Rokee is a well-known high-quality supplier of Spring Couplings and technical services in China, customize spring couplings according to user drawings, alternatively, if the user provides spring couplings parameters, we can select the model and design drawings for you, support wholesale and export.

In the complex landscape of mechanical power transmission, couplings serve as critical intermediaries that facilitate the seamless transfer of rotational energy between shafts while accommodating inherent operational imperfections. Among the various coupling designs engineered to address challenges such as misalignment, vibration, and torque fluctuations, the spring coupling stands out for its exceptional flexibility, superior vibration damping capabilities, and ability to absorb shock loads. This type of coupling leverages the elastic properties of springs to achieve reliable power transmission while protecting connected machinery from damaging stresses. Widely employed across industries ranging from manufacturing and automotive to renewable energy and marine, spring couplings have become indispensable components in systems where smooth operation and component longevity are paramount. This article provides an in-depth exploration of spring couplings, covering their structural composition, operating principles, key advantages, typical applications, and essential maintenance practices, offering a comprehensive guide to understanding their role and value in modern mechanical systems.

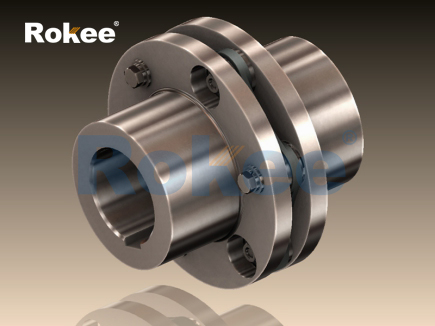

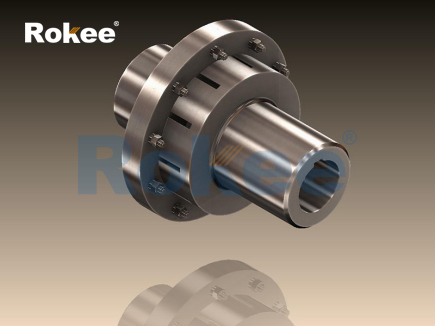

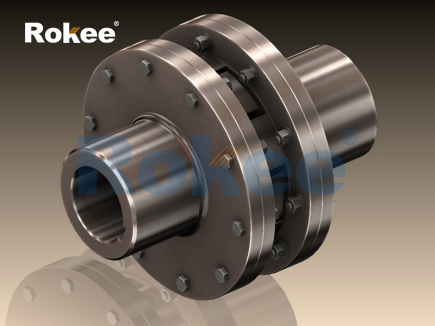

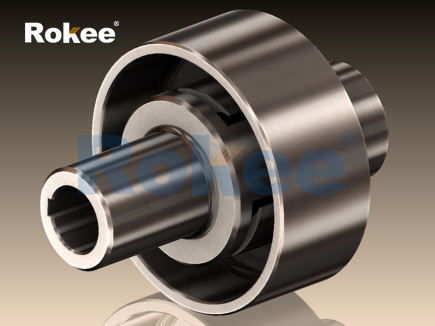

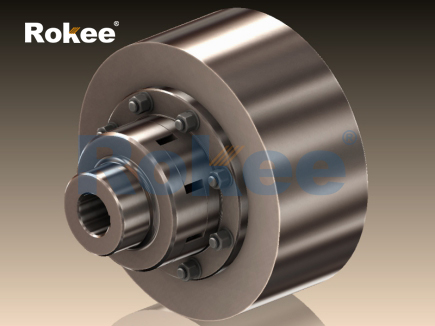

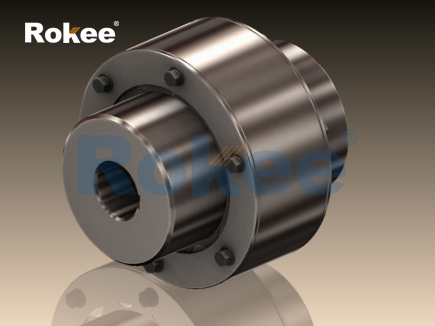

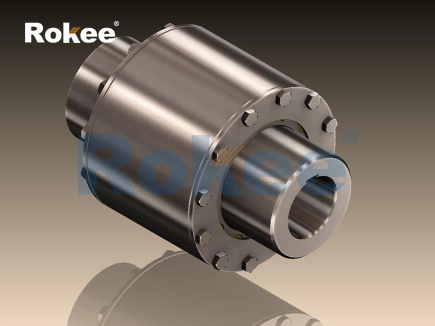

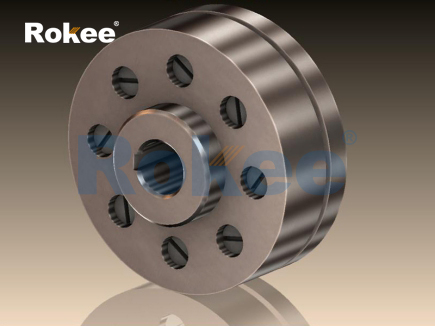

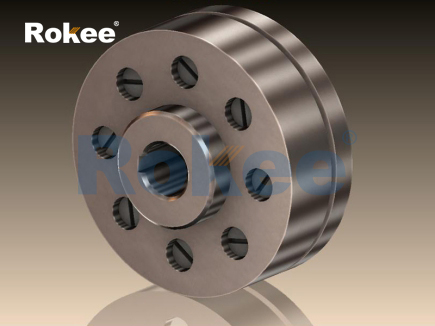

Spring couplings are distinguished by their core design feature: the integration of elastic springs that act as the primary torque-transmitting and shock-absorbing elements. While specific configurations may vary to suit different application requirements, the fundamental structure of a spring coupling comprises four main components: two hub assemblies, a set of springs, a housing or cover, and connecting elements (such as bolts or pins). Each hub is precision-engineered to mount securely on the respective driver and driven shafts, utilizing common fastening mechanisms like keyways, splines, or clamp collars. These hubs are typically manufactured from high-strength materials such as alloy steel, cast iron, or aluminum alloy, selected for their ability to withstand torque loads and resist wear over extended operational periods.

The springs, which are the defining element of this coupling type, are available in various designs, including helical springs, leaf springs, disc springs, and torsion springs. Helical springs are the most commonly used due to their excellent elasticity, uniform torque distribution, and ease of manufacturing. These springs are usually made from high-quality spring steel, which offers exceptional tensile strength and fatigue resistance—critical properties for withstanding repeated cycles of compression and extension during operation. In some specialized applications, springs may also be constructed from non-metallic materials such as polyurethane or rubber, though metallic springs are preferred for high-torque and high-temperature environments. The springs are strategically positioned between the two hubs, either in a circumferential arrangement around the shaft axis or in a axial configuration along the shaft length, depending on the coupling’s torque capacity and misalignment compensation requirements.

The housing or cover serves a dual purpose: it encloses the springs and other internal components to protect them from external contaminants such as dust, dirt, moisture, and debris, and it provides structural support to maintain the alignment of the hubs and springs. The housing is often designed with ventilation slots or ports to facilitate heat dissipation, which is particularly important in high-speed or high-load applications where friction may generate excessive heat. Additionally, some spring coupling designs incorporate flexible seals or gaskets in the housing to enhance protection against contamination and prevent lubricant leakage (when lubrication is required).

Variations in spring coupling design cater to specific operational needs. For example, torsionally flexible spring couplings feature springs that are arranged to allow for a certain degree of angular rotation between the hubs, enabling them to accommodate greater levels of angular misalignment. Conversely, axial spring couplings are designed to handle significant axial displacement between shafts, making them suitable for applications where thermal expansion or contraction causes shaft movement. Another variation is the buffered spring coupling, which includes additional rubber or polyurethane buffers between the springs and hubs to further enhance vibration damping and noise reduction. Split-hub designs are also available, allowing for easy installation and removal without the need to disassemble the entire shaft assembly—a feature that significantly reduces maintenance downtime.

The operating principle of a spring coupling revolves around the elastic deformation and recovery of the springs, which enables torque transmission while accommodating misalignments and absorbing shocks. When the driver shaft rotates, it imparts rotational motion to the driver hub. This motion is transferred to the springs, which undergo elastic deformation as they transmit the torque to the driven hub. The elastic nature of the springs allows them to flex in response to three types of shaft misalignment: angular misalignment (where the shafts intersect at an angle), parallel misalignment (where the shafts are parallel but offset), and axial misalignment (where the shafts move along their longitudinal axis). As the springs flex to compensate for these misalignments, they minimize the transfer of bending stresses and shear forces to the shafts and connected bearings, protecting these critical components from premature failure.

A key aspect of the spring coupling’s operating principle is its vibration damping capability. During operation, rotating machinery such as motors, pumps, and compressors generate vibrations due to imbalances, torque fluctuations, or operational irregularities. These vibrations, if unmitigated, can cause excessive noise, accelerate component wear, and even lead to structural damage in the mechanical system. The springs in the coupling act as natural vibration dampers: as vibrations are transmitted to the springs, their elastic deformation absorbs the vibrational energy, converting it into heat (which is then dissipated through the housing) rather than transferring it to the driven shaft and machinery. This damping effect is particularly pronounced in couplings with softer springs, though the spring stiffness must be carefully matched to the application’s torque requirements to avoid excessive deflection or loss of torque transmission efficiency.

Shock load absorption is another critical function of spring couplings. In applications where the driven machinery may experience sudden load spikes (such as in mining equipment, crushers, or material handling systems), the springs act as a buffer, absorbing the impact of the shock load. By deforming elastically under the sudden increase in torque, the springs distribute the load evenly across their structure, preventing concentrated stresses on the hubs, shafts, or connected equipment. This shock absorption capability not only protects the coupling itself but also extends the service life of the entire mechanical system by reducing the wear and tear caused by sudden load variations.

Spring couplings offer a range of distinct advantages that make them a preferred choice for numerous industrial applications. One of the most significant advantages is their exceptional flexibility and misalignment compensation capability. Unlike rigid couplings, which require precise shaft alignment and can transmit harmful stresses when misaligned, spring couplings can accommodate relatively large levels of angular, parallel, and axial misalignment. This flexibility eliminates the need for overly precise installation and alignment, reducing setup time and costs, and also compensates for misalignments that develop over time due to thermal expansion, bearing wear, or foundation settlement.

Superior vibration damping and noise reduction are additional key benefits. The elastic springs effectively absorb vibrational energy, minimizing the transfer of vibrations between the driver and driven machinery. This results in quieter operation, which is particularly valuable in applications where noise levels are tightly regulated, such as in residential areas, hospitals, food processing facilities, and pharmaceutical plants. Reduced vibration also translates to less wear on bearings, gears, and other rotating components, lowering maintenance costs and improving the overall reliability of the system.

The ability to absorb shock loads is another major advantage of spring couplings. In harsh operating environments where sudden load spikes are common, the springs act as a protective buffer, preventing damage to the shafts, motors, and driven equipment. This makes spring couplings ideal for heavy-duty applications such as construction machinery, mining equipment, and industrial crushers, where shock loads are inherent to the operational process.

Spring couplings also offer excellent torque transmission efficiency. When properly sized and maintained, the springs transmit torque uniformly across the coupling, minimizing power loss. This efficiency is particularly important in energy-intensive applications, where even small losses in power transmission can lead to significant increases in operational costs. Additionally, the elastic nature of the springs allows for smooth torque transmission, reducing torque fluctuations and ensuring stable operation of the driven machinery.

Durability and long service life are inherent characteristics of well-designed spring couplings. The use of high-strength materials for the hubs and springs, combined with protective housings, ensures that the coupling can withstand harsh operating conditions such as high temperatures, humidity, and exposure to contaminants. The springs themselves are engineered to resist fatigue, a critical property for withstanding the repeated cycles of deformation and recovery that occur during operation. With proper maintenance, spring couplings can provide reliable service for many years, making them a cost-effective investment for industrial operations.

The versatility of spring couplings is another notable advantage. With a wide range of sizes, configurations, and spring materials available, they can be tailored to suit a diverse array of applications, from small electric motors in household appliances to large industrial turbines in power generation facilities. This versatility allows engineers to select a spring coupling that precisely matches the torque requirements, misalignment compensation needs, and environmental conditions of their specific application.

Due to their unique combination of advantages, spring couplings find application in a broad spectrum of industrial, commercial, and automotive sectors. One of the most common applications is in the automotive industry, where they are used in the drivetrains of vehicles to connect the engine to the transmission or differential. In this application, spring couplings absorb the torque fluctuations generated by the engine, reduce vibration, and accommodate minor misalignments between the engine and transmission shafts, improving ride comfort and protecting drivetrain components from damage.

The manufacturing industry is another major user of spring couplings, where they are employed in a wide range of machinery, including conveyors, mixers, agitators, extruders, and machine tools. Conveyors, which are used to transport materials in factories and warehouses, often experience sudden load variations and minor shaft misalignments due to the weight of the materials and the length of the conveyor system. Spring couplings are ideal for this application, as they absorb shock loads and compensate for misalignments, ensuring smooth and reliable operation. Mixers and agitators, commonly used in the food, chemical, and pharmaceutical industries, generate significant vibrations during operation; spring couplings dampen these vibrations, preventing damage to the mixer components and ensuring uniform mixing of materials.

In the renewable energy sector, spring couplings are widely used in wind turbines and solar tracking systems. Wind turbines experience highly variable torque loads due to fluctuations in wind speed, and the rotating components (such as the rotor and generator) are prone to misalignment due to structural flexing. Spring couplings in wind turbine drivetrains absorb these torque fluctuations, dampen vibrations, and accommodate misalignments, protecting the generator and other critical components from damage and ensuring efficient power generation. Similarly, in solar tracking systems, spring couplings connect the drive motor to the tracking mechanism, allowing for smooth and precise movement while compensating for minor misalignments caused by thermal expansion and contraction.

The marine industry also relies on spring couplings for various applications, including ship propulsion systems, marine pumps, and auxiliary machinery. Ship propulsion systems operate in harsh environments with high torque loads and potential misalignments between the engine and propeller shaft. Spring couplings in these systems absorb shock loads from wave impacts, dampen vibrations, and accommodate misalignments, ensuring reliable power transmission and protecting the engine and propeller components. Marine pumps, which are used for ballasting, cooling, and fuel transfer, also benefit from the vibration damping and misalignment compensation capabilities of spring couplings, extending their service life in corrosive marine environments.

Other notable applications of spring couplings include mining equipment (such as crushers, grinders, and conveyors), where they withstand heavy shock loads and harsh environmental conditions; HVAC systems (such as fans, blowers, and chillers), where they reduce noise and vibration for improved indoor air quality and comfort; and small household appliances (such as washing machines and dryers), where they connect the motor to the drum, absorbing vibrations and ensuring smooth operation.

To maximize the performance, reliability, and service life of spring couplings, regular and proper maintenance is essential. Neglecting maintenance can lead to premature component failure, increased operational costs, and unplanned downtime. The following are key maintenance practices for spring couplings:

Regular inspection is the foundation of effective spring coupling maintenance. Inspections should be conducted at regular intervals (as recommended by the coupling manufacturer or based on operational hours) to check for signs of wear, damage, or degradation. During inspection, the coupling should be visually examined for cracked or broken springs, worn hub surfaces, loose fasteners (such as bolts, nuts, or clamp collars), and damage to the housing or seals. Additionally, the coupling should be checked for abnormal noise, vibration, or temperature rise during operation, which can indicate underlying issues such as worn springs, misalignment, or lack of lubrication. For couplings with metallic springs, magnetic particle inspection or ultrasonic testing may be required periodically to detect internal cracks or fatigue that are not visible to the naked eye.

Lubrication is a critical maintenance task for many spring coupling designs, particularly those with metallic springs and moving components. Proper lubrication reduces friction between the springs and hubs, minimizes wear, and prevents corrosion. The type of lubricant selected should be compatible with the coupling’s materials and operating conditions, including temperature, load, and environmental factors (such as exposure to moisture or chemicals). Common lubricants used for spring couplings include mineral oils, synthetic oils, and grease. Lubrication should be performed at regular intervals, and old or contaminated lubricant should be completely drained and replaced to ensure optimal performance. It is important to note that some spring couplings with non-metallic springs (such as rubber or polyurethane) do not require lubrication, as lubricants can degrade the non-metallic material and reduce its elasticity.

Replacement of worn or damaged components is essential to maintain the coupling’s performance and prevent catastrophic failure. The springs are the most vulnerable component, as they are subject to repeated fatigue cycles. Worn, cracked, or broken springs should be replaced immediately, and it is recommended to replace all springs in a coupling simultaneously to ensure uniform torque distribution and performance. Hubs that show signs of excessive wear, corrosion, or deformation should also be replaced. Fasteners that are loose, stripped, or corroded should be tightened or replaced to ensure a secure connection between the hubs and shafts. Seals and gaskets that are damaged or leaking should be replaced to maintain the integrity of the housing and protect internal components from contamination.

Proper shaft alignment should be checked and maintained regularly, even though spring couplings can accommodate significant misalignments. Excessive or persistent misalignment beyond the coupling’s rated capacity can place additional stress on the springs and hubs, leading to premature wear and failure. Shaft alignment can be measured using traditional tools such as a straightedge and feeler gauge, or more precise tools such as laser alignment systems, which provide accurate measurements and help minimize alignment errors. If misalignment is detected, corrective action should be taken immediately, such as adjusting the position of the motor or driven machinery, replacing worn bearings, or realigning the shaft supports.

Protection from external contaminants is another important maintenance practice. The coupling’s housing and seals should be regularly inspected to ensure they are intact and functioning properly. If the coupling is operating in a particularly harsh environment (such as a dusty factory, wet marine setting, or corrosive chemical plant), additional protective measures may be required, such as installing protective shields, using corrosion-resistant coatings on the housing, or selecting a coupling with enhanced sealing capabilities. Regular cleaning of the coupling’s exterior can also help prevent the buildup of contaminants that may eventually find their way into the internal components.

In conclusion, spring couplings are vital components in modern mechanical power transmission systems, offering a unique combination of flexibility, vibration damping, shock absorption, and torque transmission efficiency. Their design, which centers on the use of elastic springs, enables them to accommodate misalignments, reduce noise and vibration, and protect connected machinery from damaging stresses—features that make them indispensable in a wide range of applications across industries such as automotive, manufacturing, renewable energy, and marine.

Proper maintenance, including regular inspection, appropriate lubrication, timely replacement of worn components, maintenance of shaft alignment, and protection from contaminants, is crucial to ensuring the optimal performance and longevity of spring couplings. By understanding the structural composition, operating principles, advantages, applications, and maintenance requirements of spring couplings, engineers, maintenance professionals, and industrial operators can make informed decisions about their selection and use, ultimately improving the efficiency, reliability, and cost-effectiveness of their mechanical systems.

As industrial technology continues to advance, spring coupling designs are likely to evolve to meet the growing demands of high-performance, high-efficiency machinery. Innovations in materials (such as advanced composite springs), manufacturing processes (such as additive manufacturing for complex spring geometries), and design optimization (such as computer-aided engineering for improved torque distribution) will further enhance the capabilities of spring couplings. Despite these advancements, the fundamental principle of leveraging elastic springs for reliable and protected power transmission will remain, ensuring that spring couplings continue to play a critical role in mechanical systems for years to come.

« Spring Couplings » Post Date: 2024/4/25 , https://www.rokeecoupling.net/tags/spring-couplings.html