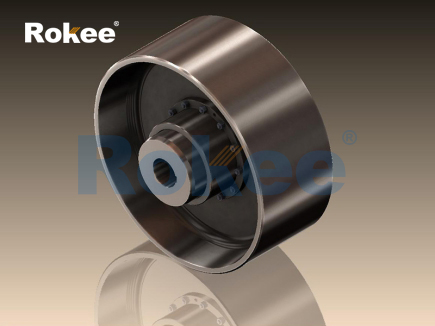

Rokee is a well-known high-quality supplier of Brake Drum Geared Couplings and technical services in China, customize brake drum geared couplings according to user drawings, alternatively, if the user provides brake drum geared couplings parameters, we can select the model and design drawings for you, support wholesale and export.

The Brake Drum Geared Coupling is an advanced mechanical transmission device that integrates braking function. It perfectly combines traditional drum gear couplings with braking systems and has a wide range of applications in modern industrial transmission fields. This type of coupling can not only transmit torque, compensate for axial, radial, and angular deviations, but also achieve rapid braking when needed, providing dual safety guarantees for mechanical equipment.

Compared with traditional couplings, Drum Geared Couplings have significant advantages such as compact structure, fast braking response, and easy maintenance. It is particularly suitable for situations that require precise control of stopping position or emergency braking, such as cranes, mining machinery, metallurgical equipment, port machinery, and other fields. Its unique design enables it to maintain stable transmission performance and reliable braking effect even under high load and high-speed conditions.

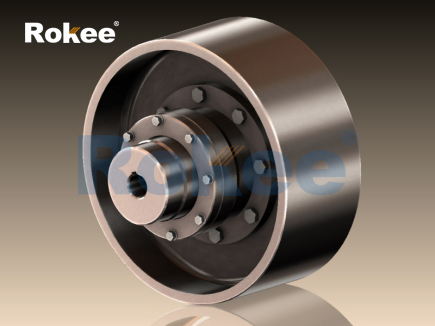

The Brake Drum Geared Coupling consists of several core components, each of which plays an irreplaceable role:

Drum shaped gear meshing part: This is the core transmission component of the coupling, consisting of an outer gear sleeve and an inner gear ring. The tooth shape of the outer gear sleeve is designed in a drum shape, which allows for a larger deflection angle (usually up to 1.5 ° -3 °) and effectively reduces edge contact stress. The internal gear ring adopts a standard involute tooth profile, forming a precise fit with the drum shaped external teeth.

Braking system: The braking device integrated on the coupling usually adopts a friction plate or multi plate design, including:

Brake discs/brake drums

Friction materials

Brake cylinder (hydraulic or pneumatic)

return spring

Brake control unit

Connecting flange and shaft sleeve: used to connect with the drive shaft and the driven shaft, usually using various connection methods such as keyway, expansion sleeve or clamping ring to meet different application needs.

Sealing and lubrication system: including dust-proof sealing rings, lubricating oil passages, and oil nozzles, to ensure that the internal gears maintain good lubrication for a long time and prevent pollutants from entering.

Shell and protective cover: Protect internal mechanisms from external environmental influences while preventing lubricant leakage.

When the equipment is operating normally, power is transmitted to the coupling through the input shaft, and the meshing between the drum shaped outer teeth and the inner gear ring transmits torque. The drum design allows for a certain degree of axial, radial, and angular deviation, effectively absorbing and compensating for installation errors, thermal expansion of the shaft, and vibration during equipment operation. Lubricating oil forms a protective film on the tooth surface, reducing wear and lowering noise.

When stopping or emergency braking is required, the control system sends a signal, and the braking mechanism (usually through hydraulic, pneumatic, or electromagnetic force) presses the friction plate against the brake disc or drum, generating braking torque. The magnitude of braking force can be precisely controlled by adjusting pressure to achieve smooth braking or emergency stop. After the brake is released, the reset spring quickly returns the friction plate to its original position, restoring the transmission function.

High torque density: Achieving high torque transmission under compact design

Excellent deviation compensation capability: simultaneously compensating for radial, axial, and angular deviations

Quick response braking: braking time can be controlled in milliseconds

Maintenance free or long maintenance cycle: High quality sealing and lubrication system extends service life

Modular design: brake units of different specifications can be configured according to different needs

Overload protection: Some designs have torque limiting function to prevent equipment damage

Due to its unique advantages, the brake drum geared coupling has been widely used in multiple industrial fields

Lifting and transportation machinery:

Bridge/gantry crane lifting mechanism

Port container crane

Tower crane slewing mechanism

Provide precise parking and emergency braking functions

Mining metallurgical equipment:

Mine hoist

Rolling mill transmission system

Continuous casting equipment

Endure heavy loads and impact loads

Energy and electricity:

Wind turbine generator set (yaw and pitch system)

Water turbine generator set

Provide reliable braking to ensure equipment safety

Ship and Ocean Engineering:

Ship propulsion system

Deck machinery (winches, cranes)

Corrosion resistant design suitable for marine environment

Other industries:

Large scale construction machinery

Oil drilling and production equipment

Papermaking machinery

Rubber and Plastic Machinery

As an outstanding representative of modern transmission technology, the brake Drum Geared Coupling perfectly combines efficient power transmission and reliable braking performance, providing safe and efficient transmission solutions for various industrial equipment. With the advancement of Industry 4.0 and intelligent manufacturing, this type of coupling will continue to develop towards intelligence and high performance, meeting the growing demand for industrial automation.

Correctly selecting, installing, and maintaining the brake Drum Gear Coupling can not only ensure long-term stable operation of the equipment, but also significantly extend its service life and reduce overall operating costs. For any transmission application that requires precise control and safe braking, this type of coupling is worth serious consideration.

« Brake Drum Geared Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/brake-drum-geared-couplings.html