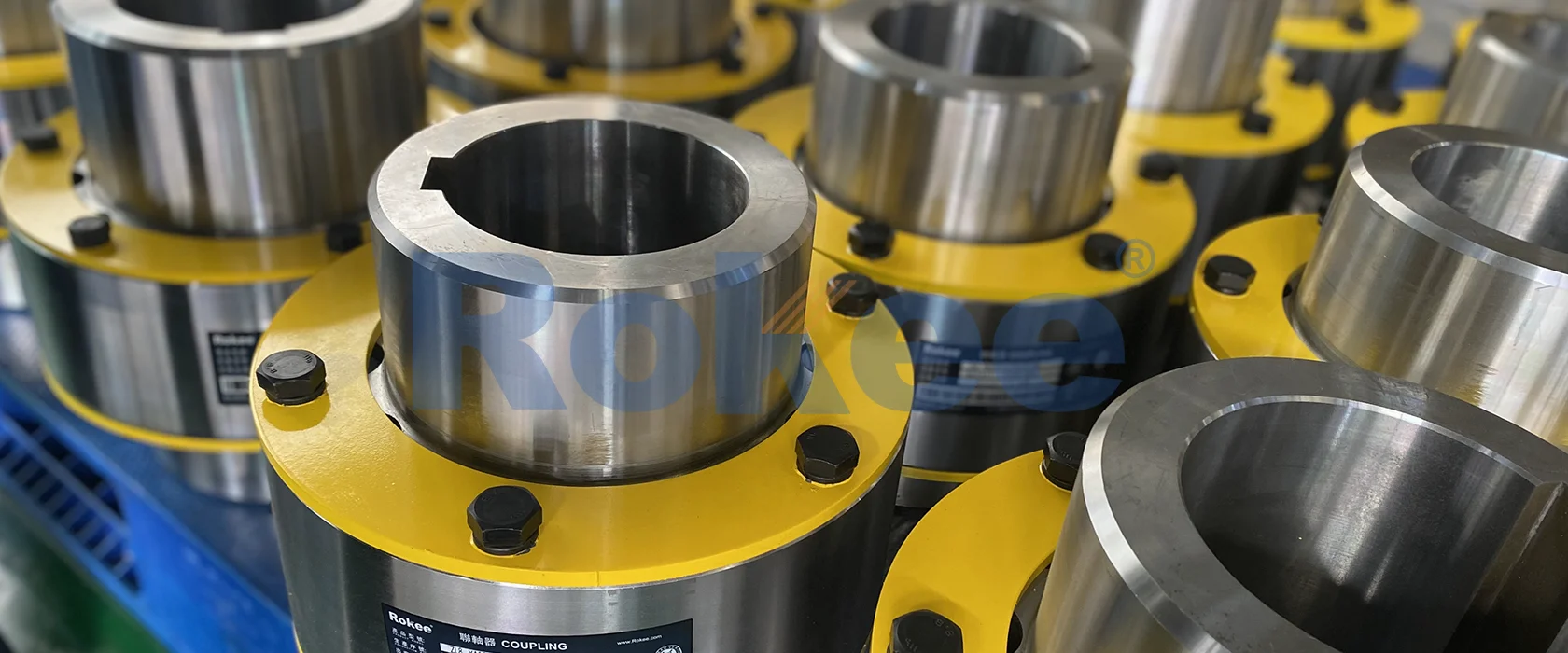

Rokee is a well-known high-quality supplier of Bush Pin Flexible Couplings and technical services in China, customize bush pin flexible couplings according to user drawings, alternatively, if the user provides bush pin flexible couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Bush Pin Flexible Coupling is a flexible coupling widely used in mechanical transmission systems. It connects two shafts through elastic elements (usually rubber or polyurethane elastic sleeves) and has the ability to compensate for axial, radial, and angular deviations. This type of coupling has been widely used in the industrial field due to its simple structure, easy maintenance, and excellent shock absorption performance.

The most prominent feature of the Bush Pin Flexible Coupling is the wrapping of an elastic material sleeve around the metal column pin. This design not only ensures the reliability of torque transmission, but also effectively buffers impact and absorbs vibration. Compared with rigid couplings, it can significantly reduce the additional load caused by centering errors in the transmission system and extend the service life of the equipment.

Half coupling: usually made of cast iron, cast steel or forged steel, divided into two parts: the driving end and the driven end

Column pin: made of high-strength alloy steel, surface hardened to improve wear resistance

Elastic sleeve: made of rubber or polyurethane material, with specific hardness and elastic modulus

Retaining ring: a safety device that prevents the elastic sleeve from falling off during operation

When the active half coupling rotates, the torque is transmitted to the elastic sleeve through the column pin, and then transmitted to the driven half coupling through the elastic sleeve. During this process:

The deformation of the elastic sleeve absorbs instantaneous impact loads

Elastic deformation compensation for slight deviation between two axes

The internal friction of polymer materials consumes vibration energy

Pump equipment: centrifugal pumps, reciprocating pumps, etc., to reduce the impact caused by water hammer effect

Fan system: induced draft fan, blower, etc., to reduce vibration caused by blade passing frequency

Conveyor machinery: Drive devices for belt conveyors and chain conveyors

Power generation equipment: small and medium-sized diesel generator sets, hydro generator sets

Construction machinery: heavy-duty starting equipment such as mixers and crushers

The Bush Pin Flexible Coupling continues to play an irreplaceable role in the industrial transmission field due to its excellent cost-effectiveness and reliable performance. Proper selection, installation, and maintenance of couplings can not only ensure stable operation of equipment, but also significantly reduce the overall lifecycle cost. With the application of new materials and technologies, this classic coupling type is emitting new vitality, continuing to provide efficient connection solutions for various mechanical systems.

In the realm of mechanical power transmission, couplings serve as indispensable components that bridge rotating shafts, enabling the seamless transfer of torque while accommodating inevitable deviations and mitigating operational stresses. Among the diverse array of coupling types, the bush pin flexible coupling stands out as a versatile and cost-effective solution, widely adopted across numerous industrial sectors for its balanced performance, simplicity in design, and adaptability to varied operating conditions. Unlike rigid couplings that demand precise alignment and offer no flexibility, this type of coupling integrates elastic elements to absorb shocks, dampen vibrations, and compensate for minor shaft misalignments, thereby safeguarding connected machinery and extending operational lifespan. Its utility spans from light-duty applications in small motors to medium-duty operations in pumps, conveyors, and industrial machinery, making it a cornerstone of modern mechanical systems.

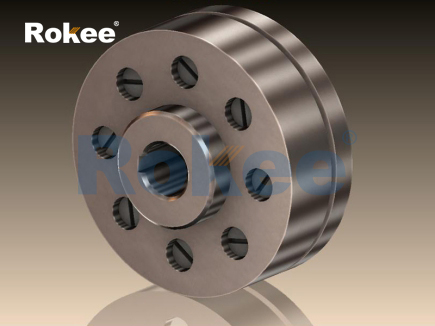

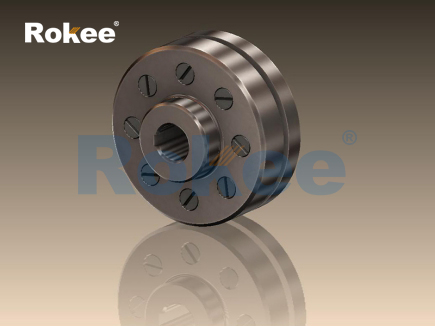

At its core, the bush pin flexible coupling comprises a set of fundamental components that work in tandem to fulfill its functional objectives. The primary elements include two flanged hubs, a series of pins, and corresponding bushes made from elastic or semi-elastic materials. Each hub is designed to be mounted on the respective shafts—one connected to the driving unit (such as an electric motor) and the other to the driven equipment (like a pump or compressor). The hubs are typically crafted from robust metallic materials to withstand the torque and mechanical loads encountered during operation, with common selections including cast iron, forged steel, and aluminum alloy, each chosen based on the specific torque requirements and environmental conditions of the application. Cast iron hubs are favored for general-purpose applications due to their durability and cost-effectiveness, while forged steel variants are employed in scenarios demanding higher torque capacity and resistance to wear. Aluminum alloy hubs, on the other hand, find use in lightweight and high-speed applications where reduced inertia is a priority.

The pins, which act as the torque-transmitting medium between the two hubs, are precision-machined to ensure a secure fit and efficient power transfer. These pins are usually attached to one of the hubs, extending outward to engage with the opposing hub through the bushes. The design of the pins is critical to the coupling’s performance; they must be strong enough to transmit the required torque without deformation while maintaining compatibility with the bushes to facilitate flexibility. In many configurations, the pins feature a cylindrical shape with threaded ends, allowing them to be fastened to the hub using nuts, ensuring a secure connection that resists loosening under rotational forces. Some advanced designs incorporate grooves or ripples along the pin surface to enhance the grip between the pin and the bush, optimizing torque transmission and reducing slippage.

The bushes, often referred to as the flexible heart of the coupling, are the key components that enable shock absorption, vibration damping, and misalignment compensation. These elements are inserted into the holes of the opposing hub, creating a buffer between the rigid pins and the hub itself. The material selection for the bushes is a critical factor that directly influences the coupling’s performance, lifespan, and suitability for specific applications. Traditional bush materials include rubber, neoprene, and leather, which offer excellent elasticity and vibration dampening properties. However, modern advancements have led to the adoption of engineering plastics and composite materials such as polyurethane, ethylene propylene diene monomer (EPDM), and nitrile butadiene rubber (NBR), each offering distinct advantages. Polyurethane bushes, for instance, exhibit superior wear resistance, fatigue strength, and temperature resilience compared to conventional rubber, making them ideal for demanding operating conditions. EPDM bushes excel in environments exposed to moisture, chemicals, and extreme temperatures, while NBR variants are preferred for applications involving oil or hydrocarbon exposure due to their excellent oil resistance.

The working principle of the bush pin flexible coupling is rooted in the synergistic interaction between its rigid and flexible components. When the driving shaft rotates, it imparts torque to the connected hub, which in turn transfers this torque to the pins. The pins then transmit the torque to the bushes, which undergo controlled deformation as they transfer the force to the second hub, ultimately driving the driven shaft. This deformation of the bushes is what enables the coupling to accommodate various types of shaft misalignment, including angular, parallel, and axial misalignment. Angular misalignment occurs when the shafts are not perfectly colinear, forming a slight angle between their axes; parallel misalignment arises when the shafts are offset parallel to each other; and axial misalignment involves linear movement of one shaft relative to the other. The bush material’s elasticity allows it to flex in response to these misalignments, preventing the transfer of excessive stress to the shafts and connected machinery.

In addition to misalignment compensation, the bushes play a crucial role in dampening vibrations and absorbing shock loads. During operation, rotating machinery often generates vibrations due to imbalances, uneven load distribution, or sudden changes in speed. These vibrations, if left unmitigated, can lead to premature wear of bearings, gears, and other components, as well as increased noise levels and reduced operational efficiency. The elastic bushes act as shock absorbers, converting vibrational energy into heat through internal friction, thereby reducing the amplitude of vibrations transmitted between the shafts. This damping effect is particularly beneficial in applications where the driving and driven units are prone to sudden load fluctuations, such as in conveyor systems, crushers, and mixers, where the coupling helps stabilize operation and protect sensitive equipment.

One of the notable advantages of the bush pin flexible coupling is its simplicity in design, which translates to ease of installation, maintenance, and disassembly. Unlike complex coupling types that require specialized tools or expertise for installation, this coupling can be assembled using basic mechanical tools. The hubs are mounted on the shafts using keys, set screws, or taper bushings, ensuring a secure fit that prevents slippage during operation. The pins and bushes are then installed by inserting the bushes into the hub holes and securing the pins with nuts, a process that can be completed quickly and efficiently. Maintenance requirements are equally straightforward, as the primary wear component—the bushes—can be inspected and replaced without disassembling the entire coupling or moving the connected shafts. This minimizes downtime and reduces operational costs, making the coupling a practical choice for industries where productivity and cost-efficiency are paramount.

Another key benefit is its lack of requirement for lubrication. Unlike gear couplings, chain couplings, or certain types of flexible metallic couplings that demand regular lubrication to reduce friction and wear, the bush pin flexible coupling operates without the need for lubricants. This is due to the self-lubricating properties of many bush materials, such as polyurethane and certain rubber compounds, which reduce friction between the pin and the bush during operation. The elimination of lubrication not only simplifies maintenance but also prevents contamination of the surrounding environment, making the coupling suitable for applications in food processing, pharmaceuticals, and other industries where cleanliness is a critical requirement. Additionally, it eliminates the risk of lubricant leakage, which can lead to equipment damage and safety hazards in industrial settings.

Despite its numerous advantages, the bush pin flexible coupling is not without limitations, and its suitability for a given application must be evaluated based on specific operational parameters. One of the primary limitations is its lower operating speed compared to rigid couplings, gear couplings, and chain couplings. The flexible nature of the bushes introduces a degree of torsional deflection, which can become more pronounced at high speeds, leading to reduced efficiency and potential resonance issues. As a result, this coupling is typically recommended for low to medium speed applications, with maximum operating speeds varying based on the coupling size, material selection, and design. For high-speed applications requiring precise torque transmission and minimal deflection, alternative coupling types such as disc couplings or diaphragm couplings may be more appropriate.

Another limitation is its relatively lower torque capacity compared to rigid couplings and metallic flexible couplings. The torque transmission capability of the bush pin flexible coupling is constrained by the strength of the bushes and pins, as excessive torque can cause permanent deformation or failure of the elastic elements. However, advancements in material technology have expanded the torque range of these couplings, with larger sizes and high-strength bush materials enabling them to handle medium to high torque loads in many industrial applications. It is essential to accurately calculate the required torque for the application and select a coupling size that provides an adequate safety margin to prevent premature failure.

Efficiency is another factor to consider, as the elastic deformation of the bushes during operation results in some energy loss through internal friction. This energy loss is typically minimal in low to medium speed applications but can become more significant at higher speeds or under heavy loads. In applications where energy efficiency is a top priority, such as in power generation or large-scale industrial processes, this energy loss may be a consideration, and more efficient coupling types may be preferred. However, for most general-purpose applications, the efficiency trade-off is acceptable given the coupling’s other benefits, such as vibration damping and misalignment compensation.

Material selection for the bush pin flexible coupling is a critical aspect of ensuring optimal performance and longevity. The choice of hub material depends on the torque requirements, operating environment, and weight constraints of the application. Cast iron is a popular choice for general industrial use due to its high strength, durability, and cost-effectiveness. For applications requiring higher torque capacity or resistance to impact loads, forged steel hubs are recommended, as they offer superior tensile strength and toughness compared to cast iron. Aluminum alloy hubs are suitable for lightweight applications, such as in small motors and portable equipment, where reducing the overall weight of the system is important.

The selection of bush material is equally important and should be based on factors such as operating temperature, exposure to chemicals or fluids, wear resistance, and vibration damping requirements. Rubber bushes are cost-effective and offer excellent vibration damping but may degrade over time when exposed to extreme temperatures, oils, or chemicals. Neoprene bushes provide better resistance to oil and weathering compared to natural rubber, making them suitable for outdoor or industrial environments. Polyurethane bushes are a versatile option, offering high wear resistance, fatigue strength, and temperature stability, making them ideal for demanding applications with high load cycles. EPDM bushes are resistant to heat, moisture, and chemicals, making them suitable for applications in harsh environments, while NBR bushes are preferred for oil-rich environments such as in automotive or hydraulic systems.

The design of the bushes also influences the coupling’s performance. Barrel-shaped bushes are a common design variant that offers enhanced flexibility and misalignment compensation compared to plain cylindrical bushes. The curved surface of the barrel-shaped bush allows for greater angular and parallel misalignment, while also providing progressively increasing stiffness as the bush is compressed, ensuring effective shock absorption and torque transmission. Some bush designs incorporate grooves or slits to further enhance flexibility and reduce stress concentrations, improving the bush’s resistance to fatigue and extending its lifespan. The geometric design of the pins and hub holes also plays a role, with precision machining ensuring a proper fit between the pins and bushes, minimizing play and optimizing torque transmission.

The bush pin flexible coupling finds widespread application across a diverse range of industries, owing to its adaptability, reliability, and cost-effectiveness. In the industrial machinery sector, it is commonly used to connect electric motors to pumps, compressors, fans, and blowers. Pumps, in particular, benefit from the coupling’s ability to accommodate misalignment caused by pipe strain or foundation settlement, while also damping vibrations that can affect pump performance and lifespan. Conveyor systems, which are integral to manufacturing, mining, and logistics operations, rely on these couplings to connect drive motors to conveyor rollers, as they can handle the variable loads and minor misalignments inherent in such systems. The coupling’s vibration damping properties also help reduce noise in conveyor operations, improving workplace conditions.

In the automotive industry, the bush pin flexible coupling is used in various applications, including connecting engine shafts to transmission systems and auxiliary components such as water pumps and alternators. The coupling’s ability to absorb shocks and vibrations helps protect the transmission and other sensitive components from the harsh operating conditions within an engine compartment, such as temperature fluctuations and mechanical stress. In marine applications, it is employed to connect engine shafts to propeller shafts, where it compensates for misalignments caused by hull flexing and dampens vibrations, ensuring smooth and reliable power transmission in marine vessels.

The construction industry also benefits from the use of bush pin flexible couplings in equipment such as cranes, hoists, and concrete mixers. Cranes, for instance, require couplings that can handle variable loads and accommodate minor misalignments between the motor and the hoisting mechanism, while also absorbing shocks during lifting and lowering operations. The coupling’s simplicity and ease of maintenance make it well-suited for construction sites, where equipment downtime must be minimized to meet project deadlines. In the agricultural sector, it is used in farm machinery such as tractors, harvesters, and irrigation pumps, where it can withstand the dusty, dirty environments and variable loads typical of agricultural operations.

Even in specialized industries such as aerospace and defense, the bush pin flexible coupling finds limited but important applications in auxiliary systems, such as connecting motors to generators or hydraulic pumps in aircraft and military vehicles. While high-performance aerospace applications often require more advanced coupling types, the simplicity and reliability of the bush pin coupling make it suitable for non-critical auxiliary systems where cost and maintenance efficiency are priorities.

Proper selection and installation of the bush pin flexible coupling are essential to ensure optimal performance and longevity. The first step in selection is to determine the operational parameters of the application, including the maximum torque, operating speed, shaft diameters, and the type and magnitude of misalignment expected. Torque calculation is particularly critical, as selecting a coupling with insufficient torque capacity can lead to premature failure. The torque requirement should include not only the nominal operating torque but also any peak torques resulting from startup, load fluctuations, or shock loads. It is recommended to select a coupling with a torque rating that exceeds the maximum expected torque by a safety margin, typically 20-50%, to account for unforeseen loads and ensure reliability.

Shaft misalignment should also be carefully evaluated, as exceeding the coupling’s misalignment capacity can lead to excessive wear of the bushes, increased vibration, and reduced lifespan. Most bush pin flexible couplings can accommodate angular misalignment up to 0.5 to 1 degree, parallel misalignment up to 0.3 to 0.7 millimeters, and axial misalignment up to 2 to 3 millimeters, depending on the design and size. It is important to measure the actual misalignment in the application and select a coupling that can handle these deviations, or to implement corrective measures such as adjusting the foundation or using shims to reduce misalignment to within acceptable limits.

Installation best practices include ensuring that the shafts are clean and free of burrs before mounting the hubs, as any irregularities can affect the fit and lead to misalignment. The hubs should be properly seated on the shafts and secured using the appropriate method—keys and keyways for heavy-duty applications, set screws for light-duty applications, or taper bushings for precise alignment. The pins and bushes should be installed with care, ensuring that the bushes are fully seated in the hub holes and that the pins are tightened evenly to avoid uneven stress distribution. After installation, a visual inspection should be performed to check for proper alignment, and the coupling should be run at low speed initially to detect any unusual vibrations or noise before increasing to full operating speed.

Maintenance of the bush pin flexible coupling primarily involves regular inspection and replacement of the bushes, as they are the primary wear components. The frequency of inspection depends on the operating conditions—couplings used in harsh environments or high-load applications should be inspected more frequently, typically every 3 to 6 months, while those in mild operating conditions may require inspection only once or twice a year. During inspection, the bushes should be checked for signs of wear, cracking, deformation, or hardening, which indicate that replacement is necessary. The pins should also be inspected for signs of bending or wear, and the hubs should be checked for loose fasteners or damage to the mounting surfaces. Replacing the bushes is a straightforward process: the nuts are removed, the pins are extracted, the worn bushes are replaced with new ones, and the pins and nuts are reinstalled and tightened to the appropriate torque.

In recent years, advancements in material science and manufacturing technology have led to improvements in the performance and versatility of bush pin flexible couplings. The development of high-performance elastomers and composite materials has expanded the operating temperature range, wear resistance, and torque capacity of the bushes, making the coupling suitable for more demanding applications. Precision manufacturing techniques, such as computer numerical control (CNC) machining, have improved the dimensional accuracy of the hubs, pins, and bushes, ensuring better fit and alignment, and reducing energy loss through friction. Additionally, the integration of sensors and condition monitoring systems in some industrial applications has enabled real-time monitoring of coupling performance, allowing for predictive maintenance and further minimizing downtime.

The future of bush pin flexible couplings is likely to be driven by the increasing demand for energy-efficient, low-maintenance, and durable power transmission components across industries. As manufacturing processes become more automated and industries strive to reduce operational costs and environmental impact, the simplicity and reliability of this coupling type will continue to make it a preferred choice for many applications. Further advancements in material technology, such as the development of bio-based elastomers or self-healing materials, may enhance the sustainability and lifespan of the bushes, while improvements in design optimization through finite element analysis (FEA) may lead to more efficient and compact coupling designs.

In conclusion, the bush pin flexible coupling is a vital component in mechanical power transmission systems, offering a balance of flexibility, reliability, and cost-effectiveness that makes it indispensable across a wide range of industries. Its simple design, ease of installation and maintenance, vibration damping capabilities, and ability to accommodate misalignment address the key challenges faced in many industrial applications, protecting equipment and improving operational efficiency. While it has limitations in terms of speed and torque capacity, these are often offset by its numerous advantages, making it a practical solution for low to medium speed, medium torque applications. With ongoing advancements in materials and manufacturing, the bush pin flexible coupling is poised to remain a cornerstone of mechanical power transmission for years to come, adapting to the evolving needs of modern industry.

« Bush Pin Flexible Couplings » Latest Update Date: 2026/1/20 , https://www.rokeecoupling.net/tags/bush-pin-flexible-couplings.html