-

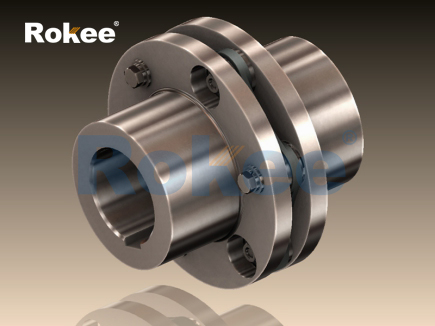

JMI Diaphragm Coupling

JMI diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMIJ Diaphragm Coupling

JMIJ diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMII Diaphragm Coupling

JMII diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

JMIIJ Diaphragm Coupling

JMIIJ diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Diaphragm coupling is a high-performance flexible coupling that uses one or more sets of metal diaphragms as elastic elements to transmit torque and compensate for shaft system deviations. Compared with traditional gear couplings or elastic couplings, steel laminae couplings have the characteristics of zero clearance, maintenance free, and high reliability, making them particularly suitable for situations that require precise transmission. Its typical applications include turbomachinery, compressors, pumps, generators, marine propulsion systems, and various precision mechanical equipment.

The core of the flexible diaphragm coupling lies in its unique elastic element - the metal diaphragm group. These membranes are usually made of high-strength stainless steel and connected to the driving shaft and driven shaft through a special arrangement. When the driving shaft rotates, torque is transmitted to the driven shaft through the elastic deformation of the diaphragm, while allowing for a certain degree of axial, radial, and angular deviation.

The elastic deformation ability of the diaphragm enables the coupling to compensate for the following deviations:

- Axial displacement: the relative movement of two axes along the axis direction

- Radial displacement: parallel offset between the centerlines of two axes

- Angular displacement: the angle between the centerlines of two axes

- Torsion displacement: relative torsion caused by instantaneous load changes

According to the arrangement and structural characteristics of the membrane, flexible membrane couplings can be divided into several main types:

- Single diaphragm coupling

Composed of a set of membranes, the structure is simple and compact, suitable for situations with moderate torque transmission and small deviation compensation. Its characteristic is small axial size, but relatively limited compensation capability. - Double diaphragm coupling

The two sets of membranes are connected through an intermediate, which has better deviation compensation ability, especially for angular and axial deviations. This structure can effectively reduce bearing load and extend equipment life. - Multi diaphragm coupling

The complex structure using three or more membrane groups is suitable for situations requiring high torque transmission and high precision, such as large generator sets, ship propulsion systems, etc. - Special structure diaphragm coupling

Including special designs such as ultra long distance couplings with intermediate shafts and vibration reducing couplings with damping characteristics, to meet specific working conditions.

Steel laminae couplings are widely used in modern industry, mainly due to their excellent performance characteristics:

- High torsional stiffness: The metal diaphragm provides nearly rigid torque transmission, ensuring transmission accuracy

- Zero backlash: No sliding parts, eliminating backlash and hysteresis during the transmission process

- Maintenance free: No lubrication required, reducing downtime and maintenance costs

- Long lifespan: The metal diaphragm has high fatigue strength and a service life of several decades

- Strong compensation capability: can simultaneously compensate for multiple shaft system deviations

- High temperature resistance: suitable for high temperature environments, with a wide range of working temperatures

- Lightweight: lighter than traditional couplings, reducing rotational inertia

- Good balance: minimal vibration during high-speed operation, suitable for high-speed applications

The correct selection of diaphragm couplings requires consideration of multiple factors:

- Torque requirements: including rated torque, peak torque, and starting torque

- Speed range: consideration of working speed and critical speed

- Axis deviation: expected axial, radial, and angular deviations

- Environmental conditions: external factors such as temperature, corrosiveness, humidity, etc

- Space limitations: radial and axial dimensions of installation space

- Inertia matching: the influence of rotational inertia on the dynamic response of the system

- Special requirements: such as explosion-proof, food grade, vacuum environment and other special working conditions

Precautions for installation of steel laminae coupling:

- Ensure that the shaft end clearance meets the manufacturer's requirements

- Use specialized tools for alignment and control deviations within the allowable range

- Bolt tightening should be carried out according to the specified torque and sequence

- Avoid forced installation that may cause pre deformation of the membrane

Maintenance suggestions for shim pack couplings:

- Regularly check the tightening status of bolts

- Monitor vibration and temperature changes

- Observe whether there are visible cracks or deformations in the membrane

- Shorten the inspection cycle appropriately under extreme working conditions

The excellent performance of steel laminae couplings has made them widely used in many industrial fields:

- Energy industry: shaft connections for gas turbines, steam turbines, and generator sets

- Petrochemical industry: rotating equipment such as compressors, pumps, fans, etc

- Shipbuilding industry: main propulsion system, auxiliary transmission

- Steel metallurgy: heavy equipment such as rolling mills and fans

- Aerospace: Auxiliary power units, testing equipment

- Precision machinery: high-precision transmission for CNC machine tools, semiconductor equipment, etc

Diaphragm couplings as an efficient and reliable transmission component, play an increasingly important role in modern industry. With the continuous advancement of technology, its application scope will be further expanded, and its performance will continue to improve, providing more excellent connection solutions for various mechanical systems.

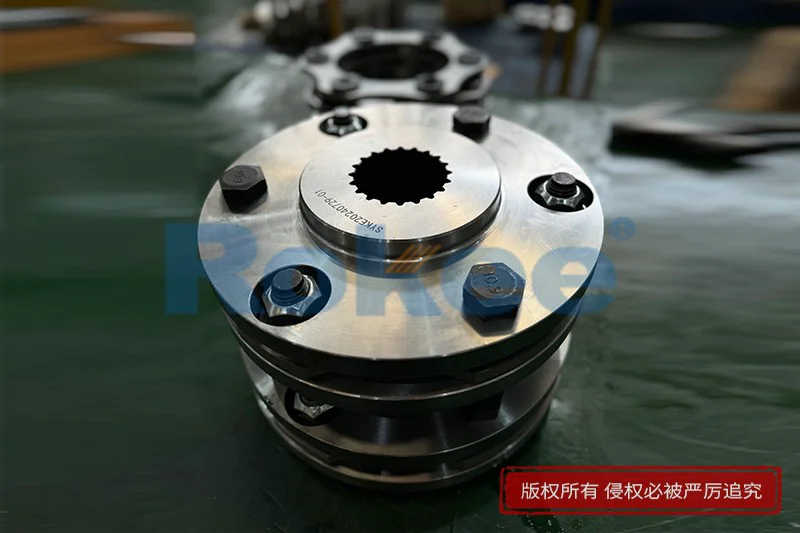

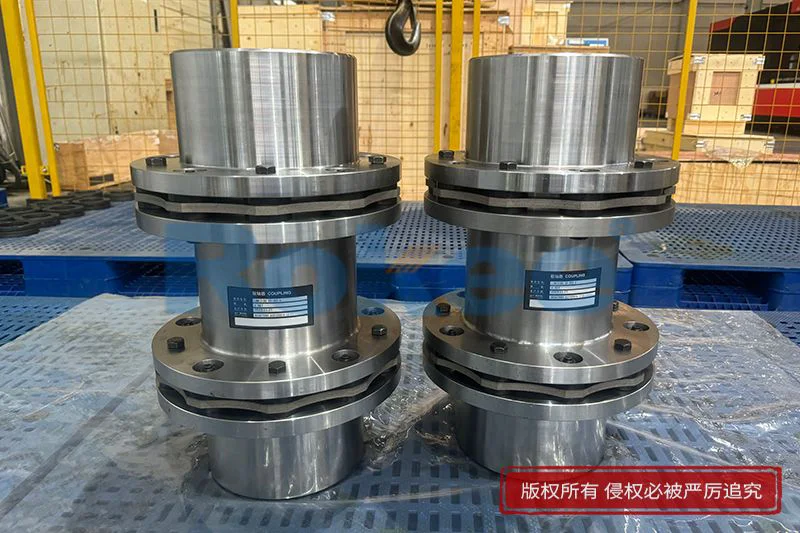

Cases of Steel Laminae Couplings

High Speed Diaphragm Couplings

High Speed Diaphragm Couplings Double Diaphragm Coupling Exported To Russia

Double Diaphragm Coupling Exported To Russia Diaphragm Coupling For Pumps

Diaphragm Coupling For Pumps Stainless Steel Laminated Coupling

Stainless Steel Laminated Coupling Metal Laminated Flexible Coupling

Metal Laminated Flexible Coupling Double Diaphragm Flexible Coupling

Double Diaphragm Flexible Coupling

Related Articles

- 2025-03-31Steel Laminae Coupling For Cement Mill

- 2025-03-31Flexible Diaphragm Coupling For Air Compressor

- 2025-03-31Lamina Coupling For Circulation Pump

- 2024-10-22Metal Diaphragm Coupling For Vertical Pump

- 2024-09-27Steel Laminae Coupling For Air Compressor

- 2024-09-27Metal Diaphragm Coupling For Ball Mill

- 2024-09-27Laminated Membrane Coupling For Blower

- 2024-09-27Steel Laminae Coupling For Reducer

- 2024-09-27Flexible Diaphragm Coupling For Cooling Tower

- 2024-09-20Single Diaphragm Couplings Picture

- 2024-09-20Grease of Double Diaphragm Coupling

- 2024-09-10Flexible Diaphragm Coupling For Silking Machine

- 2024-09-10Steel Laminae Coupling For Water Pump

- 2024-09-10Metal Diaphragm Coupling For Air Compressor

- 2024-09-10Catalogue of Single Diaphragm Couplings

- 2024-09-10Double Diaphragm Coupling Models

- 2024-09-04Flexible Diaphragm Coupling For Compressor

- 2024-09-04Steel Laminae Coupling For Circulation Pump

- 2024-09-04Laminated Membrane Coupling For Cement Mill

- 2024-09-04Metal Diaphragm Coupling For Mining Machinery