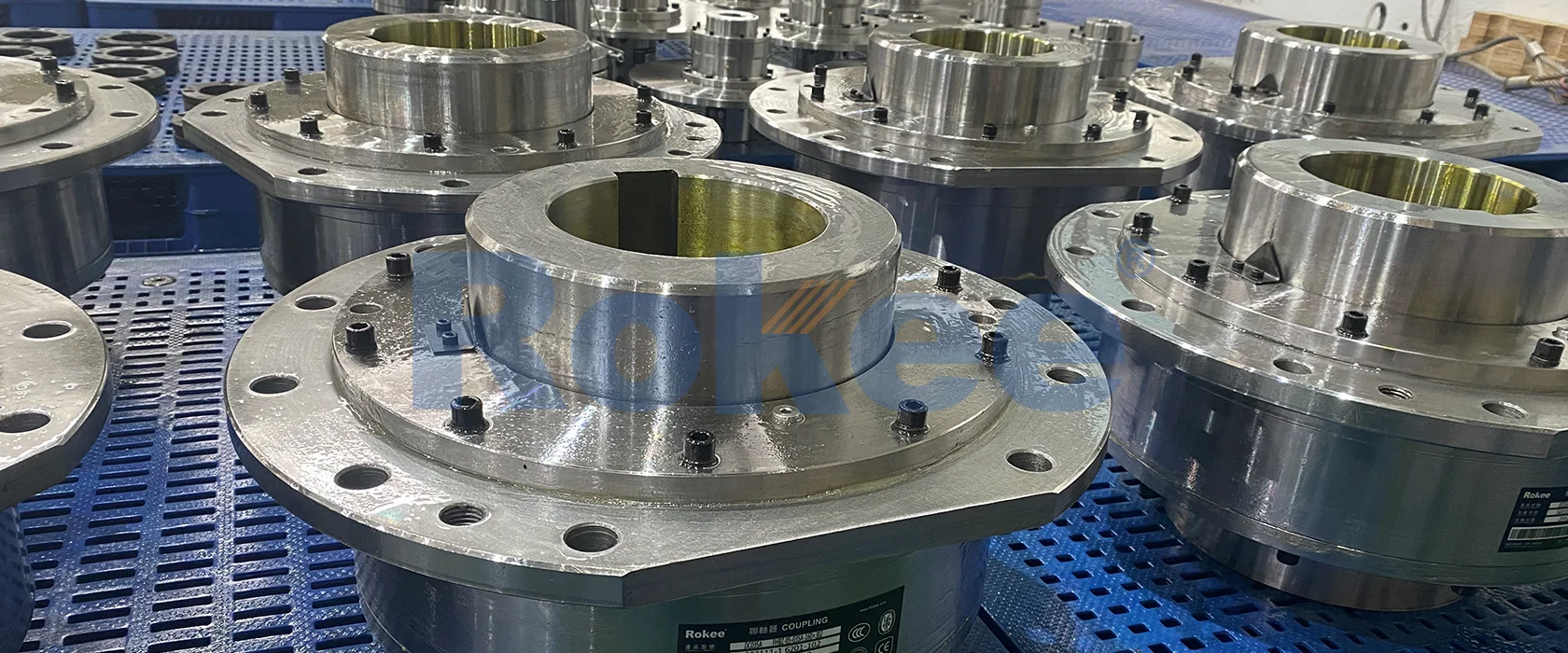

Rokee is a well-known high-quality supplier of Crane Couplings and technical services in China, customize crane couplings according to user drawings, alternatively, if the user provides crane couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the field of heavy industry, crane couplings play an indispensable role in power transmission systems. This precision mechanical component is mainly used to connect the drive shaft and the driven shaft of the crane, ensuring efficient and smooth transmission of power from the electric motor or engine to the working mechanism. Unlike simple connecting devices, modern crane couplings require the ability to compensate for axial, radial, and angular deviations while absorbing vibration and impact loads.

The core of the power transmission mechanism lies in the ability of the coupling to adapt to various complex working conditions in crane operations. When the motor starts, the coupling first absorbs the initial impact; During operation, it continuously adjusts to adapt to axis deviations caused by load changes or structural deformations; When sudden braking occurs, the coupling acts as a buffer to protect the entire transmission system from damage.

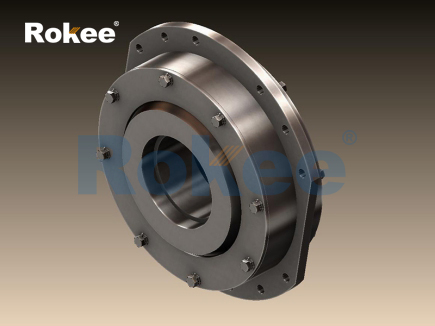

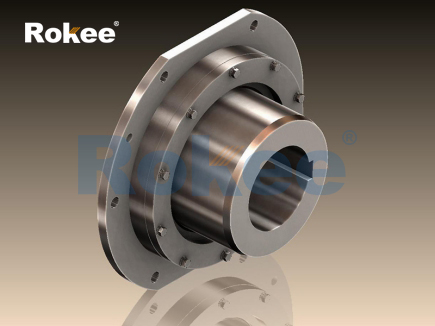

As a representative of rigid couplings, flange couplings use bolts to tightly connect the two halves of the coupling, which has the characteristics of simple structure and high torque transmission. Its manufacturing precision requirements are extremely high, and the two axis alignment error should not exceed 0.02-0.03mm, especially suitable for the main lifting mechanism of high-speed and high-power bridge cranes.

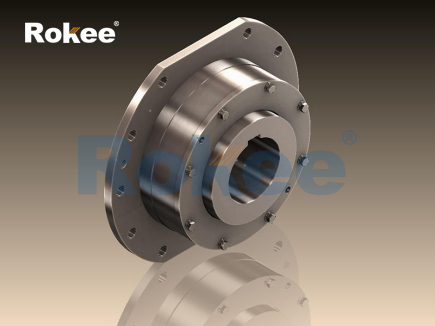

Sleeve coupling is a compact design that achieves shaft to shaft transmission through interference fit or key connection, commonly used in space limited gantry crane rotating mechanisms. However, due to the lack of deviation compensation capability, precise alignment must be ensured during installation.

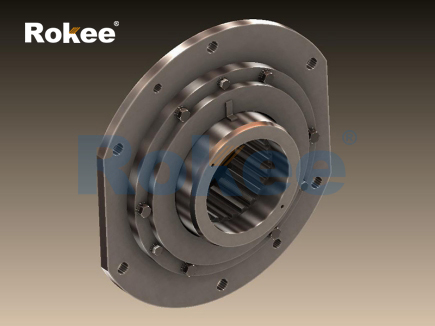

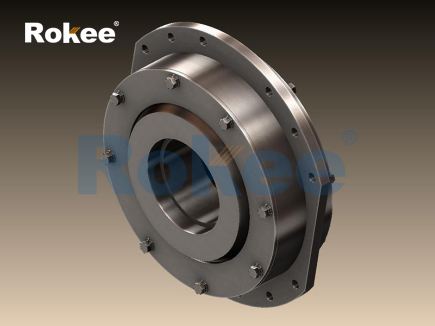

Gear coupling is the mainstream choice for heavy-duty cranes, consisting of two sleeves with external teeth and two flange half couplings with internal teeth. This design allows for angular deviations of 0.5 ° -1.5 ° and radial displacements of several millimeters, making it particularly suitable for harsh working conditions such as metallurgical cranes.

The universal joint adopts a cross axis structure, which can achieve power transmission at large angles (usually 15 ° -45 °), making it an ideal choice for the slewing mechanism of tower cranes.

Rubber component couplings utilize the elastic deformation of high-strength rubber to compensate for deviations and absorb vibrations. Their damping characteristics can reduce noise by 15-20 decibels and are widely used in noise sensitive port cranes.

Spring couplings use spiral springs or diaphragm springs as elastic elements, with precise torque transmission capability and good reset characteristics, especially suitable for crane walking mechanisms that require precise positioning.

As a key link in power transmission, the technological progress of crane couplings directly affects the safety, reliability, and energy efficiency of equipment. With the development of intelligent manufacturing and new materials, future couplings will continue to evolve towards smarter, more efficient, and more durable directions.

« Crane Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/crane-couplings.html