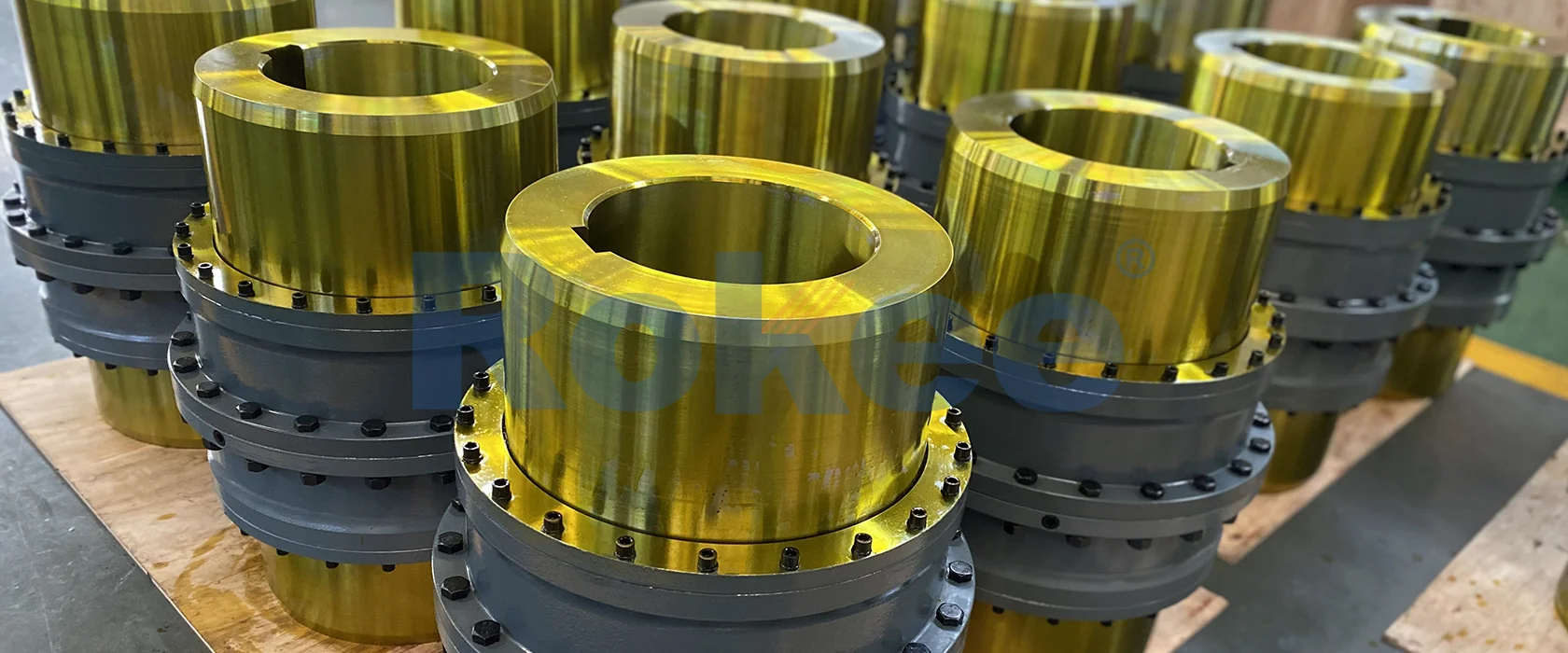

Rokee is a well-known high-quality supplier of Curved Tooth Gear Couplings and technical services in China, customize curved tooth gear couplings according to user drawings, alternatively, if the user provides curved tooth gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

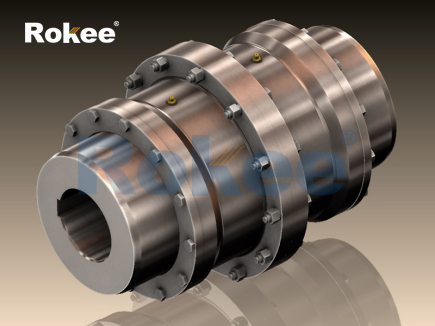

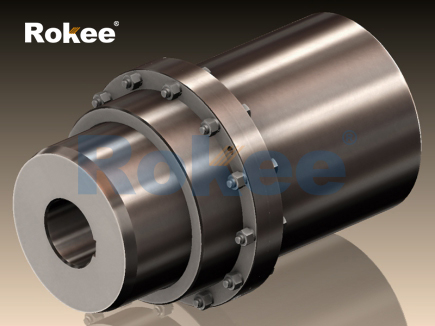

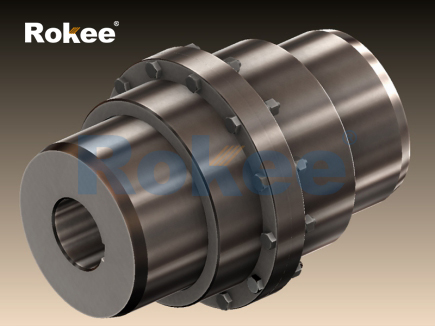

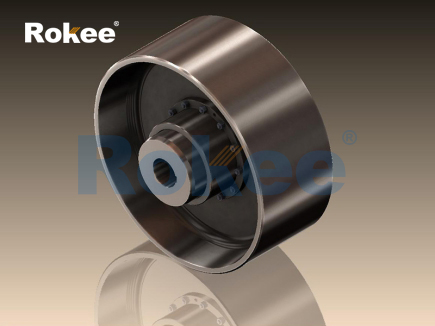

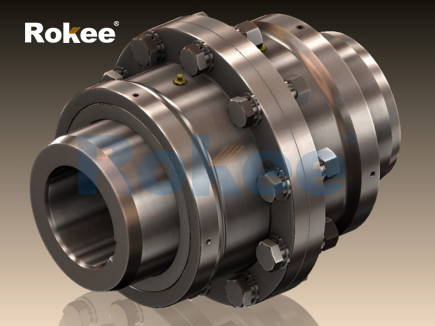

Curved Tooth Gear Coupling is a flexible coupling with a unique structure. It achieves shaft to shaft connection through a specially designed drum shaped gear profile, which can effectively compensate for radial, axial, and angular deviations between two shafts. Compared with traditional spur gear couplings, the drum tooth design significantly improves transmission efficiency and service life.

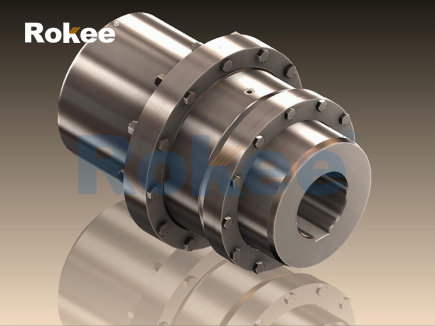

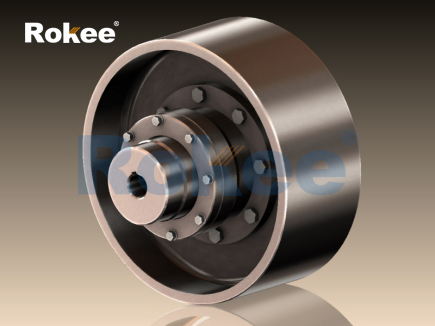

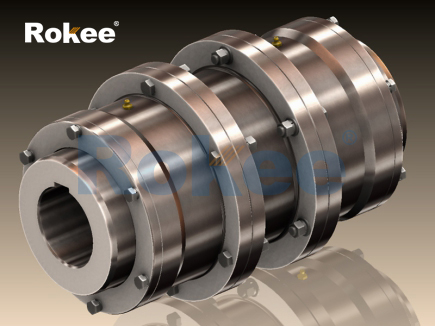

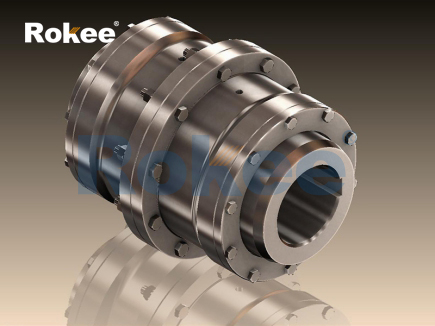

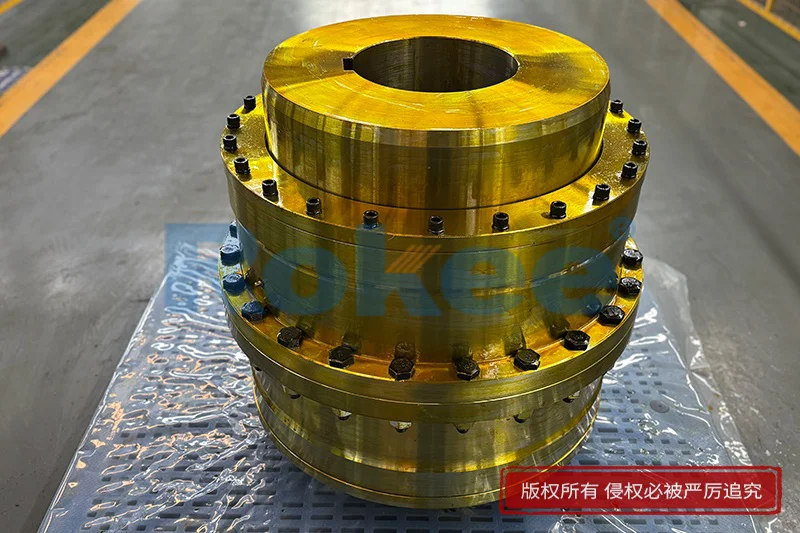

This type of coupling consists of two shaft sleeves with external gears and a drum shaped sleeve with internal gears. The external gears mesh with the internal gears through a lubricating oil film, transmitting torque while allowing for some relative motion. The "drum shape" in its name comes from the special drum shaped shape of the sleeve, which is the key to its outstanding performance.

Core structural components:

Shaft sleeve component: usually made of high-strength alloy steel, precision machined and heat-treated, with a surface hardness of HRC58-62

Drum shaped sleeve: with a special drum shaped internal tooth structure, the internal teeth are precision ground, and the contour accuracy is controlled within 0.01mm

Sealing system: adopting multiple sealing designs, including radial sealing and end face sealing, to ensure that lubricant does not leak

Lubrication channel: Built in optimized lubrication oil circuit to ensure sufficient lubrication of the tooth surface

Modern Curved Tooth Gear Couplings are usually made of high-quality alloy steels such as 42CrMo and 20CrMnTi, with surface carburizing, quenching or nitriding treatment. The tooth surface hardness can reach HRC58-62, and the core maintains the toughness of HRC30-35. Some special applications may use stainless steel or special alloy materials.

The Curved Tooth Gear Coupling achieves multifunctional compensation through its unique geometric shape:

Radial compensation: The drum shaped tooth profile allows for radial displacement of the shaft sleeve within a certain range, with a typical compensation amount of 0.5-3mm, depending on the size of the coupling.

Angular compensation: The drum shaped design allows the coupling to adapt to shaft to shaft angles of 1 ° -1.5 °, with high-end products reaching up to 2 °.

Axial compensation: By designing the tooth flank clearance, axial displacement compensation of ± 2mm to ± 10mm can be achieved.

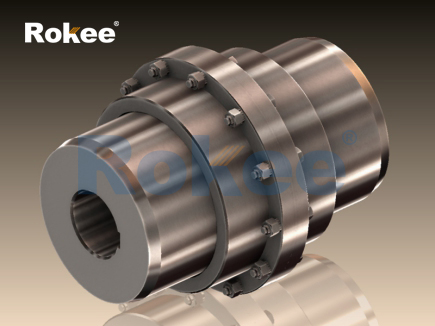

Torque is transmitted through the contact pressure of the meshing tooth surface, forming an elastic fluid dynamic lubrication film in the contact area, reducing the friction coefficient (usually 0.05-0.08). Advanced design adopts modified involute tooth profile, resulting in a more uniform distribution of contact stress. The theoretical calculation of contact stress is usually controlled within the range of 800-1200MPa.

Excellent deviation compensation capability:

Simultaneously compensate for radial, angular, and axial deviations

Compensation capability is 30-50% higher than that of spur gear couplings

Especially suitable for working conditions with foundation settlement or thermal deformation

High transmission efficiency:

Efficiency can reach 98.5% -99.2%

The power loss is only 60-70% of that of ordinary couplings

Long life design:

The design lifespan typically ranges from 50000 to 100000 hours

Excellent wear resistance, with a wear rate of less than 0.01mm/1000h

Vibration and noise control:

The dynamic balance level can reach G2.5

The noise level is 5-8dB lower than traditional couplings

Maintenance simplicity:

Adopting a long-term lubrication design, the maintenance cycle reaches 8000-10000 hours

Modular design facilitates quick replacement

Typical applications in the industrial field:

Metallurgical industry:

Main transmission system of rolling mill

Continuous casting machine sector drive

Large blower drive

Energy and electricity:

Steam turbine generator set

Large scale water pump unit

Wind turbine

Ship engineering:

Main propulsion system

Shaft connection

Auxiliary transmission

Petrochemical industry:

Compressor transmission

Large pump unit

Reaction kettle stirring system

Mining Machinery:

Ball mill transmission

Crusher drive

conveying system

As a key component of modern industrial transmission, the Curved Tooth Gear Coupling is constantly advancing towards higher performance, longer lifespan, and greater intelligence in its technological development, providing more reliable connection solutions for various industrial equipment.

« Curved Tooth Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/curved-tooth-gear-couplings.html