurethane elastomer, suitable for most general applications

- High temperature plum blossom coupling: using special high-temperature resistant elastic materials, it can withstand higher temperature environments

- Oil resistant plum blossom coupling: The elastic material has excellent oil resistance and is suitable for oil contaminated environments

- High elasticity plum blossom coupling: using a special formula of elastic material to provide higher flexibility and vibration reduction performance

- Double plum blossom coupling: using two sets of elastic bodies, providing greater compensation capability and higher torque transmission capability

The correct selection of claw coupling requires consideration of the following factors:

- Transmission torque: Calculate the required torque based on equipment power and speed

- Shaft diameter size: Ensure that the coupling matches the shaft diameter

- Work environment: Consider environmental factors such as temperature, humidity, and corrosive media

- Inaccurate situation: Evaluate the expected amount and type of misalignment of the system

- Speed requirement: Ensure that the rated speed of the selected model is higher than the actual working speed

- Space limitations: Consider size constraints for installation space

Installation steps of flexible claw coupling

- Check the fit dimensions of the shaft and coupling

- Clean the contact surface between the shaft and coupling

- Install the coupling onto the shaft using appropriate methods (hot or press fit)

- Ensure that the two axes are aligned within the allowable range

- Gradually tighten the fixing bolts using a cross tightening method

Maintenance points of jaw coupling

- Regularly check the wear and aging of the elastomer

- Check the looseness of fasteners

- Monitor abnormal vibrations and noise during operation

- Avoid contact with corrosive chemicals and solvents

- When replacing the elastomer, the entire set should be replaced at the same time to maintain balance

Plum blossom couplings are widely used in the following industries and equipment:

- General machinery: pumps, fans, compressors, etc

- Machine tool industry: precision equipment such as CNC machine tools and machining centers

- Automation equipment: robots, conveyor systems, packaging machinery

- Power generation equipment: generators, wind turbines

- Shipbuilding industry: ship propulsion systems, deck machinery

- Rail Transit: Auxiliary Transmission Systems for Subway and High Speed Rail

The plum coupling occupies an important position in the field of mechanical transmission due to its excellent performance and reliability. Proper selection, installation, and maintenance of plum blossom couplings can significantly improve equipment operating efficiency, extend service life, and reduce maintenance costs.

Cases of Plum Blossom Couplings

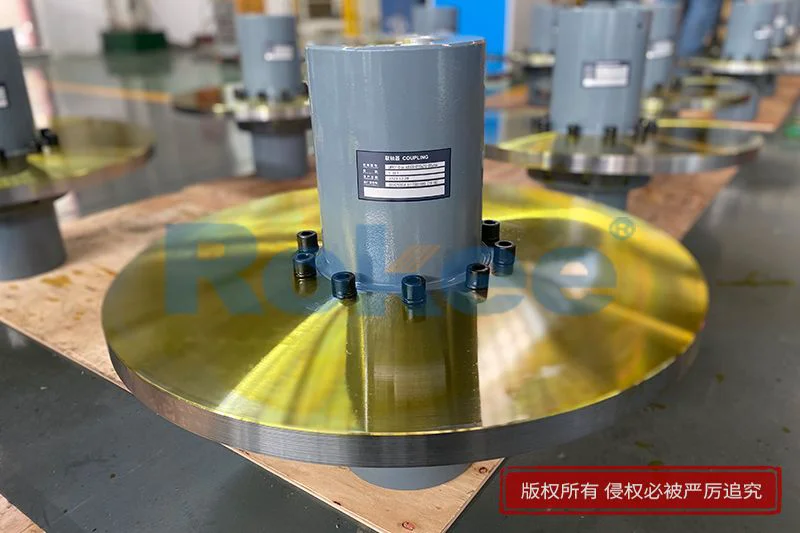

Plum Coupling With Brake Disc

Plum Coupling With Brake Disc Brake Disc Type Plum Blossom Coupling

Brake Disc Type Plum Blossom Coupling Claw Coupling With Brake Disc

Claw Coupling With Brake Disc Half Set Of Plum Blossom Coupling

Half Set Of Plum Blossom Coupling Claw Type Flexible Couplings

Claw Type Flexible Couplings ML Plum Coupling

ML Plum Coupling

Related Articles

- 2025-02-27Plum Blossom Coupling For Injection Moulding Machine

- 2024-09-27Plum Coupling For Diesel Engine

- 2024-09-27Misalignment Tolerance of Plum-shaped Coupling

- 2024-09-27Plum Blossom Coupling For Guideway

- 2024-09-20Advantages of Plum-shaped Coupling

- 2024-09-20Plum Blossom Coupling For Reaping Machine

- 2024-09-10Claw Coupling For Servo-actuator

- 2024-09-10Plum Coupling For Agricultural Machinery

- 2024-09-10Uses of Plum-shaped Coupling

- 2024-09-10Plum Blossom Coupling For Slideway

- 2024-09-04Claw Coupling For Servo Motor

- 2024-09-04Plum Coupling For Farm Machinery

- 2024-09-04Schematic Diagram of Plum-shaped Couplings

- 2024-09-04Plum Blossom Coupling For Oil Pump

- 2024-08-28Working Principle of Plum-shaped Couplings

- 2024-08-28Plum Blossom Coupling For CNC Lathe

- 2024-08-13Claw Coupling For Actuating Motor

- 2024-08-13Plum Coupling For Servo Motor

- 2024-08-13Parts of Plum-shaped Coupling

- 2024-08-13Plum Blossom Coupling For Plunger Pump