Rokee is a well-known high-quality supplier of Bushed Couplings and technical services in China, customize bushed couplings according to user drawings, alternatively, if the user provides bushed couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Bushed Coupling is a mechanical device that connects shafts through elastic sleeves, mainly used to connect two shafts or shafts with other rotating components, transmit torque, and compensate for a certain degree of axial, radial, and angular deviation. Compared with rigid couplings, Bushed Couplings have the advantages of buffering, absorbing vibrations, and compensating for deviations, which can effectively protect the transmission system from damage caused by impact loads.

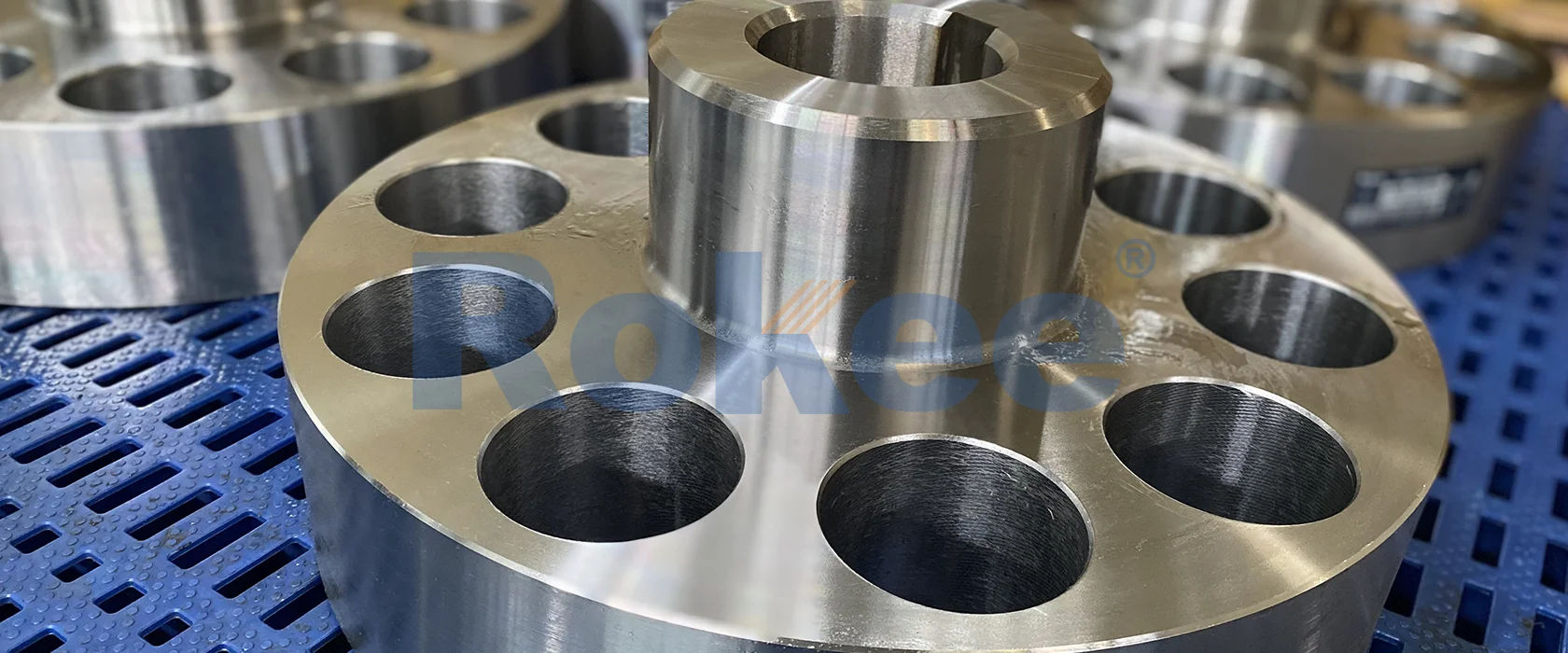

A typical bushing coupling consists of the following main components:

Wheel hub section: usually two, installed on the driving shaft and driven shaft respectively

Elastic bushing: located between two wheel hubs, it is the core component of the coupling

Connecting bolt: used to fix the wheel hub and liner

Protective cover: Some models are equipped with protective covers to prevent dust from entering and ensure safety

The Bushed Coupling achieves the following functions through the deformation of the elastic sleeve:

Torque transmission: transmitting rotational power through the shear and compression deformation of the lining

Deviation compensation: Elastic deformation allows for a certain degree of axial, radial, and angular deviation

Shock absorption and buffering: absorbing and attenuating system vibrations and impact loads

Insulation protection: Some lining materials can provide electrical insulation function

According to the different structural forms and lining materials, lining couplings can be divided into the following common types:

Plum shaped bushing coupling

Using polyurethane or rubber plum blossom shaped pads

Simple structure, easy disassembly and assembly

Suitable for small and medium power transmission systems

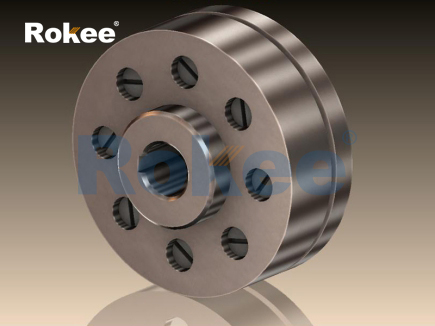

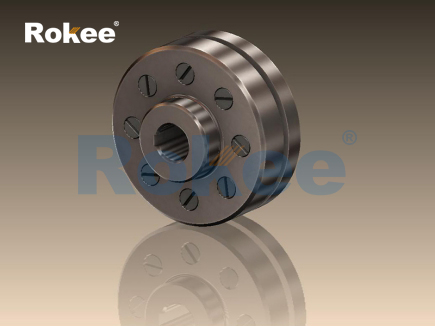

Bushed pin type coupling

Using rubber or polyurethane sleeves as elastic components

Connect the two halves of the coupling through a column pin

Strong carrying capacity and good compensation performance

Diaphragm type bushing coupling

Using metal or composite membrane as elastic element

Seamless transmission, suitable for high-precision applications

Maintenance free, long service life

Tire type liner coupling

Circular rubber tire structure

High compensation capability and good shock absorption effect

Suitable for large deviation and heavy load situations

Shock absorption performance: effectively reduces the vibration and noise of the transmission system

Compensation capability: can compensate for radial deviation of 0.5-3mm and angular deviation of 1-5 °

Insulation performance: Some lining materials can provide electrical insulation up to 10kV

Easy maintenance: Most types only require regular inspection of the wear of the lining

Economy: Compared to other elastic couplings, the cost is lower

Choosing a suitable bushing coupling requires consideration of the following factors:

Transmitting torque: Calculate the required torque capacity based on system requirements

Speed range: Ensure safe operation of the coupling at rated speed

Deviation type and magnitude: Select compensation capability based on the alignment of the shaft system

Environmental conditions: Consider factors such as temperature, humidity, corrosiveness, etc

Installation space: Determine the coupling size based on the available space

Bushed Couplings are widely used in the following industries and equipment:

General machinery: pumps, fans, compressors, etc

Material transportation: conveyors, elevators, etc

Construction machinery: excavators, cranes, etc

Power generation equipment: generators, turbines, etc

Rail Transit: Locomotive Drive System

Shipbuilding industry: propulsion system transmission

Installation requirements:

Ensure that the shaft end clearance meets the requirements

The deviation in alignment is within the allowable range

Tighten the fastening bolts to the specified torque

Daily maintenance:

Regularly check the wear of the lining

Check the tightening status of bolts

Pay attention to abnormal vibrations or noise

Regularly lubricate according to the usage environment (if applicable)

Replacement standard:

The lining shows obvious cracks or permanent deformation

Significant decrease in elasticity performance

The wear amount exceeds the allowable value

As an important component of mechanical transmission systems, the performance of Bushed Couplings directly affects the operational efficiency and reliability of the entire equipment. The correct selection, installation, and maintenance of Bushed Couplings are of great significance for extending the service life of equipment and reducing maintenance costs.

« Bushed Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/bushed-couplings.html