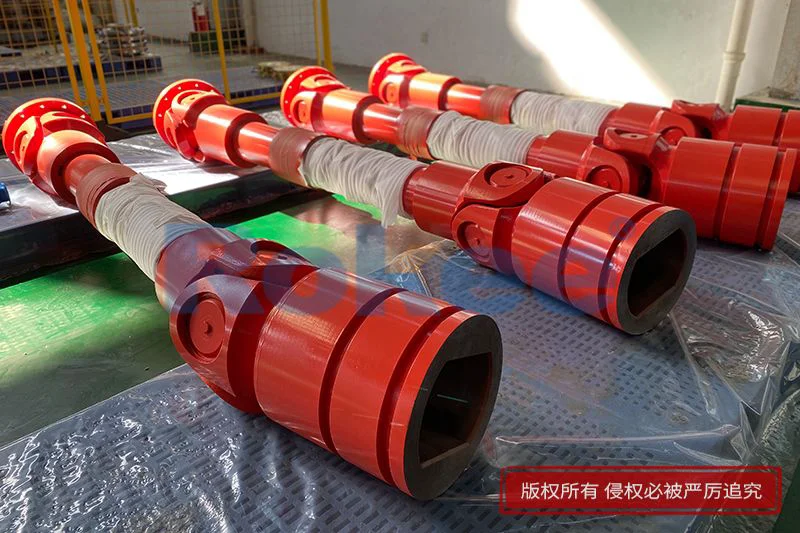

Rokee is a well-known high-quality supplier of Cross Cardan Shafts and technical services in China, customize cross cardan shafts according to user drawings, alternatively, if the user provides cross cardan shafts parameters, we can select the model and design drawings for you, support wholesale and export.

A Cross Cardan Shaft is a mechanical device used to connect two shafts that are not in the same straight line and transmit torque and rotational motion. This clever design allows for relative deflection between the connecting shafts within a certain angle range, while maintaining the continuity of power transmission.

The core structure of a Cross Cardan Shaft consists of four main components: two fork joints (commonly referred to as universal joint forks), a cross shaft, and four needle roller bearings. Two universal joint forks are connected to the input shaft and output shaft respectively, and angle compensation is achieved through a cross shaft in the middle, while bearings ensure smooth rotational motion.

The working principle of the Cross Cardan Shaft is based on the double hinge mechanism in spatial geometry. When the input shaft rotates, the first universal joint fork drives the cross shaft to rotate, and the cross shaft then transmits the rotational motion to the second universal joint fork, ultimately driving the output shaft to rotate.

It is worth noting that there is a speed fluctuation phenomenon in the transmission process of a single cross universal shaft - when there is an angle between the two shafts, the output shaft speed will show periodic changes in each rotation cycle. This speed non-uniformity intensifies as the angle increases. To solve this problem, a double Cross Cardan Shaft arrangement is often used in practical applications, and speed fluctuations can be basically eliminated by setting the phase angle reasonably.

Standard cross universal shaft: The most common type, consisting of two universal joint forks and a cross shaft, suitable for general industrial applications.

Universal shaft with sliding splines: Adding sliding splines to the standard structure allows for axial displacement compensation and is suitable for situations where shaft spacing may vary.

Constant speed universal joint: an improved design (such as a cage type universal joint) that can maintain consistent input and output shaft speeds, widely used in automotive drive shafts.

Heavy industrial universal joint: reinforced structural design, used in high torque applications such as mining machinery and metallurgical equipment.

Micro precision universal joint: designed for miniaturization, used in precision transmission fields such as instruments and robots.

Torque capacity: The maximum torque that a universal joint can transmit is the primary parameter for selection.

Working angle: The maximum working angle of a single joint universal joint is usually 15 ° -45 °, and the double joint combination can reach more than 60 °.

Speed range: Limited by centrifugal force and lubrication conditions, different specifications have different upper speed limits.

Axial displacement compensation: only applicable to models with sliding splines.

Dynamic balance level: Special consideration should be given to dynamic balance performance during high-speed applications.

Working temperature range: closely related to material selection and lubrication method.

Automotive industry: transmission shaft, steering system, four-wheel drive system, etc.

Industrial machinery: rolling mills, paper machines, mining machinery, pump equipment, etc.

Agricultural machinery: power transmission system for tractors and combine harvesters.

Ship engineering: power transmission for propulsion shaft systems and deck machinery.

Aviation field: helicopter rotor transmission system, auxiliary power unit.

Robotics technology: power transmission at the joints of robotic arms.

Determine the type based on the application scenario (standard, heavy-duty, precision, etc.)

Calculate the required torque to be transmitted and consider the safety factor

Determine the working angle range and speed requirements

Consider environmental conditions (temperature, corrosiveness, etc.)

Assess installation space limitations

Regularly check the lubrication condition and replenish or replace lubricating grease on time

Monitor bearing wear and replace damaged parts in a timely manner

Check the status of fasteners to prevent looseness

Regularly check the dynamic balance status (for high-speed applications)

Observe the operation noise and vibration situation, and promptly detect abnormalities

As a fundamental component in the field of mechanical transmission, the cross universal shaft continues to evolve with the advancement of industrial technology. While maintaining its basic principles, its performance, reliability, and applicability continue to improve, providing indispensable transmission solutions for various mechanical systems.

« Cross Cardan Shafts » Post Date: 2024/5/31 , https://www.rokeecoupling.net/tags/cross-cardan-shafts.html