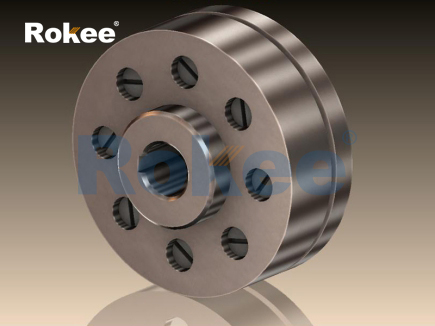

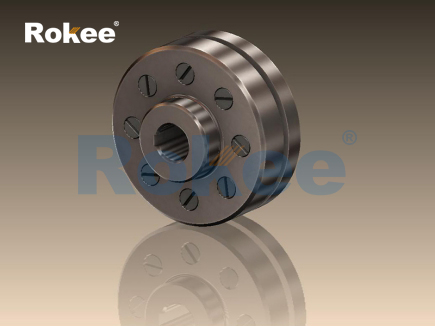

Rokee is a well-known high-quality supplier of Bush Couplings and technical services in China, customize bush couplings according to user drawings, alternatively, if the user provides bush couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Bush Coupling is a flexible connection device widely used in industrial machinery transmission systems, which achieves power transmission by introducing elastic sleeve materials between shafts. This type of coupling is widely used in various mechanical equipment due to its advantages of simple structure, easy installation, and low maintenance cost.

Compared with traditional rigid couplings, the biggest feature of Bush Couplings is the absorption and compensation of shaft system deviations, including axial, radial, and angular deviations, through elastic elements (sleeves). This design significantly reduces the requirement for precise alignment in the transmission system, effectively alleviates impact and vibration, and extends the service life of the equipment.

A typical bushing coupling consists of the following main components:

Wheel hub assembly: usually consists of two metal wheels, installed on the drive shaft and driven shaft respectively, fixed by keyway or clamping method

Elastic bushing: The core component of a coupling, made of rubber, polyurethane, or other elastic materials, providing necessary flexibility and damping characteristics

Connecting bolt: used to connect two wheel hubs and the middle lining into a whole

Protective cover (optional): Some models are equipped with protective covers to prevent external contamination and ensure safe operation

It is worth noting that the structural design of modern Bush Couplings continues to innovate, with many variants emerging to meet different application needs.

Standard bushing coupling

The most common type is cylindrical elastic lining, suitable for general industrial applications. Its characteristics are simple structure, high cost-effectiveness, and the ability to compensate for moderate shaft deviation.

Claw shaped bushing coupling

There are interlocking claws designed on the end face of the wheel hub, with elastic bushings clamped in the middle. This design improves torque transmission capability while maintaining good vibration damping performance.

Tire type liner coupling

Adopting circular tire shaped elastic elements, it has greater angle compensation capability (usually up to 5-7 degrees), especially suitable for situations with significant misalignment.

Diaphragm Bush Coupling

Combining the advantages of metal diaphragms and elastic bushings, it maintains high torque capacity while providing good flexibility, and is commonly used in high-precision transmission systems.

Separated Bush Coupling

Designed as a detachable structure, it allows for the replacement of bushings without moving the equipment, greatly simplifying maintenance work.

The Bush Coupling transmits torque and compensates for deviation through elastic deformation, and its working principle can be divided into several aspects:

Torque transmission: The driving wheel hub transmits rotational motion to the driven wheel hub through a compressed elastic bushing

Deviation compensation:

Axial deviation: The liner deforms under axial compression

Radial deviation: The lining undergoes shear deformation

Angular deviation: The liner exhibits uneven compression state

Vibration absorption: The damping characteristics of elastic materials effectively absorb and isolate vibrations from the driving or load end

Impact mitigation: The elastic deformation of the liner slows down the transmission of impact force during start-up or sudden load changes

This working principle makes the Bush Coupling particularly suitable for situations where there is a certain installation error or displacement during operation.

Advantages:

Good deviation compensation capability: can simultaneously compensate for axial, radial, and angular deviations

Excellent vibration reduction performance: effectively reducing the vibration and noise of the transmission system

Electrical insulation: Non metallic bushings provide electrical isolation between shafts

No lubrication required: Most Bush Couplings are designed for maintenance free use

Overload protection: In extreme cases, the liner may be damaged before other components, protecting more expensive equipment

Easy to install: usually does not require special tools or complex alignment processes

limitations:

Limited torque capacity: Compared to some metal couplings, the ability to transmit torque is lower

Temperature limitation: The performance of elastic materials is greatly affected by temperature

Aging issue: Rubber and other materials may experience performance degradation over time

Twisted stiffness variation: Some lining materials may exhibit nonlinear stiffness characteristics

The correct selection of Bush Couplings requires consideration of multiple factors:

Torque requirements: including normal operating torque, peak torque, and starting torque

Shaft diameter size: Ensure that the coupling matches the shaft diameter

Deviation situation: Estimate the axial, radial, and angular deviations of the system

Speed range: Consider the influence of centrifugal force on the performance of the liner

Environmental conditions: external factors such as temperature, humidity, chemical contact, etc

Space limitations: Dimensional constraints on installation locations

Special requirements: such as explosion-proof, food grade certification, etc

Industry experience shows that when choosing a coupling, a safety factor of 20-30% is usually added to the rated torque to cope with unforeseeable changes in operating conditions.

Bush Couplings are widely used in various industrial fields, mainly including:

Pump equipment: centrifugal pumps, plunger pumps, etc., use their vibration reduction characteristics to protect the pump shaft

Fan system: Dealing with vibration problems caused by changes in airflow

Conveyor machinery: application of long shaft systems such as belt conveyors and chain conveyors

Power generation equipment: power connection for small generator sets

Construction machinery: equipment with significant vibration such as excavators and loaders

Food processing: application of liner materials that meet hygiene requirements

Shipbuilding industry: power transmission of auxiliary equipment

In the wind power industry, special lining couplings are used in the transmission system of small and medium-sized wind turbines; In automated production lines, precision Bush Couplings ensure accurate positioning of the robotic arm.

Installation steps:

Check the size matching of the shaft and coupling

Clean the surface of the shaft and the inner hole of the coupling

Use appropriate tools to install the wheel hub (avoid direct tapping)

Preliminary alignment (laser alignment instrument can achieve the best results)

Tighten the connecting bolts evenly in diagonal order

Check the final alignment status and gap

Maintenance suggestion:

Regularly check the wear and aging of the lining

Pay attention to the occurrence of abnormal vibrations or noise

Check the tightening status of bolts (recommended torque wrench)

Record the operating hours and replace the lining according to the manufacturer's recommended cycle

Avoid direct sunlight and extreme temperatures when storing spare parts

Experience has shown that good installation can extend the life of the liner by 30-50%, while neglecting alignment accuracy may lead to premature failure of the liner.

« Bush Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/bush-couplings.html