Rokee is a well-known high-quality supplier of Face Gear Couplings and technical services in China, customize face gear couplings according to user drawings, alternatively, if the user provides face gear couplings parameters, we can select the model and design drawings for you, support wholesale and export.

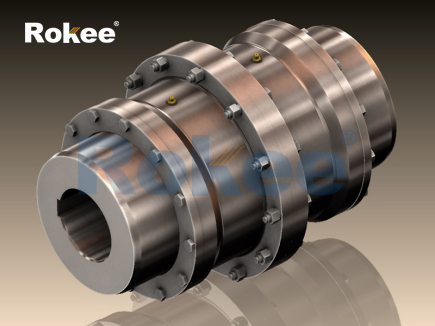

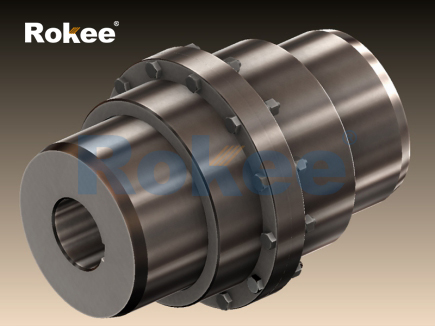

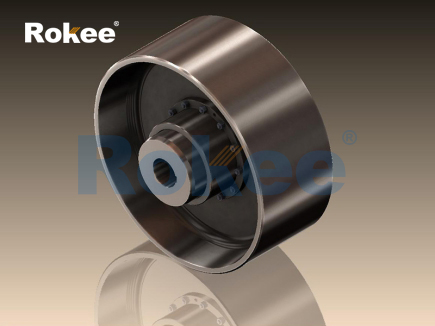

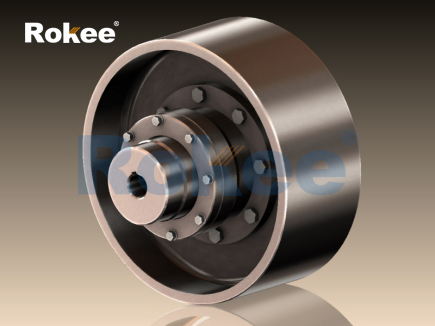

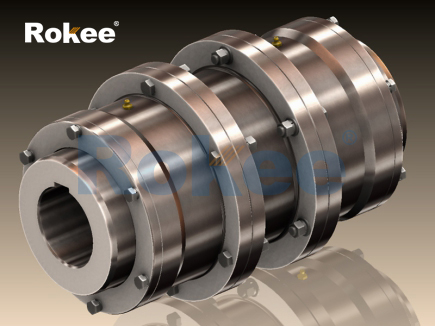

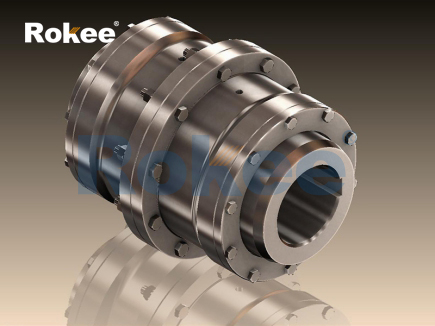

Face gear coupling is an efficient power transmission component that transmits torque through interlocking end face gears. It has significant characteristics such as compact structure, high transmission accuracy, and strong load-bearing capacity. This type of coupling plays a crucial role in modern mechanical transmission systems and is particularly suitable for industrial scenarios that require high-precision alignment and high torque transmission.

Compared with traditional radial gear couplings, the face gear coupling designs the gear meshing surface in the axial direction, which enables it to achieve higher power density in a limited space.

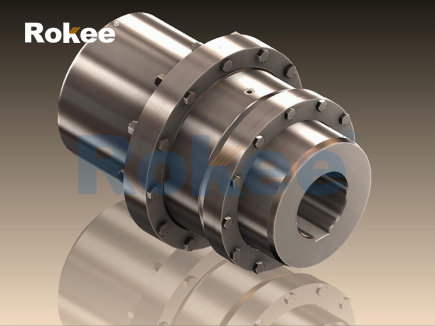

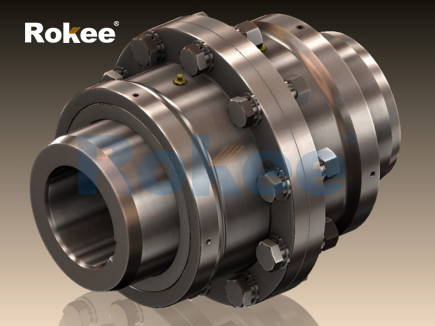

The face gear coupling is mainly composed of the following precision components:

Gear disc components: usually made of high-quality alloy steel (such as 42CrMo) that has undergone carburizing and quenching treatment, with a tooth surface hardness of HRC58-62, ensuring wear resistance and fatigue strength

Intermediate spacer: Different lengths are designed according to the axial compensation requirements, and high-strength aluminum alloy or stainless steel is often selected as the material

Pre tightening force adjustment mechanism: including disc spring group or hydraulic pre tightening device, ensuring that the gear pair always maintains moderate contact

Sealing system: multi-layer labyrinth seal combined with high-performance grease, with a protection level of up to IP67

The face gear coupling adopts multiple innovative designs:

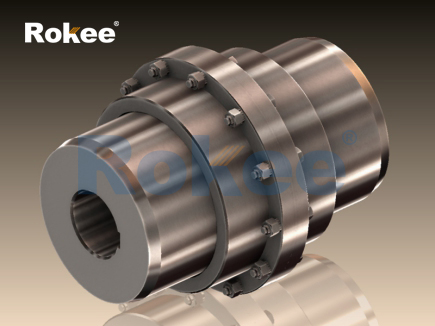

Variable tooth profile technology: By optimizing tooth profile modification, reducing edge contact stress concentration

Asymmetric tooth groove design: improves the load-bearing capacity in a single direction, especially suitable for one-way transmission systems

Modular interface: standardized flange connection size

Intelligent monitoring integration: Some high-end models have built-in temperature and vibration sensors to achieve real-time monitoring of status

The working principle of the face gear coupling is based on the axial meshing transmission of precision gear pairs. When the driving shaft rotates, torque is transmitted to the driven shaft through the meshing of the end face gear teeth, while allowing for a certain degree of axial, radial, and angular deviation compensation.

Its mechanical properties are manifested as:

Torque transmission efficiency: up to 98.5% -99.2%, 5-8% higher than traditional elastic couplings

Stiffness characteristics: The torsional stiffness coefficient is usually in the range of 10 ⁴ -10 ⁶ Nm/rad and can be adjusted according to application requirements

Critical speed: The carefully designed lightweight structure can achieve a critical speed of over 1.5 times the working speed

Dynamic response: Microscopic tooth surface modification technology effectively reduces vibration and noise during transmission process

Industrial application field

High end manufacturing equipment

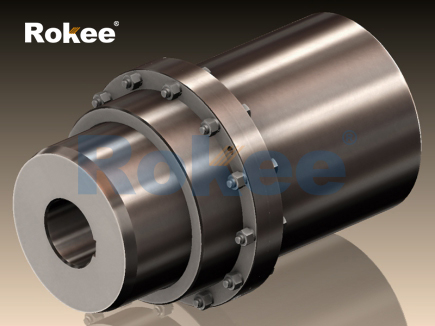

In five axis linkage CNC machine tools, face gear couplings are used to connect servo motors and ball screws, with a positioning accuracy of ± 0.001mm. Semiconductor manufacturing equipment relies on its characteristic of no reverse clearance to achieve precise motion control.

Energy and Heavy Industry

Large compressor units use heavy-duty face gear couplings to transmit tens of thousands of Newton meters of torque, and their unique damping characteristics effectively suppress torsional vibration. The connection between wind turbine gearboxes and generators is increasingly adopting this form.

Special environmental applications

Ship propulsion system: Made of corrosion-resistant special stainless steel material, suitable for marine environments

Mining Machinery: Enhanced Sealing Design, Excellent Dust and Waterproof Performance

Aerospace: Lightweight version of titanium alloy, meeting strict weight requirements

Scientific selection steps

Determine basic parameters: Calculate the maximum working torque (T=9550 × P/n), considering the peak load factor (usually 1.5-2.5)

Assess compensation needs: Measure actual installation deviations (axial, radial, angular)

Environmental considerations: special requirements such as temperature, humidity, corrosive media, etc

Dynamic characteristic matching: avoid the natural frequency of the system coinciding with the operating speed

Professional installation specifications

Alignment adjustment: use the laser alignment instrument to ensure that the deviation is within the allowable range (generally<0.05mm)

Pre tightening force setting: Apply torque accurately using a torque wrench according to the manufacturer's specified value

Lubrication management: The initial filling capacity of lubricating grease is 70% -80% of the cavity, and it is recommended to use extreme pressure lithium based grease

Trial operation monitoring: gradually increase the load, check the temperature rise and vibration situation

As a key component in the field of precision transmission, the technological progress of face gear couplings will continue to drive the development of high-end equipment manufacturing industry, providing more efficient and reliable power transmission solutions for industrial production.

« Face Gear Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/face-gear-couplings.html