Rokee is a well-known high-quality supplier of Rubber Tire Couplings and technical services in China, customize rubber tire couplings according to user drawings, alternatively, if the user provides rubber tire couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex landscape of mechanical power transmission, couplings serve as the critical interface between rotating shafts, enabling torque transfer while addressing the inherent challenges of shaft misalignment, vibration, and shock loads. Among the diverse array of flexible couplings, the rubber tire coupling stands out as a robust and versatile solution, widely adopted across heavy-duty industrial sectors for its exceptional ability to absorb vibrations, compensate for significant misalignments, and withstand harsh operating conditions. Unlike rigid couplings that require precise shaft alignment and offer no flexibility, or other flexible couplings with limited misalignment capacity, the rubber tire coupling leverages a rubber tire element as its core flexible component, providing superior damping properties and adaptability. This article comprehensively explores the design characteristics, working principles, material selections, key performance advantages, application scenarios, maintenance practices, and selection criteria of rubber tire couplings, offering a detailed insight into their role and value in modern industrial power transmission systems.

To establish a foundational understanding, it is essential to define the core functionality and distinguishing features of rubber tire couplings. A rubber tire coupling is a type of flexible mechanical coupling designed to transmit rotational power from a driving shaft (e.g., an electric motor, diesel engine, or turbine) to a driven shaft (e.g., a gearbox, pump, compressor, or conveyor) while effectively dampening vibrations, absorbing shock loads, and compensating for axial, radial, and angular misalignments. The defining attribute of this coupling type is its replaceable rubber tire (or elastomeric element), which serves as the intermediary between two metal flanges or hubs connected to the driving and driven shafts. This rubber tire element is typically reinforced with fabric or cord to enhance its tensile strength and torque-bearing capacity, ensuring reliable power transmission even under heavy loads. The unique design of the rubber tire coupling allows it to accommodate greater misalignment ranges compared to many other flexible couplings, making it particularly suitable for applications where shaft alignment is difficult to maintain or where dynamic operating conditions are prevalent.

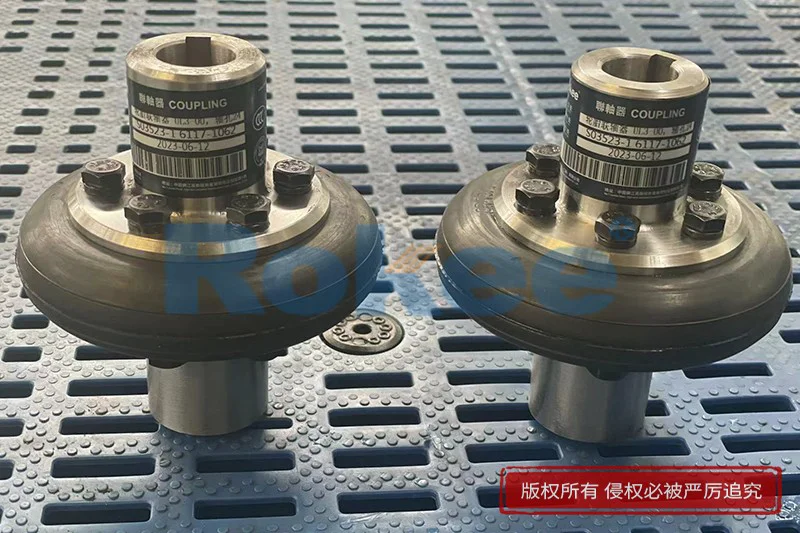

The structural composition of rubber tire couplings is engineered for durability and performance, with each component playing a vital role in ensuring efficient torque transfer and flexibility. The primary components include two metal hubs (or flanges), a rubber tire element (the flexible core), and fastening hardware such as bolts, nuts, and washers. The metal hubs are typically manufactured from high-strength materials such as cast steel, forged steel, or ductile iron, chosen for their ability to withstand the mechanical stresses of torque transmission and shock loads. Each hub features a mounting interface for attachment to the respective shafts, which may include keyways, set screws, or taper-lock bushings to ensure a secure and slip-free connection. The rubber tire element, which is the heart of the coupling’s flexibility, is designed to fit snugly between the two metal hubs. It is often shaped as a cylindrical or toroidal (doughnut-shaped) element with mounting holes or lugs that align with the holes on the metal hubs, allowing for secure fastening with bolts.

In many rubber tire coupling designs, the rubber tire element is reinforced with synthetic fibers (such as polyester, nylon, or aramid) or steel cords embedded within the rubber matrix. This reinforcement significantly enhances the tire’s tensile strength, fatigue resistance, and torque capacity, preventing premature failure under repeated load cycles. Additionally, some rubber tire couplings may incorporate a protective cover or shield to safeguard the rubber tire and metal components from external contaminants such as dust, dirt, water, and chemicals, which can degrade the rubber and corrode the metal parts over time. The cover also helps to contain the rubber tire in the event of failure, reducing the risk of damage to surrounding equipment or personnel.

The working principle of rubber tire couplings revolves around the deformation and resilience of the rubber tire element. When the driving shaft rotates, torque is transmitted from the driving hub to the rubber tire element through the fastening bolts. The rubber tire, being flexible yet resilient, deforms slightly to accommodate any misalignment between the driving and driven shafts. This deformation allows the coupling to compensate for axial misalignment (offset along the shaft axis), radial misalignment (parallel offset between shafts), and angular misalignment (tilt between shafts) without transferring excessive stresses to the connected shafts or equipment. As the rubber tire deforms, it also absorbs vibrations generated by the driving motor or other rotating components, converting the vibrational energy into heat, which is then dissipated into the surrounding environment. This vibration damping effect reduces noise levels and minimizes wear and tear on the connected machinery, extending their service life.

Furthermore, the rubber tire element acts as a shock absorber, cushioning the impact of sudden load changes or shock loads (such as those encountered during startup, shutdown, or equipment jamming). When a shock load is applied to the system, the rubber tire compresses and deforms, absorbing the impact energy and preventing it from being transmitted to the shafts and connected equipment. This shock absorption capability is particularly valuable in heavy-duty applications where sudden load fluctuations are common, as it helps to protect critical components from damage and ensures stable operation.

Material selection is a critical factor that directly influences the performance, durability, and application range of rubber tire couplings. The choice of materials for both the metal hubs and the rubber tire element is tailored to the specific operating conditions of the application, including torque requirements, temperature ranges, environmental contaminants, and misalignment levels. For the metal hubs, cast steel and forged steel are preferred for heavy-duty applications due to their high tensile strength, impact resistance, and durability. Ductile iron is also a common choice for medium-duty applications, offering a balance of strength and cost-effectiveness. In corrosive environments, stainless steel hubs may be used to prevent rust and corrosion, ensuring long-term performance.

The rubber tire element is typically manufactured from high-quality elastomeric materials that exhibit excellent flexibility, resilience, wear resistance, and resistance to environmental factors. The most commonly used elastomers include natural rubber (NR), nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and polyurethane (PU). Natural rubber offers superior elasticity and vibration damping properties, making it suitable for general-purpose applications with moderate temperature ranges (-20°C to 80°C). However, natural rubber has limited resistance to oil, fuel, and chemicals, restricting its use in environments where these contaminants are present.

Nitrile rubber (NBR) is widely used in applications involving oil, fuel, or hydraulic fluids, as it exhibits excellent oil resistance. It also offers good abrasion resistance and can operate within a temperature range of -30°C to 100°C, making it suitable for automotive, petroleum, and industrial hydraulic applications. Ethylene propylene diene monomer (EPDM) is known for its exceptional resistance to weather, ozone, and high temperatures (up to 150°C), as well as its resistance to water and steam. This makes EPDM rubber tire elements ideal for outdoor applications, HVAC systems, and steam-powered equipment.

Polyurethane (PU) rubber tire elements offer high tensile strength, wear resistance, and load-bearing capacity, making them suitable for heavy-duty applications with high torque requirements. PU also has good resistance to oil and chemicals and can operate within a temperature range of -40°C to 80°C. The reinforcement materials used in the rubber tire element, such as polyester or aramid fibers, are selected for their high tensile strength and fatigue resistance, ensuring that the tire can withstand repeated deformation without failure.

Rubber tire couplings offer a wide range of performance advantages that make them a preferred choice for numerous industrial applications. One of the most significant advantages is their exceptional misalignment compensation capability. Unlike many other flexible couplings that can only accommodate small degrees of misalignment, rubber tire couplings can compensate for radial misalignment up to 5-10 mm, angular misalignment up to 3-5 degrees, and axial misalignment up to 10-20 mm (depending on the coupling size and design). This makes them ideal for applications where precise shaft alignment is challenging, such as in large industrial machinery, mobile equipment, or applications where thermal expansion and contraction cause significant shaft movement.

Another key advantage is their superior vibration damping and noise reduction properties. The rubber tire element effectively absorbs and dampens vibrations generated by the driving motor, reducing the transmission of vibrations to the driven equipment and the surrounding structure. This not only improves the comfort of the working environment by reducing noise levels but also minimizes fatigue and wear on the connected machinery, extending their service life and reducing maintenance costs. The shock absorption capability of rubber tire couplings is also a major benefit, as it protects the system from damage caused by sudden load changes, startup shocks, or equipment jamming.

Rubber tire couplings are also known for their simplicity of installation and maintenance. The modular design allows for easy assembly and disassembly, with no need for specialized tools or expertise. The rubber tire element is a replaceable component, meaning that when it becomes worn or damaged, it can be replaced quickly and easily without removing the entire coupling or disconnecting the shafts. This reduces downtime and maintenance costs, making rubber tire couplings a cost-effective solution for industrial applications. Additionally, the rubber tire element is self-lubricating, eliminating the need for regular lubrication and reducing maintenance requirements further.

Furthermore, rubber tire couplings exhibit high torque transmission efficiency. The rigid connection between the metal hubs and the rubber tire element ensures that most of the torque generated by the driving shaft is transmitted to the driven shaft, with minimal power loss. This efficiency is particularly important in energy-intensive applications where reducing power consumption is a priority. The robust construction of rubber tire couplings also makes them highly durable, capable of withstanding harsh operating conditions such as high temperatures, humidity, dust, and minor chemical exposure (depending on the rubber material selected).

Due to their exceptional performance characteristics, rubber tire couplings find applications across a wide range of industries and mechanical systems. One of the primary application areas is the heavy machinery and construction industry, where they are used in equipment such as excavators, loaders, bulldozers, and cranes. In these applications, the coupling must withstand high torque, significant misalignment (caused by the movement of the equipment’s hydraulic systems and structural flexing), and shock loads. The rubber tire coupling’s ability to compensate for misalignment and absorb shocks makes it ideal for these harsh operating conditions, ensuring reliable power transmission between the engine and the hydraulic pumps, gearboxes, or drive wheels.

The mining industry is another major user of rubber tire couplings. Mining equipment such as conveyors, crushers, and grinding mills operate under extreme conditions, with high torque loads, significant vibrations, and frequent shock loads. Rubber tire couplings are used to connect the motors to these machines, providing reliable torque transmission while dampening vibrations and absorbing shocks. Their ability to accommodate misalignment is also critical in mining applications, where equipment is often installed in uneven or unstable environments, making precise shaft alignment difficult to maintain.

In the power generation industry, rubber tire couplings are used in both thermal and hydroelectric power plants. In thermal power plants, they connect steam turbines or gas turbines to generators, compensating for the misalignment caused by thermal expansion of the shafts during operation and dampening the vibrations generated by the turbines. In hydroelectric power plants, they are used to connect water turbines to generators, withstanding the high torque loads and accommodating the misalignment caused by the movement of the turbine shaft. The vibration damping properties of rubber tire couplings also help to protect the sensitive electrical components of the generator, ensuring stable power output.

The marine industry also utilizes rubber tire couplings in various applications, such as connecting the main engine to the propeller shaft in small to medium-sized vessels. The coupling’s ability to compensate for misalignment caused by hull flexing and absorb engine vibrations ensures smooth power transmission and reduces noise levels on board. Additionally, the corrosion-resistant materials used in marine-grade rubber tire couplings (such as stainless steel hubs and EPDM rubber) make them suitable for the harsh marine environment, where exposure to saltwater and humidity can cause rapid corrosion of metal components.

Other applications of rubber tire couplings include the automotive industry (for connecting engines to transmissions in heavy-duty trucks and buses), the pulp and paper industry (for conveyors and paper machines), the food and beverage industry (for pumps and mixers), and the wastewater treatment industry (for pumps and aerators). In each of these applications, the rubber tire coupling’s combination of misalignment compensation, vibration damping, and durability makes it an essential component for reliable and efficient operation.

Proper maintenance is essential to ensure the optimal performance and longevity of rubber tire couplings. While these couplings are relatively low-maintenance compared to other types of couplings, regular inspection and preventive maintenance practices can help to identify potential issues early and avoid unexpected failures. The key maintenance tasks for rubber tire couplings include regular visual inspection, checking for misalignment, monitoring operating temperatures, and replacing worn or damaged components.

Visual inspection is the most basic and important maintenance task. This involves examining the rubber tire element for signs of wear, damage, or degradation, such as cracks, tears, bulges, hardening, or softening. Hardening of the rubber is often caused by exposure to high temperatures or ozone, while softening may be due to exposure to oil or chemicals. Any signs of damage to the rubber tire element indicate that it should be replaced immediately to prevent failure. The metal hubs and fastening bolts should also be inspected for signs of corrosion, wear, or loosening. Loose bolts can cause excessive vibration and uneven torque distribution, leading to premature failure of the coupling.

Checking the alignment of the connected shafts is another critical maintenance practice. While rubber tire couplings can accommodate significant misalignment, excessive misalignment can put additional stress on the rubber tire element, leading to premature wear and failure. Shaft alignment should be checked periodically using tools such as laser alignment systems, straightedges, or feeler gauges. If excessive misalignment is detected, the shafts should be realigned to within the coupling’s specified limits. It is also important to check the axial movement of the shafts, as excessive axial movement can stretch or compress the rubber tire element beyond its design limits.

Monitoring the operating temperature of the coupling can help to identify potential issues such as excessive friction or misalignment. An abnormal increase in temperature may indicate that the rubber tire element is degrading due to overheating, or that there is excessive friction between the metal hubs and the rubber tire. If the temperature exceeds the maximum operating temperature of the rubber material, the coupling should be shut down and inspected immediately.

Replacement of the rubber tire element is the most common maintenance task for rubber tire couplings. The service life of the rubber tire element depends on factors such as operating temperature, torque load, misalignment, and environmental conditions. As a general guideline, the rubber tire element should be replaced every 1-5 years, depending on the application. When replacing the rubber tire element, it is important to select a replacement that is compatible with the coupling’s design and the operating conditions of the application. The replacement element should be the correct size and material, and the fastening bolts should be tightened to the specified torque to ensure a secure connection.

When selecting a rubber tire coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and most important factor is the torque capacity of the coupling. The coupling must be able to transmit the maximum torque generated by the driving shaft without failure. The torque capacity of a rubber tire coupling depends on factors such as the size of the metal hubs, the material and design of the rubber tire element, and the number of fastening bolts. It is essential to select a coupling with a torque capacity that exceeds the maximum operating torque of the system by a sufficient safety margin (typically 10-20%) to accommodate sudden load changes and shock loads.

The second factor to consider is the misalignment requirements of the application. The coupling must be able to accommodate the maximum expected axial, radial, and angular misalignment between the driving and driven shafts. It is important to consult the coupling manufacturer’s specifications to ensure that the selected coupling can meet the misalignment requirements of the application. Selecting a coupling with insufficient misalignment capacity will lead to premature wear and failure of the rubber tire element.

Operating temperature is another critical factor in coupling selection. The rubber tire element’s material must be able to withstand the minimum and maximum operating temperatures of the application. Using a rubber material that is not suitable for the operating temperature range will result in premature degradation of the rubber, leading to coupling failure. Environmental conditions such as exposure to oil, fuel, chemicals, water, or ozone must also be considered when selecting the rubber material for the tire element.

The size and space constraints of the application are also important considerations. The coupling must fit within the available space, and its dimensions must be compatible with the shaft diameters of the driving and driven equipment. The weight of the coupling is also a factor in applications where weight reduction is a priority, such as in mobile equipment or aerospace applications.

Finally, cost is a practical factor that cannot be ignored. While rubber tire couplings are generally cost-effective compared to other types of heavy-duty flexible couplings, the cost can vary depending on the size, material, and torque capacity. It is important to balance cost with performance requirements to select a coupling that meets the application’s needs without unnecessary expenditure. However, it is also important to avoid selecting a lower-cost coupling that cannot meet the torque or misalignment requirements, as this will result in higher maintenance costs and downtime in the long run.

In conclusion, rubber tire couplings are essential components in modern industrial power transmission systems, offering a unique combination of exceptional misalignment compensation, superior vibration damping, shock absorption, and ease of maintenance. Their robust design and versatile material options make them suitable for a wide range of applications across heavy machinery, mining, power generation, marine, and automotive industries, among others. By understanding the design characteristics, working principles, material selections, advantages, applications, maintenance practices, and selection criteria of rubber tire couplings, engineers and maintenance professionals can make informed decisions to ensure the reliable and efficient operation of their mechanical systems. As industrial technology continues to evolve, rubber tire couplings are expected to remain a staple in power transmission, with ongoing advancements in elastomeric materials and design further enhancing their performance and application range. Whether in harsh mining environments, high-temperature power plants, or mobile construction equipment, rubber tire couplings play a critical role in ensuring the smooth, reliable, and safe transmission of power, making them an indispensable component in the global industrial infrastructure.

« Rubber Tire Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/rubber-tire-couplings.html