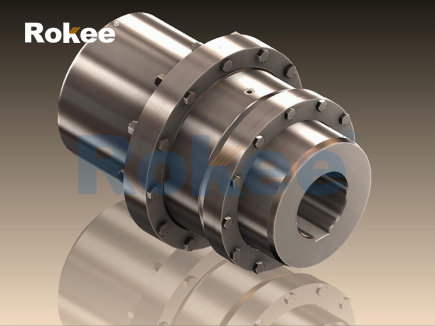

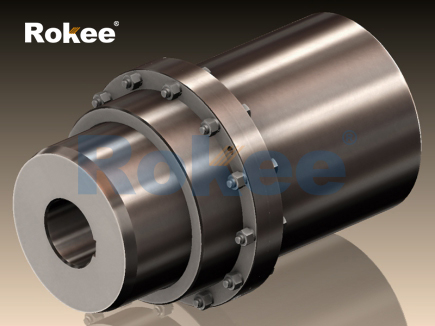

Rokee is a well-known high-quality supplier of Intermediate Shaft Couplings and technical services in China, customize intermediate shaft couplings according to user drawings, alternatively, if the user provides intermediate shaft couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex landscape of mechanical power transmission systems, the need to connect rotating shafts that are separated by significant distances or require enhanced misalignment compensation has led to the development of specialized coupling solutions. Among these, the intermediate shaft coupling (also known as a spacer shaft coupling) stands out as a versatile and robust option, engineered to bridge gaps between driving and driven shafts while ensuring efficient torque transfer and mitigating operational stresses. Unlike standard couplings that connect shafts directly, the intermediate shaft coupling incorporates a central intermediate shaft (spacer) between two end couplings, expanding the range of shaft separation and misalignment that can be accommodated. This unique design makes it particularly valuable in large-scale industrial machinery, where shaft distances are substantial or precise alignment is challenging to maintain. This article provides a comprehensive exploration of intermediate shaft couplings, delving into their fundamental working principles, structural components, material selection criteria, key performance advantages, typical application scenarios, and essential maintenance practices, thereby offering a holistic understanding of their role in enhancing the flexibility and reliability of heavy-duty mechanical systems.

The core functionality of an intermediate shaft coupling lies in its ability to transmit torque between two spatially separated rotating shafts while compensating for three primary types of misalignment: angular misalignment (shafts intersecting at an angle), parallel misalignment (radial offset between shafts), and axial misalignment (longitudinal movement of shafts toward or away from each other). This functionality is enabled by the coupling’s distinctive three-part design: two end coupling units (which can be flexible or rigid, depending on application needs) and a central intermediate shaft (spacer) that connects the two end units.

When torque is applied to the driving shaft, the force is first transmitted to the driving end coupling unit. This end unit—typically equipped with flexible elements such as gear teeth, metallic discs, or elastomeric components—accommodates any initial misalignment between the driving shaft and the intermediate shaft. The torque is then transferred through the intermediate shaft to the driven end coupling unit, which similarly compensates for misalignment between the intermediate shaft and the driven shaft before transmitting the torque to the driven shaft. The intermediate shaft itself acts as a torque-transmitting bridge, enabling the coupling to span significant distances (often ranging from a few hundred millimeters to several meters) that would be impractical for direct-coupling designs.

A key principle of intermediate shaft coupling operation is the synergy between the end coupling units and the intermediate shaft. The end units provide the necessary flexibility to accommodate misalignments, while the intermediate shaft ensures rigid torque transmission across the span. The choice of end coupling type (e.g., gear, disc, or elastomeric) dictates the coupling’s overall misalignment capacity, torque rating, and vibration damping characteristics. For example, gear-type end units offer high torque capacity and moderate misalignment compensation, making them suitable for heavy-duty applications, while elastomeric end units provide superior vibration damping but are limited to lower torque ranges. Additionally, the intermediate shaft’s length and diameter are engineered to withstand the torsional and bending stresses generated during operation, ensuring that torque is transmitted efficiently without excessive deflection or vibration.

Another critical aspect of intermediate shaft coupling operation is its ability to handle axial expansion and contraction of shafts due to thermal changes. In high-temperature applications (such as in power plants or steel mills), shafts can expand or contract longitudinally, leading to axial misalignment. The end coupling units of intermediate shaft couplings are designed to absorb these axial movements, preventing excessive stress on the shafts, bearings, and other components. This thermal compensation capability is particularly important in large industrial systems, where temperature fluctuations are significant and can lead to premature component failure if not addressed.

Intermediate shaft couplings feature a modular, precision-engineered structure consisting of three primary components: end coupling units, an intermediate shaft (spacer), and fastening/connecting hardware. Each component is designed to work in synergy to ensure reliable torque transmission, misalignment compensation, and long-term operational stability—even in the most demanding industrial environments.

End coupling units are the critical flexible or rigid components that connect the intermediate shaft to the driving and driven shafts. The design of these units varies based on the application’s torque requirements, misalignment needs, and environmental conditions. Common types of end coupling units include gear couplings, flexible disc couplings, elastomeric jaw couplings, and universal joints. Gear-type end units consist of meshing gear hubs and sleeves, offering high torque capacity and moderate misalignment compensation. Flexible disc end units use metallic disc packs to provide flexibility without lubrication, making them suitable for clean, high-precision applications. Elastomeric jaw end units rely on rubber or synthetic elastomer spiders for flexibility and vibration damping, ideal for medium-torque, low-maintenance applications. Universal joint end units (such as Cardan joints) are used for applications requiring high angular misalignment compensation, often in automotive or agricultural machinery.

The intermediate shaft (spacer) is the central component that spans the distance between the two end coupling units. Typically manufactured as a solid or hollow cylindrical shaft, its dimensions (length and diameter) are determined by the required span distance, torque capacity, and rotational speed. Solid intermediate shafts are used for high-torque applications, as they offer greater torsional rigidity and strength. Hollow intermediate shafts are preferred for applications where weight reduction is critical (such as in aerospace or automotive systems) or where the shaft needs to accommodate other components (such as lubrication lines or electrical wiring). The ends of the intermediate shaft are precision-machined to ensure secure connection to the end coupling units, often using keyway fittings, interference fits, or flange connections.

Fastening and connecting hardware play a vital role in maintaining the integrity of the intermediate shaft coupling. This hardware includes high-strength bolts, nuts, lock washers, keys, and splines. Bolts and nuts are used to secure the end coupling units to the intermediate shaft and the driving/driven shafts, ensuring a slip-free connection. Lock washers or thread-locking compounds are often used to prevent fastener loosening due to vibration. Keys and splines are used to transmit torque between the shafts and coupling units, with splines offering greater torque capacity and uniform load distribution compared to keys. In some designs, hydraulic couplings or clamping collars are used for quick installation and removal, minimizing downtime during maintenance.

Additional structural components may include bearings, supports, and guards. Bearings are often installed along the length of the intermediate shaft to support its weight and reduce bending stress, particularly in long-span applications. These bearings are typically mounted in housings attached to the machine frame, ensuring that the intermediate shaft remains aligned during operation. Guards (such as metal covers) are used to protect the coupling components from external contamination (dust, dirt, moisture) and to prevent accidental contact with rotating parts, enhancing operational safety.

The performance, durability, and suitability of an intermediate shaft coupling for a specific application are heavily dependent on the materials used for its components. Given the wide range of operating conditions (including high torque, high speed, extreme temperatures, and corrosive environments) that these couplings may endure, material selection is focused on strength, durability, wear resistance, corrosion resistance, and weight efficiency. Key factors influencing material selection include operating temperature, torque requirements, rotational speed, span distance, environmental conditions (exposure to chemicals, moisture, or abrasives), and weight constraints.

For the intermediate shaft, the most commonly used materials are high-strength alloy steels and stainless steels. Alloy steels (such as 4140, 4340, and 300M) are preferred for high-torque, heavy-duty applications due to their excellent tensile strength, torsional rigidity, and wear resistance. These steels can be heat-treated (through quenching and tempering) to further enhance their mechanical properties, making them suitable for use in power plants, steel mills, and mining equipment. Stainless steels (such as 316 and duplex stainless steel) are used in corrosive environments, such as marine applications or chemical processing plants, due to their excellent corrosion resistance. For lightweight applications (such as aerospace or automotive systems), aluminum alloys (such as 6061-T6) or titanium alloys are used, offering a balance of strength and weight reduction.

End coupling units are manufactured from materials that complement their design and application. Gear-type end units are typically made from the same high-strength alloy steels as the intermediate shaft, with gear teeth often subjected to surface treatments (carburizing, nitriding, or induction hardening) to enhance wear resistance. Flexible disc end units use metallic discs made from stainless steel (17-4 PH) or nickel-based alloys (Inconel), which offer high strength and corrosion resistance. Elastomeric end units use hubs made from alloy steel or aluminum, with elastomer spiders made from nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), or fluorinated elastomers (Viton) depending on the operating environment.

Fastening hardware is selected based on the application’s torque requirements and environmental conditions. High-strength alloy steel fasteners (Grade 8 or 10.9) are used for general-purpose, high-torque applications. Stainless steel fasteners are used in corrosive environments to prevent rust and degradation. In high-temperature applications, nickel-based alloy fasteners are used to maintain strength and integrity at elevated temperatures. Bearings used to support the intermediate shaft are typically made from chrome steel or stainless steel, with ceramic bearings used in high-speed or corrosive applications for enhanced durability.

Surface treatments and coatings may also be applied to intermediate shaft coupling components to enhance their performance. For example, intermediate shafts and end coupling units may be coated with zinc, chrome, or epoxy to improve corrosion resistance. Gear teeth may be coated with wear-resistant materials (such as tungsten carbide) to extend service life in abrasive environments. These treatments help to protect the components from harsh operating conditions, ensuring reliable performance over an extended period.

Intermediate shaft couplings offer a range of performance advantages that make them a preferred choice for applications requiring shaft connection over long spans or enhanced misalignment compensation. These advantages include extended span capability, superior misalignment compensation, flexibility in design, high torque capacity, thermal expansion accommodation, and enhanced safety.

One of the most significant advantages of intermediate shaft couplings is their ability to span large distances between driving and driven shafts. Unlike direct-coupling designs, which are limited by the maximum distance they can bridge (typically a few hundred millimeters), intermediate shaft couplings can span distances of several meters, making them ideal for large industrial machinery such as rolling mills, turbines, and conveyor systems. This extended span capability eliminates the need for additional support structures or shaft modifications, reducing installation complexity and cost.

Intermediate shaft couplings also offer superior misalignment compensation compared to many direct-coupling designs. By incorporating flexible end coupling units, they can accommodate higher levels of angular, parallel, and axial misalignment. For example, gear-type end units can typically handle angular misalignment of up to 1-2 degrees and parallel misalignment of up to 0.5-1 millimeter per end, while universal joint end units can accommodate angular misalignment of up to 30 degrees or more. This enhanced misalignment compensation reduces stress on shafts, bearings, and other components, extending their service life and minimizing the risk of premature failure. It also simplifies installation, as precise shaft alignment is less critical compared to direct-coupling designs.

Flexibility in design is another key advantage of intermediate shaft couplings. The modular nature of their design (end units + intermediate shaft) allows for customization based on specific application requirements. For example, different types of end coupling units can be combined to meet unique misalignment, torque, or vibration damping needs. The length and diameter of the intermediate shaft can be tailored to the required span distance and torque capacity. This customization makes intermediate shaft couplings suitable for a wide range of applications, from light-duty automotive systems to heavy-duty industrial machinery.

High torque capacity is a critical advantage for heavy-duty applications. By using high-strength materials for the intermediate shaft and end coupling units, intermediate shaft couplings can transmit extremely high levels of torque—often exceeding 100,000 Nm in large industrial designs. This makes them suitable for use in power generation (turbines, generators), steel processing (rolling mills), mining (crushers, conveyors), and marine (ship propulsion) applications, where large amounts of torque need to be transmitted over long distances.

The ability to accommodate thermal expansion and contraction is another important advantage. In high-temperature applications, shafts can expand or contract longitudinally, leading to axial misalignment. Intermediate shaft couplings with flexible end units can absorb these axial movements, preventing excessive stress on the shafts and bearings. This thermal compensation capability ensures reliable operation even in environments with significant temperature fluctuations, such as power plants or industrial furnaces.

Enhanced safety is also a benefit of intermediate shaft couplings. The inclusion of guards and protective covers prevents accidental contact with rotating components, reducing the risk of injury to personnel. Additionally, the modular design allows for easier maintenance and inspection, ensuring that potential issues (such as worn bearings or loose fasteners) are detected and addressed before they lead to catastrophic failure.

Due to their unique combination of advantages—including extended span capability, superior misalignment compensation, high torque capacity, and design flexibility—intermediate shaft couplings are used in a wide range of heavy-duty and specialized applications across various industries. They are particularly well-suited for applications where shafts are separated by large distances or require enhanced misalignment compensation.

In the power generation industry, intermediate shaft couplings are used in steam turbines, gas turbines, hydroelectric turbines, and generators. These applications often require the transmission of high torque over significant distances (e.g., between a turbine and a generator in a power plant). The intermediate shaft coupling’s ability to span these distances while accommodating misalignment and thermal expansion makes it an ideal choice. Additionally, the high torque capacity of these couplings ensures reliable power transmission, which is critical for power generation facilities where downtime is extremely costly.

The steel and metal processing industry relies heavily on intermediate shaft couplings for use in rolling mills, extruders, and metal forming machinery. Rolling mills, which are used to shape steel and other metals, require the transmission of high torque over long distances between motors, gearboxes, and rolling stands. Intermediate shaft couplings bridge these distances while accommodating the misalignments that can occur due to the heavy loads and thermal expansion of the machinery. Extruders, which are used to shape plastic and metal materials, also benefit from the coupling’s high torque capacity and misalignment compensation, ensuring continuous operation even under variable load conditions.

In the mining and mineral processing industry, intermediate shaft couplings are used in crushers, conveyors, and pumps. Crushers, which are used to break down large rocks and minerals, often have shafts separated by significant distances, requiring the extended span capability of intermediate shaft couplings. Conveyors, which transport minerals and materials over long distances (often kilometers in mining operations), use intermediate shaft couplings to connect the drive motor to the conveyor shaft, spanning the distance between the motor and the conveyor head. The coupling’s misalignment compensation capability is particularly valuable in these applications, as conveyors are often installed on uneven terrain, leading to significant shaft misalignment.

The marine industry uses intermediate shaft couplings in ship propulsion systems, auxiliary engines, and pumps. Ship propulsion systems require the transmission of high torque from the engine to the propeller shaft, which can be separated by several meters (depending on the ship’s design). Intermediate shaft couplings bridge this distance while accommodating misalignments caused by the ship’s movement and thermal expansion of the shafts. The use of corrosion-resistant materials (such as stainless steel) ensures durability in the saltwater environment. Auxiliary engines and pumps on ships also use intermediate shaft couplings for reliable power transmission over extended spans.

Specialized applications for intermediate shaft couplings include aerospace systems (such as aircraft engines and auxiliary power units), automotive systems (such as heavy-duty trucks and buses), and industrial fans and blowers. In aerospace applications, lightweight intermediate shaft couplings (using aluminum or titanium alloys) are used to connect components over limited spans while minimizing weight. In automotive systems, intermediate shaft couplings are used in drivetrains to connect the transmission to the rear axle, accommodating misalignments and spanning the distance between the front and rear of the vehicle. Industrial fans and blowers, used in power plants and industrial facilities, benefit from the coupling’s extended span capability and misalignment compensation, ensuring efficient and reliable operation.

While intermediate shaft couplings are designed for durability and reliability, proper maintenance is essential to ensure their long-term performance, extend their service life, and prevent unexpected downtime. The key maintenance practices for these couplings include regular inspection, proper lubrication, shaft alignment checks, bearing maintenance, and replacement of worn components.

Regular inspection is the cornerstone of effective maintenance for intermediate shaft couplings. Inspections should be conducted periodically—typically every 3-6 months, depending on the application and operating conditions—to check for signs of wear, damage, or misalignment. During inspection, the end coupling units should be examined for worn gear teeth, damaged disc packs, or degraded elastomer components. The intermediate shaft should be checked for cracks, corrosion, or excessive deflection. Fasteners (bolts, nuts, keys) should be inspected for tightness, wear, or corrosion, with any loose fasteners tightened immediately. Additionally, the coupling should be inspected for excessive vibration or noise during operation, which may indicate misalignment, worn bearings, or damaged components.

Proper lubrication is critical for intermediate shaft couplings equipped with lubricated components (such as gear-type end units or bearings). The meshing gear teeth and bearings require continuous lubrication to reduce friction, minimize wear, dissipate heat, and prevent corrosion. Lubrication intervals depend on the operating conditions, including speed, temperature, and load. As a general guideline, lubricants should be checked and replaced every 6-12 months, or more frequently for high-speed, high-load applications. It is important to use the lubricant recommended by the manufacturer, as using the wrong type of lubricant can lead to premature wear, overheating, and failure. Seals should also be inspected regularly to ensure they are functioning properly and preventing lubricant leakage and contamination.

Shaft alignment checks are essential to ensure that the intermediate shaft coupling is operating within its misalignment limits. While the coupling can accommodate moderate misalignment, operating beyond its rated limits will accelerate wear on the end units and bearings. Shaft alignment should be checked using laser alignment tools or dial indicators, which provide precise measurements of angular, parallel, and axial misalignment. Any misalignment beyond the coupling’s rated limits should be corrected immediately by adjusting the position of the driving or driven shaft, or by replacing worn components.

Bearing maintenance is particularly important for intermediate shaft couplings with long spans, as bearings support the intermediate shaft and reduce bending stress. Bearings should be inspected regularly for signs of wear, damage, or insufficient lubrication. Worn or damaged bearings should be replaced immediately to prevent excessive deflection of the intermediate shaft, which can lead to premature failure of the coupling or other components. Proper lubrication of bearings is also critical, with lubricants selected based on the operating temperature and load.

Replacement of worn components is necessary when signs of excessive wear or damage are detected. Common worn components include end coupling units (gear teeth, disc packs, elastomer spiders), bearings, fasteners, and seals. When replacing components, it is important to use parts that are compatible with the coupling’s design and specifications. In some cases, the entire intermediate shaft may need to be replaced if it is cracked or severely corroded. It is recommended to schedule component replacement during planned shutdowns to minimize downtime.

In addition to these maintenance practices, it is important to follow the manufacturer’s guidelines for the specific coupling model. Manufacturers often provide detailed maintenance instructions, including recommended lubrication intervals, torque specifications, and replacement parts. Adhering to these guidelines ensures that the coupling operates at peak performance and extends its service life. It is also important to keep the coupling clean and free from external contamination (dust, dirt, moisture), as these can accelerate wear and corrosion.

Intermediate shaft couplings have established themselves as a versatile and reliable solution for power transmission in applications requiring shaft connection over long spans or enhanced misalignment compensation. Their unique modular design—combining end coupling units with a central intermediate shaft—provides a range of advantages, including extended span capability, superior misalignment compensation, high torque capacity, and design flexibility. The selection of appropriate materials (such as high-strength alloy steels, stainless steels, and lightweight alloys) and end coupling types is key to optimizing the coupling’s performance for specific operating conditions.

The key advantages of intermediate shaft couplings make them an attractive choice for industries such as power generation, steel processing, mining, marine, and aerospace. From turbines and rolling mills to crushers and ship propulsion systems, these couplings play a vital role in ensuring the efficient and continuous operation of critical mechanical systems.

Proper maintenance—including regular inspection, proper lubrication, shaft alignment checks, bearing maintenance, and timely replacement of worn components—is essential to maximizing the service life of intermediate shaft couplings and minimizing downtime. By following these maintenance practices and adhering to manufacturer guidelines, users can ensure that their intermediate shaft couplings operate reliably for years to come.

As technology advances and industrial requirements evolve, intermediate shaft couplings are likely to see further improvements in material performance, design optimization, and maintenance efficiency. The development of new high-strength, corrosion-resistant materials and advanced manufacturing techniques (such as additive manufacturing) will expand their application range, making them suitable for even more demanding environments. With their proven performance and versatility, intermediate shaft couplings are poised to remain a key component in heavy-duty mechanical power transmission systems across industries for the foreseeable future.

« Intermediate Shaft Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/intermediate-shaft-couplings.html