Rokee is a well-known high-quality supplier of Drum Gear Couplings and technical services in China, customize drum gear couplings according to user drawings, alternatively, if the user provides drum gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

Drum gear coupling as an efficient and reliable mechanical transmission connection device, plays a crucial role in modern industrial equipment. This type of coupling overcomes many limitations of traditional gear couplings through its unique drum shaped tooth design, becoming the preferred connection solution for heavy-duty, high-precision transmission systems.

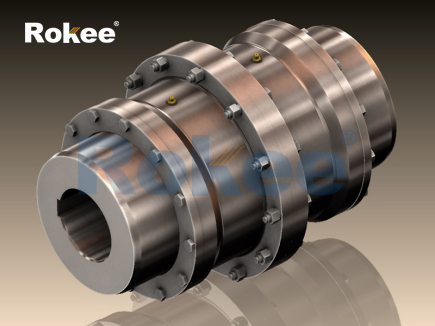

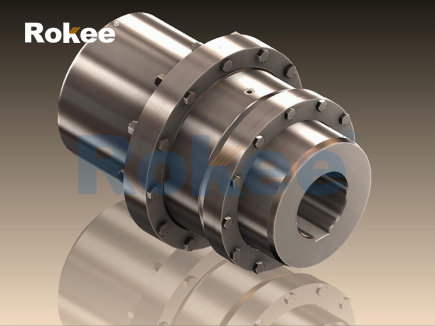

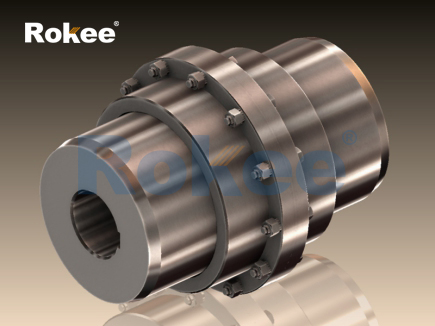

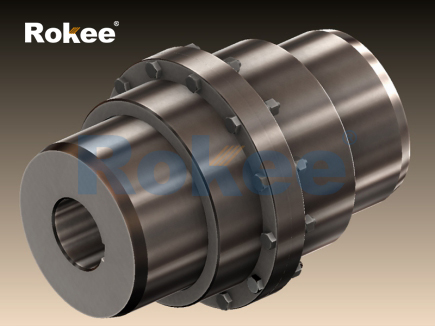

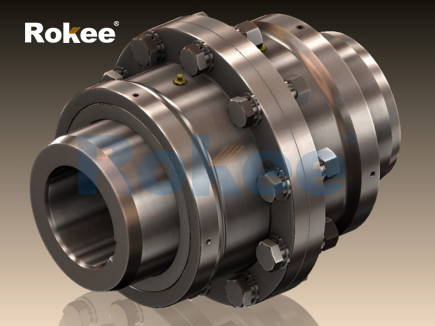

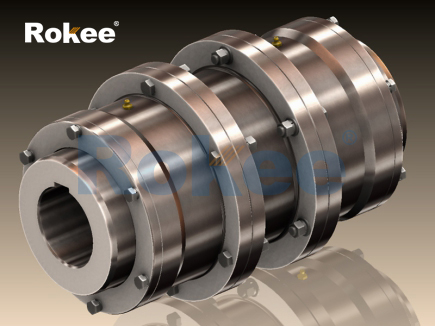

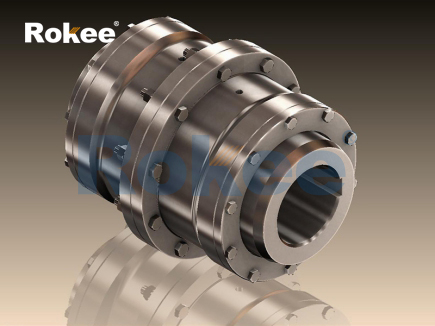

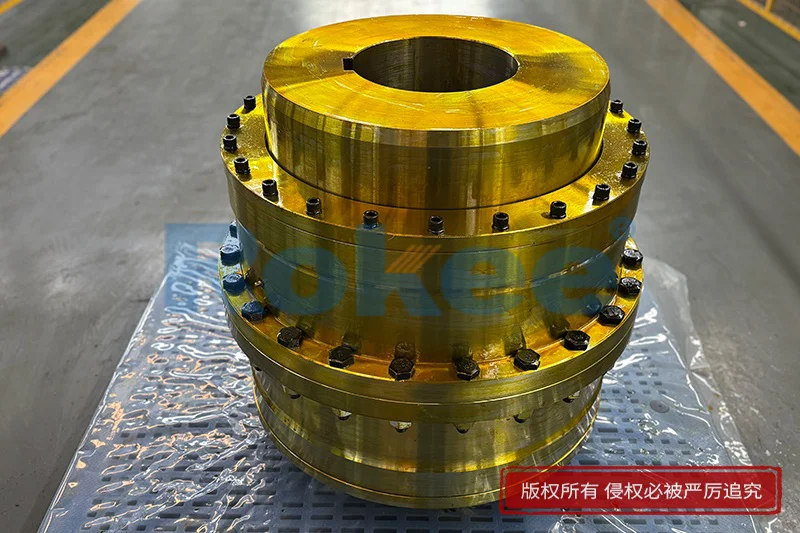

Basic structure and working principle: The core of the drum gear coupling lies in the precise fit of its inner and outer teeth. The tooth tips of the outer gear shaft sleeve are drum shaped and mesh with the standard straight or involute teeth of the inner gear ring. This design allows for compensating for axial, radial, and angular deviations while transmitting torque. When the driving shaft rotates, power is transmitted to the driven shaft through the meshing of the inner and outer teeth. Even if there is a certain degree of deviation between the two shafts, the drum shaped tooth surface can maintain continuous contact, ensuring the smoothness of power transmission.

The reason why drum gear couplings can be widely used in many industrial fields is due to a series of outstanding technical advantages:

Excellent deviation compensation capability: The drum tooth design can simultaneously compensate for radial deviation (usually 0.5-3mm), axial displacement (± 5-15mm), and angular deviation (usually 1 ° -1.5 °), far exceeding the compensation range of traditional spur gear couplings. This multi-directional compensation capability significantly reduces the requirement for equipment accuracy and reduces installation and debugging time.

High torque transmission efficiency: By optimizing the tooth profile design and surface treatment process, the transmission efficiency of modern drum gear couplings can reach 98-99.5%, with almost no power loss. For example, a 500mm drum gear coupling from a certain brand can transmit up to 150kNm of torque at 3000rpm.

Excellent vibration and noise reduction performance: The progressive contact characteristics of the drum shaped tooth surface effectively absorb vibrations and impacts in the transmission system, reducing noise by 15-20dB compared to straight tooth couplings. It is particularly suitable for precision machine tools, generator sets, and other vibration sensitive equipment.

Long life and low maintenance: Made of high-quality alloy steel material that has undergone carburizing and quenching treatment, the tooth surface hardness can reach HRC58-62. Combined with a forced lubrication system, the service life can reach 5-8 years (depending on the working conditions), and the maintenance cycle can be extended to 6-12 months.

Drum gear couplings have developed various structural forms according to application requirements to meet the special requirements of different industrial scenarios

G series standard drum gear coupling: the most common basic type, consisting of two outer gear shaft sleeves and one inner gear ring, suitable for general industrial transmission. The typical specification range is from G1 (shaft diameter 20mm) to G20 (shaft diameter 500mm), with a torque capacity of 0.5-500kNm.

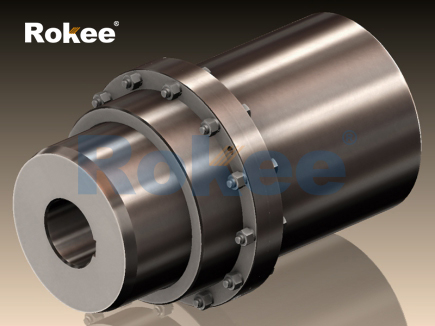

Extended type with intermediate shaft: By adding an intermediate connecting shaft (up to 10m in length), the problem of large spacing shaft system connection is solved. It is commonly used in long-distance transmission scenarios such as ship propulsion systems and steel mills. The specially designed intermediate shaft support bearing can prevent sagging deformation.

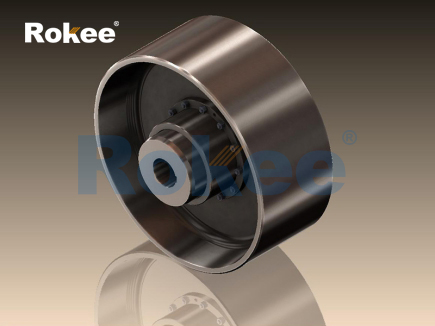

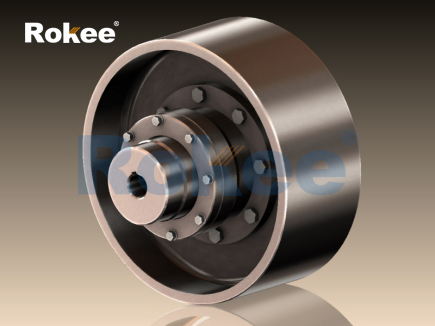

Flange connection type: using high-strength bolt flange connection instead of traditional clamping sleeve, suitable for ultra large torque transmission (up to 2000kNm) and heavy load impact conditions, such as mining machinery, shield machines, etc.

Special material type: Stainless steel (316L) or nickel based alloy versions developed for corrosive environments; Titanium alloy or high-strength aluminum alloy models are used to reduce weight (weight can be reduced by 40%).

Intelligent monitoring type: integrating temperature sensors, vibration probes, and wireless transmission modules, it can monitor the working status of couplings in real time, achieve predictive maintenance, and is particularly suitable for key equipment such as wind power and petrochemicals.

drum gear couplings have been widely used in various industrial fields due to their excellent performance:

Energy and power industry: steam turbine generator sets (compensating for thermal expansion displacement), wind turbine gearboxes (anti torsional vibration), water turbines (high torque transmission).

Metallurgical equipment: main drive of rolling mill (bearing impact load), continuous casting machine (high temperature environment), coiler (large deflection angle).

Ship engineering: propulsion shaft system (compensating for hull deformation), deck machinery (anti-corrosion design), servo (high-precision positioning).

Petrochemical equipment: compressor (anti vibration), pump set (sealed and explosion-proof), reactor stirring (corrosion-resistant).

Precision machinery: CNC machine tools (micrometer level transmission accuracy), robot joints (compact design), semiconductor equipment (dust-free requirements).

Proper installation and maintenance are key to ensuring the long-term reliable operation of drum gear couplings

Installation specifications:

The laser alignment instrument is used for alignment adjustment, and the deviation is controlled within 80% of the manufacturer's allowable value

During heating and assembly, the temperature should not exceed 120 ℃, and direct heating with open flames should be avoided

The bolts are tightened using a torque wrench, and are tightened in three stages in a cross pattern

Perform segmented test runs at 50%, 75%, and 100% load for the first operation

Lubrication management:

Oil filling amount: 60-70% of the internal space, too much can cause excessive temperature rise

Supplementary period: 6 months for regular working conditions and 3 months for harsh environments

It is recommended to use an oil lubrication system (pressure 0.2-0.5MPa) for high temperature or continuous operation

Common faults and countermeasures:

Abnormal vibration: check the alignment status, bearing wear, and foundation stiffness

High temperature: Confirm the lubrication condition and whether the load exceeds the standard

Tooth surface pitting: increase lubricating oil viscosity or add extreme pressure agents

Abnormal noise: Check for tooth wear and foreign object intrusion

State monitoring technology:

Infrared temperature measurement: Ring gear temperature difference>15 ℃ indicates abnormality

Vibration analysis: Pay attention to the changes in the 2 × frequency components

Oil detection: Iron spectrum analysis of wear particles

Acoustic emission technology: early identification of tooth surface damage

With the development of industrial equipment towards high efficiency and intelligence, drum gear couplings will continue to play an irreplaceable role, and their technological innovation will bring more possibilities to the field of mechanical transmission. Correctly selecting and applying drum gear couplings can significantly improve equipment reliability, reduce maintenance costs, and create greater value for enterprises.

« Drum Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/drum-gear-couplings.html