Rokee is a well-known high-quality supplier of Flexible Pin Bush Couplings and technical services in China, customize flexible pin bush couplings according to user drawings, alternatively, if the user provides flexible pin bush couplings parameters, we can select the model and design drawings for you, support wholesale and export.

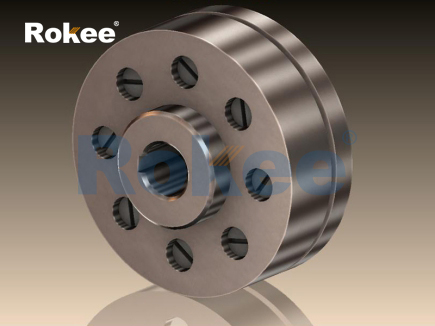

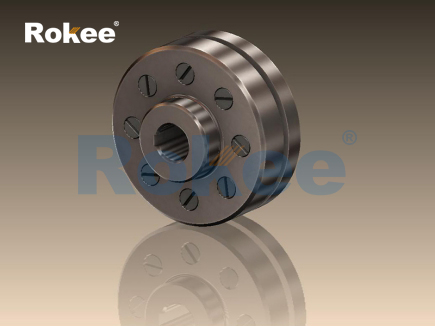

Flexible Pin Bush Coupling is a flexible coupling device widely used in industrial transmission systems. It connects two shafts through special elastic elements and can compensate for axial, radial, and angular deviations while transmitting torque. This type of coupling has become a key component in modern mechanical transmission systems due to its advantages of simple structure, low cost, and easy maintenance.

Compared with traditional rigid couplings, Flexible Pin Bush Couplings have significant buffering and shock absorption performance, which can effectively absorb and alleviate vibrations and impacts during system operation, and protect connected equipment from damage. Its working principle is based on the deformation ability of elastic materials, compensating for axial deviation through the elastic deformation of elastic sleeves such as rubber or polyurethane, while transmitting torque through column pins.

The Flexible Pin Bush Coupling is mainly composed of the following core components:

Half coupling: usually made of cast iron or steel, divided into two parts: the driving end and the driven end, which are respectively connected to the driving shaft and the driven shaft.

Column pins: generally made of high-strength steel, cylindrical or conical in shape, usually 6-12 in number, evenly distributed on the circumference of the coupling, and are the main carrier for transmitting torque.

Elastic sleeve: Made of rubber, polyurethane, or other elastic materials, it is fitted onto the column pin to provide cushioning, shock absorption, and compensation for deviations.

Retaining ring: used to fix the position of the elastic sleeve and prevent it from falling off or shifting during operation.

Nut and washer: used to secure the column pin, ensuring the stability and safety of the entire component.

Modern Flexible Pin Bush Couplings constantly innovate in material selection, and the use of high-performance engineering plastics and composite materials greatly enhances their durability and load-bearing capacity. Couplings used under special working conditions will also use special elastic materials that are resistant to high temperatures, oil, or corrosion.

The working principle of the Flexible Pin Bush Coupling is based on the combination of elastic deformation and friction transmission. When the driving shaft rotates, the torque is transmitted to the elastic sleeve through the column pin, and the elastic sleeve then transmits the torque to the column pin at the driven end through friction and deformation, ultimately driving the driven shaft to rotate. During this process, the deformation ability of the elastic sleeve enables the coupling to:

Compensation deviation: It can absorb radial deviation of 0.5-3mm, angular deviation of 1-5 °, and a small amount of axial displacement.

Buffer and shock absorption: Elastic materials can effectively absorb and attenuate system vibrations, reducing peak loads.

Overload protection: When the torque exceeds the rated value, the elastic sleeve will first deform or be damaged, which serves to protect the equipment.

The significant features of the Flexible Pin Bush Coupling include:

Simple structure, easy to assemble and disassemble

No lubrication required, low maintenance cost

Has good electrical insulation performance

Economical price and high cost-effectiveness

Capable of absorbing and reducing vibrations and impacts

When choosing an Flexible Pin Bush Coupling, the following key parameters need to be considered:

Nominal torque Tn: The maximum torque that a coupling can stably transmit over a long period of time, usually measured in N · m.

Permissible speed [n]: The maximum working speed allowed by the coupling, measured in r/min.

Shaft hole diameter range: The shaft diameter size range suitable for the coupling needs to match the equipment shaft diameter.

Compensation capability: including radial, axial, and angular deviation compensation.

Working temperature range: depends on the temperature resistance of the elastic sleeve material.

The main factors to consider when selecting:

Transferred power and torque

The rotational speed of the shaft

Diameter and shape of the connecting shaft

Installation space restrictions

Working environment conditions (temperature, humidity, corrosiveness, etc.)

Required deviation compensation capability

System vibration characteristics

Modern coupling models are usually formulated according to national or industry standards, such as GB/T 4323-2002 "Flexible Pin Bush Coupling" which specifies the standard models and parameters of such products in China.

Proper installation and maintenance are crucial for the performance and lifespan of Flexible Pin Bush Couplings

Installation steps:

Check if all components of the coupling are intact, clean the shaft and coupling holes

Install the half couplings onto the two shafts separately, using either hot or press fitting methods

Preliminary alignment of the two halves of the coupling, leaving appropriate clearance

Install the elastic sleeve and column pin, and tighten the fixing nut evenly

Conduct final alignment adjustment, and control the radial deviation within 0.2mm

Check if all fasteners are secure

Maintenance points:

Regularly check the wear of the elastic sleeve, and replace it when the rubber ages, cracks, or wears more than 1mm

Check for bent, worn or loose pins

Keep the coupling clean and avoid oil and dust accumulation

Pay attention to abnormal noise or vibration during operation and promptly investigate the cause

Avoid long-term overload operation

Common faults and solutions:

Abnormal vibration: check the alignment, wear degree of elastic sleeve, and status of fasteners

High temperature: Check for overload or improper lubrication (some models require lubrication)

Increased noise: It may be due to damaged elastic sleeve or loose column pin

Decreased transmission efficiency: Check if the elastic sleeve has aged and failed

Flexible Pin Bush Couplings are widely used in various industrial fields, including:

General machinery: pumps, fans, compressors, mixing equipment, etc

Conveyor equipment: conveyor belts, elevators, screw conveyors, etc

Construction machinery: excavators, cranes, concrete machinery, etc

Power generation equipment: hydroelectric generator sets, diesel generator sets, etc

Metallurgical equipment: rolling mills, crushers, rotary kilns, etc

Shipbuilding Industry: Ship Power Transmission System

« Flexible Pin Bush Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/flexible-pin-bush-couplings.html