Rokee is a well-known high-quality supplier of Bushed Pin Couplings and technical services in China, customize bushed pin couplings according to user drawings, alternatively, if the user provides bushed pin couplings parameters, we can select the model and design drawings for you, support wholesale and export.

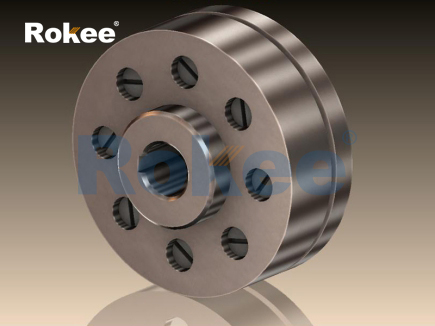

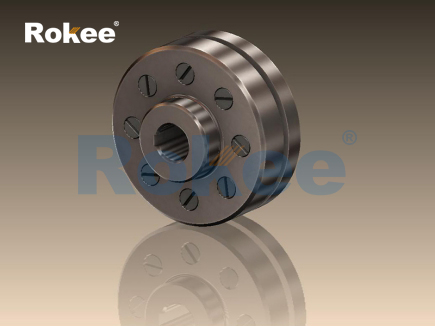

Bushed Pin Coupling is a type of elastic coupling widely used in mechanical transmission systems, belonging to a type of flexible coupling. It is known for its simple structure, easy installation, easy maintenance, and good vibration damping performance, and occupies an important position in the field of industrial transmission.

This type of coupling mainly consists of two half couplings, a sleeve (or sleeve column), and an elastic pin. It compensates for the relative displacement of the axis through the deformation of the elastic element, while absorbing and buffering the impact and vibration during the transmission process. Compared with traditional rigid couplings, Bushed Pin Couplings can effectively reduce the additional load caused by centering errors and extend the service life of equipment.

A typical Bushed Pin Coupling is mainly composed of the following parts:

Half coupling: usually made of cast iron or steel flange, with one at each end, installed on the driving shaft and the driven shaft respectively

Sleeve: A cylindrical sleeve made of metal or nylon, usually 4-12 in quantity, evenly distributed around the circumference of the coupling

Elastic pin: a cushioning element made of elastic materials such as rubber and polyurethane, installed inside the sleeve column

Connecting bolt: a fastener used to fix the sleeve column and half coupling

According to specific application requirements, various structural variants have been developed for Bushed Pin Couplings:

Single row sleeve column pin coupling: the most basic form, with a single row arrangement of sleeve columns

Double row sleeve column pin coupling: The sleeve columns are arranged in a double row staggered manner, with higher load-bearing capacity

Coupling with brake wheel sleeve and column pin: One end integrates a brake wheel for easy installation of the braking device

Flange type column pin coupling: using flange connection method, easy to install and disassemble

The working principle of the Bushed Pin Coupling is based on the principle of elastic deformation. When the driving shaft rotates, torque is transmitted to the sleeve column through the half coupling, and then transmitted to the other half coupling through the elastic pin, ultimately driving the driven shaft to rotate. During this process:

Elastic pins undergo shear and compression deformation, absorbing vibration and impact

The gap between the sleeve column and the pin allows for a certain degree of radial, axial, and angular displacement

The deformation characteristics of elastic elements determine the stiffness and damping characteristics of couplings

The Bushed Pin Coupling has the following significant characteristics:

Compensation deviation capability:

Radial deviation: usually compensated for 0.2-0.6mm

Axial deviation: generally allowed 0.5-3mm

Angular deviation: usually 0.5 ° -1.5 °

Vibration damping and buffering performance:

Elastic components can effectively absorb the impact during start-up and braking

Reduce the vibration and noise of the transmission system

Other advantages:

Simple structure and low manufacturing cost

No lubrication required, easy to maintain

The installation requirements for alignment are relatively low

Easy replacement of elastic components

Proper installation is crucial for the performance of the Bushed Pin Coupling:

Preparation work:

Clean the shaft end and coupling inner hole

Check the fit between the shaft diameter and the coupling aperture

Prepare appropriate installation tools

Install the half coupling:

Install the half coupling onto the shaft using hot or press fit methods

Ensure accurate axial positioning

Centering adjustment:

Use a dial gauge or laser centering device to perform axis centering

Radial and axial deviations are controlled within the allowable range

Install the sleeve column and elastic pin:

Tighten the connecting bolts evenly

Use a torque wrench to tighten in diagonal order

The maintenance of the column pin coupling is relatively simple, mainly including:

Regular inspection:

Check the tightening status of bolts every month

Observe whether the elastic components have aged or cracked

Check for any abnormal vibrations or noise

Replacement cycle:

Elastic components are usually replaced every 2-5 years

Shorten replacement cycle under high load or harsh environment

Attention:

Avoid contact with substances such as oil that may corrode elastic materials

Do not modify or process coupling parts arbitrarily

When replacing, the elastic components should be replaced in groups

The Bushed Pin Coupling is widely used in the following industries and equipment:

General Machinery:

Pumps (centrifugal pumps, reciprocating pumps, etc.)

Fan (centrifugal fan, axial flow fan)

Compressor (piston type, screw type)

Industrial equipment:

Conveyor belt drive system

mixing equipment

textile machinery

Other fields:

Ship auxiliary equipment

Power plant auxiliary equipment

metallurgical equipment

Pump drive system:

Compensation for installation deviation between pump and motor

Absorb the impact generated by water hammer effect

Fan transmission system:

Reduce vibration transmission caused by blade rotation

Allow axis deviation caused by thermal expansion

Production line conveyor system:

Torque balance in multi motor drive

Protect the gearbox from load impact

« Bushed Pin Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/bushed-pin-couplings.html