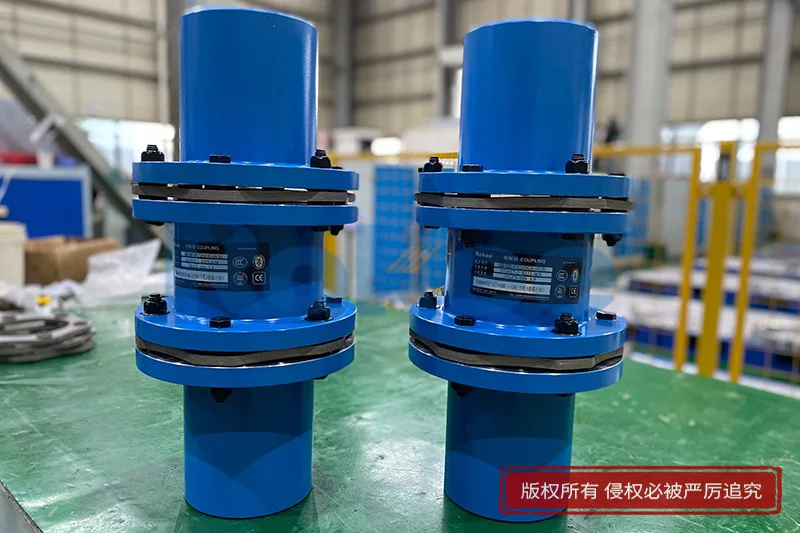

Rokee is a well-known high-quality supplier of Lamina Couplings and technical services in China, customize lamina couplings according to user drawings, alternatively, if the user provides lamina couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the domain of high-precision mechanical power transmission, the demand for couplings that can ensure accurate torque transfer while maintaining exceptional rigidity and alignment accuracy has been consistently growing. Among the various high-performance coupling solutions available, the lamina coupling (also referred to as disc coupling in some contexts) stands out as a preferred choice for precision-driven industrial applications. Distinguished by its use of thin, flexible metal laminae (discs) as the core torque-transmitting and misalignment-compensating component, the lamina coupling offers unique advantages such as zero backlash, high torsional stiffness, and excellent fatigue resistance. Unlike flexible couplings that rely on elastomeric elements, which may degrade over time or introduce torsional lag, lamina couplings leverage the inherent flexibility and strength of metal materials to achieve reliable power transmission. This article comprehensively explores the structural characteristics, working principles, material selections, key performance advantages, application scenarios, maintenance practices, and selection criteria of lamina couplings, providing a detailed overview of their role and value in high-precision mechanical systems.

To establish a fundamental understanding, it is essential to define the core functionality and distinguishing features of lamina couplings. A lamina coupling is a type of rigid-flexible coupling designed to transmit rotational torque between two coaxial shafts while accommodating small to moderate degrees of axial, radial, and angular misalignment. The defining feature of this coupling type is its use of one or more sets of thin metal laminae (typically arranged in a stack or a single disc with precision-cut slots) that connect the driving and driven hubs. These laminae are engineered to flex elastically under the influence of misalignment, allowing for relative movement between the shafts without compromising the integrity of torque transmission. Unlike elastomeric couplings that exhibit hysteresis and potential for wear, lamina couplings maintain consistent performance over extended periods, making them ideal for applications requiring high precision and reliability. Additionally, the absence of sliding or rolling components eliminates the need for lubrication, further enhancing their suitability for clean and maintenance-sensitive environments.

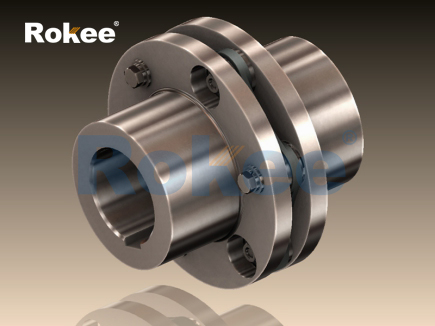

The structural composition of lamina couplings is meticulously engineered to balance rigidity, flexibility, and torque-bearing capacity, with each component playing a critical role in overall performance. The primary components include two hubs (driving and driven), a set of laminae (discs), and fastening hardware such as high-strength bolts and nuts. The hubs are typically machined from high-strength metallic materials to ensure a secure connection with the shafts and to withstand the mechanical stresses of torque transmission. Common hub designs include cylindrical hubs with keyways, taper-lock bushings, or clamp-style connections, which facilitate easy and secure mounting on the shafts. The design of the hubs also incorporates flanges or mounting surfaces that interface with the laminae, ensuring uniform load distribution across the lamina discs.

The laminae themselves are the most critical component of the coupling, as they determine the coupling’s flexibility, torque capacity, and fatigue life. These laminae are thin, flat discs (or stacked discs) made from high-performance metal materials, with a thickness ranging from a few tenths of a millimeter to several millimeters, depending on the application requirements. To enhance flexibility and misalignment capacity, the laminae are often precision-machined with slots, holes, or cutouts arranged in a specific pattern (such as radial, circular, or spiral patterns). These cutouts allow the laminae to flex elastically in response to axial, radial, or angular misalignment between the shafts, while maintaining torsional rigidity to ensure accurate torque transmission. In some designs, multiple laminae are stacked together to increase the coupling’s torque capacity and fatigue resistance, with the number of laminae determined by the maximum torque requirements of the application.

The fastening hardware used to connect the laminae to the hubs is also a critical component, as it must ensure a secure and rigid connection while avoiding excessive stress concentration on the laminae. High-strength bolts made from alloy steel or titanium are commonly used, along with lock washers or thread-locking compounds to prevent loosening under dynamic operating conditions. The bolts are typically arranged in a circular pattern around the hub flanges, ensuring that the torque is distributed evenly across the laminae. Some lamina coupling designs also incorporate spacers or distance sleeves between the laminae to maintain uniform spacing and prevent friction between the discs during operation.

The working principle of lamina couplings revolves around the elastic deformation of the metal laminae. When the driving shaft rotates, torque is transmitted from the driving hub to the laminae through the fastening bolts. The laminae, being rigid in the torsional direction, transmit the torque efficiently to the driven hub, which in turn rotates the driven shaft. When misalignment exists between the driving and driven shafts (axial, radial, or angular), the laminae flex elastically to accommodate this misalignment. For example, angular misalignment causes the laminae to bend slightly along their circumferential axis, while radial misalignment results in a small lateral deflection of the laminae. Axial misalignment is accommodated by the stretching or compressing of the laminae along the shaft axis. Importantly, this elastic deformation is fully reversible, meaning the laminae return to their original shape once the misalignment is corrected or the load is removed, ensuring no permanent deformation or loss of performance.

A key aspect of the lamina coupling’s working principle is its ability to maintain zero backlash during operation. Backlash, which is the amount of free movement between the driving and driven components, can introduce inaccuracies in precision applications such as robotics, machine tools, and automation systems. Since lamina couplings rely on the elastic deformation of metal laminae rather than sliding or meshing components, they exhibit no backlash, ensuring precise and instantaneous torque transmission. This zero-backlash characteristic makes lamina couplings particularly suitable for applications where positional accuracy and repeatability are critical.

Material selection is a pivotal factor that directly influences the performance, torque capacity, and service life of lamina couplings. The choice of materials for the hubs and laminae is tailored to the specific operating conditions of the application, including torque requirements, operating speed, temperature range, and environmental factors. For the hubs, high-strength materials such as alloy steel, stainless steel, and aluminum alloy are commonly used. Alloy steel hubs offer excellent tensile strength and torque-bearing capacity, making them suitable for heavy-duty precision applications. Stainless steel hubs are preferred for corrosive environments, as they exhibit superior resistance to rust and chemical degradation. Aluminum alloy hubs are lightweight and offer good thermal conductivity, making them ideal for high-speed applications where weight reduction and heat dissipation are important.

The laminae are typically manufactured from high-performance metal materials that exhibit excellent elastic properties, fatigue resistance, and tensile strength. The most commonly used materials for laminae include spring steel, stainless steel (such as 304 or 316), and titanium alloy. Spring steel is widely used for general-purpose lamina couplings due to its excellent elastic deformation capacity and fatigue resistance. It can withstand repeated flexing without permanent deformation, ensuring long service life under normal operating conditions. Stainless steel laminae are preferred for applications in corrosive environments or high-temperature conditions, as they offer superior resistance to oxidation and chemical attack. Titanium alloy laminae are used in high-performance applications where weight reduction, high strength, and excellent fatigue resistance are critical, such as in aerospace and high-speed robotics.

In addition to the base material, the surface treatment of the laminae can also enhance their performance and durability. Common surface treatments include electroplating (with zinc or nickel), passivation, and shot peening. Electroplating and passivation improve the corrosion resistance of the laminae, while shot peening enhances their fatigue strength by introducing compressive stresses on the surface, reducing the likelihood of crack initiation and propagation.

Lamina couplings offer a range of unique performance advantages that make them particularly suitable for high-precision and high-performance industrial applications. One of the most significant advantages is their zero-backlash operation, which ensures precise torque transmission and positional accuracy. This is critical in applications such as CNC machine tools, robotics, and automated assembly systems, where even small amounts of backlash can lead to dimensional inaccuracies or positional errors.

Another key advantage is their high torsional stiffness. Torsional stiffness refers to the coupling’s resistance to torsional deformation under torque load. Lamina couplings, with their rigid metal laminae, exhibit high torsional stiffness, ensuring that the rotational motion of the driving shaft is transmitted to the driven shaft with minimal torsional lag. This is particularly important in high-speed applications and applications requiring rapid acceleration and deceleration, as it helps to maintain system stability and responsiveness.

Lamina couplings also offer excellent fatigue resistance and long service life. The metal laminae are engineered to withstand repeated elastic deformation without permanent damage, and their fatigue life is significantly longer than that of elastomeric components used in other flexible couplings. This makes lamina couplings a reliable choice for continuous-duty applications where downtime is costly, such as in industrial automation and power generation systems.

Additionally, lamina couplings are maintenance-free in most applications. Since they have no sliding or rolling components, there is no need for lubrication, which eliminates the risk of lubricant contamination in clean environments (such as food processing, pharmaceutical manufacturing, and semiconductor production). The absence of lubrication also reduces maintenance costs and downtime associated with lubricant replacement and system cleaning.

Another advantage is their ability to operate in a wide range of temperature conditions. Unlike elastomeric couplings, which can degrade at high temperatures or become brittle at low temperatures, metal laminae maintain their elastic properties and performance over a wide temperature range (typically from -50°C to 200°C, depending on the material). This makes lamina couplings suitable for applications in extreme temperature environments, such as in aerospace, automotive engine compartments, and high-temperature industrial processes.

Finally, lamina couplings are compact and lightweight, making them suitable for applications where space is limited. Their simple design, with no bulky elastomeric components or complex housing, allows for easy integration into tight mechanical assemblies, such as in small robotics, medical equipment, and precision instrumentation.

Due to their unique performance characteristics, lamina couplings find applications in a wide range of high-precision and high-performance industries. One of the primary application areas is the machine tool industry, where they are used in CNC (Computer Numerical Control) lathes, milling machines, grinders, and machining centers. In these applications, the zero-backlash and high torsional stiffness of lamina couplings ensure precise torque transmission between the servo motor and the lead screw or spindle, resulting in accurate machining of complex components. The maintenance-free operation of lamina couplings also makes them ideal for machine tools, as it reduces downtime and ensures continuous production.

The robotics and automation industry is another major user of lamina couplings. Robotic arms and automated guided vehicles (AGVs) require precise and responsive torque transmission to achieve accurate positioning and movement. Lamina couplings are used to connect the servo motors to the reducers and joints of robotic arms, providing zero-backlash operation and high torsional stiffness. This ensures that the robotic arm moves exactly as programmed, with no lag or positional error, making them suitable for applications such as pick-and-place operations, assembly, and welding.

In the aerospace and defense industry, lamina couplings are used in a variety of applications, including aircraft engines, missile guidance systems, and satellite components. The high strength, lightweight, and excellent fatigue resistance of lamina couplings make them suitable for these demanding applications, where reliability and performance under extreme conditions are critical. For example, in aircraft engines, lamina couplings are used to connect the turbine to the generator or other auxiliary systems, ensuring reliable torque transmission even under high temperatures and vibrations.

The medical equipment industry also utilizes lamina couplings in precision devices such as surgical robots, diagnostic equipment, and medical imaging systems. These applications require high precision, low noise, and maintenance-free operation, which are all characteristics of lamina couplings. For example, in surgical robots, lamina couplings ensure precise movement of the surgical instruments, allowing surgeons to perform minimally invasive procedures with high accuracy.

Other applications of lamina couplings include the semiconductor manufacturing industry (in wafer handling equipment and lithography machines), the automotive industry (in electric vehicle drivetrains and precision steering systems), the power generation industry (in small gas turbines and generators), and the food and pharmaceutical industries (in cleanroom processing equipment). In each of these applications, the unique combination of zero backlash, high torsional stiffness, maintenance-free operation, and wide temperature range makes lamina couplings an essential component for reliable and precise operation.

While lamina couplings are generally maintenance-free, proper installation and periodic inspection are essential to ensure optimal performance and longevity. The key maintenance and installation practices for lamina couplings include proper shaft alignment, careful handling during installation, periodic visual inspection, and monitoring of operating conditions.

Proper shaft alignment is critical for the performance and service life of lamina couplings. Although lamina couplings can accommodate small to moderate degrees of misalignment, excessive misalignment can put additional stress on the laminae, leading to premature fatigue failure. During installation, the driving and driven shafts should be aligned as accurately as possible, within the coupling’s specified misalignment limits. Shaft alignment can be performed using precision tools such as laser alignment systems, dial indicators, or feeler gauges. It is important to check both radial and angular alignment, as well as axial movement, to ensure that all are within the recommended limits.

Careful handling during installation is also important to prevent damage to the laminae. The laminae are thin and can be easily bent or damaged if mishandled. During installation, it is important to avoid applying excessive force to the laminae, and to ensure that the fastening bolts are tightened evenly and to the specified torque. Over-tightening the bolts can cause stress concentration on the laminae, leading to cracks or premature failure. Under-tightening the bolts can result in loose connections, which can cause vibration and uneven load distribution.

Periodic visual inspection is another important maintenance practice. This involves examining the laminae for signs of wear, damage, or fatigue, such as cracks, bends, or discoloration (which may indicate overheating). The hubs and fastening bolts should also be inspected for signs of corrosion, wear, or loosening. If any signs of damage or wear are detected, the coupling should be replaced or repaired immediately to prevent catastrophic failure.

Monitoring of operating conditions is also recommended to ensure that the coupling is operating within its design limits. This includes monitoring operating temperature, vibration levels, and torque loads. An abnormal increase in temperature may indicate excessive friction or misalignment, while increased vibration may indicate loose connections or damage to the laminae. If any abnormal operating conditions are detected, the system should be shut down and inspected immediately.

When selecting a lamina coupling for a specific application, several key factors must be considered to ensure optimal performance and reliability. The first and most important factor is the torque capacity of the coupling. The coupling must be able to transmit the maximum torque generated by the driving shaft without failure. The torque capacity of a lamina coupling depends on factors such as the material and thickness of the laminae, the number of laminae, and the diameter of the lamina disc. It is essential to select a coupling with a torque capacity that exceeds the maximum operating torque of the system by a sufficient safety margin to accommodate sudden load changes and shock loads.

The second factor to consider is the misalignment requirements of the application. Lamina couplings are designed to accommodate small to moderate degrees of misalignment, typically up to 0.5-2 degrees of angular misalignment, 0.1-0.5 mm of radial misalignment, and 1-5 mm of axial misalignment (depending on the coupling size and design). It is important to select a coupling that can accommodate the maximum expected misalignment in the application, as excessive misalignment will lead to premature fatigue failure of the laminae.

Operating speed is another critical factor in coupling selection. Lamina couplings are suitable for high-speed applications, but their maximum allowable speed is limited by factors such as the material of the laminae, the diameter of the coupling, and the centrifugal forces generated during operation. It is important to select a coupling with a maximum allowable speed that exceeds the system’s operating speed to prevent vibration, fatigue, or catastrophic failure.

Environmental conditions such as temperature, humidity, and exposure to corrosive substances must also be considered. For applications in corrosive environments, stainless steel or titanium alloy laminae and hubs should be selected to ensure resistance to rust and chemical degradation. For high-temperature applications, materials with high-temperature resistance (such as Inconel or other superalloys) may be required.

The size and space constraints of the application are also important considerations. The coupling must fit within the available space, and its dimensions must be compatible with the shaft diameters of the driving and driven equipment. The weight of the coupling is also a factor in applications where weight reduction is a priority, such as in aerospace and robotics.

Finally, the cost of the coupling is a practical factor that cannot be ignored. While lamina couplings are generally more expensive than elastomeric couplings, their superior performance, long service life, and maintenance-free operation make them a cost-effective choice for high-precision applications where downtime and inaccuracies are costly. It is important to balance cost with performance requirements to select a coupling that meets the application’s needs without unnecessary expenditure.

In conclusion, lamina couplings are high-performance power transmission components that offer unique advantages such as zero backlash, high torsional stiffness, excellent fatigue resistance, and maintenance-free operation. Their robust design and versatile material options make them suitable for a wide range of high-precision applications across industries such as machine tools, robotics, aerospace, medical equipment, and semiconductor manufacturing. By understanding the structural characteristics, working principles, material selections, advantages, applications, maintenance practices, and selection criteria of lamina couplings, engineers and maintenance professionals can make informed decisions to ensure the reliable and precise operation of their mechanical systems. As industrial technology continues to advance, the demand for high-precision power transmission solutions is expected to grow, and lamina couplings are poised to remain a key component in meeting this demand. With ongoing advancements in material science and manufacturing technology, lamina couplings will continue to evolve, offering even higher performance, greater flexibility, and expanded application ranges, further solidifying their position as an indispensable component in modern high-precision mechanical systems.

« Lamina Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/lamina-couplings.html